Esu LokProgrammer v 4.0 User manual

LokProgrammer v4.0

Instruction manual

Forsoftwareversions4.4.13andon

Article no.: Unofficial (See “About this manual” pg 42)

September2014

1

Table of contents

Declaration of Conformity 3

WEEE-Declaration 3

1. Important notes –Please read this first 4

2. Installation and start-up of the LokProgrammer 4

2.1 System requirements 4

2.2. Connecting the LokProgrammer 4

2.3. Installing the software 4

2.4. Starting the program 4

2.5. Software updates 5

2.6. Firmware updates 5

3. LokSound basics 5

3.1. Sound characteristics of locomotives 5

3.2. User defined sounds 6

3.3. Automatic / Random sounds 7

3.4. Digital system / Protocols 7

3.5.CVs 7

3.6. Further information about LokSound decoders 7

4. Purpose of the LokProgrammer software 8

4.1. Overview 8

4. 2. Assistant 8

5. Main screen 9

5.1. View Panes 9

5.2. Task bar 9

2

5.3. Tools 9

6. Driver’s cab 11

7. Decoder Information, Read / Write CVs 11

8. The “decoder settings” register 12

8.1. Decoder address 12

8.2. DCC / Analogue 12

8.3. Compatibility 12

8.4. DCC Settings 13

8.5 Driving characteristics 13

8.6. Function views 14

8.7. Identification 17

8.8. Manual CV Input 17

8.9. Motor Settings 17

8.10. Smoke Unit 19

8.11. Sound settings 19

8.12. Sound slot settings 20

8.13. Special options 21

9. Information 22

9.1.Functions 22

9.2General 22

10. Sound modeling, adding sounds 23

10.1.Soundsectionoverview(openingviewpage) 23

10.2.Soundfiles 26

11. Sound modeling, flow charts 29

11.1.Soundflowchartbasics 29

11.3.Containersandcontainerproperties 31

11.4.Complexsoundflow 32

11.5.Steamsoundflowchart 35

11.6.Soundmodelingterminology 37

12. Sound modeling, Examples and Tips 38

12.1.Flowchartdrawingexample 38

12.2.74482GEP42AMD103projectexamples 39

13. Errors and troubleshooting 41

13.1.Lasttransitionmustbeunconditioned 41

13.2.Danglingoutgoingtransition 41

13.3...exitDanglingincomingtransition 41

13.4.Unhandledexception 41

13.5.Problemswhenreadingthedecoder 42

13.6.Troubleshootingproblems 42

13.7.Customerservice–Assistanceandsupport 42

Aboutthismanual: 42

Declaration of Conformity

We, ESU electronic solutions ulm GmbH & Co KG, Industrie-

straße 5, D-89081 Ulm, declare herewith in sole responsibility

compliance of the product "LokProgrammer“ to which this

declaration is related to, with the following standards:

EN711-3:1988/6:1994–EN50088: 1996–EN55014, part

1 + part 2 : 1993

EN61000-3-2:1995–EN60742:1995 –EN 61558-2-7: 1998

The „LokProgrammer“ bears the CE-mark according to the

guidelines as per

88 / 378 / EWG –89 / 336 / EWG –73 / 23/ EWG

WEEE-Declaration

Disposal of old electrical and electronic devices (applicable in

the European Union and other European countries with sepa-

ratecollectionsystem).Thismark on theproduct, thepackaging

or the relevant documentation indicates, that this product may

not be treated as ordinary household garbage. Instead this

product has to be delivered to a suitable disposal point for

recycling of electrical or electronic equipment.

By disposing of this product in the appropriate

manner you help to avoid negative impact on

the environmentand healththat could becaused

byinappropriate disposal.Recycling ofmaterials

contributestoconserveournatural environment.

For more information on recycling this product

please contact your local administration, the rubbish disposal

service or the shop where you have purchased this product.

Batteries do not belong into household trash!

Pleasedonotdisposeof dischargedbatteries inyourhousehold

trash: take them to a collection point at your local town hall or

dealer. Thus you assure an environmentally friendly way of

disposal.

Copyright 1998 - 2009 by ESU electronic solutions ulm GmbH & Co KG. Irrtum,

Änderungen die dem technischen Fortschritt dienen, Liefermöglichkeiten und alle

sonstigen Rechtevorbehalten. Elektrischeund mechanische Maßangaben sowieAb-

bildungen ohne Gewähr. Jede Haftung für Schäden und Folgeschäden durch nicht

bestimmungsgemäßen Gebrauch, Nichtbeachtung dieserAnleitung, eigenmächtige

Umbauten u. ä. ist ausgeschlossen. Nicht geeignet für Kinder unter 14 Jahren. Bei

unsachgemäßem Gebrauch besteht Verletzungsgefahr.

Märklin® ist ein eingetragenes Warenzeichen der Firma Gebr. Märklin® und Cie.

GmbH, Göppingen. RailCom® ist ein eingetragenes Warenzeichen der Firma Lenz

Elektronik GmbH, Giessen.Alle anderen Warenzeichen sind Eigentum ihrer jeweili-

genRechteinhaber.

ESU electronic solutions ulm GmbH &Co. KGentwickelt entsprechendseiner Politik

die Produkteständig weiter. ESU behält sich deshalb das Recht vor, ohne vorherige

Ankündigung an jedem der in der Dokumentation beschriebenen ProdukteÄnderun-

genundVerbesserungenvorzunehmen.

Vervielfältigungen und Reproduktionen dieser Dokumentation in jeglicher Form be-

dürfen der vorherigen schriftlichen Genehmigung durch ESU.

3

4

Installation and start of the

LokProgrammer

1. Important notes –Please read this first

Thank you for purchasing the LokProgrammer set 53450/

53451.With the LokProgrammer youcan program ESULokPilot-

andLokSounddecoders.

The LokProgrammer 53450 consists of two elements: An

interface module that serves as the physical connection

between the PC and the locomotive, and the software that

can be run on any PC usingMSWindows. The set 53451has

an additional USB adapterbut is otherwisethe sameas53450.

Never was it easier to program a digital decoder than with

LokProgrammer. Thanks to the graphic interface of MS

Windows you can achieve the optimal adaptation of LokSound

decoders even if you have very little or no experience in

programming digital decoders. This combination allows you to

easily manipulate and adjust the many features and properties

of LokSound decoders with your PC.

LokProgrammer also allows youto modify allsound fragments

andsound effects stored on thedecoder as often as youdesire.

ESU provides over 100 different sound files on the ESU web

site at www.esu.eu. You will certainly find the right sound for

yourlocomotive.

Please also take note of the license agreement regarding

downloadingandusingthesoundfilescontainedintheappendix.

Thismanualdescribesindetailhowtomodifysounds andwhich

methods to usetoachieve the desired results.

We wish you lots of fun in the world of LokSound.

ESUelectronic solutions ulmGmbH& CoKG, November 2013

2. Installation and start-up of the

LokProgrammer

Please note the remarks regarding installation to assure that

your LokProgrammer software keeps working to your full

satisfaction!

2.1 System requirements

Inorderto usethis softwareyou needacommerciallyavailable

PC with the following requirements:

• Operating system: Microsoft Windows 98, 2000 or XP, Vista,

Win7 32/64bit, Win8 and 8.1

•CD-ROM drive

• One serial port or an USB interface on your PC

• Audio card

• 20MB minimum available memory on your hard disc

For the utilization of the soundfiles withthis software an Audio

Card must be installed. All cards with a Windows driver are

suitable.

2.2. Connecting the LokProgrammer

The LokProgrammerhas to beconnectedas shown in Figure1:

Usethe serial cable respectivelythe USB-adaptercableprovided

to connect the LokProgrammer to any available COM port (or

USB-port) of your PC. Which port you select is immaterial.

Please make sure that the programming track is completely

isolatedfrom the rest of the layout toavoid possible damage of

your LokProgrammer hardware!

Also make sure that there are no electrical connections

between the individual wires.

Fig.1.: Wiring the LokProgrammer

Fig.2.: Polarity of Power Supply Connector

There are two options for the power supply:

• Use the power pack with mains plug provided with the

LokProgrammer. Connect the output of the power pack to

the powersupplyterminals oftheLokProgrammerasper Figure

2.

• Use the AC power output of a model train transformer and

wire it to the screw terminals. We recommend this option for

programminggauge 1 locomotives

Never connect both terminals at the same time. This could

destroy the LokProgrammer!

After connecting the power supply the green LED on the

LokProgrammer should light up.

The terminals „Track Out“ on the LokProgrammer are to be

wired to the programming track. Polarity is irrelevant.

Make sure that the programming track is fully isolated from

the layout!

The two LEDs on the LokProgrammer indicatethe following:

Green LED:

• Is lit continuously when supply voltage is available.

• Blinks when the LokProgrammer receives data from the PC.

YellowLED:

• Blinks quickly when voltage is applied to the programming

track and data is transferred.

• Blinks slowly if the LokProgrammer detects a high current and

is disconnecting the programming track.

2.3. Installing the software

Make sure that the LokProgrammer is connectedas described

above and is ready foruse.

As soonas youinsert the CD-ROM into thedrive theinstallation

program is starting automatically.

Should this not be the case select the CD-ROM drive in „Desk

Top“ or in the „Windows Explorer“ and click onto „Set up“.

Alternatively youmay click on the START button inthe toolbar

and select „Run“. Then type „x:\setup.exe“ and „OK“. Of

course you must enter the name of the CD-ROM drive instead

of the „x“ (usually „D“):

After a short while the program should start. Follow the

instructions on the monitorand wait untilthe program is installed

on the hard disk.

2.4. Starting the program

The installation program creates an entry in the start menu.

Select „LokProgrammer vX“ in the Start menu under „Pro-

grams“; „X“ stands for the version number of the software.

Select „LokProgrammer“. Then the program will start.

LokSound Basics

2.5. Software updates

ESU offers the latest version of the LokProgrammersoftware

on the web page www.esu.eu. You will find it in the „Down-

loads“ menu under „Software“. Click onto the Download-

symbol at the end of the line. A window opens. Click „Run“.

Now the program will guide you through the installation

procedure.

Fig.3.: Start Window for Internet Update

There is also an option for an automatic update provided the

software is already installed on yourcomputer:

• Go into the Start Menu and select Program „LokProgrammer

vX“, (the X stands for the version number of your software).

• Click onto „Internet Update“. A window as per Fig. 3 opens.

• Click onto „Next“. The note „Downloading required Files. Please

be patient“ appears. While this window is shown the files

required for the updatewill be installed. Subsequently you can

start the LokProgrammer software from the installation

window.

Please note thatsoftware version 4.4.7+ runs and opens

appropriate data (meant for decoder versions 3.5 and v4.0)

thus this software incorporates software 2.6.6 and on for

v3.5 decoders and versions 4.4.1 and on for v4.0 decoders.

You cannot mix and match features of decoder versions,

software and firmware is distinctly different for each decoder

version, but this software will open sound projects for both

decoder architectures. Specifics for version 3.5 decoders

are available in the programmer manual for that decoder.

This manual is specific to v4 decoders.

2.6. Firmware updates

The firmware is the operating system of the LokPilot- or

LokSound decoders.

Pleasenote: Certain newsoftware options canonlybe activated

with LokSound decoders with the latest firmware-update.

Firmware installs as required when sound data is written to

the decoder.

PrivacyProtection:

ESU guarantees that no information will be downloaded from

yourPCto the ESU website. Data transmissionisstrictly limited

to sending data from the ESU home page to your PC. Your

personal data are protected at any time.

3. LokSound basics

In the following chapter it is explained how the LokSound

decoder reproduces prototypical sounds, what options are

available with digital command control for model trains and

which protocols of digital systems are currently available in the

market.Shouldyoualreadyhaveexperiencewithdigitalsystems

and also be familiar with locomotive sounds you may skip this

chapter and continue reading on page 16.

3.1. Sound characteristics of locomotives

With LokProgrammer and LokSound decoders you can

reproduce sounds of steam locomotives, diesel-hydraulic and

diesel-electric locomotives, electric locos or locos with manual

transmission(e.g.: rail car). Of course thesound sequences are

subjectto the type of locomotive.

