Eubiq SH1 User manual

FLOOR/HOME FIXTURE

Technical SpecificationPLEASE READ BEFORE INSTALLING

Keep away from fire.

Keep away from water.

Not for outdoor use.

To be installed by a

qualified electrician/

installer.

CAUTION

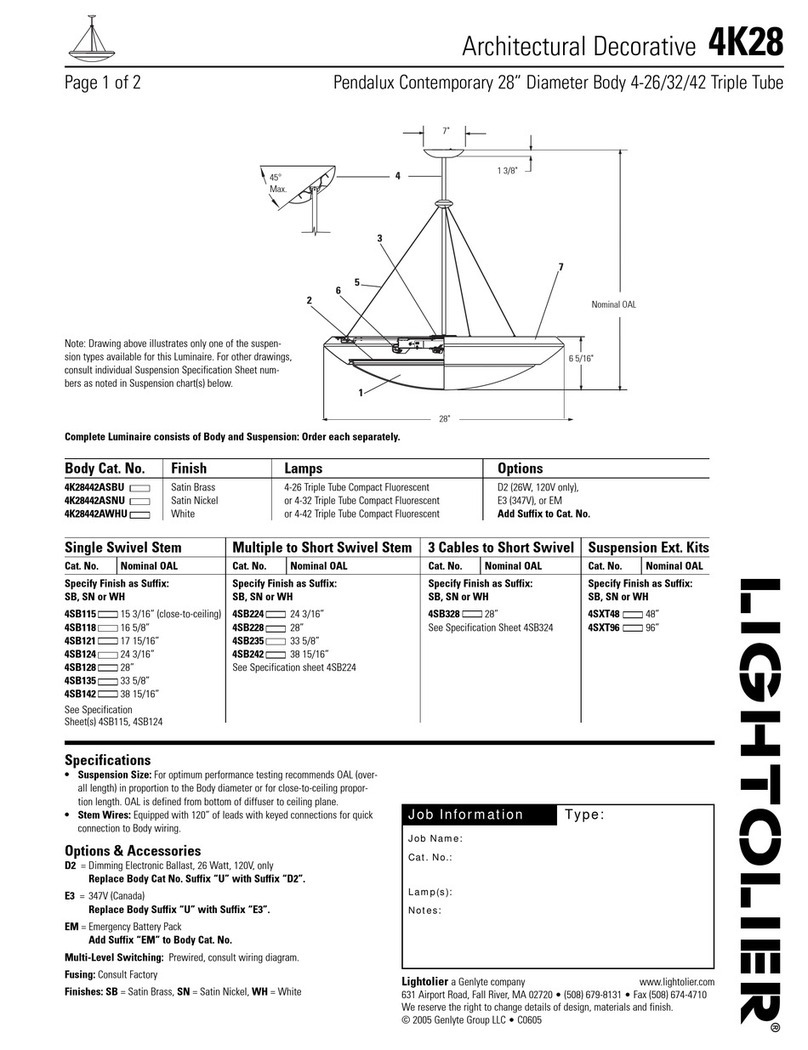

Backplate Guide

INSTALLING PARTY

All Power Tracks must be installed by a qualified

electrician.

USE OF EARTH LEAKAGE CIRCUIT BREAKER (ELCB)

It is a mandatory requirement that all installations of

electrical

power source must be connected to an ELCB to provide

protection against overload, short circuits and earth

leakages

faults. Failure to comply can be harzadous.

INSTALLATION LOCATION

All Power Tracks must be installed at location that

complies with safety rules and regulations of respective

country.

INSTALLATION SURFACE

All Power Tracks must be installed on flat surface.

RECOMMENDED INSTALLATION CLEARANCE

Refer to FIG.1 on the right for more information on the

minimum clearance (from the floor or any furniture

fixtures) required for ‘twist-on’ adaptors and accessories.

Prepare leads as shown:

10mm

10mm

50mm

40mm

1) Do not use in damp environment.

2) If in doubt, please consult a qualified electrician.

Live (Brown or Red)

Earth (Green or Green/Yellow)

Neutral (Blue or Black)

Product Orientation

V-GROOVE AT BOTTOM

SH1

Power and Data Track (With SFC3)

