452515

•

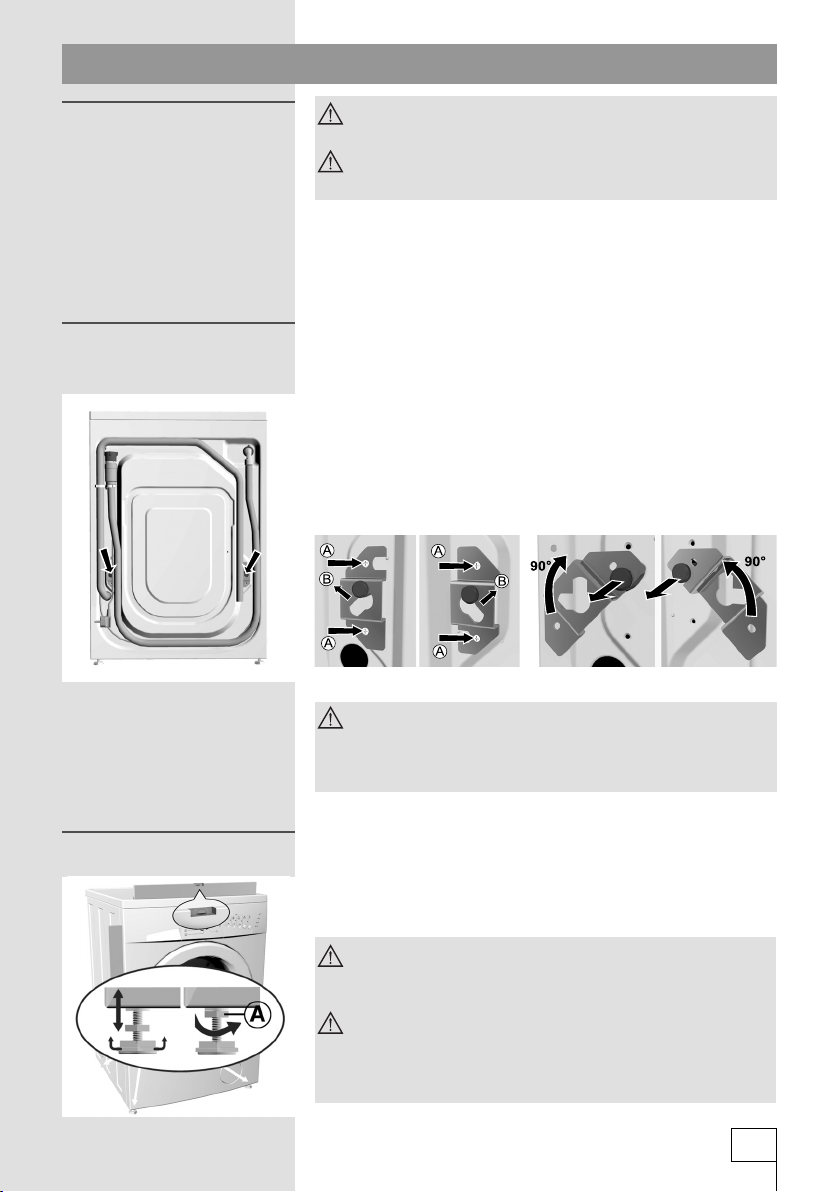

Be sure to remove transport brackets prior first use of the appliance. Attempted operation of the

blocked machine may result in irreparable damage which is not covered by the manufacturer’s

warranty!

