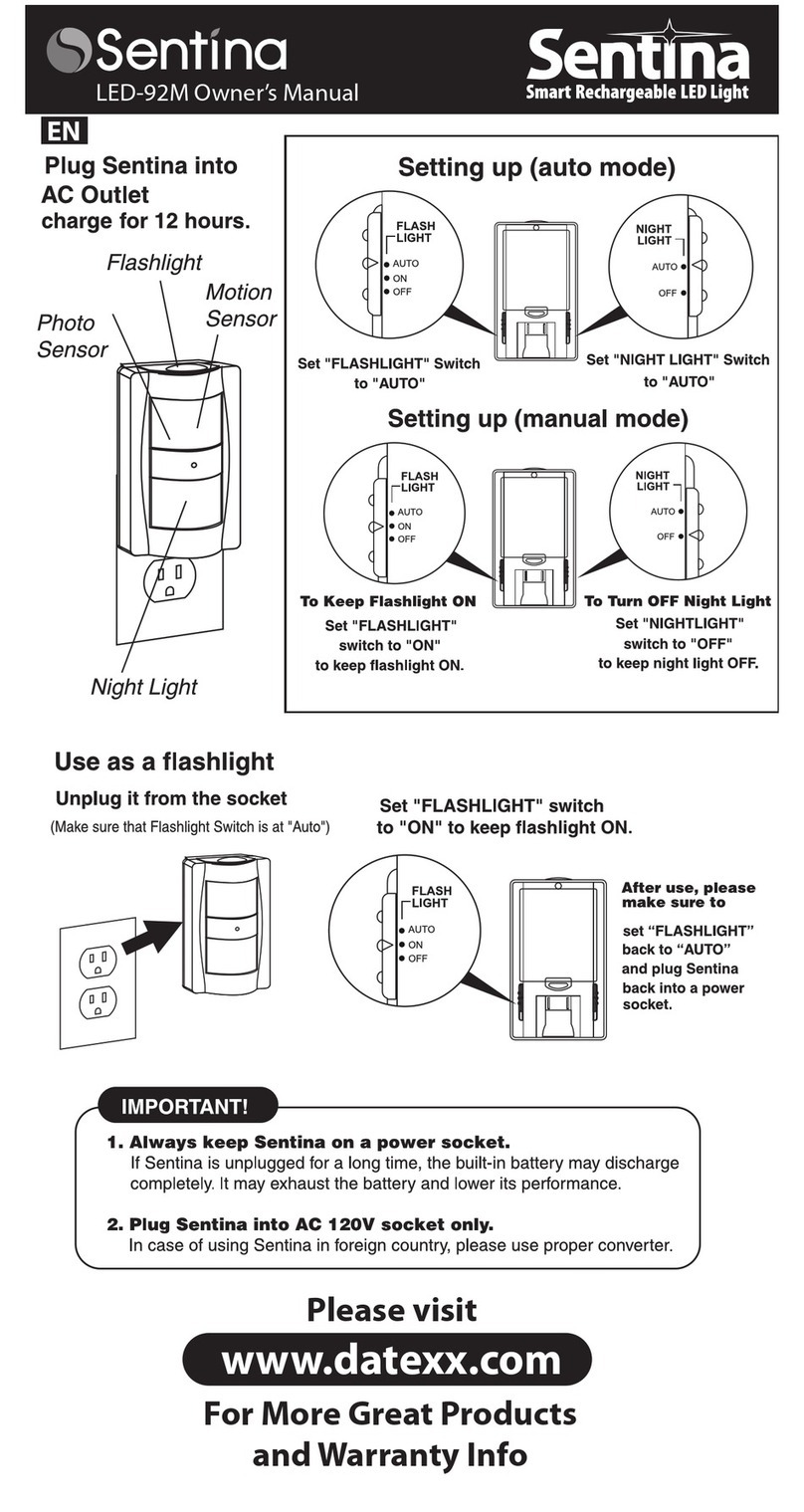

Operating Instructions Safety Systems

MGB-L0…-AR.-… and MGB-L0…-AP.-…

2(translation of the original operating instructions) 2112657-13-05/18

Contents

1. About this document............................................................................................. 4

1.1. Scope............................................................................................................................................4