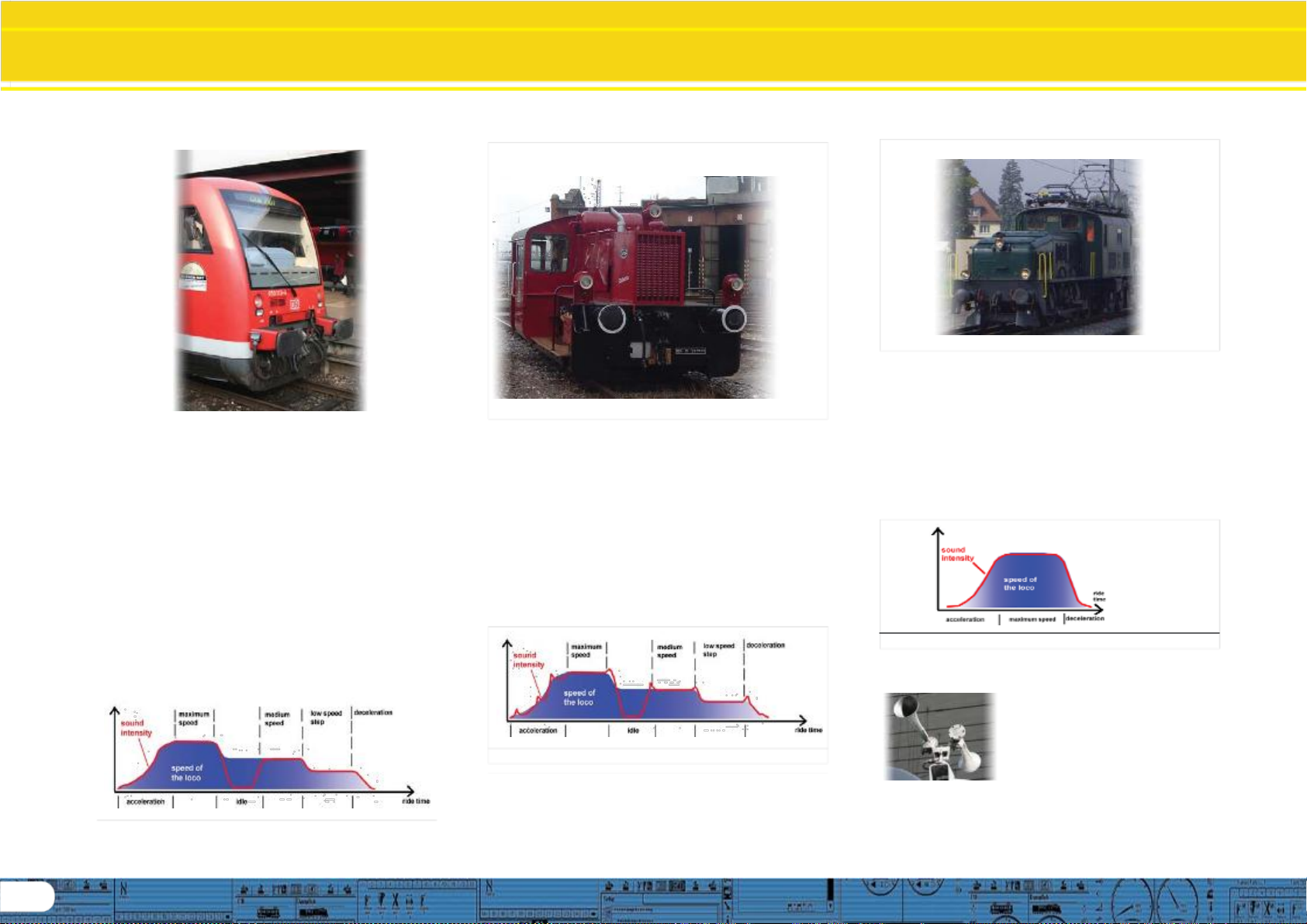

3.1.1. Steam locomotive

The dominant sounds of a steam locomotive are the hissing of

the boiler and the exhaust chuffs when the locomotive is

running. The chuffs are synchronized to the revolutions of the

drivers and therefore accelerate or slow down whenever the

locomotive runs faster or slower. We differentiate between

locomotives with 2or4 cylinders andothers with 3cylinders.A

steam locomotive with 3 cylinders generates either 3 or 6

exhaust chuffs per revolution of the drivers while a 2- or 4-

cylinder locomotive generates 4 exhaust chuffs per revolution.

The exhaust chuffs appear to be louder and harder during

acceleration compared to normal running at constant speed.

Whenever the valves are closed the only audible noiseis the

clank of the driving rods.

When the locomotive starts moving, the cylinder valves are

open in order to push out any condensed steam and thus to

avoid breakage of the driving rods.

This behaviorcanbe simulated withLokSound decoders and

with the aid of the LokProgrammer. The individual stages are

divided into separate Driving notches. The differentsounds of

the respective stages consist of individual recordings of the

exhaust chuffs (also refer to Fig. 4 and chapter 11.5 for

detailedexplanations).

Fig.4.: Performance of a Steam Locomotive

3.1.2. Diesel locomotive (diesel-electric)

Diesel-electric locomotives are in principle electric locomotives

with electrical generators that are powered by diesel engines.

The diesel locomotive is generally driven at constant Driving

notches subject to thespeed of the locomotive. Therefore the

noise generated changes (driving) step by (driving) step. The

quiet electric motor can hardly be heard over the noise of the

diesel powered plant. Most diesel-electric locomotives have 4

to 8throttle notches.

Examples of diesel-electric locomotives are the DB class 232

(„Ludmilla“), most American diesel locomotives by GE or ALCO

or the MZ-locomotives by the Danish State Railways.

Fig.5.: Performance of a diesel-electric locomotive

5

6

LokSoundBasics

3.1.3. Diesel locomotive (diesel-hydraulic)

The main item of equipment of a diesel-hydraulic locomotiveis

the torque-converter that uses fluids for power transmission.

This energy flow is literally „fluent.“

That is thereason whydiesel-hydraulic locomotives howlaudibly

oncethethrottleisopened andbeforethelocomotiveisactually

moving. Since the revs of the motor sound depend on the

speed, the noises generated during driving change without

audible thresholds. Simply put, the sound is directly proportio-

nal to the speed.

Locomotives with LokSound decoders behave the same way;

first the diesel engine revs up and once the revs are high

enough the locomotive starts moving. The pitch of thesound

can be adjusted subject to the speed. This is only possible in a

combined unit (decoder plus sound module in one piece –for

further info also refer to chapter 8.5.4). Examplesfordiesel-

hydrauliclocomotives aretheDBclassV200(class 220)andthe

Regio-Shuttleor the DMU41 by the SNCB/NMBS.

Fig.6.: Performance of a Diesel-hydraulic Locomotive

3.1.4. Diesel locomotive with manual transmission

(manual gear gear box)

Diesel locomotives withmanual transmissionemploypinion gear

for transmitting the power from the motor to the wheels

similar to automobiles. The clutch is pressed during shifting

from one gear to the next and thus the power transmission is

interrupted for a short moment. The shifting of gears can

clearly be heard in many a diesel locomotive with manual

transmission. With theLokProgrammer software you can either

store the original sound of gear shifting or you maychoose the

option „gear shift“ (User-SoundSlot14) as described inchapter

9.6.2:

Examples of diesel locomotives with manual transmission are

the German rail cars VT95orsomeshuntinglocomotives, since

manual transmissions are only practical in vehicles of relatively

low weight and with low maximum speeds.

Fig.7.: Performance of a Diesel Locomotive with Manual Transmission

3.1.5. Electric locomotive

There are different sound types for electric locomotives. On

the one hand the hum of theelectric tractionmotor(s)is audible;

it changes its pitch with the speed similar to diesel-hydraulic

locomotives.

Other electric locomotives generate very dominantfan sounds.

In some electric locomotives the sound of the fan is constant

and therefore the sound does not change during driving.

By and large electric locomotives are not as noisy as other

locomotive types and therefore they are ideal for applying

User Sounds such as the whistle, horn, compressor, etc. (for

more info please refer to chapter 9.5 and 9.6).

Fig.8.: Performance of an Electric Locomotive

3.2. User defined sounds

User-defined sounds („User-Sounds“)

couldbe horns andwhistles,couplerclank,

sanding, etc. These sounds can be

triggered by pressing a function button

on your throttle once you have

programmed them onto the decoder.

CurrentlyLokSound decoders supportup

to28 functionssuch as head lights, smo-

ke generator, etc. The latest versions of digital command

stations suchasthe ESU ECoS canfully utilizethis range.

LokSound Basics

3.3. Automatic / Random sounds

Random Sounds are triggered automatically and irregularly

and canbe used for safety valves, fans,compressors, etc.

With the LokProgrammer you can select the time between

Random Sounds (detailsin chapter 8.5.3).

Other possibilities for triggering sounds automatically such as

squealing brakes are contained in Decoder Settings and the

appropriate flow chart (see chapter9). Such sounds will be

triggeredat specific times based on those settings.

3.4. Digital system / Protocols

In this chapter we list all digital protocols for running model

trains and setting signals and turnouts that are supported by

the LokProgrammer.

3.4.1. DCC (NMRA)

DCC stands for „Digital Command Control“ and was formulated

as standardbytheNMRA (National Model RailroadAssociation).

Inthe earlystages operation was limitedto 14 speedsteps and

80 addresses; today up to 10,000 addresses and 128 speed

steps areavailable.

DCC is downward compatible in terms of control and decoders,

e.g. older decoders can be controlled with up-to-datecommand

stations / throttles and with certain limitations new decoders

can be operated and programmed with oldercontrol devices.

3.4.2. Motorola®

The Motorola®-protocol goes back to 1984 is one of the oldest

digital systems formodel trains. Due to its age the operational

options are limited.

The Motorola®-protocol can only handle 80 locomotive

addresses with14speedsteps and besidesthe headlightfunction

onlyfour additionalfunctionoutputs can becontrolled(functions

5-8 can beselected with the second Motorola®-address).

Sincethe Motorola®-protocolisstill used inmany digitalsystems

ESU decoders are designed to work with this protocol as well.

3.4.3. M4

Since 2004 the MFX®-system is onthemarket.Theoretically

this couldrunmore than16,000model locomotivessimultaneously

with 128 speed steps.

The LokProgrammer software deals with certain settings

somewhat differently to DCC.

For instance, instead of locomotive addresses the name of the

locomotive has to be entered (e.g.: „class 01“ or „ICE“). The

allocatement of certain parameters to the CVs is also different

toDCC.

Do not usethe DCC-CVs mentioned from chapter 3.5 onwards

for M4!

Whatdoes M4 mean?

At some points in thismanual you will notice the term „M4“ for the first

time and rightlywonder what this might mean.

This question canbe answeredquite simply: from 2009forward,M4 isthe

name of a data protocol that was chosen by ESU to be implemented in

their decoders. Decoders with the M4 protocol are onehundred percent

compatible with command stations using mfx®. At such stations (e.g.

Märklin® Central Station®) they will be recognized automaticallyand all

playing functions are available just like when using mfx®. On the other

hand, ourESU command stations using M4 will recognize all (Märklin®

and ESU) mfx® decoders without any restrictions and will still work

without any problems. As the (mutual) inventor of mfx® we can assure

you of this.

Inshort: thetechniquestaysthe same,onlythe namehas been changed.

3.4.4. Selectrix®

Selectrix® is another digital system. In contradiction to DCC

the locomotive addresses are not transmitted individuallybut in

groups. Thus it is limited to the driving sounds and Random

Sounds but it is not possibleto trigger any user defined sounds

(e.g.: a whistle or bell). Selectrix® is almostexclusivelyused for

N scale and Z scale; therefore it is also supported by the ESU

LokSoundmicrodecoder.

It is important not to confusethesesystemswhen programming

any sounds. For instance is it not possible to store any M4-

project files on a DCC-decoder let alone to replaythem.

3.5.CVs

3.5.1 Definition and application

CV stands for „Configuration Variable“. CVs can have values in

bits or bytes. The CVs with bytes can have a range from 0 to

255 while the CVs programmed in bits function as on / off-

switches.

Examples:

CV 63 (sound volume) is a CV that can be programmed byte-

wise witha maximum value of 192. Thevalue 0 means no sound

while 192 standsfor maximumsound volume. (150%)

In CV 49, bit 0 is a „switch“ for activating load compensation

(asper8.3.2). Ifthis bitset to0,loadcompensationis deactivated,

is it set to 1, and then load compensation is active.

TheNMRA(NationalModelRailroadAssociation)hasallocated

certain CVs to certain functions. For instance CV 1 is always

used for the address, CV 5 for the maximum speed.

Advantages / Disadvantages

Digital decoders can be programmed without the need of

comprehensive programming knowledge or equipment. Many

digital command stations also offer internal programming

menus.

Furthermore the programming with bits and bytes requires

littlememoryspace. Programmingsolelywith CVsisnoteasyto

remember and depending on the type of command station it

can be quite cumbersome.

Furthermore CVs have only limitedeffect on soundsinLokSound

decoders (e.g.: sound volume). The actual sounds cannot be

adjusted with CVs but depend on the actual sound recording.

In the LokProgrammer software CVs are shown in registers or

as slide controls and can therefore easily be set to the desired

values.

3.6. Further information about LokSound decoders

3.6.1. General

At the core of a LokSound decoder is a powerful processor. It

is supported by an audio amplifier and a sound memory that

can store up to 268.44seconds ofsound.

