Eternus DX80 S2 User manual

Slide 0

Welcome to this Web Based Training session providing an introduction to the

hardware installation for the ETERNUS DX80 S2 and DX90 S2.

1

In this first chapter we will look at the steps involved in the hardware installation of

the system.

Following subjects will be covered:

First some words about the package contents

Then we will continue with the Controller and Disk Enclosure rack mounting

As next we take a look at the AC Power Cabling as well as the SAS backend cabling

also known as QSFP.

Power on and power off procedures will be described before we finish this Web

Based Training session by explaining the use of the Function Button located in the

Operator Panel.

2

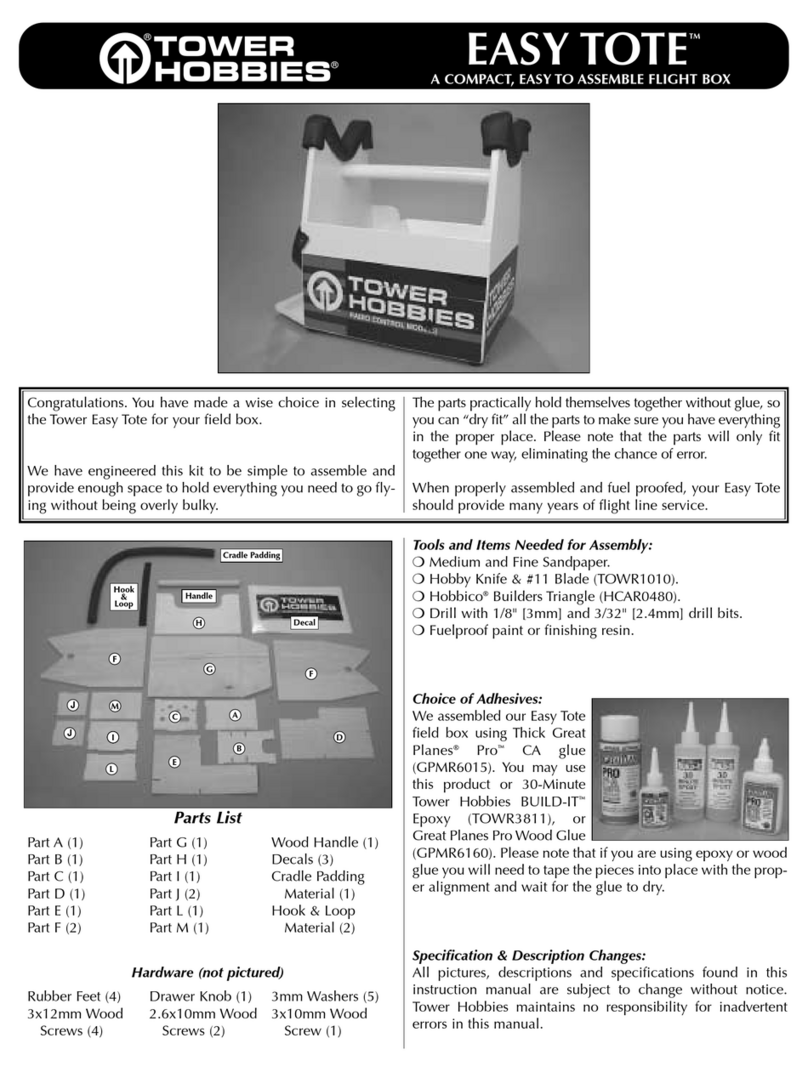

The following two slides show the contents of the packages for a Controller

Enclosure and Drive Enclosure. Both packages include a rack-mount kit, two power

cords and the documentation for the installation and use of the system.

The plastic flange covers are meant to be fitted on the front of the system at the right

and left hand side after having carried out the hardware installation.

The delivered push pin tool can be used to push the tiny Function Button at the

Operator Panel. Its use and the meaning of the Function Button will be covered as

the last item in this Web Based Training module.

3

The Drive Enclosure package includes the necessary backend SAS cables. These

cables are also called QSFP cables and are used for cabling between the Drive

Enclosures and the Controller Enclosure.

The abbreviation QSFP stands for Quad Small Form-factor Pluggable, in other words

an SFP with four SAS channels.

If the customer has ordered an ETERNUS DX S2 Entry system in a single Controller

Module configuration, the Drive Enclosure also comes as default with a single I/O

Module only. In that case only one IOM6 module per Drive Enclosure is available.

Since both packages can be rather heavy if fully configured, it may be a good idea to

have somebody helping when unpacking and installing the system in the rack.

