4 www.eta.co.at

General information General

1 General

1.1 General information

Copyright

All contents of this document are property of ETA

Heiztechnik GmbH and are protected by copyright.

Any reproduction, transfer to third parties or use for

other purposes is prohibited without written permission

from the owner.

Subject to technical changes

We reserve the right to make technical modifications

without notice. Printing and typesetting errors or

changes of any kind made in the interim are not cause

for claims. Individual configurations depicted or

described here are only available optionally. In the

event of contradictions between individual documents

regarding delivery scope, the information in our current

price list applies.

Software Description

The software version described in this documentation

corresponds to the version valid at the time of publica-

tion. The software version installed on your product

may differ from that described in this documentation.

A software update to a more recent version can

always be performed. With the appropriate au-

thorisation, the required files can be found at

"www.eta.co.at".

Explanation of symbols

Instructions and information

Layout of safety instructions

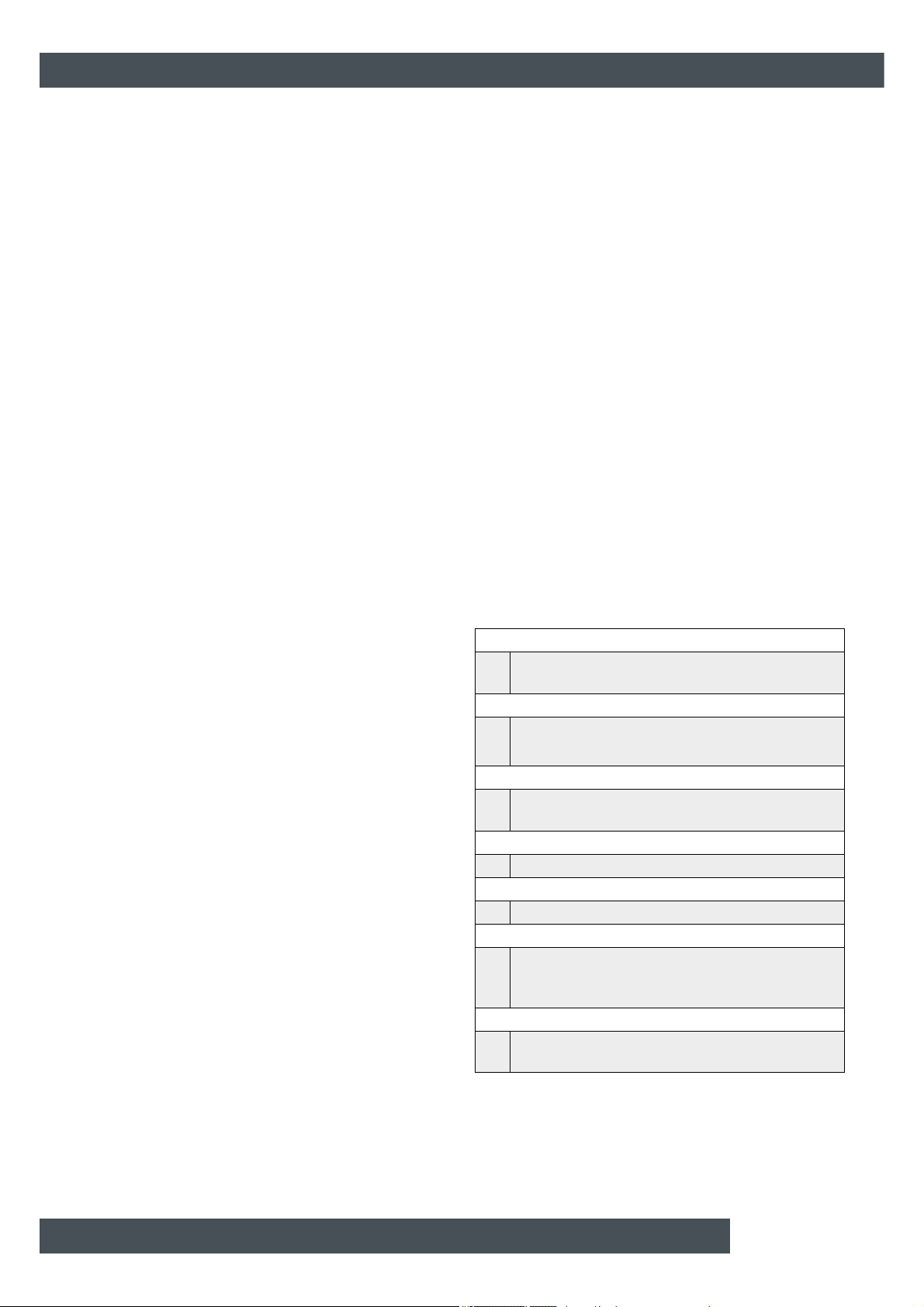

SIGNAL WORD!

Type and source of danger

Possible effects

• Measures for avoiding the danger

Types of safety instruction

CAUTION!

On non-compliance with this safety instruction, there is

a risk of material damage.

WARNING!

On non-compliance with this safety instruction, there is

a risk of physical injury.

DANGER!

On non-compliance with this safety instruction, there is

a risk of major physical injury.

1.2 Warranty, guarantee and liability

Installation in a dry, frost-proof room

A dry, frost-proof room is required for the installation.

Heed the drinking water ordinance

In terms of drinking water, the chemical, physical and

bacterial limits stated in the applicable national

drinking water ordinance must not be exceeded. See

chapter on 8 "Information on cold water".

Calcification

Potential calcification of the fresh water module is

excluded by the warranty. In the case of water with par-

ticularly high scale-forming properties, water softening

or regular descaling may be necessary. You can find

more information in the chapter on 8 "Information on

cold water".

Safety valve for the drinking water line

Before each closed drinking water heater (=TWE /

tank) a membrane safety valve is to be installed in

accordance with DIN 1988 and 4753, Part 1 and

TRD 721. This valves opens automatically when a set

operating pressure is exceeded (6, 8, 10 bar), and

after a pressure reduction it closes again automatical-

ly.

Except flow heaters with a nominal volume of less than

3 litres.

The ETA fresh water module falls under this

exception rule. That is why no additional safety

valve is required.

With the optional circulation set, however, a

safety valve is required on the drinking water side

(10 bar) and that is why it is already installed at the

factory. This must not be blocked nor removed.

pH value between 8 and 9

The pH value of water used to fill the heating system

must be between 8 and 9.