The eight channel mixer with active filter can replay eight diffe-

rent sounds simultaneously: One channel is reserved for the

driving sounds while theother seven can be used for othersounds

(such as bells, whistles, etc.), Random Sounds (e.g.:

automaticsafety valvesor shoveling coal), and brakesounds.

Alleight channels will be mixed to one output in the decoder

and transmittedto the speaker.

The memory of the LokSound decoder can be deleted at any

time to make room for new sounds. Thus it is no problem

whatsoevertomodifyasteamsounddecoderintodieselsound.

You can easily do that yourself with the aid of the ESU

LokProgrammer whenever you want to!

Please note: this unimpeded change of sounds is limited to

decoders sold for installation into locomotives by the user.

LokSound decoders that areinstalledinlocomotives bya model

train manufacturer may not always offer this option!

A field at the lower edge of the screen shows the available

memoryspace during programming(in seconds and bytes) as

well as the total capacity of the particular decoder. Select the

„Sound“ register and then one of the sound displays in order

to see this (also refer to chapter 9.).

If you wishto save some files but donot have enough memory

space onthedecoder you mayhavetodeletesomesoundfiles

from this project. Alternately you can shorten some of the

sound fragments with your audio-program.

3.6.2. Connecting the speaker

The speaker is the end piece of the sound equipment. Of

course we can only install small speakers into our model

locomotives.

Therefore the speaker must meet a very demanding

specification. ESU offers a range of speakers of different size

and for different decoder types.

Please note that the audio output of the LokSound v3.5 decoder is

designed for100 Ohm whilst v4.0 and XL require 4,8, and other

ohm ratings. Please seeyour decoder for specific speaker

ratings.

7

8

Tasks of the LokProgrammer

Software

3.6.3. Suitable sounds

ESUoffers many different soundfiles forall sorts of locomotives

on the website www.esu.eu. Please take note of the licensing

conditions mentioned in the appendix regarding the download

of sound files. Of course you can program your own sound

projects on your LokSound decoder.

Generally you may use all files in Windows *.wav-format for

LokSound decoders. WAV is the standard format for storing

sounds of anykind on windows. If the recording is noise, music

or speech makes no difference.

The files can originate from the CD-ROM supplied with the

LokProgrammer, they could be downloaded from the internet

or theycould be created by you.

Wave-files can be stored in different levels of sound quality on

the hard disc. The better the sound quality, the more memory

space isrequired.

In ordertoachieve optimal sound quality you should record and

edit wav files at CD quality (44100hz / 16bit). The program

automatically converts the files to the suitable

formatmatchingthe particulardecoder.

Hint:

With the advent of v4 decoder architecture a new high

capability conversion utility is included in the programmer

software, therefore best audio quality for all v4.0 decoders is

realized by recording and editing at CD quality (44100hz /

16bit, stereo or mono) and allowing the programmer software

to convert your files as they are imported into the sound

project. In this manual we cannot provide comprehensive

instructions on how to edit or convert sound to digital files and

how to save them on ahard disc. Pleaseobserve the manuals

thatwere supplied with your PC or with your audio card,

recording device, and the sound editing software you are

using tocapture and produce your user produced sounds.

3.6.4 Supported hardware

The LokProgrammersoftware as from version 2.5.0 supports

only the LokProgrammer 53450 „LokProgrammer V3.0“.

The number of supported decoders varies subject to the

LokProgrammer version.

Theversions from 2.6.1.SupportthefollowingESU-decoders:

• LokSound V3.5 with 8 and 16 MBit memory for 0 scale andH0

scale(DCCandMotorola®)

• LokSound micro for TT and N scale (DCC, Motorola® and

Selectrix®)

• LokSoundXL V3.5 for G and I gauge (DCC and Motorola®)

• LokSound M4 for 0 and H0 scale for the users of Märklin®

systems.

In addition the following (partly older product versions) are

supported:

LokSound V3.0, LokSoundXL V3.0, LokSound2, LokSoundXL

V2.0, LokPilot, LokPilotDCC, LokPilotXL,LokPilotXL DCC.

Software versions from 4.4.7 support v3.5 and v4.0 decoders.

The LokProgrammer software is subject to continuous

development. In order to assure that you always work with the

latest software version you should regularly call up the internet

update facility. Whenever a new version with extended

functionality and bug fixing is available it will be placed in the

download section on our website.

The appearance on the screen may change subject to the

features of a specific decoder. Therefore in certain cases only

some of the features described here will be active or even

more options may be available. Please always refer to the

manual supplied with the decoder.

4. Purpose of the LokProgrammer software

In the following chapters the program functions of the

LokProgrammer will be described. First the general functions

andthenthemorespecial possibilitiesofadjustingESUdecoders

(LokPilotandLokSound).

The appropriate CV inthe DCC protocolfor each option will be

named as well as which setting is supported by which ESU

decoder. LP stands for LokPilot, LS for LokSound.

Please bear in mind that you can only fully utilize the potential

features of a decoder with the latest firmware.

4.1. Overview

• Setting / changing of all parameters of ESU decoders: alloptions

can be set comfortably on the PC. Ofcourseit is still possible to

manually adjust any CV via digital command stations such as

theESUECoS-commandstation.

• Modification of sound files, that are stored on an ESU LokSound

module: itis possibletochangeall soundfiles onthe LokSound

module at any time, e.g. also at a later stage. Thus you can

compose your own sounds using anything as source that can

be saved on your PC: locomotive sounds, music, speech, etc.

There are no limits to what youcando.

It is for instance easily possible to change the sounds from a

steam locomotive to a diesel or electric locomotive - or vice

versa.

• Test new ESU sounds: With the aid of the virtual cab (see

chapter 6) you can test decoders on the programming track.

Limitations: Select decoders only allow full sound project

installs, no individual sounds may be written. V4 project must

not be protected in order to change individual files. Sound

project must be available and open in LSP (LokSound

Programmer Software) in order to change sound files.

Decoder sound cannot be read into the software from the

decoder. (See chapter 10 and on.)

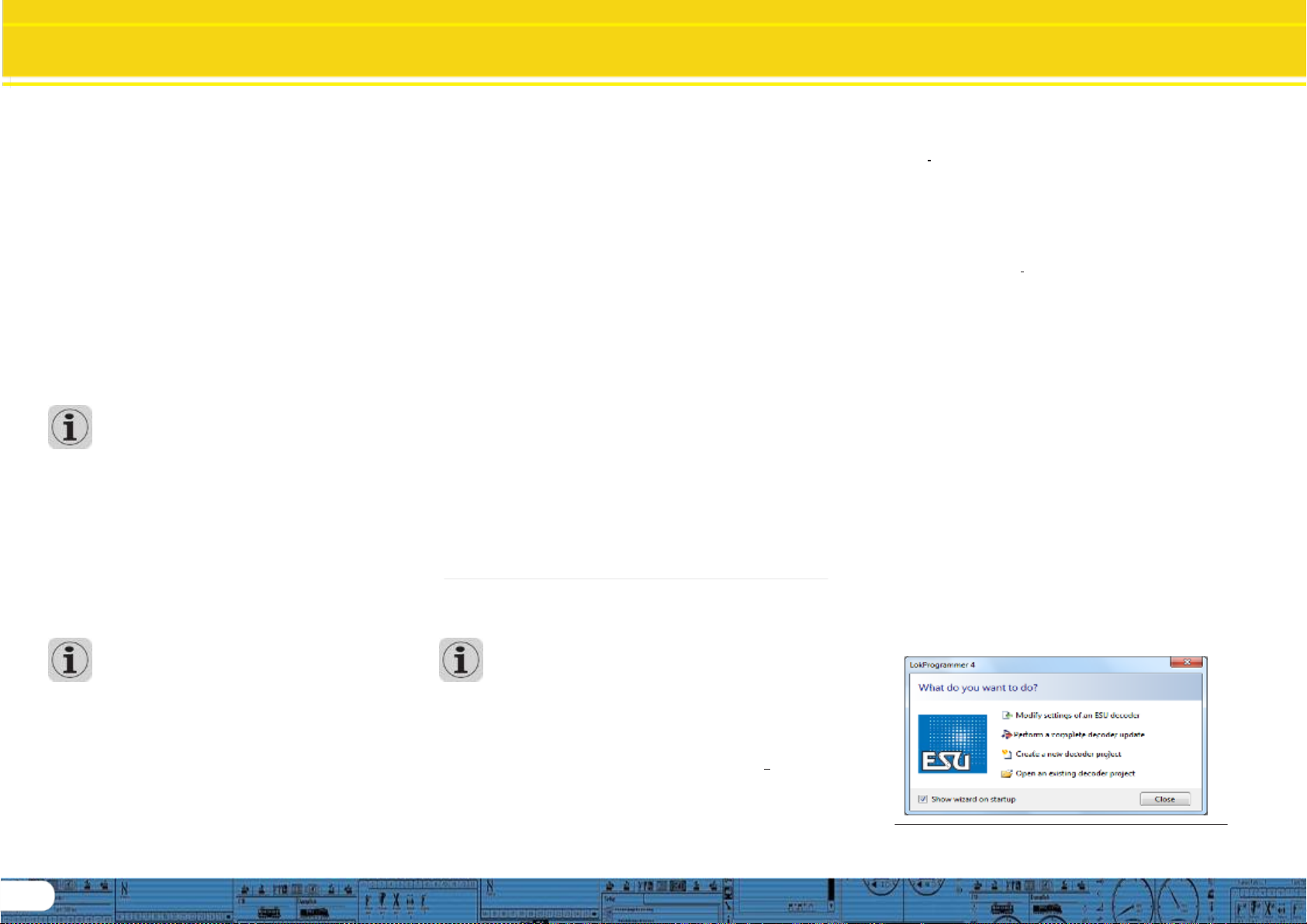

4. 2. Assistant

As soon as the software isstarted the assistant window pops

uponthemonitor.Thisenablesyoutocallupthemostimportant

functions of the program. Subject to which function you select

the appropriate window appears immediately. With the help

of the assistant you can deal with important tasks easily and

quickly.

The assistant helps you to carry out the following tasks:

• To read out decoder data for comfortable evaluation and

modification.

• To completely modify the sound files of a decoder in order to

easily change a steam sound decoder into one for a diesel

locomotive.

• To generate a completely new project

• To open an already saved project.

In order to do this, select the desired option and follow the

instructions in the small window

Fig.9. Assistant

Main Screen

5. Main screen

5.1. View Panes

According to the different tasks, the program is divided into

different viewpanes andmenus. Figure 10 shows the main

screen of the LokProgrammer software and its main

components:

• Drivers Cab: Here you can test decoders in an easymanner

• Read/Write CV’s: individual adjustment of CVs provided the

decoder supports DCC(NMRA).

• Decoder: for comfortable programming of ESU decoders with

agraphicdisplay

• Information: for viewing information regarding functions and

for general information about the file, such as type, country,

etc.

• Sound: this serves for modifying sounds or to generate new

sound compositionsforLokSounddecoders.

Fig.10.: Main screen

5.2. Task bar

Fig.11. Task bar

•File: in this menu you can do the following with projects:

NewProject, Open, Import Project (converts v3.5 projects to

v4.0 projects (Project to be converted must be first saved to

version 2.7.9 or version 4.7.+ software as a v3.5 file)

You can also call up the internet update facility (refer to 2.5)

and close the LokProgrammer software.

