ETH-messtechnik DRBK User manual

tel. +49 (0)79 72 93 10-0

hagstrasse 10 . D-74417 gschwend

English

messtechnik

Torque Sensor

DRBK / DRBK-n

DRBK-A

Operating Instructions

messtechnik

2

© ETH messtechnik gmbh

This operator manual is not a quality agree-

ment or durability guarantee as set out in

Section 443 of the German Civil Code.

Specification changes, typing and

printing errors reserved.

messtechnik

3

Inhalt

Important instructions: ...................................................................................................4

1. Introduction................................................................................................................. 5

2. Field of application and application instructions.........................................................5

3. Structure and mode of operation................................................................................ 6

3.1 Torque Shaft.........................................................................................................6

3.2 Case .....................................................................................................................6

3.3 Measurement ......................................................................................................6

3.4 Disturbances and their compensation.................................................................7

4. Conditions on location.................................................................................................8

4.1 Ambient temperature..........................................................................................8

4.2 Moisture and dust................................................................................................8

4.3 Chemical effects................................................................................................... 8

4.4 Deposits ...............................................................................................................8

5. Mechanical installation................................................................................................9

5.1 Precautions when assembling .............................................................................9

5.2 General assembly guidelines ...............................................................................9

6. Structure of the measurement chain ........................................................................10

7. Connection ................................................................................................................11

7.1 Hints for connection ..........................................................................................12

7.2 Connector ..........................................................................................................12

7.3 Pinout of the connector.....................................................................................12

7.4 Extension of cable..............................................................................................12

8. Pinout ........................................................................................................................13

9. Output .......................................................................................................................14

10. Functions of the display (at DRBK-A).......................................................................15

10. Recalibration............................................................................................................16

11. Disposal ...................................................................................................................16

13. Datasheet ................................................................................................................17

13.1 Technical specifications....................................................................................18

13.2 Mechanical dimensions DRBK..........................................................................19

13.3 Sizes DRBK........................................................................................................19

13.4 Mechanical dimensions DRBK-A ......................................................................20

13.5 Sizes DRBK-A ....................................................................................................20

13.6 Mechanical values and load limits DRBK + DRBK-A ........................................21

messtechnik

4

Important instructions:

The torque transducers of the DRBK-A series can be used as machine elements

(e.g. test bench). In the case of mass-critical applications, the installation positi-

on of the drive and measurement side must be taken into account.

Please note that the transducers are not designed with the safety factors (2...20)

customary in machine designs in favor of high measurement sensitivity.

Pay particular attention to the specified overload factors.

Where people and property could be injured in the event of breakage, the user

must take appropriate safety measures (e.g. covers, overload protection) (obser-

ve the relevant accident prevention regulations!).

The torque transducer is not approved for use in hazardous areas.

If the transducer is opened or dismantled within the warranty period, the war-

ranty claim becomes void.

The transducer may only be opened by qualified personnel.

messtechnik

5

1. Introduction

Torque transducers measure torques in Nm.

2. Field of application and application instructions

The torque transducers measure both right-hand and left-hand loads. With a

right-hand load, the signal direction is positive. The nameplate provides informa-

tion about the final value of the measuring range.

The torque transducers measure dynamic moments just as precisely as static

torques. Here, the low masses and the high torsional rigidity are of particular

advantage.

Note the signal rise of the transducer specified in the data sheet.

The torque transducers are maintenance-free due to their non-contact measure-

ment signal transmission. Your electrical measurement signals can be transmit-

ted to remote measurement stations and displayed, registered, processed and

used for control and regulation tasks.

As a precision measuring device, the torque transducers require careful handling

during transport and assembly, since impacts or falls can damage the transducer.

Torque peaks in excess of the permissible overload can lead to the destruction

of the torsion shaft. Where such peaks cannot be ruled out with certainty, they

must be intercepted.

The limits for the permissible mechanical, thermal and electrical stresses are

listed in the data sheet. It is imperative that they are complied with. Please take

this into account when planning the measuring arrangement, during installation

and finally during operation.

Channel A

(PIN G)

messtechnik

6

3. Structure and mode of operation

3.1 Torque Shaft

The torsion shaft is made of hardened steel. The torque-proportional torsion of

the torsion shaft within its elastic range is evaluated with strain gauges (DMS)

applied to it. The strain gauges are arranged in a Wheatstone bridge circuit. The

non-positive connection takes place via suitable couplings on the cylindrical shaft

ends.

