L

Disconnect power supply before beginning wiring

to prevent electrical shockorequipment damage.

If a new gas control is to be installed, turn off gas

supply before starting installation. Conduct Gas

Leak Test according to gas control manufac-

turer’s instructions after the gas control is in-

stalled.

lf module must be mounted near moisture or

water, provide suitable waterproof enclosure.

PERFORM PREINSTALLATION SAFETY INSPECTION

Ifthis is a replacement installation, check the appliance

and venting system carefully before installing new module.

If a condition which could result in unsafe operation is

detected, the appliance should be shut off and the owner

advised of the unsafe condition. Any potentially unsafe

condition must be corrected before proceeding with the

installation.

MAINTENANCE REQUIREMENTS IN SEVERE ENVI-

RONMENTS

Regular preventive maintenance is important in any ap-

plication, but especially so in agricultural and industrial

applications because

l In many such applications, the equipment operates

1OO,OOO-200,000 cycles per year. Such heavy cy-

cling can wearoutthegascontrolinonetotwoyears.

A normal forced air furnace, for which the controls

were originally intended, typically operates less than

20,000 cycles per year.

l Exposure to water, dirt, chemicals, and heat can

damage the module or the gas control and shut

down the control system. A NEMA 4 enclosure can

reduce exposure to environmental contaminants.

See Electronic Ignition Service Manual, form 70-

6604.

The maintenance program should include regular

checkout of the system as outlined under Checkout, page

11.

FIRE OR EXPLOSION HAZARD

MAY CAUSE PROPERTY DAMAGE, SEVERE

INJURY OR DEATH

Do not attempt to take the module apart or to

clean it. Improper reassembly and cleaning may

cause unreliable operation.

1

Maintenance frequency must be determined individu-

ally for each application. Some considerations are:

l Cycling frequency. Appliances that may cycle more

than 20,000 times annually should be checked

monthly.

l Intermittent use. Appliances that are used season-

ally should be checked before shutdown and again

before the next use.

9 Consequence of unexpected shutdown. Where the

cost of an unexpected shutdown would be high, the

system should be checked more often.

l Dusty, wet, or corrosive environment. Since these

environments can cause the controls to deteriorate

more rapidly, the system should be checked more

often. Protective enclosures, as outlined under

“Planning the Installation”, are recommended re-

gardless of checkout frequency.

Any control should be replaced if it does not perform

properly on checkout or troubleshooting. In addition, re-

place any module if it is wet or looks like it has ever been

wet.

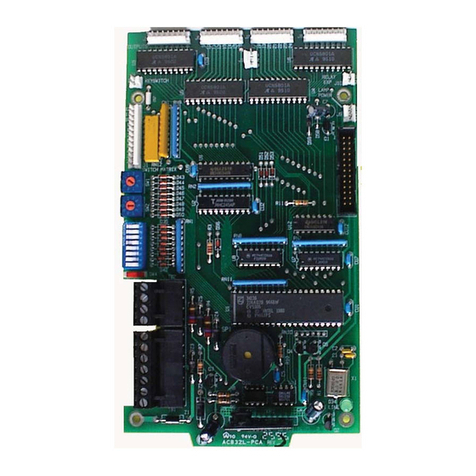

MOUNT IGNITION MODULE

Select a location close enough to the burner to allow a

short, direct cable route to the igniter. Ambient tempera-

ture at the module must be within the range of minus 40”

F to plus 175” F [minus 40” C to plus 79” C]. The module

must be protected from water, moisture, corrosive chemi-

cals and excessive dust and grease.

The module can be mounted in any position. Fasten

securely with four No. 6-32 machine or No. 8 sheetmetal

screws 1 in. [25 mm] long.

MOUNT THE SYSTEM CONTROLS

Mount any required controls, such as the gas control,

hot surface igniter, flame sensor, thermostat, limit and

transformer according to manufacturer’s instructions.

1. Check the wiring diagram furnished by the appli-

ance manufacturer, if available, for circuits differ-

ing from the wiring hookups shown. Carefully

follow any special instructions affecting the gen-

eral procedures outlined below.

2. Disconnect the power supply before making wir-

ing connections to prevent electrical shock or

equipment damage.

I I

IMPORTANT

1. All wiring must comply with applicable electrical

codes and ordinances.

2. When installing the hot surface igniter, the lead-

wires should be kept as short as possible and

should not be allowed to rest against grounded

metal surfaces.

3. A common ground is required for the S89/S890

and the main burner. The 24 V (GND) terminal

internally grounds one side of the transformer.

Any auxiliary controls or limits must not be in the

grounded leg. In addition, the appliance should

be earth-grounded.

4. Make sure thetransformer has adequate VA. The

ignition module requires at least 0.2 A at 24 Vat.

Add the current draws of all other devices in the

control circuit, including the gas control, and

multiply by 24 to determine the total VA require-

ment of these components. Add this total to 4.8

VA (forthe ignition module). The result isthe mini-

mum transformer VA rating. Use a Class IItrans-

former if replacement is required.

5. Check that Ll (hot) and L2 (neutral) are wired to

the proper terminals. If Ll and L2 are inter-

changed, the S89/S890 will not detect the flame,

and will go into safety shutdown.

Connect Igniter

Prepare wiring harness. See Igniter wiring, page 3.

1. On models with quick connects, use insulated 114in.

female quick connects to connect the wiring harness leads

to the HSI terminals on the ignition module.

2. On models with leadwires, use solderlessconnectors

to connect the wiring harness leads to the blue leads from

the module.

3. Connect the wiring harness to the igniter.

5 68-007&l