During file save, alldata, settings and sound files will be written

into the project file. Project files are saved with the ending

”.esu“ for v3.5 decoder and .esux for v4.0

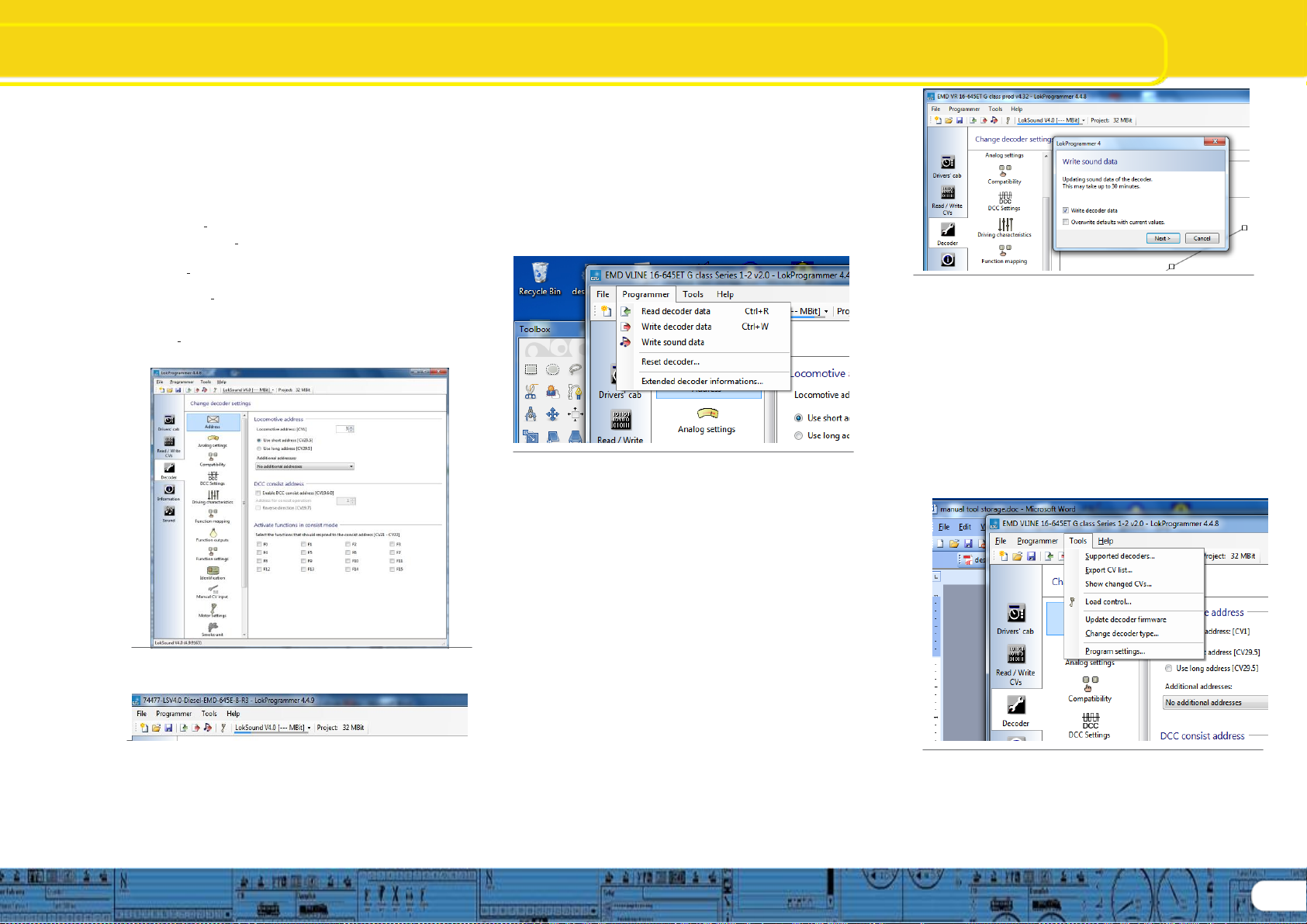

• Programmer: here you can read and write decoder data and

write sound files. Extended decoder data such as type of

decoder and version number ofthe firmware can also be read

here.

Fig.12.: Menu „Programmer“

“Read Decoder Data“: Prior to changing any data on the

decoder it is advisable to read out all decoder data. Place the

locomotive on the programming track and make sure the

programming track is correctly connected.

Then click “Read decoder data“ in the task bar at the top of

the screen. The program startsto read the data immediately.

Pleasebe patient,this process may take one or two minutes.

The status isdisplayed inthe progressbar.

“Write Decoder Data“: The CVs contained in the project file

will be written onto the decoder connected to the

LokProgrammer. Click „Continue“ in the window that opens

first in order to write the CVs. All data on the decoder will be

replaced by the new data.

“Write Sound Data“: The entire sound project will be written to

the decoder using this command, replacing all sound data.

Partial sound information cannot be written, therefore to use

this command the project file for the decoder is required to

have been opened first, using the file menu. A submenu

dialog opens immediately after issuing this command: (next

column)

Fig.13.: Write Sound Data „Programmer“

If “Write decoder data” is checked, the decoder data in the

project will be written first, followed by sound. If “Overwrite

defaults with current values” is checked, then the current

decoder data will become the defaults for when the

command “reset decoder,,,” is issued. When “Next” is

clicked, the information write begins and will take up to 30

minutes to complete, depending on amount of sound data

being written.

“Reset Decoder“: Resets decoder to either factory

defaults or current defaults if “Overwrite defaults” has

previously been used.

5.3. Tools

Fig.14.: Menu „Tools“

The Tools menu provides options that provide information

about the current decoder and allow you to take certain

actions in regards to the current decoder you are working

with: (see next page)

7

9

Main Screen page Cont.

“Supported decoders,,“: This provides a listing of all the

decoders currently supported by the programming software

version you are currently using.

“Export CV List,,“: Creates a .txt file and opens a file save

dialog, allows you to save a listing of the current CV’s for

future use, such as comparisons, etc.

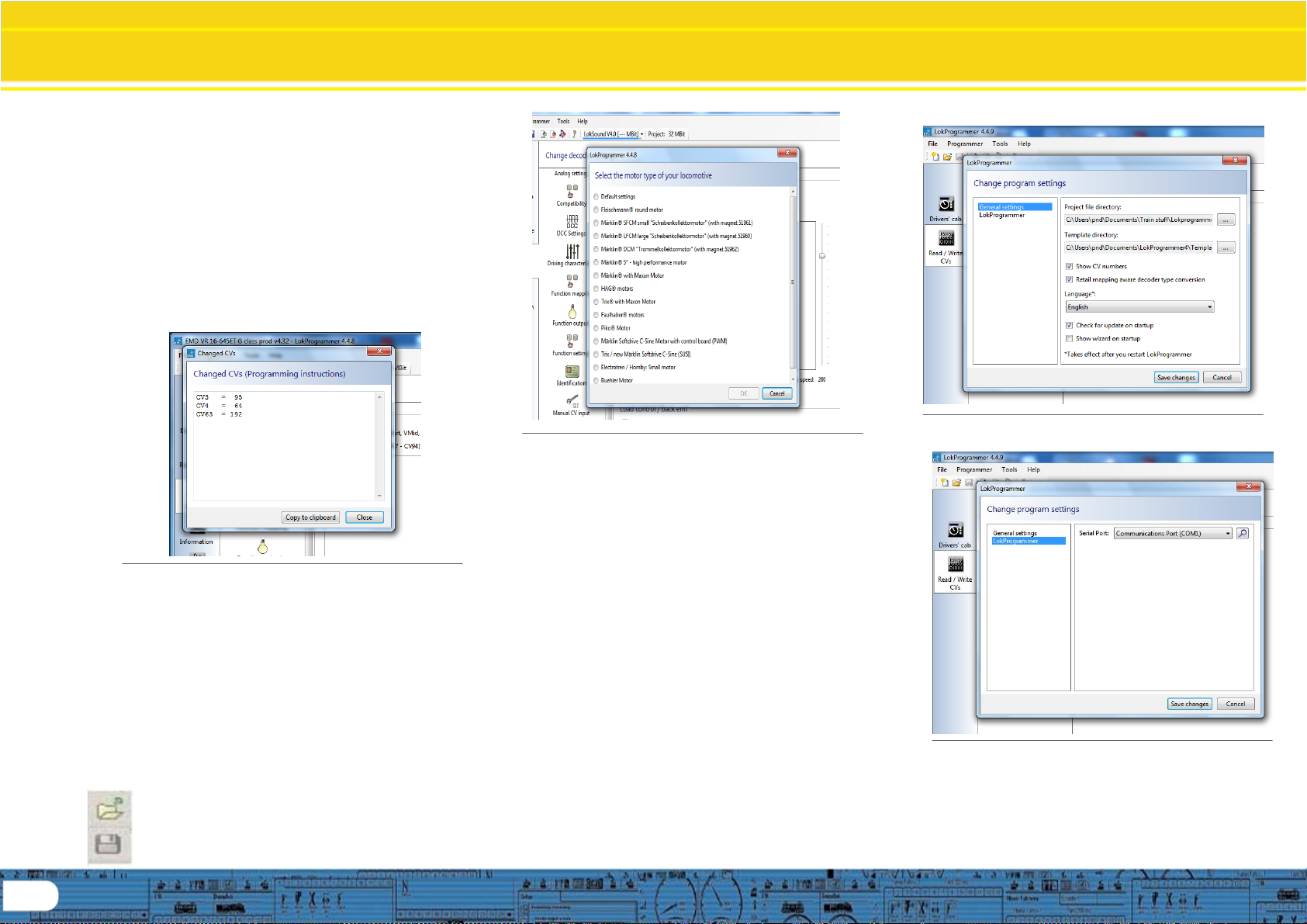

“Show changed CV’s,,“: Opens a sub-dialog box that

displays a listing of only the CV’s that have been changed

since the last time the project file was opened. This is

extremely useful if you intend to perform an action such as

manually programming a decoder. See figure 15 below:

Fig.15.: Changed CV’s, sub dialog „Tools“

“Load Control,,“: Opens a sub-dialog box that lists common

DCC motors that have performance templates built into the

software based on each motor type. Selecting one from this

list that matches or closely matches the motor you are using

in your model and provides a starting point for setting up

your model. See fig 16 at top of next column:

10

Fig.16.: Load Control, sub dialog „Tools“

“Update decoder firmware“: Commands an activity that will

either confirm the current decoder is at the current firmware, or

will write the current firmware to the decoder. Note, this action

is also incorporated in the commands that write decoder data.

“Change decoder type“: This allows you to open a project such

as one for a LokSound Micro or Standard, and change the

decoder type to another supported decoder, such as an XL.

Note; it is not possible to change a decoder type from a v4

project to a v3.5, this option is reserved for working within the

same decoder architecture.

“Program Settings“: Opens a sub-dialog that allows you to set

or change current programmer settings; such as file

directories, languages, display CV’s, etc. This is also where

com settings are controlled for communication with the

LokPprogrammer hardware. See figures 17 and 18 next

column:

Fig.17.: Program Settings, sub-dialog„General“

Fig.18.: Program Settings, sub-dialog „LokProgrammer“

Drivers Cab, Decoder

Information, Read / Write CV’s

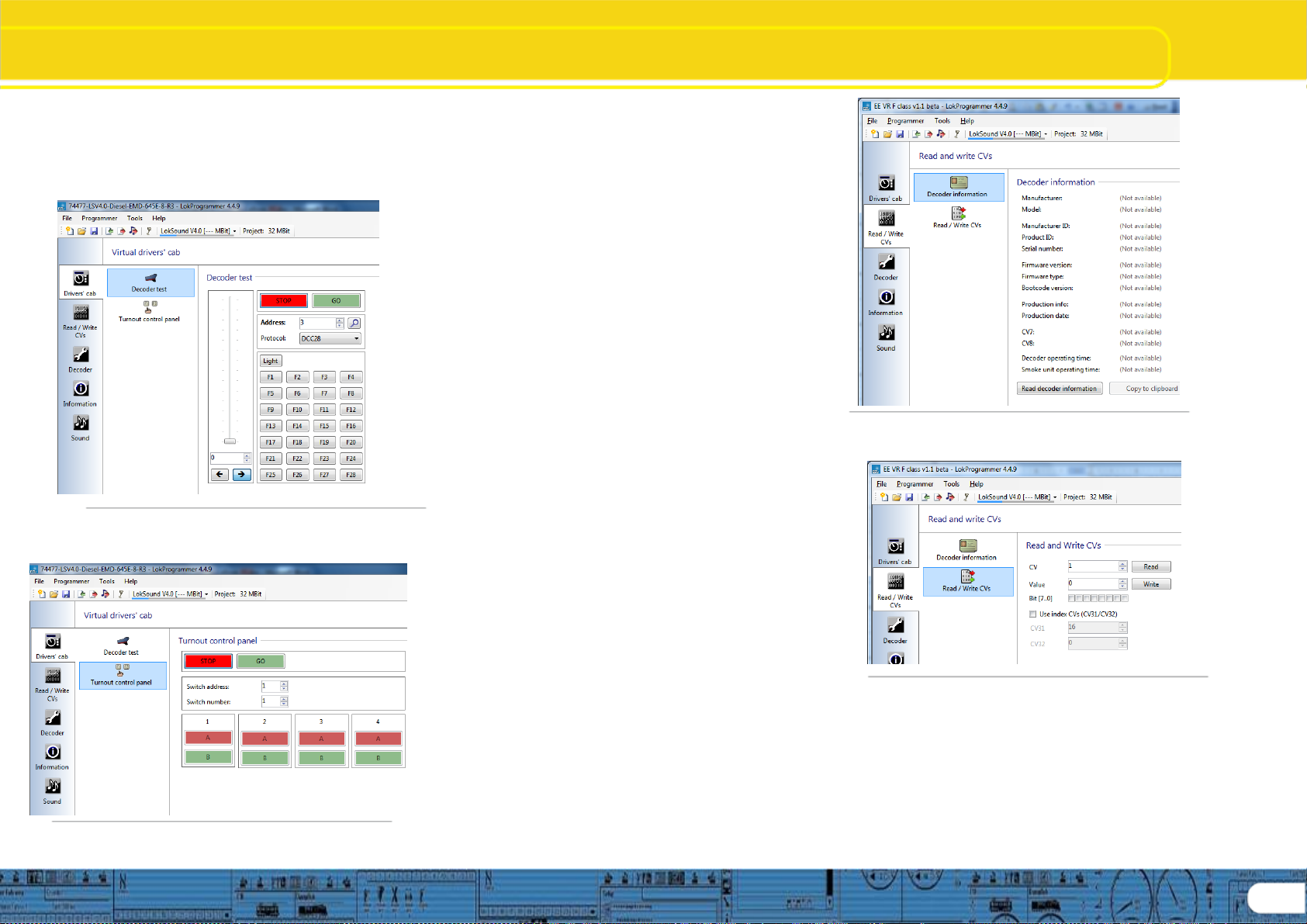

6. Driver’s cab

With the aid of the driver’s cab you can test decoders and sound

projects. You can run the locomotive and trigger all functions.