Optionally, the torsion shaft of the DRBK can be equipped with a speed measure-

ment (see data sheet).

3.2 Case

The torque transducer housings are made of high-strength aluminum and the

surface is hard-anodized for protection. The torsion shaft is mounted twice in the

housing via deep groove ball bearings. The transducer is mechanically fastened

via threaded holes on the bottom of the housing. An evaluation electronics for

torque and speed is mounted on the housing.

3.3 Measurement

The torsion shaft and thus the DMS are elastically deformed by the torsional

force. The strain gages change their ohmic resistance in proportion to their

change in length. The downstream electronics transmit the measurement signal

optically frequency-modulated to the external electronics.

The conversion in the external electronics into the two output signals voltage/

current takes place in proportion to the change in frequency. These are available

for further evaluation.

A square-wave signal with 60 pulses/revolution is available at the speed output

messtechnik

7

3.4 Disturbances and their compensation

Avoid bending, axial and radial forces. When you have problems with this, use

ETH clutches.

To connect the transducer to a measurement unit you need a shielded cable.

The transducers are EMC-tested and are complying with

EN 55011:1998 + A1:1999 + A2:2002

EN 61326-1:2006-05 and

EN 61000-6-2:2005.

messtechnik

8

4. Conditions on location

4.1 Ambient temperature

For best results, the device must be operated within the nominal temperature

range. The best operating conditions are constant and, if necessary, slowly

changing temperatures. The specified temperature errors apply if the tempera-

ture does not change faster than 5K/h. One-sided thermal radiation or cooling

should be avoided and appropriate technical preventive measures taken, if

necessary.

4.2 Moisture and dust

The torque transducers comply with protection type rating IP40 as per DIN

40050.

Note: There should be no moisture inside the transducer connector

4.3 Chemical effects

The torque transducers are not protected against chemical effects. They must

not be used in caustic or corrosive environments.

4.4 Deposits

Dirt, dust or other foreign substances should not accumulate so that they can

enter the bearing or the connectors.

messtechnik

9

5. Mechanical installation

5.1 Precautions when assembling

• Handle transducer carefully.

• Important note:

When installing the couplings, do not overload the transducer,

not even temporarily.

It is strongly recommended to remove the transducer before

mounting connect electrically and the torque signal with too

monitor in order not to exceed the measuring range!

• Misalignments in the axial and radial directions must be avoided.

The axis offset should be max. 50% of the permissible values of the

coupling used (axial, angular and lateral misalignment) be.

Please refer to the data sheet for your coupling for this data.

• A good electrical connection of the housing to grounded parts

must be observed.

5.2 General assembly guidelines

The drive and transducer sides should not be swapped, otherwise measure-

ments (readings) will be invalidated during accelerations, for example.

When reading the device label, the drive side is on the right and the transducer

side on the left of the transducer. There is a small cavity in the cover on the

measurement side.

Flexural, axial and radial forces are disturbances that cause incorrect

measurements.

Be careful with the thermal expansion of the assembly.