Installation Guide

Product Overview Wiring Instructions

Screw Cap

Pan Head Self Tapping Screw

SH1 End Cap

SH1 Internal Corner Cap

MF1 Mounting Frame

SH1 Corner Link

SH1 External Corner Cap

SH1 Housing

SFC3 Modular Track

DS4 Data Socket Housing

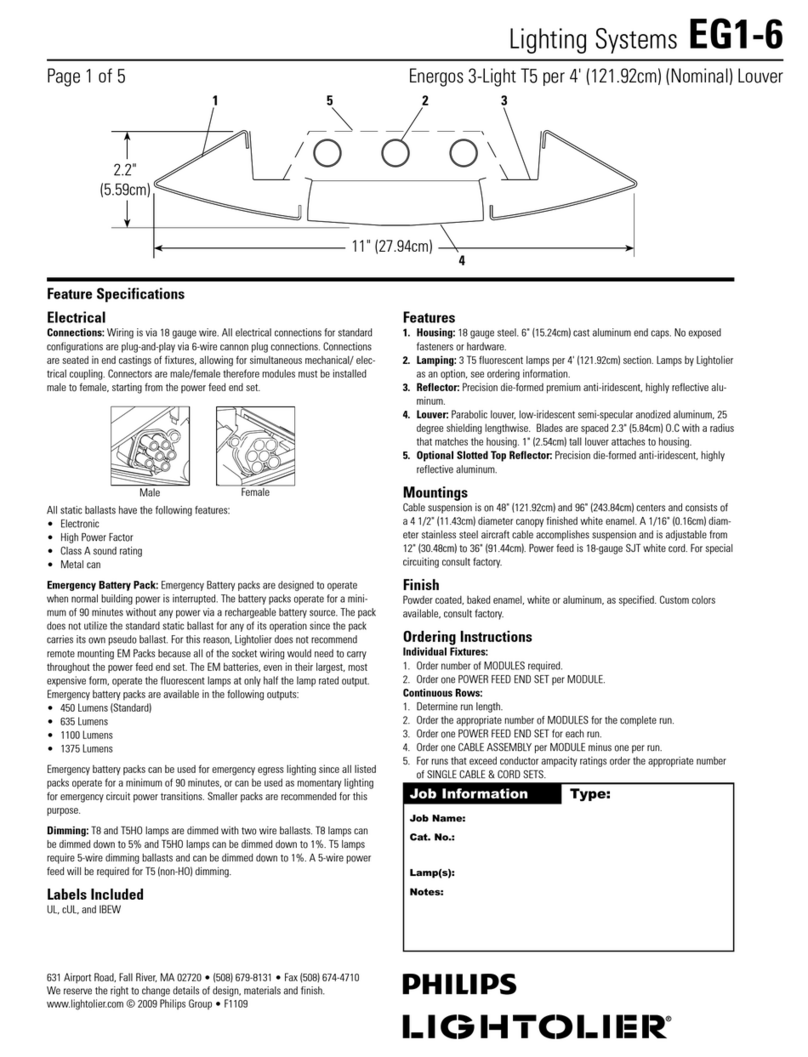

FIG. 1 Minimum Clearance for SH1 Installation

Minimum clearance of 25mm from the bottom required.