As you are unpacking the systems make sure that everything is included in the

package.

4

Now we will start off the first part of the hardware installation: fitting the system in a

rack. The next five slides describe the rack installation for a Fujitsu rack type used

primarily by Fujitsu Technology Solutions. In the rack-mount kit, you can find:

A bracket

Left hand side and right hand side slide rails

A bag with screws and nuts

The overview shows how the parts are installed in a rack.

5

The rack installation starts by attaching the bracket to the right rear rack pillar.

The M5 centering screws should be inserted in the 1st and 6th holes above the base

line of the Controller enclosure. Base line refers to the rack height where the bottom

of the system resides.

Insert the pins of the left hand side slide rail in the 1st and 3rd hole counting from the

bottom of the 2U bracket.

6

An M5 cage nut must be pushed in the 2nd hole counting from the base line; this

must be done before you fix the rail.

Secure the left hand side rail to the front pillar using the M5 centering screws and the

M5 pan head screws.

7

To fix the right hand side rail, insert the pins in the holes of the rear pillar. Secure

then the other side of the slide rail to the front pillar as you did before with the left

slide rail.

8

This illustration provides an overview showing the front of the rack installation of an

ETERNUS DX S2 Entry system including all screws, rails and enclosure positions.

9

Now the Controller Enclosure and/or Drive Enclosure can be fitted in the rack. As

each unit can have a weight of up to 35 kilos, it is recommended to have somebody

helping when lifting and fitting the system in the rack.

Always start filling up a rack from the bottom because that prevents the rack from

tilting forward whenever an Enclosure has to be pulled out from the rack.

After having the system fitted in the rack, use the appropriate screws to fasten it in its

place.

Please also make sure you wear the appropriate ESD gear to avoid damages from

electrostatic discharges.

10

Now we can move to the back side of the rack for the AC power cabling.

Please note that the power cabling described here is predominantly used by Fujitsu

Technology Solutions.

Each rack is delivered with two independent rack Power Distribution Units.

Two power distribution strips allow dual power feed whereby the two PDUs are

connected to separate main power phases.

IMPORTANT: Always follow the local electrical safety regulations.

Before connecting the IEC/CEE power cable to the Controller or Disk Enclosure,

make sure that the AC power switches are turned off.

For both power redundancy reasons and for better electricity load balancing, each

power supply of an Enclosure should be connected to different phases; should one of

the phases fall out, each Enclosure can continue operating normally with only one

power supply.

The picture on this page shows that the power supply number zero of all Enclosures

is connected to the rack PDU at the left hand side and all power supplies number one

are connected to the right hand side rack PDU.

11

The next step refers to the backend cabling also known as signal cabling between

the Enclosures, which with the ETERNUS DX S2 systems is very straightforward

daisy-chain cabling; The SAS (OUT) port of the lower residing shelf connects to the

SAS (IN) port of the shelf above it.

In case of the extremely rare maintenance situation that one shelf in the middle has

to be removed, it is recommended to power off the whole ETERNUS DX S2 system

before removing or replacing the Enclosure in the middle.

With the DX 80 S2 and DX90 S2 the Controller Enclosure is considered to be the first

Enclosure, therefore the first Drive Enclosure gets automatically an Enclosure ID one.

12

The backend connectors and backend cables are labeled with symbols to ensure

easy and correct cabling.

Each connector and each cable that relate to "SAS out" is marked with a square

symbol and each connector and each cable that relate to "SAS in" is marked with a

circular symbol.

A connector with a square symbol should be connected to a SAS-out port with a

matching square symbol.

13

Some words to the backend cabling between two racks.

In general, the maximum ten Enclosures of the ETERNUS DX80 S2 or DX90 S2

should be installed in the same rack.

If it is however necessary to install the Enclosures in separate racks, a longer QSFP

cable has to be ordered.

14

This slide illustrates how to upgrade a single controller system to a dual controller

system.

If a customer orders a single controller configuration, the ETERNUS DX S2 Entry

system is shipped with one CM in the Controller Enclosure. By default any Drive

Enclosure ordered in the same order is delivered with a single IOM6 module. With

this configuration, only one QSFP backend cable per Drive Enclosure is provided.

Additional DEs for a single controller configuration should be ordered equally with

one I/O module only.

An upgrade to a dual controller configuration is possible but please note that

downgrading the system back to a single controller configuration is not supported.

These are the parts needed for upgrading a single controller configuration with two

Disk Enclosures to a redundant dual controller configuration.