messtechnik

10

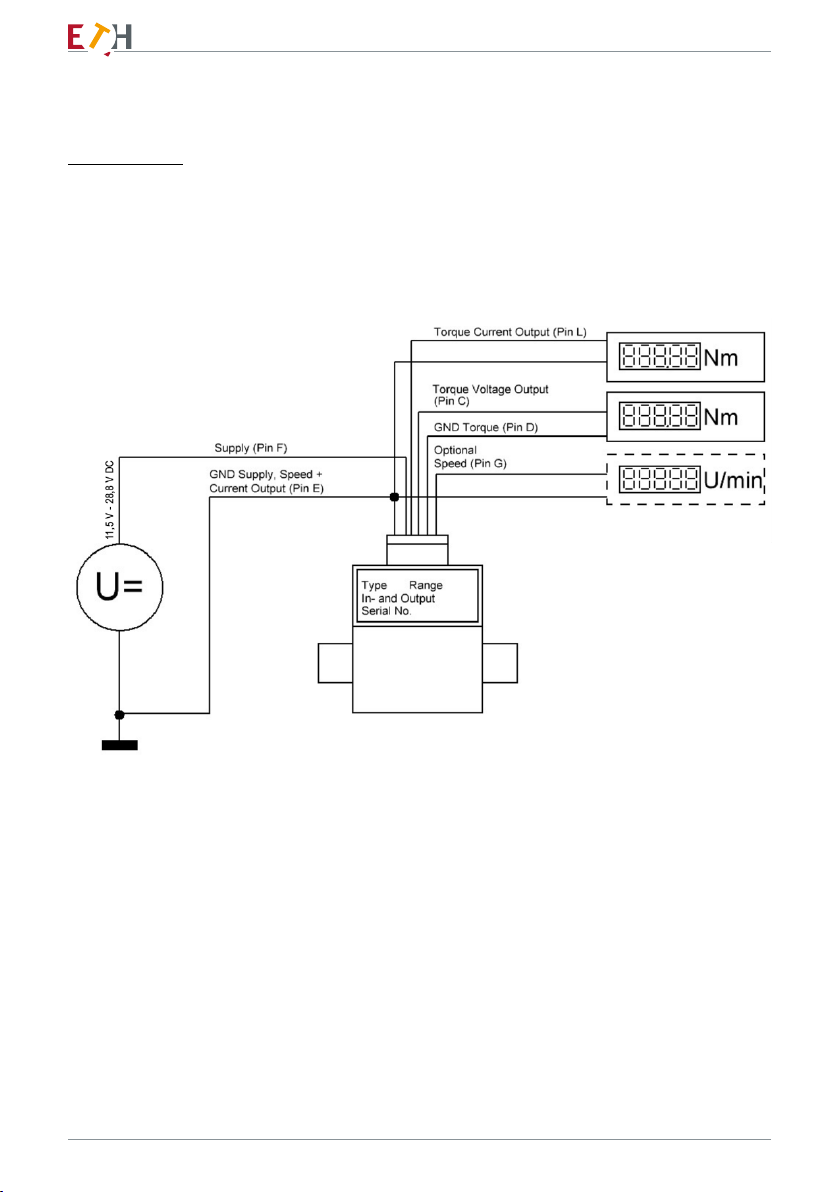

6. Structure of the measurement chain

In order to be able to measure with the transducer, a complete measurement

chain must be set up.

This consists of:

• torque transducer

• connection cable

We recommend using our ETH cables.

They are optimized in design and shielding.

• Supply and evaluation device (e.g. PLC)

A supply unit is necessary to supply the transducer with the necessary operating

voltage. The transducer includes the complete measuring amplifier, so that no

additional amplifier is necessary. The measuring signal can be further processed

directly (e.g. PC) or displayed and evaluated with supply and evaluation devices.

messtechnik

11

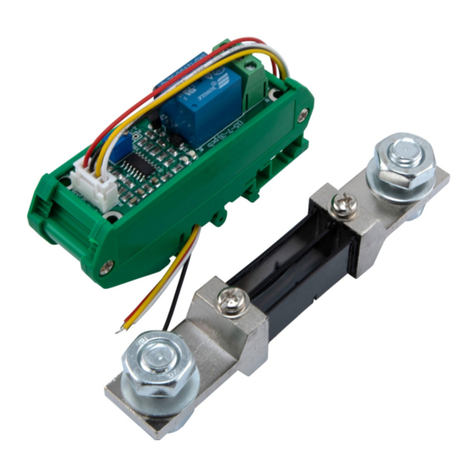

7. Connection

Connection of a torque transducer with a 12-pin connector

messtechnik

12

7.1 Hints for connection

Electric and magnetic fields cause interference with the measuring signal. This

interference is mainly caused by power cords, relays or motors installed nearby.

Besides these, interference can be caused by multiple grounding of the measure-

ment chain on more than one point.

Pay attention to the following:

• Use only shielded cables with low capacitance

(like our measuring cables).

• Connect supply voltage correctly (no reverse polarity protection).

• Measuring cables shouldn’t be nearby high voltage or control cables.

• Magnetic radiation from transformers, motors or relays

must be avoided.

• Don’t ground transducer and display unit multiple.

• Connect all devices of the measurement chain to the same ground.

7.2 Connector

The transducer is equipped with a 12 pin fitted connector type Binder.

7.3 Pinout of the connector

The pinout of the connector is showed on the next page.

7.4 Extension of cable

Extension cables must be shielded and low-capacitance.

We recommend using the cables we offer that meet these requirements.

In the case of cable extensions, care must be taken to ensure a perfect connec-

tion and good insulation. It is important to ensure that the cable cross-section is

large enough to ensure sufficient supply voltage at the transducer.

Recalibration is not necessary when the cable is extended.