Therefore you can test run your locomotive on the programming

track with the LokProgrammer.

Fig.19.: Virtual Driver’s Cab

Included in the Drivers Cab section is the Turnout Control Panel

which allows you to also test the Switch Pilot decoder.

Fig.20.: Turnout Control Panel

There are some limitations though: the LokProgrammer power

supply limitsthe permitted current to about 400 mA. Should the

motor of the locomotive draw a higher current then the over

current protection will be triggered and the power to the

programming track will be shut off. This is indicated by the

blinking yellow LED on the LokProgrammer. In this case

deactivate the virtual cab and then turn it on again.

All otherfunctions inthis register areself explanatory:You can

entertheaddressand thenumber ofspeedsteps.Pleasemake

sure that the speed steps matches the ones set on the

LokProgrammer.

The LokProgrammer can run locomotives in DCC format, as

from version 2.5 also in the Motorola® format. Due to the

hardware the LokProgrammer cannot handle M4. Test your

M4 projects in the Motorola® format.

Please check that your programming track is fully isolated from

the mainline of your layout prior to turning on the virtual cab.

Should there be any electrical bridge it could damage the

LokProgrammer (also refer to 2.2.)!

Activate the locomotive for the test run by clicking the field

„Activate Cab“.

Control the speed of the locomotive with the slide throttle.

Clicking into the appropriate fieldsturns functions on and off.

Up to function F12 you may also press the numbers on your

computer keyboard.

Please bear in mind that running a locomotive with the

LokProgrammer cannot and should not substitute a command

station: due to the limited power of the power pack you will

not be able to run more than one locomotive at any one time.

The virtual cab simply gives you the opportunity to quickly test

run your locomotive.

7. Decoder Information, Read / Write CVs

In the register „Read / Write CVs“ you can perform 2 actions, first

in the list is an icon labeled “Decoder Information” (see figure 21),

when the button titled “Read decoder information” is clicked, the

decoder currently connected to the programmer will be read, and

the information will be displayed on the decoder information dialog

as shown in figure 21.

Also within this register you can read and write individual CV’s on

the currently active decoder attached to the programmer (see

figure 22) , this is done as follows: Select the register „Read /

Write CVs“. Then to ReadaCV:

• Enter the number of the CV you want to read in the upper

data entry field.

• Press the button „Read CVs“.

• The result will be shown in binary and decimal format.

Fig. 21.: Decoder Information

Fig.22: Read / Write CV’s

Write a CV:

• Enter the number of the CV you want to write in the field at

the top.

• Write the new value of the CV in the lower data entry field.

• Click onto the button „Write CVs“.

• The CV will be overwritten with the new value.

• The Index CV’s are also shown, and should be set correctly

in order to write values correctly.

Note: Similar to POM (Program on the Main), does not change

sound project values.

11

Change Decoder Settings

Address

8. The “decoder settings” register

All settings regarding the motor control and CV configuration

(such as Function mapping, Sound settings, DCC settings,

etc.) of the decoder are handled in the “Change decoder

settings” register. Please note that this Register is initially empty

when you start the program. Information will only be displayed in

this field after you have generated a new project, opened an

existing project or read out a decoder. Projects are an image of

all data stored on a decoder.

Fig. 23.: The „Change decode settings“ register

The buttons that let you go to the different options are on the

left of thescreen.Besides movement andsound behavior you

12

can adjust specific settings such as brake mode, address, etc.

On the following pages we will explain the parameters and

options.

8.1. Decoder address

8.1.1. Address (CV 1, CV 17, CV 18)

All modifications of the address are done in the window

„Address“. Subject to the decoder type so called short (two

digits, CV1) or longaddresses (four digits, CV17 and CV18)can

be used.

Pleasenotethatanysettings intheseCVsareonlyeffective for

operation with NMRA-DCC compliant command stations.

When operating decoders with the Märklin® / Motorola®-

protocol a separate address, namely the Märklin®-address is

valid.

Youmayenter asecondaddress forM4-decoders inMotorola®

mode in order to activate F5 to F8. Normally this would be the

address of the decoder plus 1.

8.1.2. Consist settings (CV 19)

The DCC consistaddress is useful for multipletraction.It is also

possible to activate function outputs for consists as well as

function buttons for consist mode.

In some cases it is desirable to set certain functions in consist

mode in such a way that the function is actually triggered by

pressing one button in both (or all) locomotives (e.g.: lights).

Click onto the appropriate button of the function that should

be activated in consist mode.

8.2. DCC / Analogue

Supported analogue modes and settings (CVs 13, 14, 50,

125, 126, 127, 128, 129, 130). In analogue mode load

compensation is not active. Therefore by using the appropriate

slide control you can adapt the start voltage and the maximum

speed separately for AC or DC Analogue mode to match the

characteristics of your motor or transformer. Furthermoreyou

can select thefunctions that should be active in analoguemode

(DC, ACor both; CV 50).

8.2.1. Active functions in analog mode (CV13, CV14)

Sincemostanalogue layoutsdonothave input devicestotrigger

functions, these parameters allow you to pre-select which

functions should be automatically active in analogue mode.

It is recommended to turn on the sound (default value F1 for

European projects, F8 for USA) and the smoke generator of

steam locomotives (often F4). Also lighting should be active if

desired. Checked functions cannot be controlled during analog

operation, they are either on (checked), or off (unchecked).

8.2.2. AC Analogue mode (CV 29, CV50)

Activates the AC analogue mode, and allows setting of Start

voltage (minimum speed) (CV127) and Maximum speed

voltage (CV128).

8.2.3. DC Analogue mode (CV29, CV50)

Activates the DC analogue mode, and allows setting of Start

voltage (minimum speed) (CV125) and Maximum speed

voltage (CV126).

8.2.4. Analogue voltage hysteresis (CV 130,

CV129)

The motor will stop when the voltage falls below start voltage

minus motor hysteresis voltage. Functions will be activated

when the voltage reaches the motor start voltage minus the

function difference.

8.3. Compatibility

ESU v4 decoders have certain characteristics built into them to

allow them to be configured to enhance operational

compatibility with certain dcc command stations. Compatibility

settings are enable by checking certain boxes in the

programming software. These selection boxes are identified in

the compatibility section. Options available are:

8.3.1 LGB MTS (CV49.5)

Checking this box enables serial function mode for f1 through

f8 and improves compatibility with LGB Multi Train Systems

command stations

8.3.2 Marklin Delta mode (CV49.2)

This option enables Marklin Delta mode in support of Marklin

delta dcc systems.

8.3.3 Zimo Manual function (CV49.6)

Zimo manual function can be enabled by checking this option.

8.3.4 Serial user standard interface (CV 124.3)

Selecting this opetion will enable the decoder Serial User

Standard Interface (SUSI), this will the decoder to communicate

with up to 3 SUSI devices.

Change Decoder Settings

DCC Settings/Driving Characteristics

8.4. DCC Settings

There are 2 groups of items you can configure in this view

window as shown in figure 24. These are RailCom settings

and Speed step mode.

Fig. 24.: The „DCC Settings“ register

8.4.1 RailCom settings CV29, CV28)

These settings allow the enabling or disabling of RailCom

information. Checking the first option enables RailCom feedback

and allows setting the other 3 items as you desire. LokSound v4

decoders are RailCom enabled and thus offer you the features

RailCom provides.

8.4.2 Speed step mode (CV49, CV29)

Here you can adjust more settings for running your locomotive.

In DCCmode you havethe optionof settingthespeed steps manuallyto

14, 28 or 128. Optionally youcancheck the first option box andallow the

speed stepstobedetectedautomatically.

8.5 Driving characteristics

Items within this view window allows the adjustment of

several variables that affect overall driving features that

are available, such as; acceleration and deceleration

(momentum), brake options, speed trimming, and other

power handling features.

Fig. 25.: The „Driving characteristics“ register

8.5.1 Acceleration and deceleration (CV3, CV4)

Selecting the check boxes for acceleration and deceleration

enables and sets momentum values for speeding up and slowing

down. Setting momentum values allows the model being driven

to act in a more realistic manner, and it allows certain sound

features to be enjoyed.

Acceleration (CV3) can be adjusted using the variable

slider within a decimal value range of 1 to 255 providing

acceleration times of .1 seconds up to 63.75 seconds.

Deceleration time (CV4) can be adjusted using the

deceleration time across the same range, allowing you

to set values for coasting. Higher Momentum settings

also allow certain sound features to operate realistically,

such as coasting sounds and acceleration sounds.

8.5.2 Allowed brake sections (CV27, CV134,

CV123)

A variety of automatic brake sections can be enabled

for the v4 decoder; this allows the layout on which the

decoder is running to be configured to trigger

locomotive braking when a section of track is reached,

perhaps a curve, and then the locomotive returns to

prior speed upon exit. The various types of brake

section detection are enabled by checking the boxes

that match your layout(s).

ABC brake mode can be set for either right rail

(CV27.0), left rail (CV27.1), or both having a more

positive voltage than the other. Voltage difference

(CV134) to enable the trigger can be set with a variable

slider with a range of 4 to 32, providing a significant

flexibility in setting up layouts. The second slider

(CV123) allows setting the amount of speed reduction

over a range of values from 0 –255, allowing automatic

speed reduction from very slight to a complete stop.

Also available is compatibility with ZIMO (HLU) brake

sections (CV27.2) by selecting the option to enable

them.

You can also enable auto stop brake sections carrying

a either a forward DC polarity (CV27.4) or reverse DC

polarity (CV27.3) by selecting the appropriate check

box.

8.5.3 Constant brake distance (CV254, CV255,

CV253, CV27.7)

Constant brake distance allows you to precisely control

where your trains will stop on your layout. This effect

works in conjunction with brake sections, and it can be

used without brake sections by setting only CV254 to

determine a distance for braking, along with setting

CV27 bit 7. With these settings made the v4 will

generate a stop command when ever speed control is

set to speed step 0. Stop distance will be based on the

value set in CV254. See v4 decoder manual chapter

10.6 “Constant Brake Distance for detail.

13

...

14

ChangeDecoderSettings

DrivingCharacteristics/Functions

Fig. 26.: The „Driving characteristics“ register

8.5.4. Reverse mode (CV 29)

A tick at „Reverse mode“ changes the direction of travel

and the directional characteristics of the headlights. This is

useful in case the wiring has been done incorrectly

(swapping of track

leads or motor leads).

8.5.6 Trimming (CV66, CV95)

The trim function allows you to set the maximum speed

separately for forward and reverse movement. The factor

that is used to multiply the motor voltage, results from

dividing the CV-value by 128 (forward CV 66 and reverse

CV 95).

8.5.7 Power Pack (CV 113)

V4 decoders (HO and N) provide for the installation of capacitors

or power packs (so called “keep alive” devices). CV113 allows

control of the amount of time the device is active. Setting range is

0 to 255 via the adjustment slider; an estimated active time is

shown to the right of the setting in seconds. Information for

installing capacitors or power packs can be found in the decoder

manual chapters 10.9 (configuring) and 6.11 (wiring).

8.5.8 Preserve Direction (CV124.0)

Checking this option keeps the direction constant when the v4

equipped loco transitions from DCC control to Analog controlled

track sections.

8.5.9 Starting delay (CV124.2)

Usually, when the LokSound V4.0 sound is idling and you turn up

the throttle, the locomotive begins to move only after the Diesel

engine has reached notch 1. A steam loco will even release its

brakes first and fill the cylinders. Although this behavior is very

prototypical, one might not like it because it causes some delay.

You can control this startup delay by simply not checking this

option. This will cause the LokSound V4.0 decoder to immediately

start moving when the throttle is turned up. However, the start up

sound will not be synchronized with the motion anymore.

8.6. Function views

Both LokSound V4.0 and LokSound micro V4.0 decoders have

identical function mapping. M4 and XL decoders have different

screen displays. The display will shift when the decoder type for

any given project is changed; therefore, the screen display

depends on decoder type. Shown here is the display for V4

standard and micro decoders. A great deal of information is

available in the v4 decoder manual concerning function mapping.

