44010-52-01 Welding and grinding table 3

Contents

Contents .....................................................................................................................................3

1.General instructions............................................................................................................4

2.Product identification..........................................................................................................5

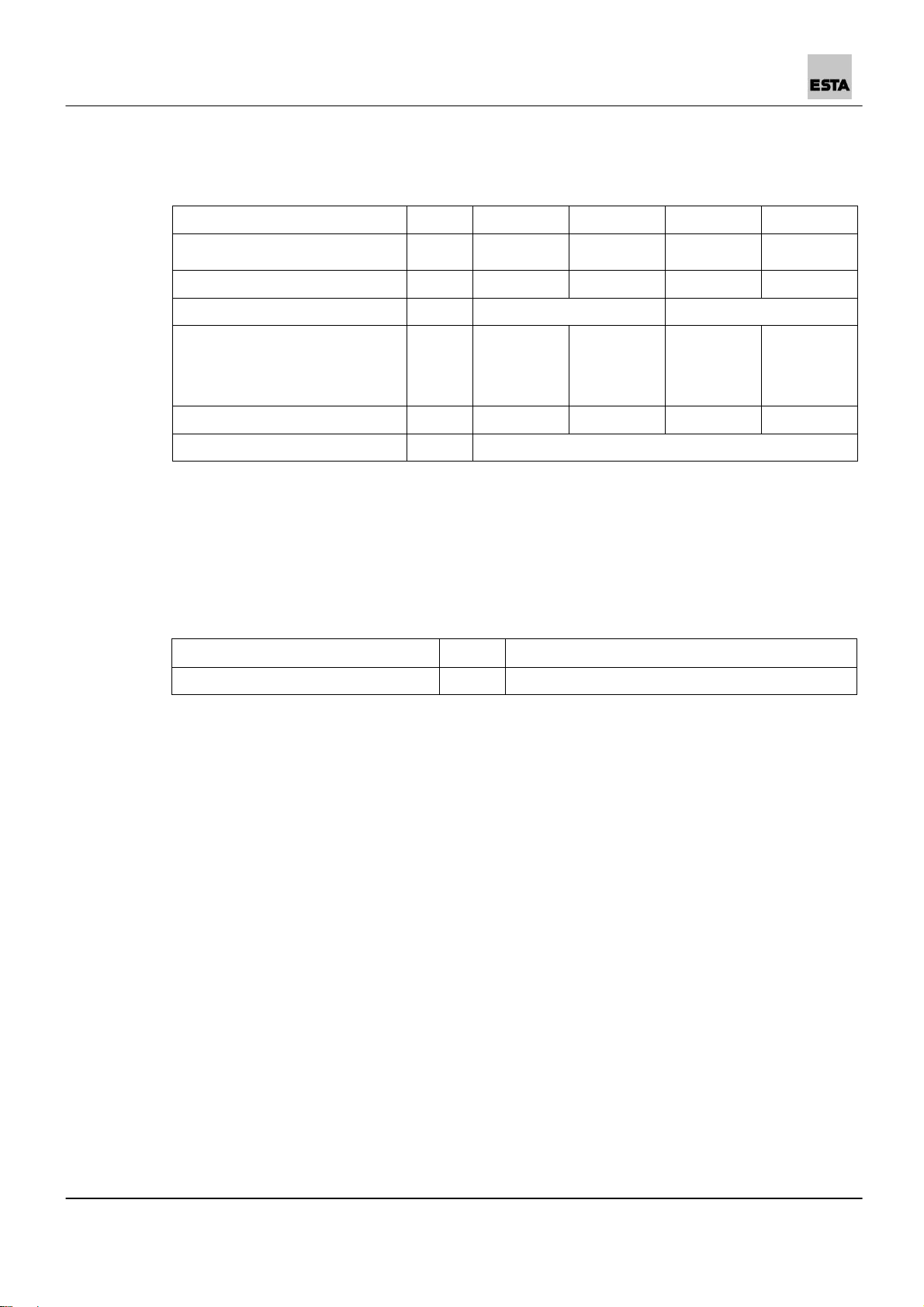

2.1Technical data.................................................................................................................5