1.1.1. Notes on older product versions ......................................................................................4

1.2. Target group ..................................................................................................................................4

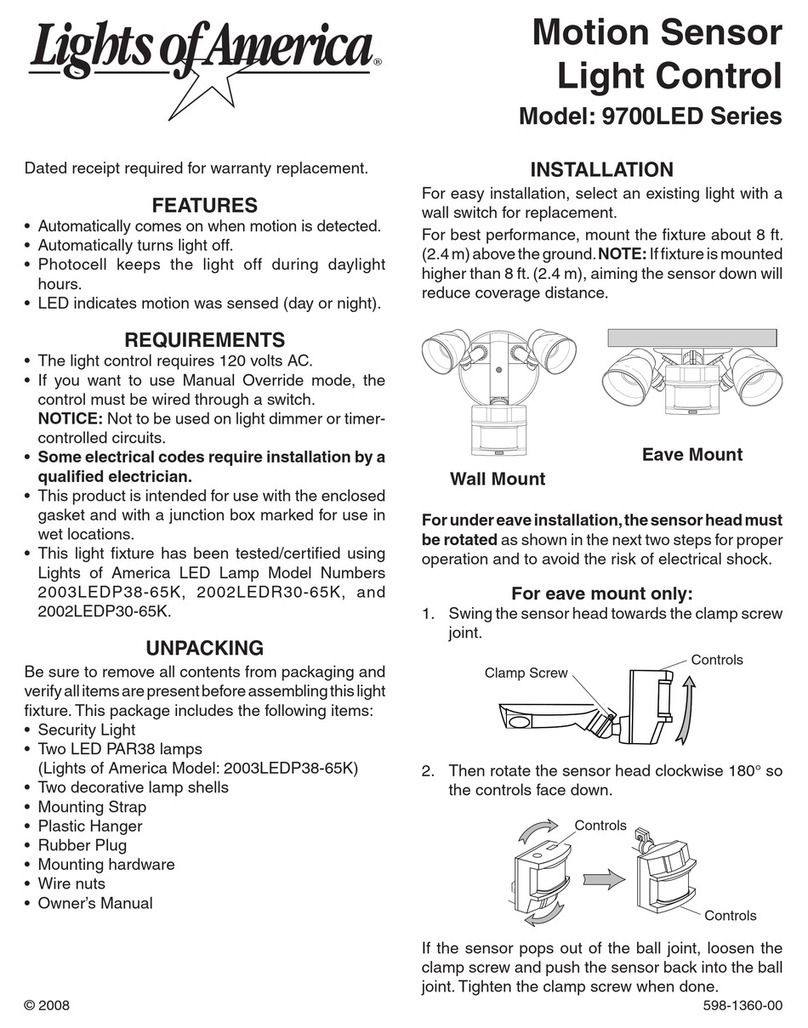

1.3. Key to symbols...............................................................................................................................4

1.4. Supplementary documents ..............................................................................................................5

2. Correct use .......................................................................................................... 6

2.1. Main differences between MGB-AP and MGB-AR.................................................................................7

3. Description of the safety function .......................................................................... 8

4. Exclusion of liability and warranty ......................................................................... 9

5. General safety precautions ................................................................................... 9

6. Function............................................................................................................. 10

7. System overview................................................................................................. 11

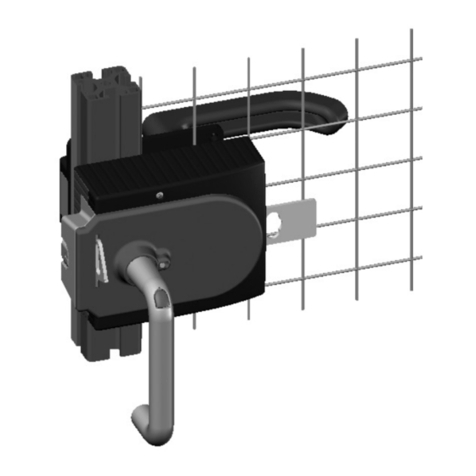

7.1. Interlocking module MGB-L0-… ......................................................................................................11