Of course, which sound is assigned to which sound slot may vary

depending on the decoder project. You will find a list with all

available project files “Download/Sound files/LokSoundV4.0/“ on

our home page at www.esu.eu. You may also view and print a list

with all functions and the sound slots employed.

The LokSound V4.0 decoder offers powerful and flexible function

mapping options:. Each function button can switch as many

outputs as desired. Each output can be activated by several

function buttons. Function buttons can be linked (e.g.: F3 AND F5

pressed simultaneously)

Function buttons can be inverted (e.g.: NOT when F8 is on).

Besides the buttons F0 to F28 you can also incorporate the

direction of travel or the speed (locomotive is moving / has

stopped)

You may connect as many as 5 external sensors. While

many model train enthusiasts need precisely these functions

for optimal running of all their locomotives setting up

function mapping represents so to speak the “free style”

version of decoder programming. Take your time to

understand the concept behind it before you start changing

any settings. For a complete review of all function mapping

CV’s, see the v4 decoder manual.

HINT: Even if you do not have LokProgrammer hardware,

you can still use the software as an aid in making mapping

changes in conjunction with the “Show changed CV’s”

capability.

Fig. 27.: The „Function mapping“ register

The function mapping view is arranged as a matrix with

vertical columns for conditions, physical outputs, logical

functions and sounds. Horizontal rows list each condition

and function key for use in mapping as desired. See figure

27.

8.6.1 Function mapping, “Conditions”

The input block (conditions block) shows which condition is

required to achieve a certain output. Conditions are for

instance “F3 On” or “Locomotive is stationary with direction

set to forward, and F8 is switched on”. Configuring the

outputs to behave as desired begins by deciding which

function or function key you wish to configure to enable an

output that will perform the desired action when the function

is on, or off.

ChangeDecoderSettings

FunctionMappingCont.

The figure below; figure 28, displays an example of

setting a condition against function key F11 in which

the direction is set to reverse, and the key must be ON

in order for the condition to equate to “true”, This then

becomes the condition that must be fulfilled in order for

the desired output to be enabled.

Fig. 28.: Establishing a condition for F11

In this manner all the functions available to the decoder

can be configured to behave as desired. The next task

is to set the desired output for the function.

8.6.2 Function mapping, “Physical outputs”

In the output block it is shown what action must be

carried out when the condition(s) is/are met. This could

be, for instance, switching a function output or a sound

effect. LokSound decoders have up to 12 physical

function outputs. “Headlights“and “Rear lights“are used

for lighting, the remaining ones are freely available.

Other functions include “Shunting Mode“, “Acceleration

/ Deceleration On/Off“ as well as virtual functions like

“Sound On/Off“. The function buttons (“F buttons“) of

your command station or throttle activate the function

outputs. Generally, F0 is the lighting button, while we

count the remaining buttons from F1 upwards.

See figure 29, next column, for an example of

configuring the Physical output for F0 to enable the rear

light to come on when the condition “F0 is on and

direction is reversed” becomes true.

Fig. 29.: Setting a Physical output for Rear Light

Complicated lighting configurations can be set by selecting more than 1

output. For example, we wish to have the front light on bright when

running forward, and dim when running in reverse. this can be done

setting front light(1) and front light(2) on, and then setting the function

outputs for front light(1) as on and front light(2) as dim in the function

outputs section. (See figure 30 and 31)

Fig. 30.: Setting a Physical output for Front / Rear

8.6.3 Function outputs, “Configuration”

Configuring the function outputs is done on a separate

screen from the mapping portion, each output can be

configured discretely, and some outputs such as Front

and Rear lights, and Aux1 and Aux2 can each have 2

configurations, to satisfy certain needs, such as

running with the front light on bright when going

forward, and on dim when reversed. There are many

configuration options available, as pictured in figures

31 and 32 dropdown menu options:

Fig. 31.: Physical output configuration for Front(2) dim

Fig. 32.: Setting a Physical output to trigger smoke chuff

15

16

ChangeDecoderSettings

FunctionMappingCont.

8.6.4 Function mapping, “Logical functions”

Logical functions may be applied to any of the function

keys selected for mapping. As with the other parameters

defined by the mapping columns, it is not required that a

logical function be selected, this is an additional option to

provide control in order to get the desired effect. Figures

33 through 34 display the various items the can be applied

to the function key selected.

Fig. 33.: Logical function column

Figure 33 indicates the Logical function column, the next 2

figures show the logical function contents. Assigning

logical functions to function keys enables some very

powerful actions that are available with the v4 decoder

family, as shown below: (figures 34 and 35)

Fig. 34.: Logical function contents, part 1

Note:multiplelogicalfunctionsmaybeassignedtoeachfunction

key,inthiswayonecanfullyconfigureakeyasdesired.

Fig. 35.: Logical function contents, part 1

ListedherearedescriptionsofeachLogicalfunction:

Acceleration-assigningthisoptiondisablesmomentumeffects

Switchingmode–thisoptionhalvesspeed,usefulinyardoperations

Dynamicbrake–effectivelyhalvesthedecelerationmomentumvalue

(CV4)

Firebox–producesafireboxflickereffect

Dimmer–reducesthebrightnessofallphysicaloutputsthataresetto

“dimmable” by 60%

Gradecrossing–enablesgradecrossinglightingeffects,asconfiguredin

thefunctionoutputsection

Dopplereffect–simulatesaDopplersound effectbasedonspeedwhen

enabled

Fadeoutsound–whenenabledfadesthesoundtothevolumesettingfor

“Fade sound” (CV133) in the “sound settings” section; allows simulating

goingintotunnels,buildings,etc.

Dieselnotchup-fordiesel/electricsoundprojects,allowsnotchingupof

onenotchperkeypress(~1seccycle),orengageformultiplenotchpoints.

Notchesupregardlessofspeed.

Dieselnotchdown–notchdownasabove. Note: onceengagedmanual

notchingremainsineffectuntillocomotiveisstoppedandnotchpointisat

idle.

Shiftmode-whenselectedsoundflowpathwillbranchonthosesound

flow charts where “shift” is used as a condition, such as “shift = true” (e.g.

alternatestartuppathsuchascoldstart,dynamicbrakeactionsassociated

withdynamicbrakeengaged,suchasenginerpmmoves toidle followed

bynotch4)

ESUsmokeunit–whenengagedwillturnonsmokeeffectsassociated

withintelligentsmokeunits,suchasESU, KM-10,Kissandothers,also

standardsmokeunits. Note:alsorequiressettingofappropriatefunction

output,andsmokeunitsettings

Volumecontrol–whenset,allowssettingvolumein6stepsbytogglingthe

functionkeyonandoff,onceperstep. Changesthemastervolumein6

steps(CV62)

Disablebrakesound–when engagedturnsoffautomaticbrakesound

(CV459(CV32=1))

Uncouplingcycle–turns onautomaticcoupleraction,alsorequiressetting

offunctionoutputcouplertypeandfunctionsettingssectionforautomatic

uncoupling.

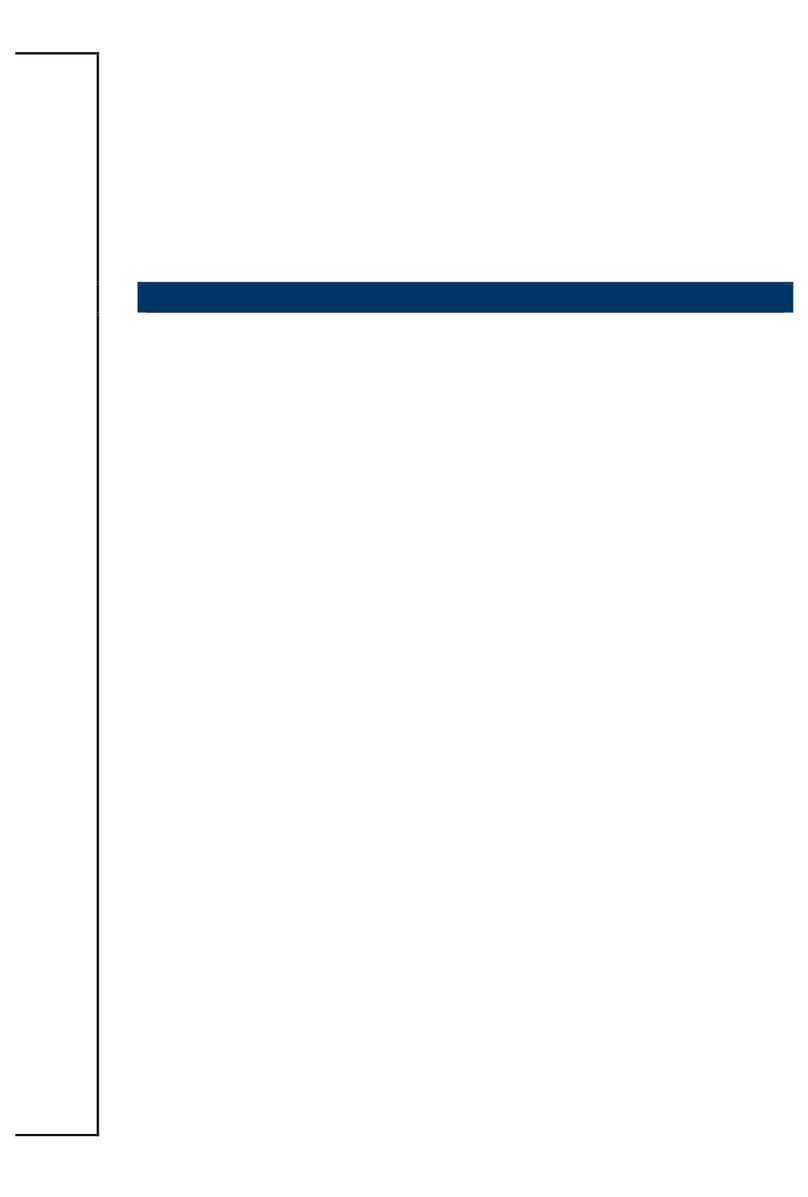

8.6.5 Function mapping, “Sounds”

Hereistheareaoffunctionmappingwheresoundsarelinkedtospecific

functionkeys. Ifsoundslotshavebeennamed,thenamewilldisplayinthe

listwhenexpanded. Youcanassignmultiplesoundstoasinglekey,and

youcanassignsoundstomultiplelocations.Ifdesired. Seefigure36

below.