2.2Intended use...................................................................................................................6

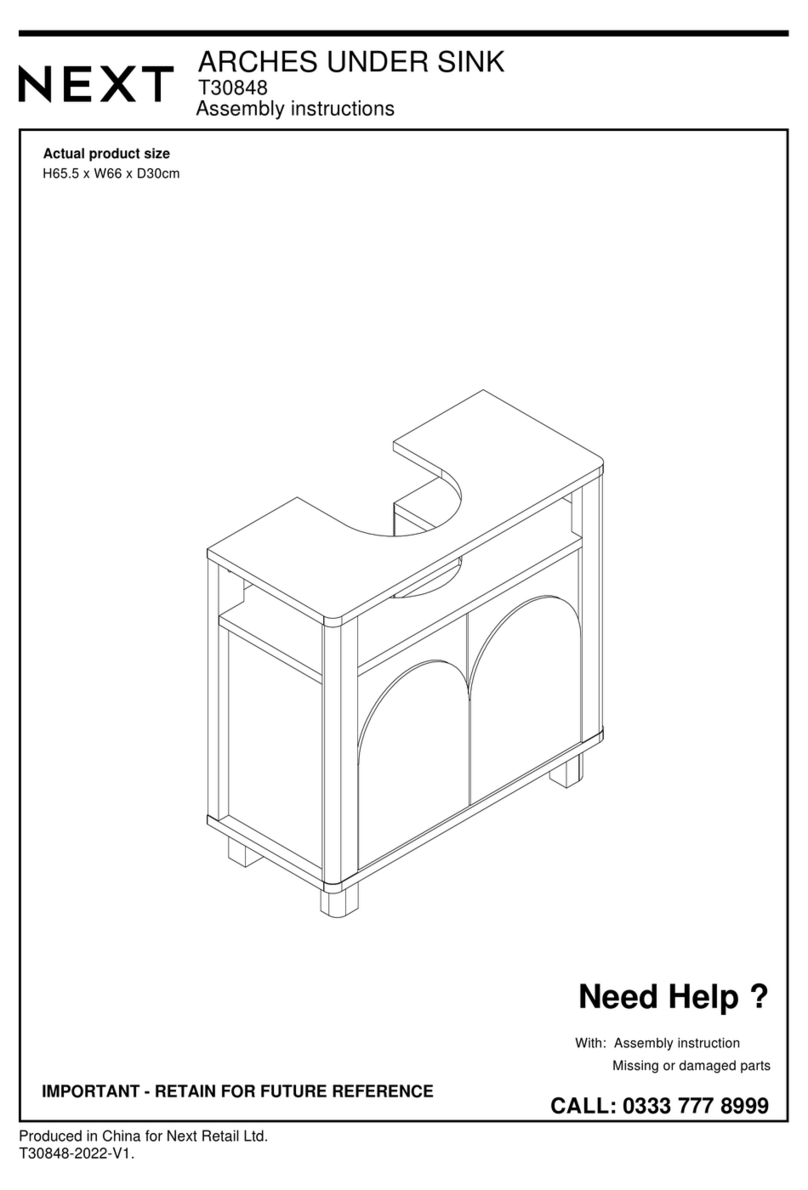

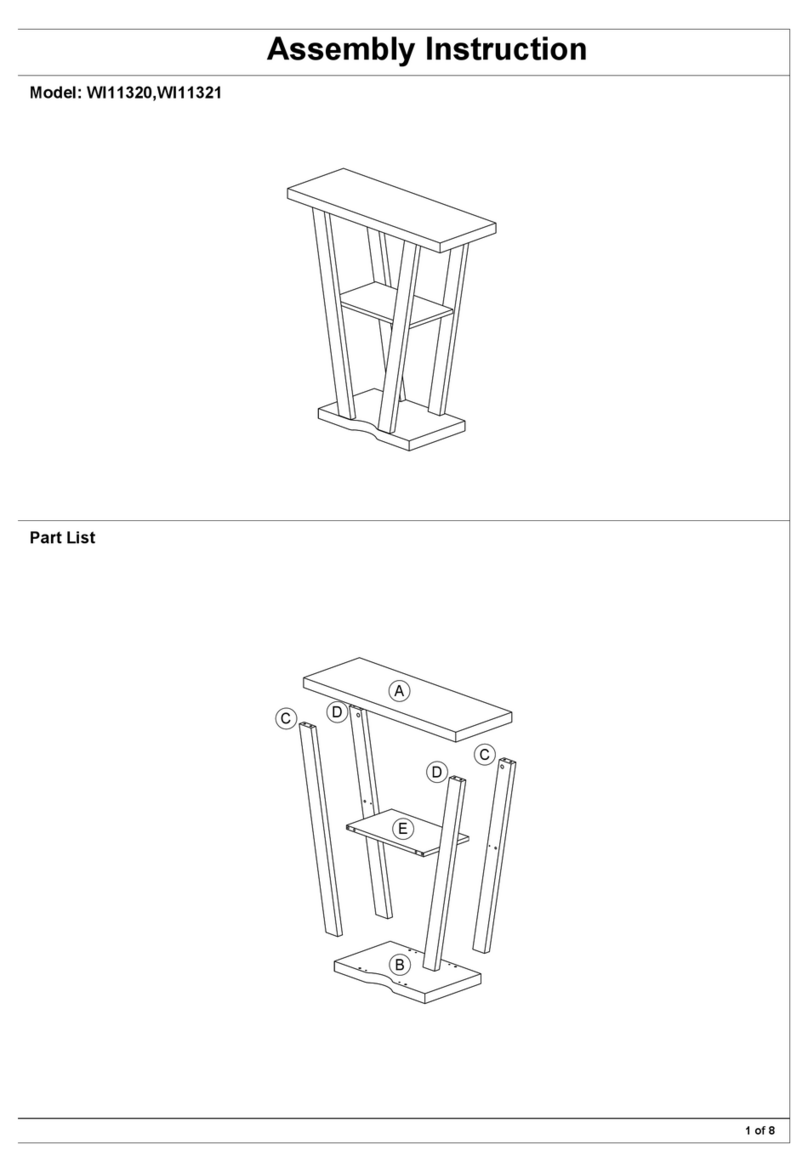

3.Product description.............................................................................................................8

3.1Device diagram...............................................................................................................8

3.2Functional description.....................................................................................................9