Housing Joint Pin

75mm

SFC Blank Cover

SH1 Retainer

25mm

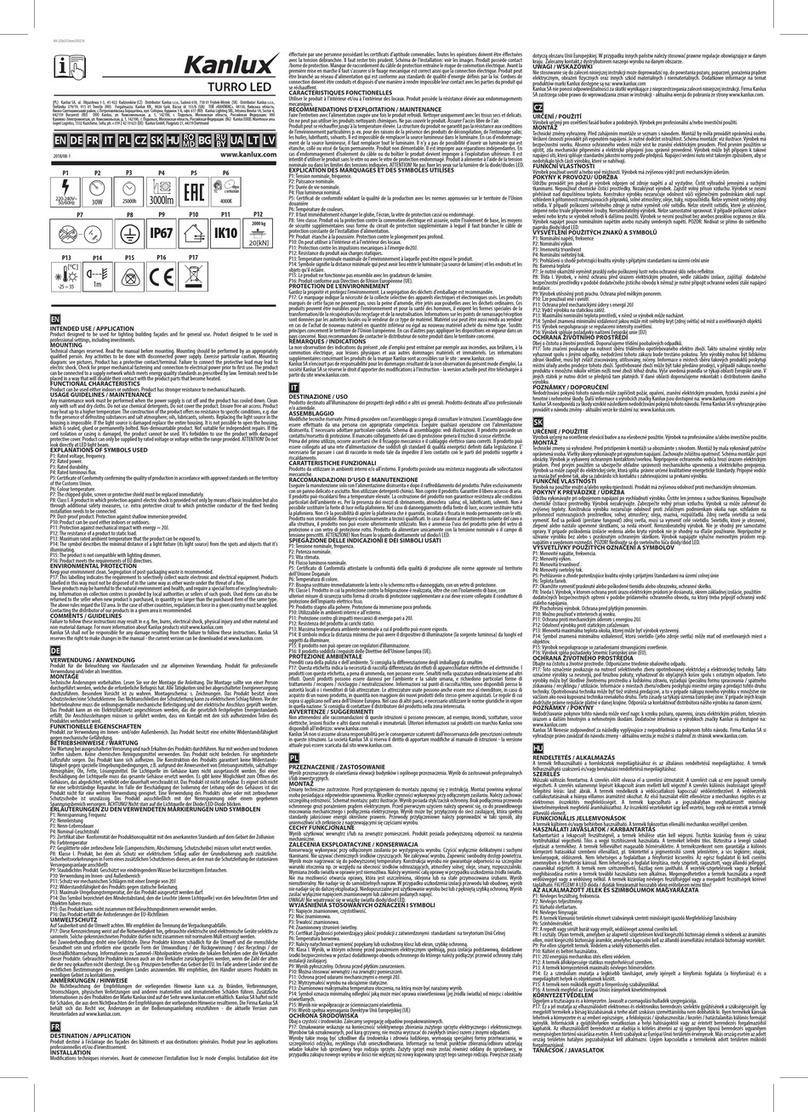

Measurement Guide

ATTACHING ACCESSORIES*

5mm

Overall Wall Length

x

y

DESCRIPTION

For internal corner joint:

Width of gap = 37mm

Width of end cap = 5mm

MEASUREMENT GUIDE

FormulaSH1 Housing Length

(x - 37 - 5)mma

(y - 37)mmb

(z - 5)mmc

z

SH1 Housing

Length

a

b

c

End Cap

End Cap

* Compatible Accessories:

KH Kitchen Hook

KR Kitchen Rail

Live Terminal

Neutral TerminalLive and Neutral Indicator

Earth Terminal

SFC3 Track

For SFC3 Modular Track

Rated Voltage : 250V a.c. Single-phase

Rated Current : 32Amp maximum

Frequency : 50Hz / 60Hz

Rated Impulse Withstand Voltage : 4000V a.c.

Connection of Adaptor or

Tap-off Unit : Intended to be connected

and disconnected when

when system is energized

and with a load connected

Terminal Connecting Capacity

(Live, Neutral and Earth) : 1.25mm² to 6mm²

Ambient Operating Temperature : -5°C to +55°C (not to

exceed an average of more

than 35°C in any 24 hours

period)

Maximum Installation Altitude : 2000 metres

Degree of Protection : IP4X

Resistance to Impact : Heavy Impact

Degree of Pollution : 2 (Non-conductive pollution

with temporary conductivity

caused by condensation)