Fig. 36.: Mapping sound to function key

ChangeDecoderSettings

Functions/Identification/CVs

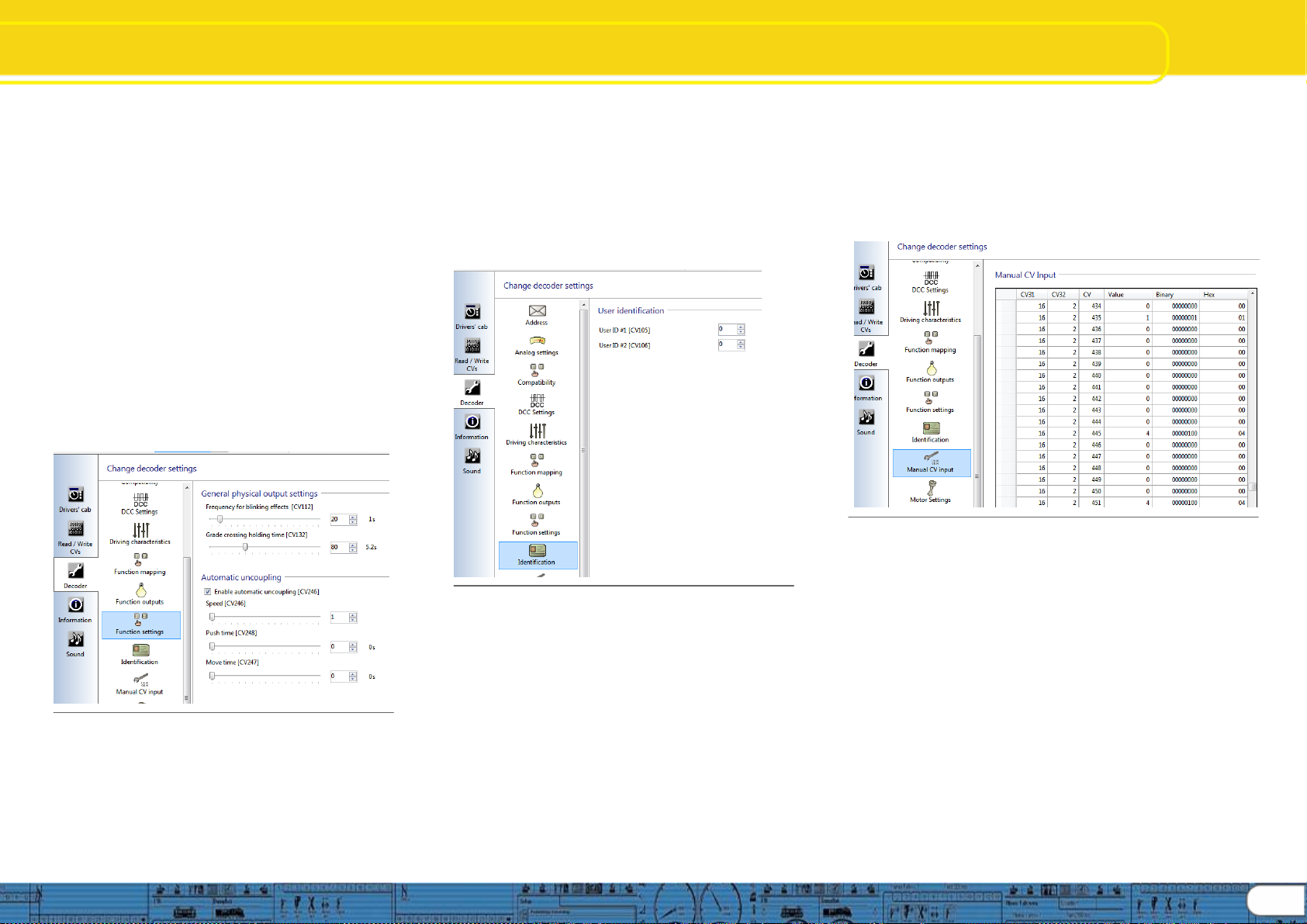

8.6.6 Function settings, “General” and “Automatic uncoupling”

Asmentioned in8.6.5above,whenmappinglogical

functionstoafunctionkey,insomecasesyoushouldalso

use Functionsettingsinorderto enabletheresponse you

desirewhenthefunctionkeyisengaged. Generalsettings

areforconfiguringlightingeffects,andallowyoutosetthe

blink frequencyforlightingsituationsthatrequireblinking

lights (CV112),andforsettinggradecrossingholdingtime

(CV132). Holdingtimeistheamountoftimethegrade

crossingeffect isenabled.

Automaticuncouplingis whereautomaticuncouplingis

enabled(CV246),andwhereyoucansettheuncoupling

speedacrossarangeof1–255(sameasthespeedtable

range),defaultis1(CV246). Pushtime(CV248)isthetime

insecondstheautomaticpushisineffect;andMovetime

(CV247)isthetimeinsecondsthelocomotivemoves away

from the uncoupled car(s). Of course “time” relates directly to

distancetraveled atthespeedsetfor thedurationofthe

automaticuncouplingcycle. See figure 37.

Fig. 37.: Configure Function settings

8.7. Identification

8.7.1 Data fields, “User identification”

Theuseridentificationfieldsareopenfieldsthatcanbeusedforany

purpose. These are designated as “User ID #1” and “User ID #2”.

CV’s are CV105 and CV106 respectively. Value range for both is 0 –

255andtheycanbesetindividually or together. Setting these CV’s

doesnotchangeanydecoderbehavior,theyareanopencode

sectionandcanbeusedforanypurpose,perhapstotrackacertain

version, or function key structure. Default value is 0 for both CV’s.

Seefigure38

Fig. 38.: User Identification

8.8. Manual CV Input

8.8.1ManualCVInput

Thissectionofthechangedecoderdatascreensismadeavailable

shouldyouwishtomakemanualCVchangeswithoutusingthe

preformatteddecodersetupscreensandviews. Itisalsoveryuseful

for researching CV’s. WhenyouexportthedecoderCVlisting(See

“5.3 Tools”, Export CV list) the text file that is created during the export

willconsistofthesamedatadisplayedinthisview.

8.8.2CVchanges

CVchangescanbemadedirectlybyoverwritingthedatainanyof

the data fields; “Value”, “Binary”, or “Hex”,simplyenterthevalueyou

wishandthentaboutofthefieldandthedatawillbechangedandthe

othertwodatacolumnswillupdate. Ofcourseitismucheasierto

enter direct numeric data in the “Value” column than it is to write

BinaryorHexdata.

Afteryouarefinishedmakingchanges,thenewvaluesmaybe

written to the decoder using “Write decoder data” (See “5.2

Programmer”,Figure12)

Note:Theabilitytomakemanualchangesisverypowerfuland

shouldbeusedwithcare. Considersavingthechangedproject

fileunderanewnameinordertoprovideawaytorewritelast

knowngooddatatothedecodertorecoverfrommistakes. See

figure39.

Fig. 39.: Manual CV Input

8.9. Motor Settings

Hereiswhereyouconfigurespeedtable,loadcontrol,PWM

frequency,andoverloadprotectionsettingsonthev4decoder

series. Informationpresentedheredealsdirectlywithmaking

desiredsettingsusingtheLokProgrammertooltoconfigurethe

decoder,thereforethelevelofdetailpresentedisnotatthesame

level asisfoundinthev4decodermanual. Pleaseusethe

detailedinformationfoundinthedecodermanual,chapter10,as

thepreferredsourcefordecoderinformation.

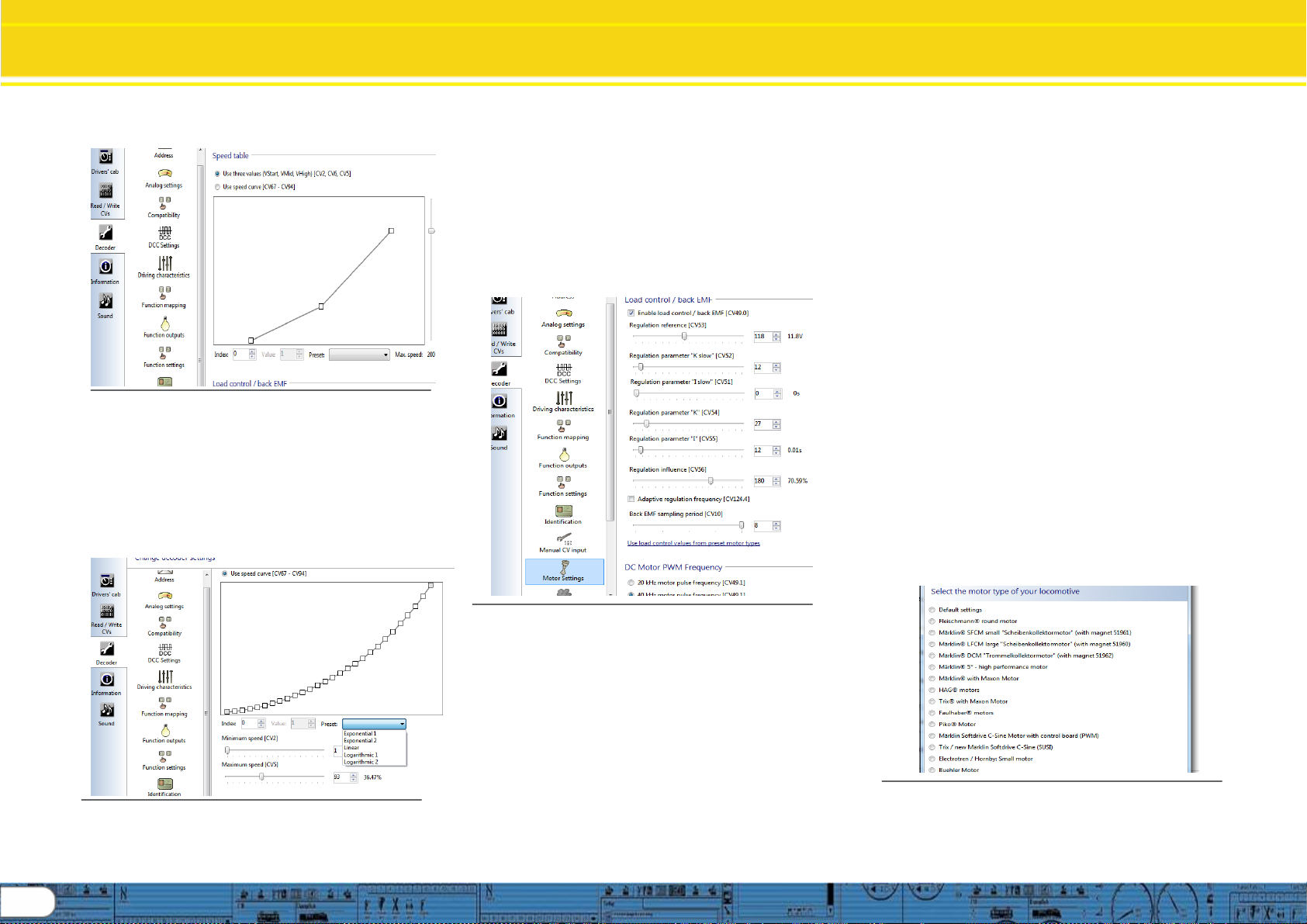

8.9.1Speedtableselectionandconfiguration (CV2,CV

5,CV6,CV26,andCV67-97)

Hereyoumayselecteithera3pointspeedtable(figure40)ora

customspeedcurve(figure41). Ifyouusethe3point tableyou

shouldsetminimum andmaximumspeed(CV2andCV5)and

thenpickthemidrangespeed(CV6)asdesired. Youmayalso

usethesliderontherighthandsidetosetbothmaximumand

midrangespeeds. Inordertoavoidpossibleroughorunusual

running,pleaseensure

17

18

Change DecoderSettings

MotorSettings

midrangespeedis higherthanstartspeedandmaximum

speedishigherthanmidrangespeed(CV2<CV6<CV5).

Fig. 40: 3 point speed table

Youmayalsodefineyourownspeedcurve:simplyenter

thedesiredvaluesintheCVs 67to94(alsorefertoFig.16).

Thedecoderwillsuperimposethese28valuesontothereal

speedsteps.Thus,youcanadaptthedrivingperformance

optimallytoyourlocomotive. Anotheroptionisavailable

usingthespeedcurveoption,thereare5predefinedspeed

curvesstoredintheprogrammersoftware,youmayselect

anyofthesebysimplyclickingontheoneyoudesiretostart

with,andthenyoucanmodifythemasdesired. Seefigure

41.

Fig. 41: Speed curve options and set up

Speedcurveshapeissetbyadjustingthe28pointcurveas

desired,thenminimumandmaximumspeedissetasitis

with the speed table (CV’s 2 and 5), the decoder then fits the

Speedcurvebetweentheminimumandmaximumspeedsettings

resultinginasmooth28pointspeedcurvewithinthedecoder. Please

seethedecodermanual,chapter10formoredetail.

8.9.2 Load control / Back EMF (CV’s 53, 52, 51, 55, and 56)

LoadcontrolcompensationisenabledviatheLokProgrammerby

checkingtheboxatthetopoftheloadcontrolsection,followingthat,

the CV’s can be adjusted as desired. HINT:Ifthedecoderisinstalled

in a model locomotive, there is an “auto set” feature you can use to set

theinitial parameters. See decodermanual,chapter11fordetailson

howtousethis feature. Thenifyouneedfurtheradjustmentyoucan

“read decoder data” to load the automatic settings into the

programmerforfinetuning. Seefigure42.

Fig. 42: Load control / back EMF setup

LokSounddecodersenableyoutoadaptloadcompensationtothe

motorwithCVs53,54and55.Iftherecommended values above

donotleadtoacceptableresults,youcanfurtheroptimizethem.

Especiallyfortheslowdrivingsector(speedstep1)theLokSound

V4.0withCV 51andCV52tochangethegaincontrol.Thishelpsto

avoidanyjerkingwhiledrivingextremelyslowly.

ParameterK,storedinCV54,influenceshowstronglyloadcontrol

will affect thedrivingperformance.Thehigherthevalue,themore

loadcontrolwillrespondtoanychangesandtrytoadjusttherevsof

themotor.ParameterKneedsadjustmentifthelocomotiveruns

unevenly(jerks). ReducethevalueofCV54by5andtest-runthe

locomotivetoseeifthereareanyimprovements.Repeatthese

stepsuntilthelocomotiverunssmoothlyatspeedstep1.

ParameterI,storedinCV55,provides importantinformationtothe

decoderonhowmuchinertiathemotorhas.Motorswithlarge

flywheelsnaturallyhavemoreinertiathansmalleronesorcorelessmotors. Adjust

parameterI ifthelocomotivejerkssomewhatjustbeforeitstops orjumpsatlower

speeds(lowerthirdofthespeedsteprange)orsimplydoesnotrunsmoothly.

Increasethevalueby5startingwiththeinitialvalueformotorswithverysmallorno

flywheels. Reducethevalueby5startingwiththeinitialvalueformotorswithlarge

flywheels.Testagainandrepeatthisprocedureuntilyouarriveatthedesiredresult.