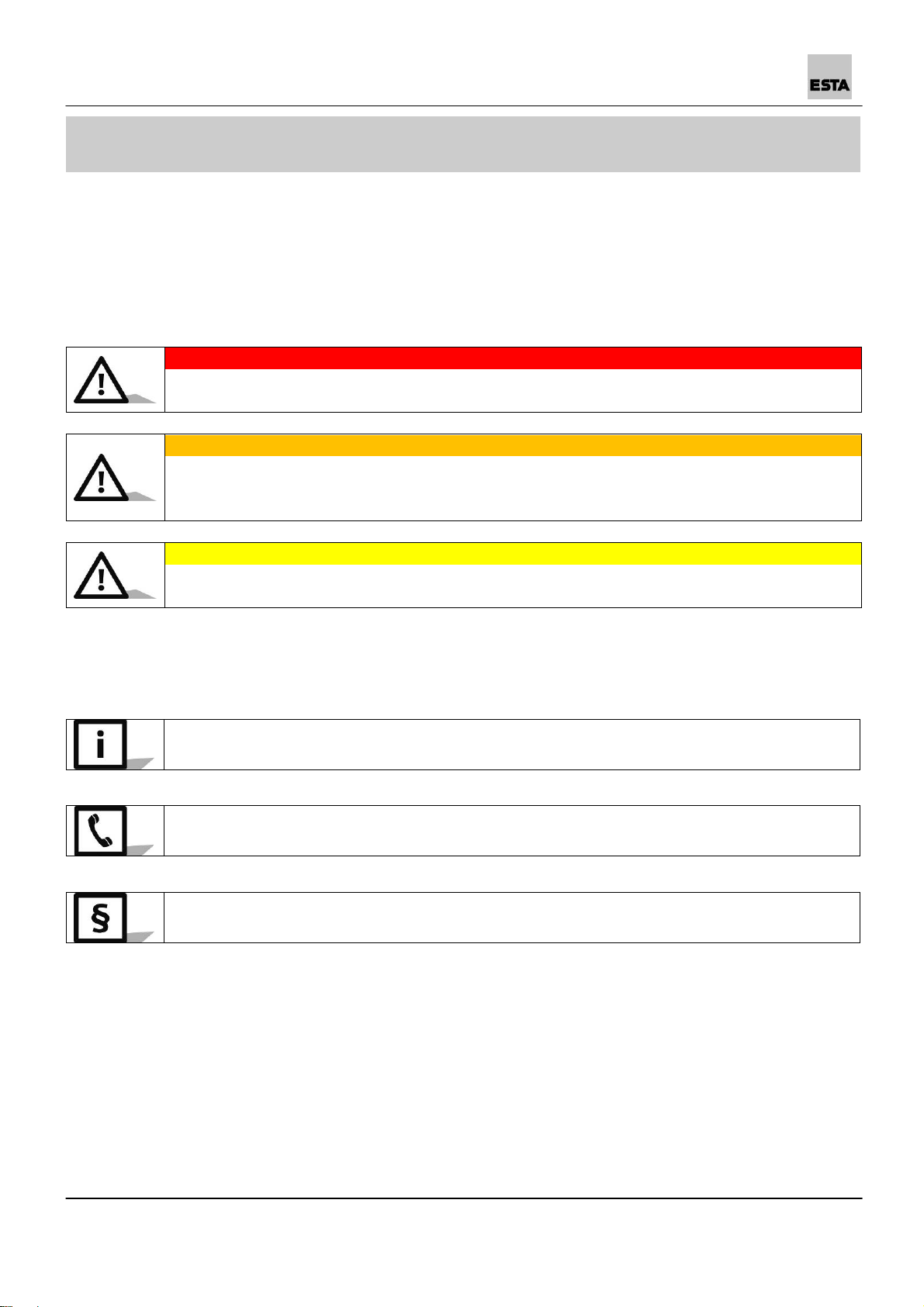

4.Safety instructions ............................................................................................................10

4.1Hazard classes .............................................................................................................10

4.2Explanation of symbols.................................................................................................10

4.3General safety instructions ...........................................................................................11

4.4Preventing mechanical hazards....................................................................................11

4.5Preventing dust hazards...............................................................................................12

5.Delivery and start-up.........................................................................................................13

5.1Delivery and transport...................................................................................................13

5.2Connection....................................................................................................................14

6.Operating instructions ......................................................................................................14

6.1Processing large work pieces on the device.................................................................14

7.Maintenance & troubleshooting.......................................................................................15

7.1Maintenance instructions..............................................................................................15

7.2 Inspection and maintenance intervals...........................................................................16

7.3 Cleaning the device ......................................................................................................17

7.4 Troubleshooting............................................................................................................17

8.Disposal..............................................................................................................................18

8.1Disposing of collected dust...........................................................................................18

8.3Disposing of the device.................................................................................................18

9.Optional equipment...........................................................................................................19

9.1Fastening a vice............................................................................................................19

9.2Turntable.......................................................................................................................19

9.3Lighting.........................................................................................................................19

9.4Electrical sockets..........................................................................................................20

9.5Compressed air connection ..........................................................................................20

9.6Fibreglass-reinforced work surface grate......................................................................20

9.7Wood slatted frame work surface..................................................................................20

9.8Work surface with ball casters ......................................................................................21

9.9Mobile version...............................................................................................................21

9.10Electrically conductive throughout .............................................................................22

10.Declaration of incorporation.............................................................................................23

Notes.........................................................................................................................................25

Notes.........................................................................................................................................26

Notes.........................................................................................................................................27

Notes.........................................................................................................................................28