Track and Housing Material : Aluminium

Insulation Material : Polycarbonate

Internal Corner

Cap

External

Corner Cap

a

b

c

x

y

z5mm

5mm

37mm

DMK-005-016-03 ENG

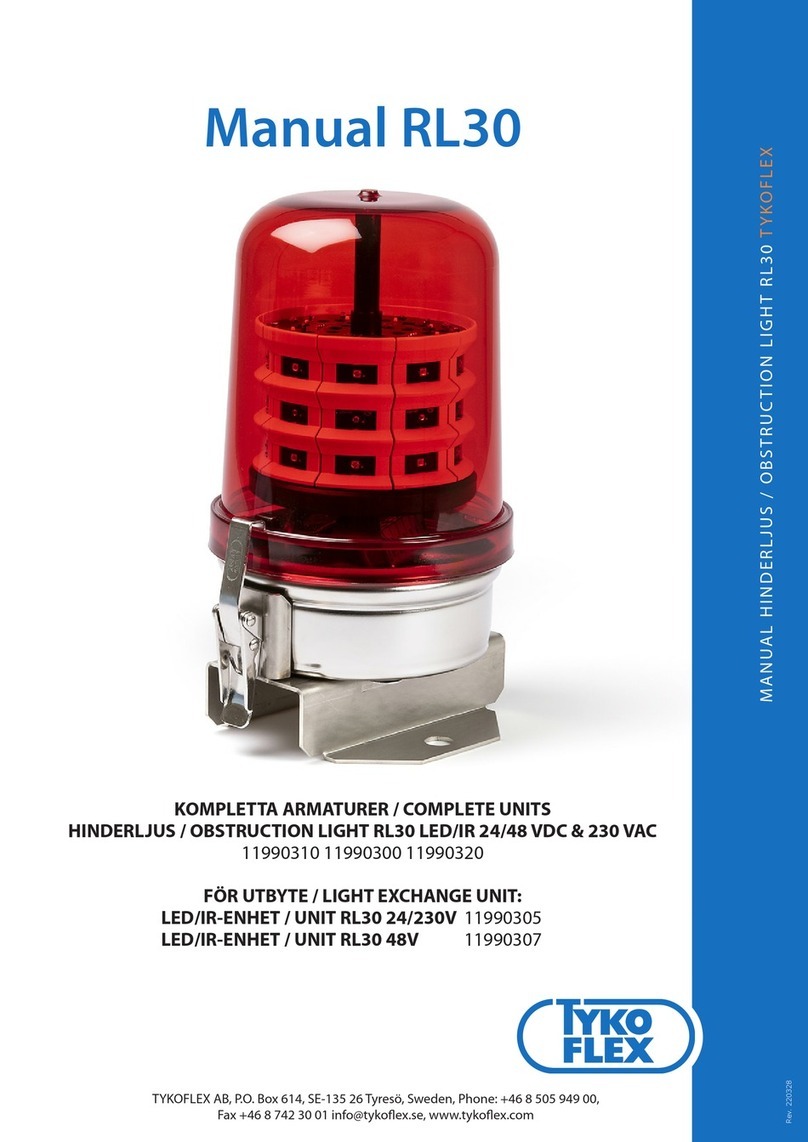

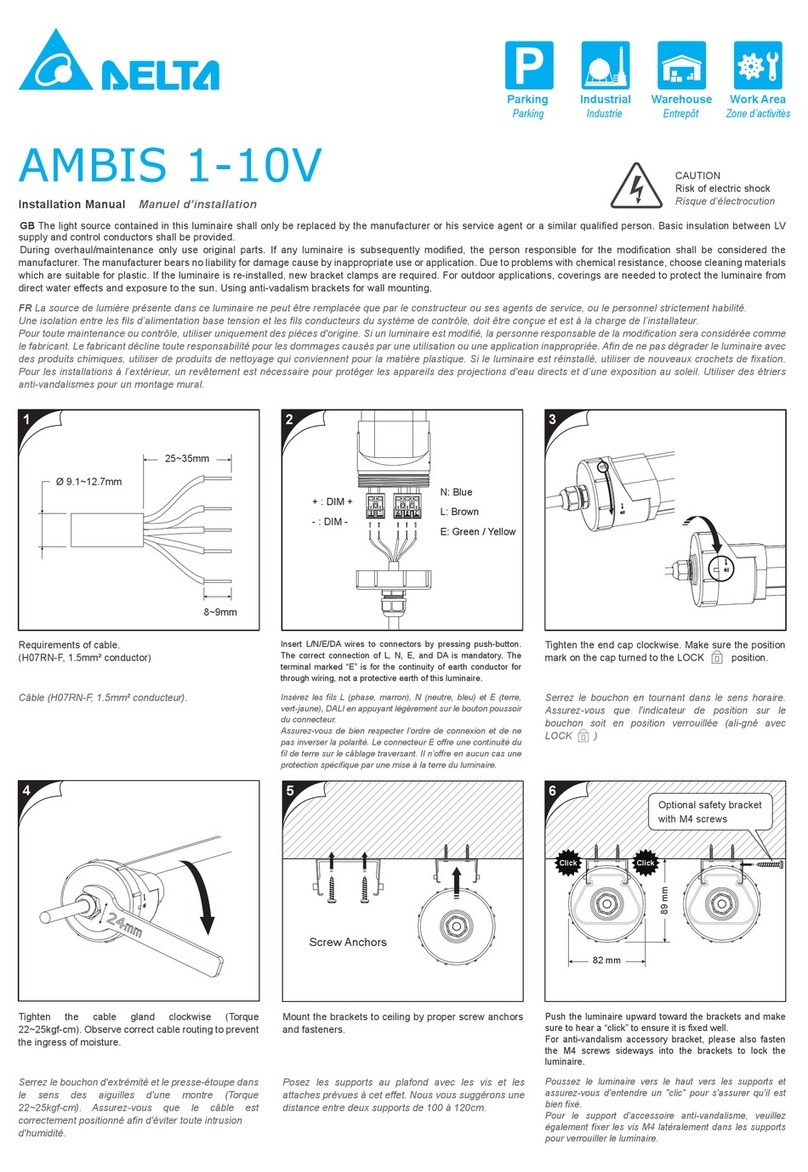

SFC3 Track Length

< 400mm

400 - 600mm

601 - 1100mm

1101 - 1500mm

1501 - 2500mm

2501 - 3300mm

3

4

6

9

12

15

3

2-2

3-3

3-3-3

3-3-3-3

3-3-3-3-3

-

100mm

160mm

160mm

160mm

160mm

Quantity (Pcs) Arrangement

a (mm)

SFC3 Track

Housing

a a

*Where ais the length between the edge of the SFC3 Track to

the outermost edge of the backplate.

Attaching Multiple Backplates

Replace the end terminal

cover and fasten the screws.

End terminal cover with

cable entry blanks removed.

Terminate the wires to the

respective terminals.