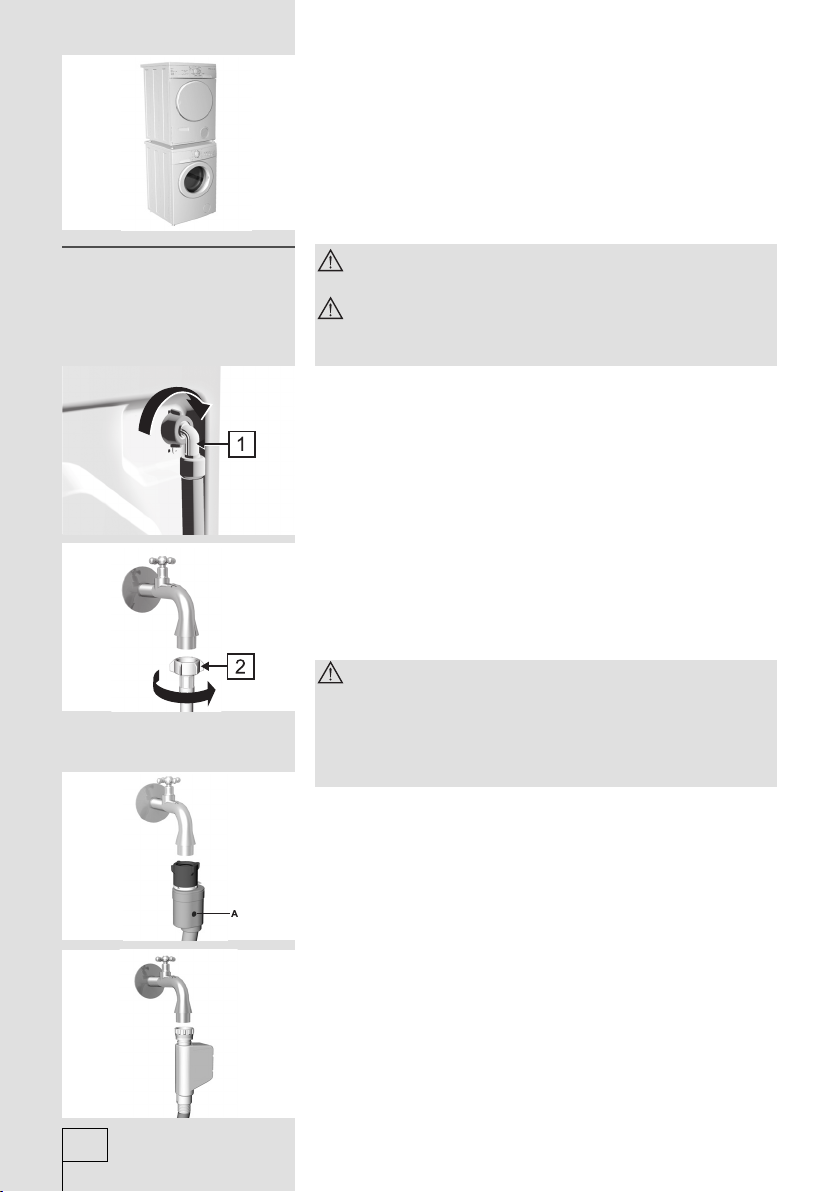

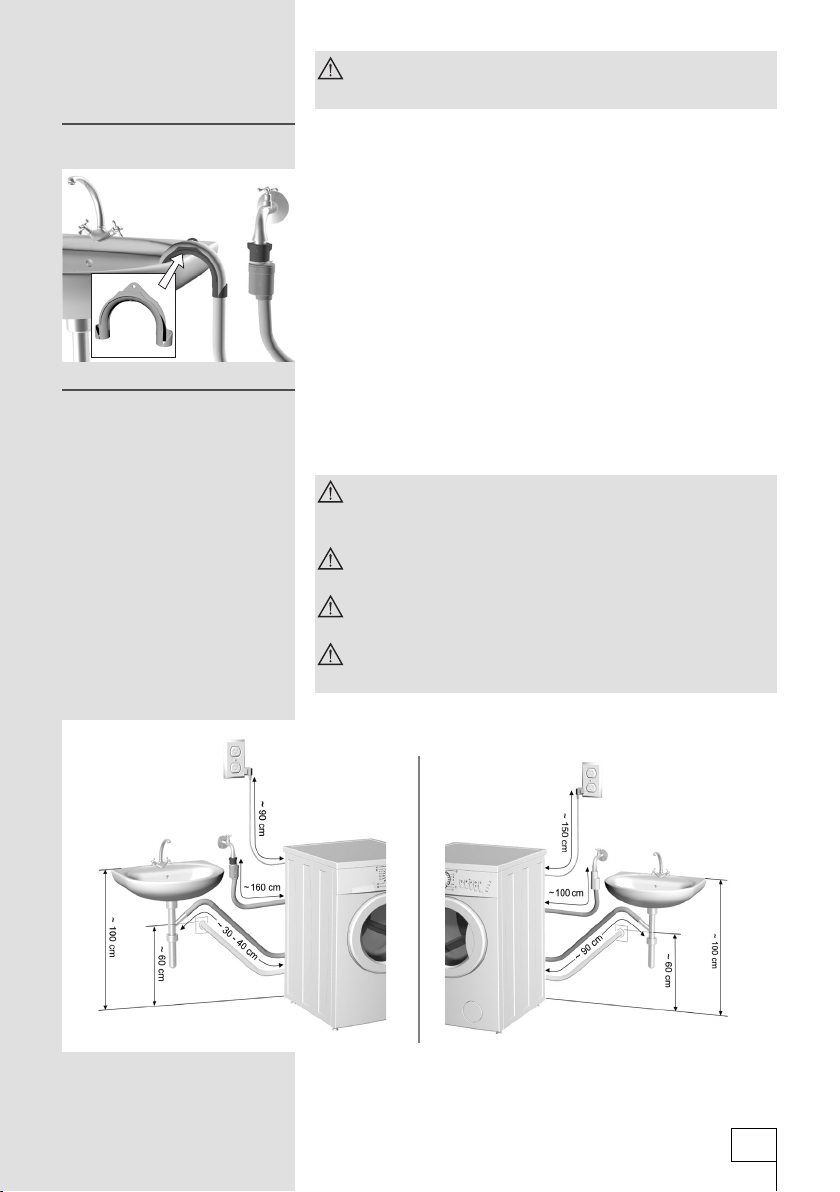

• When connecting your washing machine to water supply, be sure to use brand new water inlet

hose and appropriate sealing gaskets (attached).

• Do not locate the machine in a room with temperature below 0°C. Parts of the machine may be

damaged if frozen.

• Install the washing machine in a perfectly horizontal position, on solid flat concrete floor.

• Follow the instructions for correct installation and water and mains connections.

• Never immerse the end of the drain hose into the draining water.

• Prior starting the washing cycle lock the door by pressing them at the designed spot.

• Door may not be open during the washing cycle.

• We recommend running the self-cleaning program before the first wash in order to remove any

impurities from the washing machine drum (see chapter on” Selecting additional functions”).

• Use only detergents and softeners for machine wash. Manufacturer may not assume responsibility

for any damage and eventual discoloring of gaskets and plastic components as a consequence of

incorrect use of bleach and/or coloring agents.

• For removal of lime residues use such agents with added anti-corrosion agents. Follow the

manufacturer’s instructions. Finish the lime removal by multiple rinsing to remove completely

eventual acid residues.

• Never use detergents containing solvents, since there is a danger of creating toxic gasses which

may damage the machine and result in ignition or explosion.

• This product does not release silver ions during the washing cycle.

• Upon completion of washing operation close the water faucet.

• Before any transport block the machine by inserting at least one transport blocking rod. Prior this

operation disconnect the appliance from the mains power!

• Rating plate with basic information is located above the opening of the machine.

• The warranty shall not apply to consumables (bulbs), minor discoloration or deviations of color,

increased noise level as a consequence of appliance age, which does not affect appliance

functionality, and aesthetical deficiencies which do not affect appliance functionality or safety.

• The appliance is manufactured in compliance with all relevant safety standards; however, it is

recommended that persons with impaired physical, motional, or mental abilities, or persons with

inadequate experience and knowledge, do not use the appliance without due supervision. The

same recommendation applies to minors using the appliance.

Before connecting the appliance read these instructions carefully. Repairing the failure

arising from inappropriate connections or use of the appliance is not covered by the

guarantee.

The symbol on the product or on its packaging indicates that this product may not be

treated as household waste. Instead it shall be handed over to the applicable

collection point for the recycling of electrical and electronic equipment. By ensuring

this product is disposed of correctly, you will help prevent potential negative

consequences for the environment and human health, which could otherwise be

caused by inappropriate waste handling of this product. For more detailed information

about recycling of this product, please contact your local city office, your household

waste disposal service or the shop where you purchased the product.

4

Cautions