InCV53,yousettheEMFreferencevoltagegeneratedbythemotoratmaximum

revs.This parametermayhavetobeadaptedsubjecttothetrackvoltageandthe

efficiencyofthemotor. Ifthelocomotivereachesmaximumspeedwhenthethrottle

issettoaboutthree-quarterandthetopthirdofthethrottlehas noinfluenceonthe

speed,thenyoushouldreducethevalueofCV53.Reducethevalueby5–8and

testthelocomotiveagain.Repeatthisprocessuntilthelocomotivejustreachesits

maximumspeedwhenthethrottleisfullyopen. Ontheotherhand,ifthelocomotive

movestooslowlyatfullthrottlethenyoushouldincreasethevalueofCV53stepby

stepuntilthemaximumspeedisreached.

TogetherwiththeLokSoundV4.0decoderanadditionalCV52hasbeenintroduced

whichseparatelydetermines thegaincontrolconsiderablyforthewholeslowdriving

sectorinspeedstep1. If youarenotsatisfiedwiththedrivingbehavior whenthe

locomotivedrives slowlyorstarts,whileeverythingisfinewiththemediumandhigh

speedsteps,youshouldincreasethevalueofCV52by5-10higherthanthevalue

setinCV54. Hereyoucanadjusttheinertiaofthemotorseparatelyforslowspeeds

andstartingfromastop.ThedesiredvalueistobeenteredintoCV 51.The

parameters “K slow” and “I slow” jointly influence the behavior at speed steps 1 and 2

while the parameters CV 54 (“K) and CV 55 (“I”) are responsible for theremaining

speedsteps.Thedecodercomputesaspeedcurveinordertoavoidanyabrupt

changes.

Thedecoderoperatesexworkswithamutable(adaptive)regulationfrequencyto

drivethemotoraspreciselyaspossible.However,asaresultsomemotorsmight

showanastybuzzingnoise. Forsuchmotorsyouareabletosettheregulation

frequencyonaconstantvaluebycheckingtheboxtoenableadaptiveregulation

frequency. YoumayalsoadjusttheBackEMFsamplingperiodusingtheslider,

valuesrangefrom4to8(CV10).

Fig. 43: Load control preset motors

YoumayapplypresetsthathavebeentestedbyESUformanytypesof

motors by clicking the option “use motor control values from preset

motor types “ See figures 42 and 43. See v4 decoder manual for mote

detail.

Change DecoderSettings

MotorSettings/Smoke/Sound

8.9.3DCMotorPWMFrequency(CV49.1)

LokSounddecodersloadcontrolworksnormallywith40kHz.

Sometimesitcanbeusefultoreducethisfrequencybyhalf:

Formotorswithlittlepowerduetohighinductivity.

•Ifsuppressors(suchascapacitors,chokes,etc.)disturbload

controlbutcannotberemoved(e.g.someolderGützold®

locos).

CheckthedesiredsettingintheProgrammersoftwaretoset

CV49bit1asdesiredforeither40or20kHz.

8.9.4MotorOverloadProtection(CV124.5)

ESUv4decoders offer asettingtoenablemotor overload

protectionif needed. Thisisseparatefromthenormalthermal

protectionforthedecoderasdescribedindecodermanual,

chapter6.10.1. Motoroverloadprotectionenablesthedecoder

tomonitorBEMFreactionsofthemotortovariousoperational

loads;ifthedecoderdetectsmotoroverworking(possiblydue

tomechanicalissuesorstress)thedecoder willstopthemotor

withoutaffectingotherdecoderoperationorsound.

8.10. Smoke Unit

ESUv4DCCdecodersenableawidevarietyofoutput

choices,oneofwhichis smokegenerators,suchas ESU

smokegeneratorsorthosefromothervendors.

YoucanwireanykindofloadsuchasLEDs(lightemitting

diodes),smokegeneratorsorsimilardevicestothefunction

outputsprovidedthemaximumcurrentdrawislessthanthatof

thedecoderoutput.Thepermittedmaximumcurrentdrawper

functionoutputislistedinchapter20ofthedecodermanual

under „Technical Data.“,pleaseconfirmyourintendedsmoke

generator loadissuitableforyourdecoder. Itisimportantto

staywithinthecurrentcapabilitiesofthedecoderyouare

installingandprogramminginordertoavoidpossibledamage.

Thissectionofthedecodersettings worksinconjunctionwith

severalfunctionsettingitemslistedinsection8.6ofthis

manual,suchasfunctionmapping,physicalandlogical

outputs,andfunctionoutputs. Pleaseset up allareasinorder

tocontrolyoursmokeoutputasdesired.

ESUv4XLdecodercandriveseveraltypesofsmokeunits

directly,thestandardv4decoderandthemicro v4maynotbe

able to fully drive a smoke unit, but you can still provide “smart”

orsounddrivensmokeunitoperationifyouconsideroptions

suchasSUSIorrelays. Placingmagnetsorfoilsystemsor

othercomplicatedtriggerdevicesisnotrequiredifyouusethe

smokeunitcapabilityofESUdecoders. Seefigures44, and

thefunctionmappingfiguresinsection8.6fordetail.

Fig. 44: Smoke Unit set up

8.10.1 ESU Smoke unit (CV’s 140,138,139)

HereyoucansetvariablestocontrolESUandothersmokeunits. You

cansettimeofoperationuntilsmokeunitpoweroffacrossarangeof1to

120(1to600seconds)(CV140). Youcantrimbothfanspeed(CV138)

andtemperature(CV139)toprovidesmokedensitytoyourchoosing

usingtheappropriateslidervalue. Trimsettingsdefaultto128(100%)

acrossarangeof0to255.

8.10.2Smokechuffs(CV’s 143,141,142)

Thissegmentofthesmokeunitsetupallowsyoutocontroldurationofthe

smoke “puff” relative to trigger distance (CV143), across a range of 0-255

providingupto1seconddurationpertriggerevent. Minimum(CV141)

andmaximum(CV142) durationofthesmokepulseisadjustableina

rangefrom 0-255,thisprovidesamaximumsmokepulsedurationof1

second,withminimumandmaximumrangingfrom0–1.04seconds.

Thesesettingsallowthesmokepulsetovarywithlocomotivespeed,

similartothewaythechuffsoundvarieswithspeed.

AllsmokesettingsaredirectvalueswhichlendthemselvestoPOM

programming for easy fine tuning. SUSI interface will provide “intelligent”

smokeifyourdecoderfunctionscannotmeetthecurrentratingforthe

smokeunit. IfusingSUSIinterfacepleaseremembertoenableSUSIfor

thedecoder,seesection8.3“Compatibility” for details.

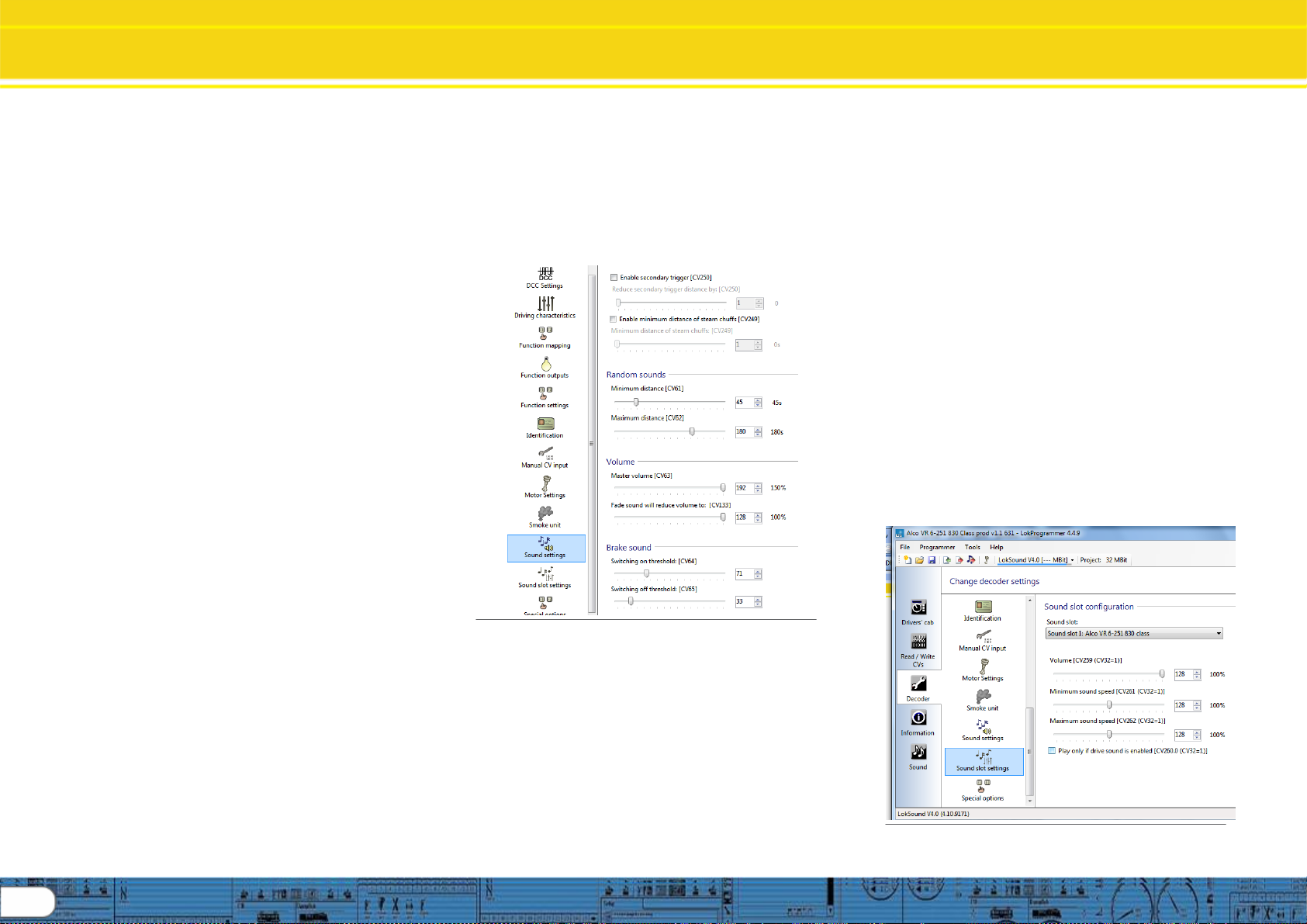

8.11. Sound settings

Soundsettingssectionallowsconfigurationofseveralareasthataffectthe

reproduction of soundsstoredonthedecoderwhenthesoundprojectis

writtentothedecoder,thusallowingtheusertoselectoperationtomatch

themodellocomotive. Pleaserefertofigures45and46aseachsection

iscovered.

Fig. 45: Sound settings part 1

8.11.1Soundselection(CV48)

Version4decodersandsoftwareallowtheuseofpre-

configuredgroupsofsoundswhicharekepttogetherin

templatesthatcanbeplacedinasoundproject. Examples

arewhistleandhornpacks. Withineachgroup,eachspecific

sound,suchasaNathan-P3horn,aregivenanindexnumber

whenthepackiscreated, thenumberrangeis1through16,

withaspecificsoundassignedtoeachnumber. Usingthe

Soundselectionconfigurationnumberyoucanselectwhich

hornorwhistleyouprefertosoundwhenthehornpackis

assignedtoafunctionkeyviafunctionmapping. CV48can

alsobewrittendirectly,allowingforchangeswhileoperating.

(Powercyclemayberequiredafterchange)

8.11.2Steamchuffs(CV’s 57,58,250,249)

Synchronizingsteamlocochuffsoundtowheelrevolutionis

performedinthissectionoftheprogrammer. Anabbreviated

methodislistedhere,forfulldetail,pleasereadthedecoder

manual,chapter13.4.

(Continuednextpage)

19

20

Change DecoderSettings

Soundsettingscontinued

Ifusinganexternalchufftrigger,suchasmagnetsoratrigger

switch, check the option titled “use external sensor”, then you

haveanoptionwiththesliderbartoenterthenumberof

triggersrequiredtomakeachuff. E.G.ifamagnetwas

mountedon agearthatrequired4revolutionstoprovide

enoughdrivewheelprogresstorequireachuff,thenyouwould

put4inthesliderbox;thiswouldmeanit wouldtakeatotalof

16revolutionsofthegeartoequateto4chuffsperdrivewheel

revolution.

Beforecomplicatingyourassemblybydevisingatrigger

method, try the chuff option “Play steam chuffs according to

speed”. Select that option, and then set the chuff sync sliders

inordertoproducethecorrectautomaticchuffsounds. A

significantnumberofmodelerswhooncealwaysusedchuff

triggershavefoundautomaticchufftimingisjustasaccurate

andsignificantlyeasiertosetup.

CV57is usedtosetthechuffsequencefor1completedrive

wheelrevolutionatspeedstep1(1of28).Timeonedrive