Cut and remove the side and rear cable entry blanks from the

end terminal cover.

Loosen the screws with Philips

head screw driver, and remove

the end terminal cover.

Flip open and hold the soft flap in position. Insert the bit of

the flat head screw driver into the slot, push down at a 45°

angle to release the catch.

Insert the end terminal into

the anchor, pushing it all the

way until a ‘click’ sound is

heard to secure the end

terminal.

Refer to SFC3 Guide

(DMK-005-023) for steps to

attach backplates.

13

24

DMK-005-016-03 ENG

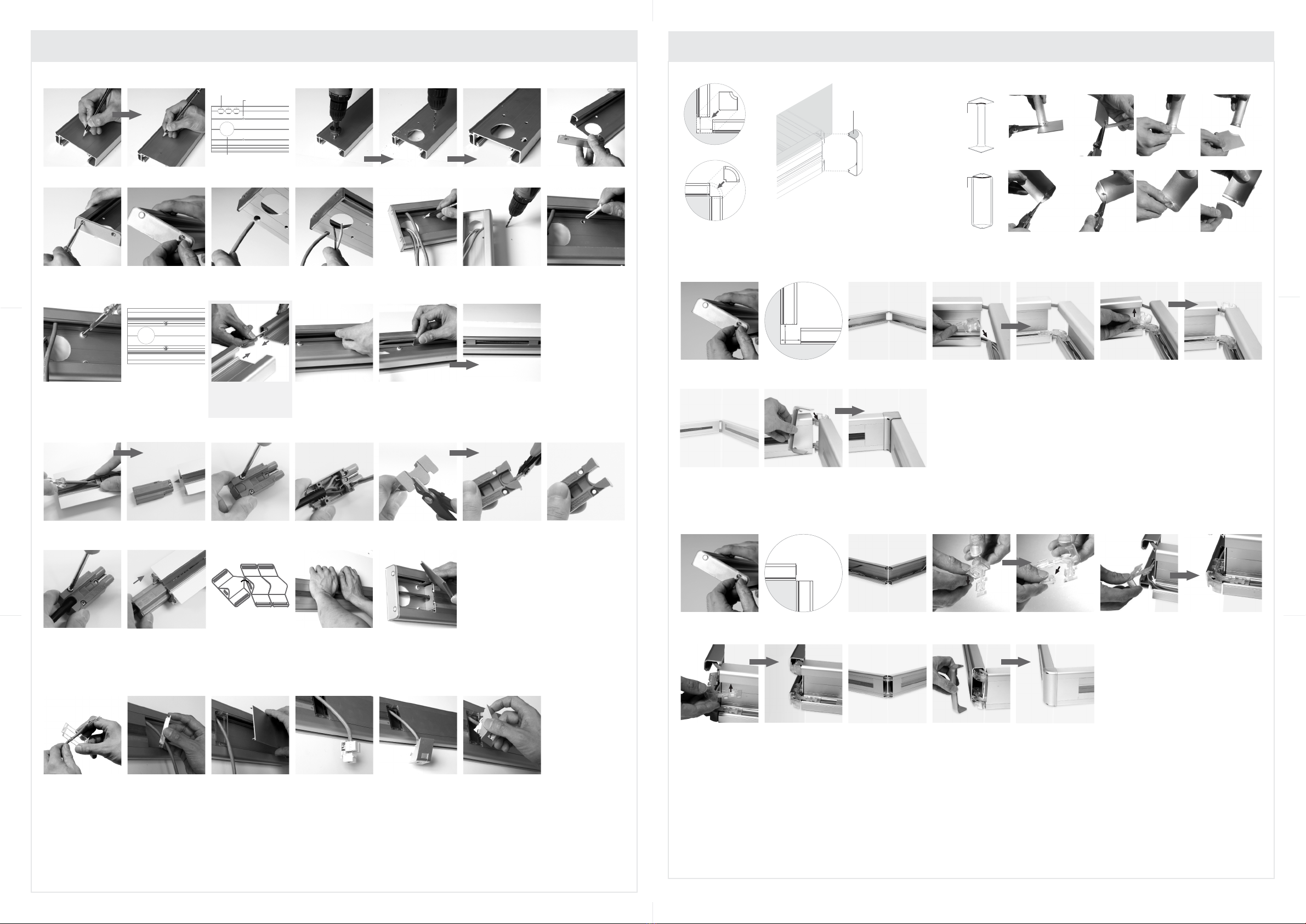

Installation

5

CABINET/

OFFICE

FURNITURE

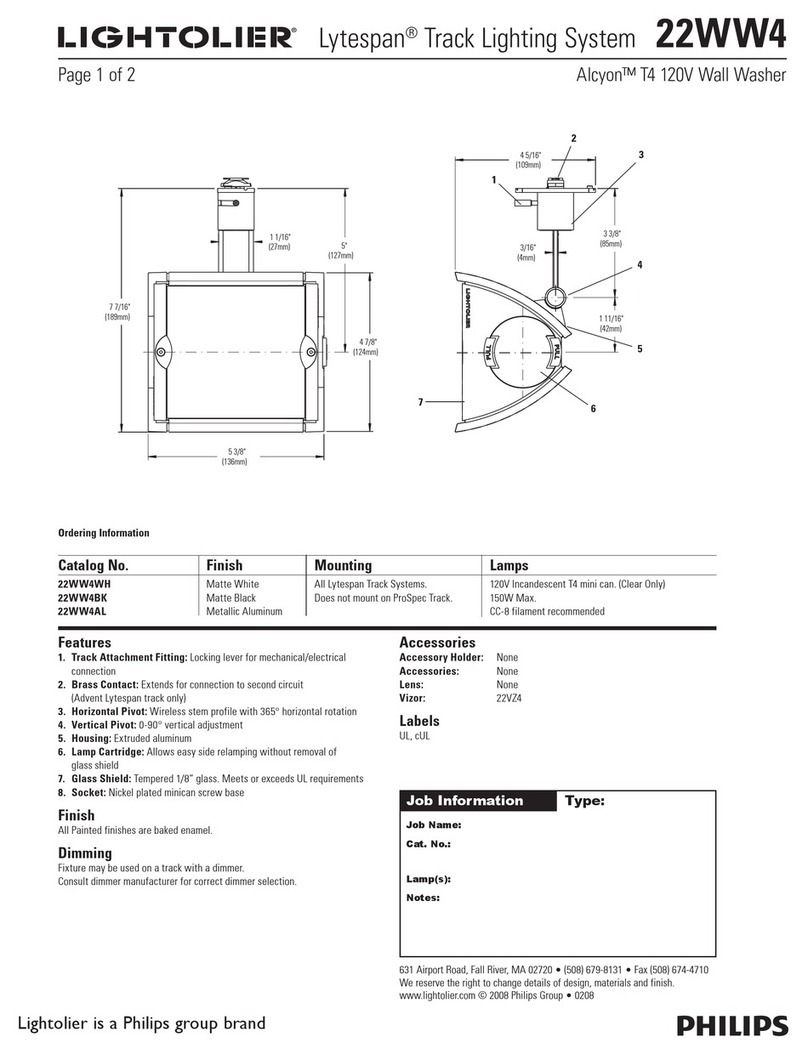

Remove the top cover of the internal/

external corner cap before attaching to

housing. Refer to (a) and (b) on the right

for instructions on removing the top cover.

Top cover to be

removed

6 7

ii

(a) Removing the top cover of internal corner cap

(b) Removing the top cover of external corner cap

iii iv v

ii iii iv v

A. INSTALLING INTERNAL CORNER JOINT

B. INSTALLING EXTERNAL CORNER JOINT

For installation of internal and external corner joints, refer to “Corner Joint Installation”.

3

7

Attach external corner cap to complete installation.

5

6

Attach corner link onto top of housing as shown. * Terminate cables and

install power track, data