7.2. Handle module MGB-H-…...............................................................................................................11

7.3. Escape release MGB-E-… (optional)................................................................................................11

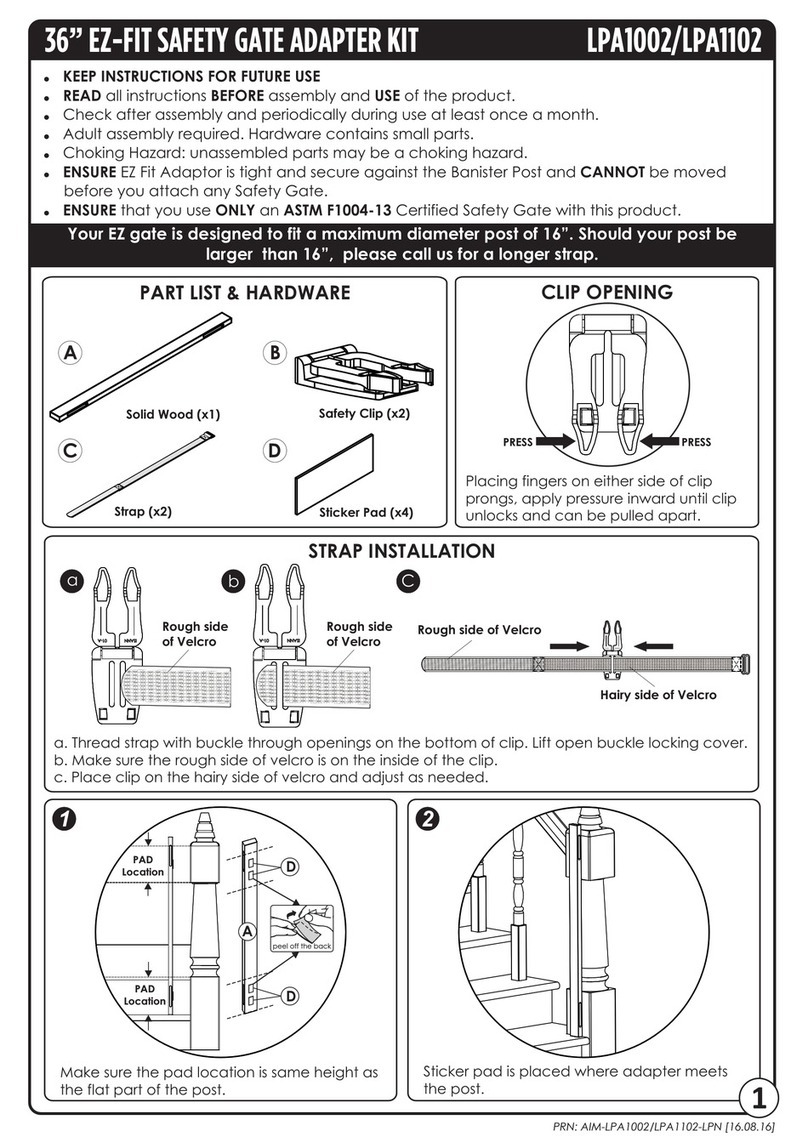

7.4. Dimension drawing .......................................................................................................................12

7.5. Lockout mechanism......................................................................................................................13

7.6. Escape release (optional) ..............................................................................................................14

7.6.1. Preparing escape release .............................................................................................14

8. Installation ......................................................................................................... 16

8.1. Mounting lens...............................................................................................................................17

9. Changing actuating direction (here: from right to left).......................................... 19

10. Protection against environmental effects............................................................. 20

11. Electrical connection .......................................................................................... 21

11.1. Notes about .........................................................................................................................22

11.2. Safety in case of faults..................................................................................................................22

11.3. Fuse protection for power supply...................................................................................................22

11.4. Requirements for connection cables...............................................................................................23

11.5. Notes on cable laying....................................................................................................................23