If the cable has to bridge a longer distance, we recommend using the current

output.

messtechnik

13

(Connection on the transducer seen from the front)

Pin

Standard cable

AK12.4

Colour

Robot cable

AK12.5

Colour

Pinout DRBK

A Green Black message ready

B Red / Blue Red NC

C Yellow Brown moment voltage output

D White White moment voltage mass

EGrey Yellow supply + speed + current ground

F Pink Purple supply +11…28V

G Grey / Pink Green speed output

H Purple Pink memory chip

J Black Grey NC

KRed Grey/Pink NC

L Brown Blue/Red moment current output

M Blue Blue NC

8. Pinout

• Standard measuring cable AK12.4

• Robot cable AK12.5

Connector: 12 pin

messtechnik

14

9. Output

The transducer`s output is a proportional voltage of 0 - ±5V and a current of

10 - ±8mA.

With clockwise torque the output is positive; with counter clockwise torque the

output voltage is negative.

The outputs for rotation speed and angle

measurement have an open collector

stage, with an internal 10 KΩ pull up resi-

stor in series with a diode. See schematic

below.

With this circuit you can measure speed

of more than 15,000 RPM and with a

cable of up to 33 ft.

The signal level of the circuit on the left

hand side is suitable for opto couplers,

frequency counters, oscilloscopes and

for (H)CMOS logic. If you need standard

TTL levels you can add the circuit on the

right hand side.

The ‘ready‘ signal is activated as soon

as the supply voltage is within the permitted voltage range and the overvoltage

protection has not been activated.

The voltage level on the ‘ready’ output is equal to the applied supply voltage.

The output can be loaded with max. 100mA.

messtechnik

15

10. Functions of the display (at DRBK-A)

The displayed torque is always shown in 4 digits. For example, with a nominal

torque of 200 Nm, a value is displayed as „199.2Nm“. The torque is updated

every 100ms.

The speed is represented as an integer. The valid range is between 0 and 32000

RPM.

The update occurs every second.

In standard the display is in track mode (LED off).

To change the measuring mode, press the „PEAK / TRACK“ button. If the peak

mode is active, the LED below the display lights up. The peak mode shows the

respectively applied peak torque in right-hand load. It is only available for values

greater than 5% of the full scale value in right-hand load. The current torque is

displayed for values that are smaller or with left-hand load.

With the „TARE“ key, the zero point can be reset in track mode. However, this

function is only available if the torque is less than 5% of the end value of the

measuring range.

In the peak mode, the „TARE“ key has the function of deleting the displayed peak

value.

messtechnik

16

10. Recalibration

Regardless of usage, the sensor must be calibrated after the period specified by

ETH - every 2 years by default

(see certificate and sticker sensor).

We also carry out a complete check (e.g. wearing parts).

To ensure that the calibration can be carried out quickly, we recommend making

an appointment before returning the device.

11. Disposal

The transducer can be returned to us free of charge for disposal, complete

with the measuring cable. As soon as this is packed by you, send a message to

sales@eth-messtechnik.de, we will then commission our parcel service to collect

it.

Unfortunately, we cannot accept parcels sent to us without prior notice.

messtechnik

17

13. Datasheet

Hagstraße 10 · 74417

Gschwend

www.eth-messtechnik.de

Torque Transducer

DRBK + DRBK-A

Torque ranges from 0,5 to 1000 Nm

Features

• Low-Cost Torque transducer

• Current output and voltage output

• Very short

• Measurement accuracy: ≤ 0.5% of full scale

• Contactless transfer of measurement signal

• Proven strain gage technology

• Integrated signal amplifier

• Single power supply

• wide range of applications

• Optional speed measurement

Extra Features DRBK-A

• Simultaneous speed/torque indication

• 4-segment display with sign

• Peak mode (clockwise only)

• Indication area on LCD display 30 x 11 mm

• Speed indication updated 1x sample/second

• Torque updated 1,000 samples/second

The Series DRBK torque transducers are suitable for

lab and industrial applications because of their small

size and multiple mounting options.

As supply voltage and output signal are transmitted

without contact, the device can operate continuously

with low wear and nomaintenance.

These transducers are also available with speed mea-

surement for a host of applications.

Series DRBK-A torque transducers are custom made

for applications where an extra analyzer should not

be used or is not needed.

Production monitoring data can be clearly displayed

at very small cost!