housing and blank cover.

4

Break and remove inner latch on corner link as shown. Attach corner link onto bottom of housing as shown.

REMOVAL OF CORNER CAP TOP COVER FOR INSTALLATION OF SH1 UNDER CABINET OR FURNITURE FIXTURE

i

i

Trim Line

Trim Line

INTERNAL CORNER JOINT

EXTERNAL CORNER JOINT

1 2

Follow step 6 to 12 of

“Installation (A)” sequence to

secure and prepare housing.

Follow step 1 to 5 of

“Installation (A)” sequence

to prepare SH1 housing.

Align housing to wall with

reference to “Corner Joint

Guide”.

B. INSTALLING SFC3 MODULAR TRACK SIDE TERMINATION

8 9 10

Wherever necessary, snap

blank cover onto housing.

Snap SFC3 Modular Track

onto housing.

C. INSTALLING DATA POINT

23

Wherever necessary, snap

blank cover onto housing.

Route data cable

through mounting frame.

514

Snap mounting frame

onto housing.

Attach data jack to DS4

data housing with reference

to DS4 User Guide

(DMK-006-010).

Terminate data cable to

data jack.

8

1 2

6

Drill mounting holes on

marked locations.

Align housing to the wall

and insert wall plugs into

drilled holes.

Use the SH1 retainer to secure data cables to the

compartment as shown.

Mark out the positions of cable entry and mounting openings on drill lines provided on the

back of the housing. FIG. A shows the positions of cable entry and mounting openings.