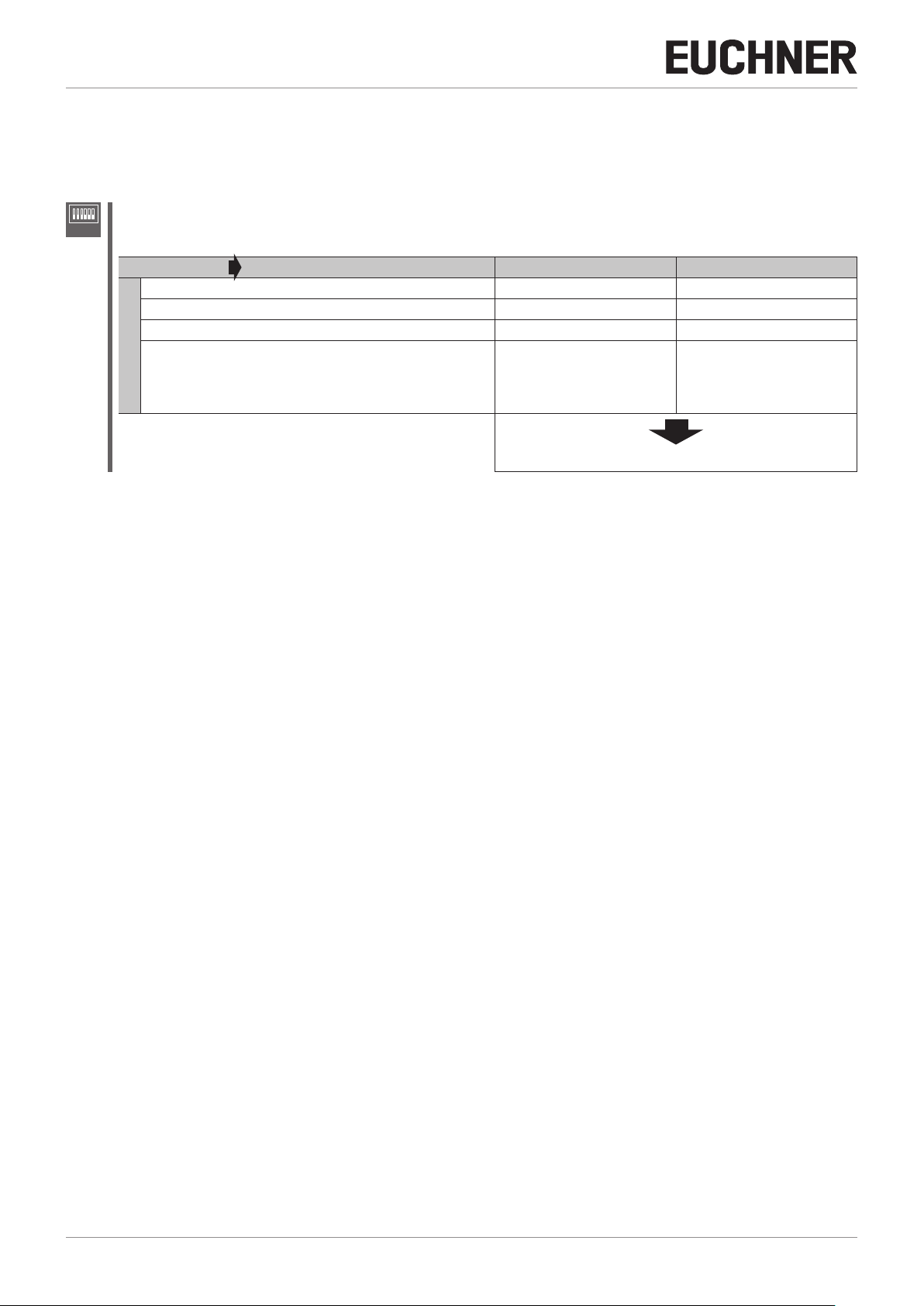

11.6. Changing device conguration (using DIP switches) .........................................................................24

11.6.1. Changing system family (AR/AP switching)......................................................................24

11.7. Notes on operation with control systems ........................................................................................25

11.8. Terminal assignment and contact description..................................................................................26

11.9. Operation as separate device ........................................................................................................27