15

Now we are ready to power on the ETERNUS DX S2 system. First we have to turn

on the AC power switch of the Power Supply Units in each Enclosure.

After the AC power is turned on, the PSU fans run at full speed for approximately 30

seconds creating a loud noise.

By pressing the "Power On" Switch of the Controller Enclosure, the DC power is

switched on. Also the green Power LED of the CE is illuminated.

The power on sequence takes approximately two minutes for the Controller and Drive

Enclosures.

There is no other visible indicator for the power on sequence, only after the CMs

have started up and are fully functional, the Ready LED of the Controller Enclosure

lights up in green. The same goes for the Power LED of the Drive Enclosure that also

lights up in green to show that the IOM6 modules have started up and are fully

functional.

16

After having explained the Power and Ready LEDs, now let us have a closer look at

the other LEDs of the Controller Enclosure front panel.

The Fault LED blinking in amber indicates a need for a preventive parts replacement.

When the LED is lit permanently in amber, the ETERNUS DX system has a defective

component which needs to be replaced as soon as possible.

Use the ETERNUS Manager GUI to find out what component is marked defective.

The MAINT/ID is a multifunctional LED.

This LED lights in green when the DX system status is "Maintenance".

This LED lights up in solid green when the system has been put to Maintenance

mode either using the ETERNUS Manager GUI, with the CLI or by applying the

Function Button in the operating panel.

This LED can also be used to locate the system being serviced. It can be activated

with the ETERNUS Manager GUI or Command Line Interface.

The Cache LED is lit whenever the DX cache is accessed. Blinking light indicates

that the cache content is being written to the CompactFlash as a result of a power

outage.

17

Here a functional description of the LEDs and the two digit indicator located in the

front panel of the Drive Enclosures.

The Line LED lights green after the ETERNUS DX system is switched on and the

Drive Enclosure is being initiated.

The Fault LED is lit in amber when a failure has occurred in the Enclosure.

A green Power LED indicates that the Drive Enclosure including the backend cabling

is fully functional.

The two digit DE-ID indicator is automatically set based on the daisy-chained

backend cabling so that the first DE next from the CE gets the number zero-one, the

next gets number zero-two and so on.

18

This slide shows the power off sequence.

In general, it is never necessary to power of an ETERNUS DX RAID subsystem

because normally all hardware is redundant and maintenance tasks can be done on-

the-fly.

Should it however be necessary to shut down the storage system, before doing that

always check that all server I/O is stopped and all cache data is written to the data

disks - meaning the Cache LED must be off.

Subsequently, to power off all connected Drive Enclosures and the Control Enclosure

you have to press the Power Switch in the front panel of the Control Enclosure for

about five seconds.

The same can be achieved by selecting "Shut down" from the ETERNUS Web GUI.

Consequently, the system shuts down in about 30 seconds.

In the case of moving the ETERNUS DX system to a new location, do not forget to

disconnect the AC power cords from the rack Power Distribution Units.

19

The tiny Function Button is accessible after pulling off the plastic flange cover at the

left hand side.

The tiny Function Button is located next to the Power Switch on the Operator Panel;

please note that the layout is slightly different in 2.5 inch and 3.5 inch Enclosures.

To operate the button use the pin tool delivered with each system.

20

There are three different functionalities that can be managed with the Function

Button.

The status of the ETERNUS DX S2 Entry system can be changed to "Maintenance"

by keeping the Function Button pressed for three seconds. Consequently the

"MAINT/ID" LED lights up in green.

By pushing the button again the ETERNUS DX S2 system changes back to "Normal"

status and the "MAINT/ID" LED switches off.

The Function Button can also be used to switch the Master role of the controllers.

By pressing the button twice within three seconds the Master role can be toggled

between the controllers. The controlled having the Master role has its Master LED lit

in green.

As the third functionality of the button it can be used to reset the IP address of the

MNT-LAN port of the CM.

The address is set back to 192.168.1.1 by pushing the Function Button three times in

three seconds. The "MAINT/ID" LED indicates this reset by blinking green for a few

seconds.

21

This finishes off the introduction to the Hardware Installation of the ETERNUS DX80

S2 and DX90 S2 systems and brings us to the end of this Web-Based-Training

session.

For additional information about the training sessions or other offered trainings, go to

the Fujitsu Technology Solutions training web site.

Thank you for your attention.

Other manuals for DX80 S2

1

This manual suits for next models

1

Table of contents

Other Eternus Storage manuals