Drill holes at marked locations for cable entry and mounting openings. Use a hole saw

for the power cable entry holes.

Route power and data cables through cable entry

openings and prepare to mount the housing.

4

Using a screwdriver, secure

end cap with screws

provided.

9

Mark out positions of

mounting holes onto the

wall.

7

13

3

Attach end cap to housing.

5

Attach screw caps. Repeat

steps 4 to 6 on opposite

end of housing if corner

joint is not required.

Push data cables into the

data compartment.

12

A. MOUNTING SH1 HOUSING

Snap data housing

onto mounting frame.

6

Installation of Corner Joints

FIG. A

Tighten screws to secure housing onto the wall. FIG. B

shows an example of mounting openings with screws

attached.

10

Data Cable Entry

Power Cable Entry

Mounting Opening

FIG. B

3

8

Follow step 6 to 12 of

“Installation (A)” sequence to

secure and prepare housing.

Attach internal corner cap to complete installation.

5

6 7

* Terminate cables and

install power track, data

housing and blank cover.

4

Attach corner link onto bottom of housing as shown. Attach corner link onto top of housing as shown.Follow step 1 to 5 of

“Installation (A)” sequence

to prepare SH1 housing.

1 2

Align housing to wall with

reference to “Corner Joint

Guide”.

37mm

* For side termination of SFC3 Modular Track, refer to “Installation (B)”

For installation of data points, refer to “Installation (C )”.

8

11

If extension of the housing

length is required, use the

housing joint pin to align

the additional SH1 housing.

Kindly visit our website at www.eubiq.com for product warranty information. ALL RIGHTS RESERVED. EUBIQ AND GSS ARE THE REGISTERED TRADEMARKS OF EUBIQ PTE LTD.

* For side termination of SFC3 Modular Track, refer to

“Installation (B)”

For installation of data points, refer to “Installation (C )”.