DB_DRBK/DRBK-A_EN_Rev03 07.11.2022

messtechnik

18

Technical Specifications: DRBK + DRBK-A

Supply voltage: 11,5 to 28,8 V DC

Current consumption: DRBK approx. 200 mA / DRBK-A approx. 250 mA

Rise time 10-90 %: 1 ms

Limit frequency –3 dB: 1 kHz

Voltage output:

Internal resistance:

0 to ± 5 V

100 Ω

Current output: 10 ± 8 mA Burden max 500 Ω

Ripple: < 100 mVss

Nonlinearity: < 0,3 %

Hysteresis: < 0,3 %

Deviation at zero point: ≤ ± 100 mV / ± 200 µA

Max. measurement error 0,5 % (FS / of full scale)

Operating temperature: 0 - 60 °C

Compensated temperature range: 5 - 45 °C

Temperature error

Zero point:

Sensitivity:

0,05 % / K

0,02 % / K

Mechanical overload: 100 %

Internal protection: IP40

Connection: 12pin- connector

EMV Immunity for interference (DIN EN 61326-1 / EN 61000-6 ) *1

Enclosure

HF line interference

150 kHz - 80 MHz (AM)

Severity

3 V

Criterion

A

(ESD) Electrostatic discharge Air 8 kV

Contact 4 kV

A

A

Enclosure

Electromagnetic Field

80 MHz - 1000 MHz (AM)

80 MHz - 2700 MHz (AM)

10 V/m

10 V/m

A

A

Leads - Connection Cable

Burst (fast transients) 2 kV A

Surge voltage (Surge) 1 kV B

Interference Emission (EN 61326-1 / EN 55011)

Disturbance Voltage

(Electromagnetic Disturbances)

Radiated Emission

(Electromagnetic Disruption axis)

-

-

Class B (150 kHz - 30 MHz)

Class B (30 MHz - 1000 MHz)

Speed Option (n) only DRBK *2

max. rev.: up to 10 000 min -1 *3

Output: Open-Collector

Internal pull up: 4,7 kΩ (5 V level)

External pull up: 24 V max / 20 mA

Pulses/rev.: 60

*1 Severity / Criterion: industrial environment;

Cable lenght ≤ 30m.

Application not outside buildings.

*2 standard on DRBK-A

*3 by proper external connections til speed max.

13.1 Technical specifications

messtechnik

19

Mechanical Dimensions DRBK

Type: 0 I II III

Torque Ranges: (Nm) | 0,5 | 1 | 2 | | 5 | 10 | 20 | | 50 | 100 | 200 | | 500 | 1000 |

Dimensions:

L (mm) 66 80 90 120

Ø B1 (mm) 45 70 75 105

B2 (mm) 45 53 53 76

H (mm) 56 72 77,5 97,5

H1 ± 0,05 (mm) 18 28 30 40

Ø D g6 (mm) 6 15 24 40

L1 (mm) 42 48 52 65

L2 (mm) 10 15 18 26

A1 (mm) 33 39 42 50

A2 (mm) 20 31 35 55

MM3 x 5 deep M4 x 6 deep M4 x 6 deep M5 x 10 deep

General tolerances DIN 2768 - m

Weight approx.: (g) 230 550 850 2450

Speed max.: (1/min ) 20000 18000 16000 9000

Sizes DRBK

13.2 Mechanical dimensions DRBK

13.3 Sizes DRBK

messtechnik

20

Mechanical Dimensions DRBK-A

Sizes 0 I II III

Torque Ranges: (Nm) | 0,5 | 1 | 2 | | 5 | 10 | 20 | | 50 | 100 | 200 | | 500 | 1000 |

Dimensions:

L (mm) 66 80 90 120

Ø B1 (mm) 45 70 75 105

B2 (mm) 54 53 53 76

H (mm) 90 100 106 122

H1 ± 0,05 (mm) 18 28 30 40

Ø D g6 (mm) 6 15 24 40

L1 (mm) 42 48 52 65

L2 (mm) 10 15 18 26

L3 (mm) 51 48 52 65

A1 (mm) 33 39 42 50

A2 (mm) 20 31 35 55

A3 (mm) 22 ---

MM3 x 5 deep M4 x 6 deep M4 x 6 deep M5 x 10 deep

General tolerances DIN 2768 - m

Weight approx.: (g) 310 610 910 2530

Speed max. (min-1 ) 20000 18000 16000 9000

Sizes DRBK-A

13.4 Mechanical dimensions DRBK-A

13.5 Sizes DRBK-A

This manual suits for next models

2

Table of contents