37mm

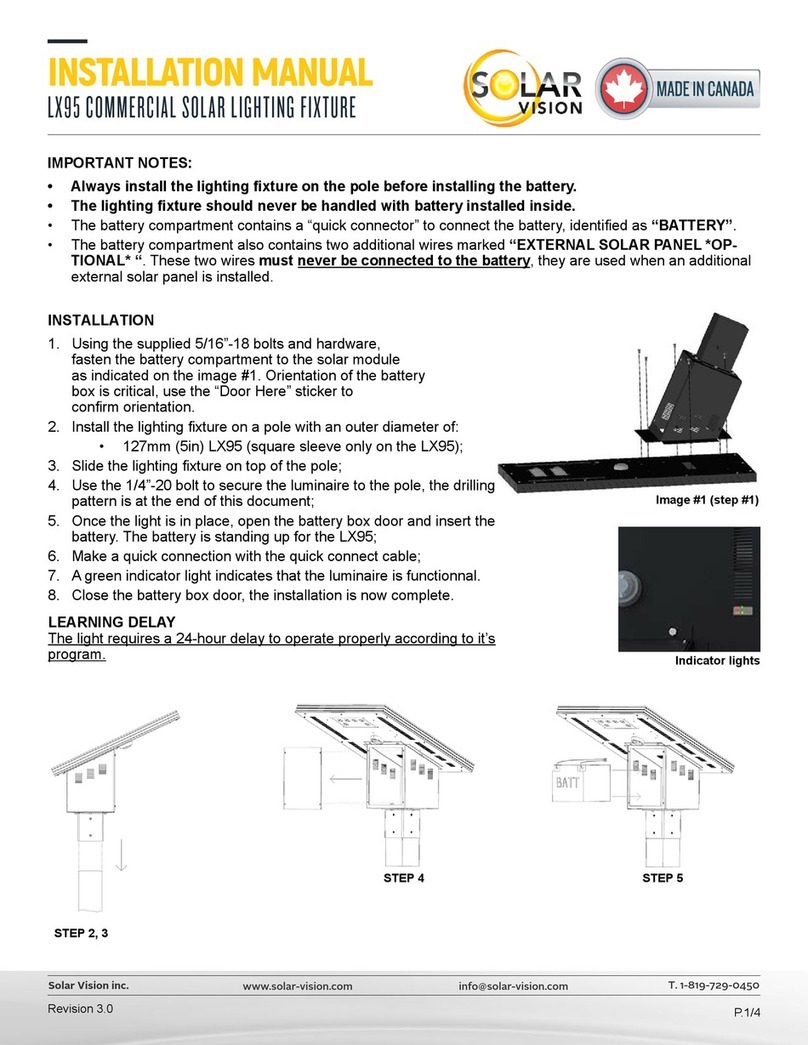

Popular Light Fixture manuals by other brands

Martin

Martin Exterior 1200 Wash user manual

SOLAR VISION

SOLAR VISION LX95 installation manual

Xtralite

Xtralite NiteSafe Duo-Lux instruction manual

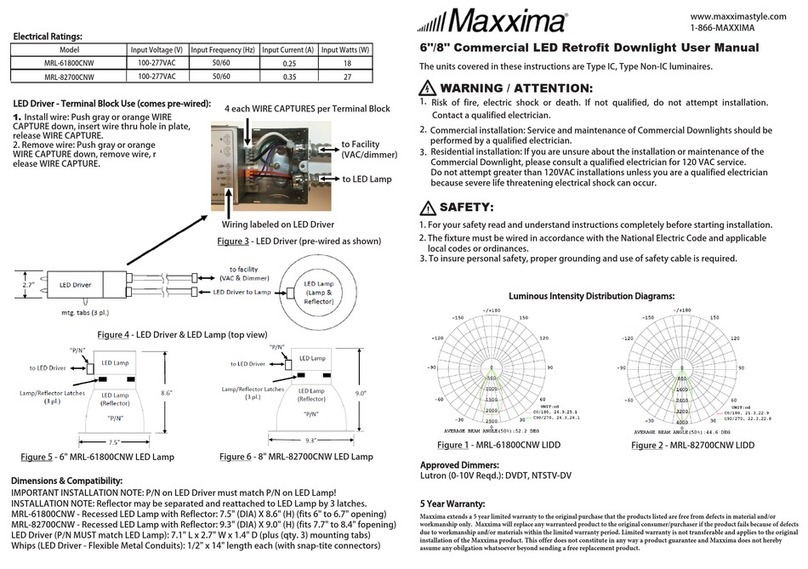

Maxxima

Maxxima MRL-61800CNW user manual

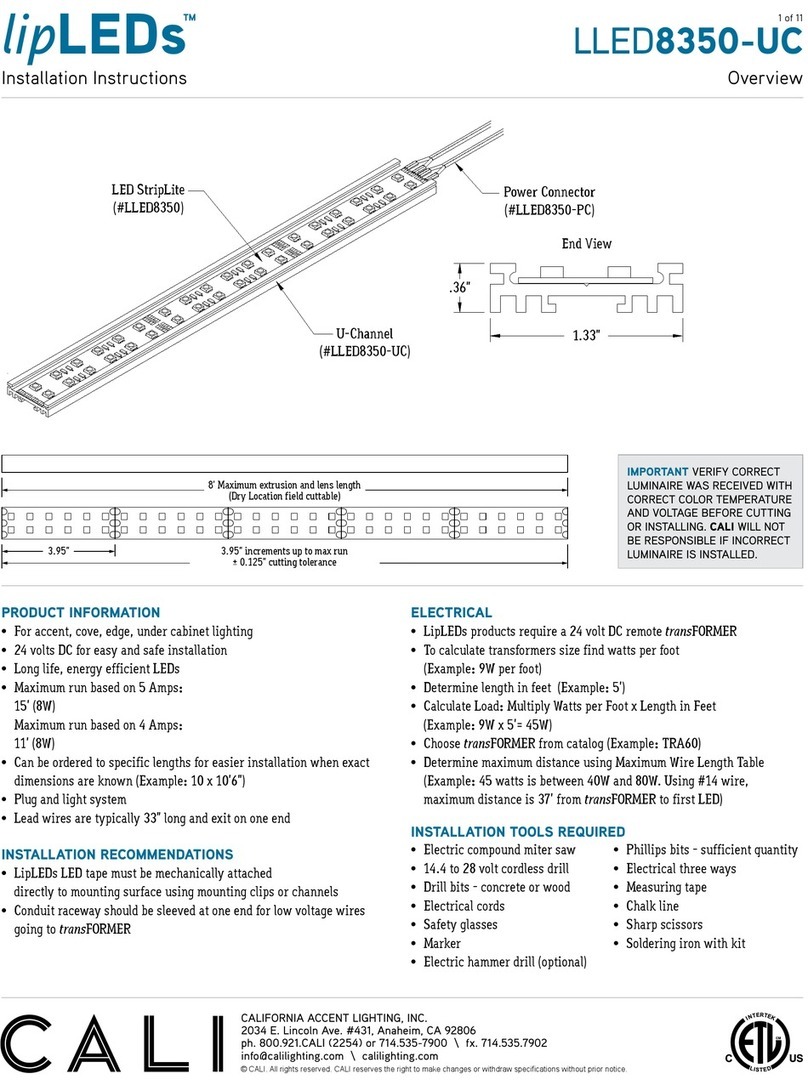

California Accent Lighting

California Accent Lighting lipLEDs LLED8350-UC installation instructions

ACME

ACME GEIST BEAM user manual