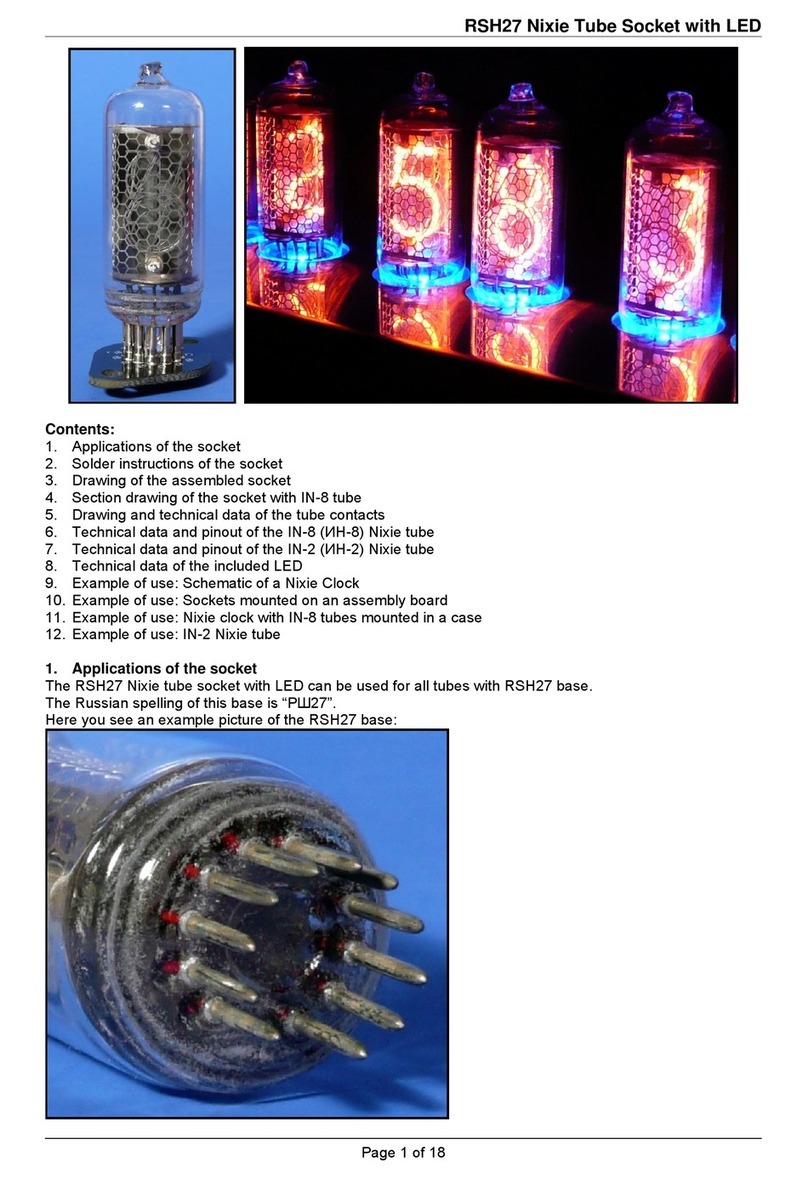

euclid The Time Traveler's Clock User manual

THE TIME TRAVELER’S

CLOCK

The Project’s History and User Manual

Euclid Laboratories, Inc. -- Teaticket, MA

The Time Traveler’s Clock User Manual

“A Man with a watch knows what time it is. A man with two watches is never sure.”

--Lee Segall

“A man with three clocks is more sure than a man with two clocks.”

--Tim Van Baak

Table of Contents

Description and Background of the Time Traveler’s Clock, the “TTC”

•Description of the TTC Functional Modules

oGPS Receiver and Clock

oCesium Reference

oSilicon Receiver and Clock

oHamilton 21 Marine Chronometer

oGPS and Silicon Clock Display Panel

oUTC Navigational Time

•Origin of the TTC

oHow Did This Project Begin?

oWhy Do You Need a Time Traveler’s Clock?

oWhat if Time Travel is Impossible?

•History of Prototypes

oCesium Breadboard Prototype

oPyramid Cesium CSACGPSDO Prototype

oWinding Mechanism

oCube Box Rubidium Prototype

oMetal Cube Box Final Prototype

•How the TTC Works

oMarine Chronometer Advantages and Deficiencies

oGPS Clock Advantages and Deficiencies

oSilicon Clock Advantages and Deficiencies

oAtomic Reference Advantages and Weaknesses

oServoSync Design Evolution

Installation and Connections

•What’s Included

oThe Time Traveler’s Clock

oTiming Printer and Supplies

oMain Power Battery, Charger, and Connecting Cable

oBackup Battery Charger

oGPS Antenna

•Connections

oMain Power Input

oBackup Battery Charger Input

oGPS Antenna Input

oCesium 10MHz Output

oCesium 1pps Output

oGPS 1pps Output

oChronometer Tick Output

oTiming Printer

•Initial Setup

oConnecting the Power Supplies

oConnecting the GPS Antenna

oWinding and Setting the Chronometer

Normal Operations

•Daily Operation

oReading Times from the Display Panel

oReading Time and Winding Reserve from the Chronometer

•Time-keeping Verification

•Servo Controls

oServoSync

oRate Atomic and Rate Error Measurement

oRate Now

oSet RTC

•Winding Controls

oWind Now

oAutoWind

oManual Winding

•Other Control Panel Indicators and Buttons

•Printer

oNormal Operation

•Metal Cube Case Operation and Alternate Configurations

Maintenance Operations

•Setting the Silicon Clock by GPS

•Warm Resetting the Electronics

•Cold Resetting the Electronics

•Changing the Printer Paper

•Locking the Chronometer for Storage or Shipment

Appendices

•Schematic Diagram

•Description of the Circuit Operation

•Firmware

Description and Background of the TTC

Description of the TTC Functional Modules

GPS Receiver and Clock

The most precise and accurate time signal currently available on Earth is from the global

constellations of navigational satellites, such as GPS (US), Glonass (Russia), Beidou

(China), and Galileo (European Union). To provide position data to GPS receivers, the

satellites contain cesium atomic clocks which are continuously monitored and adjusted

by their respective countries. A GPS timing receiver can provide time to within as little

as 10 nanoseconds as long as it has at least four satellites in view. When satellite

reception is lost, the GPS timing receiver goes into “holdover” mode, in which it uses an

internal quartz oscillator to maintain time. In holdover mode a GPS timing receiver by

itself can maintain time to within 100 parts per billion, or a few seconds per year.

Cesium Reference

The cesium reference oscillator is known as a “chip-scale atomic clock” (CSAC). In the

CSAC, the oscillations of an isotope of cesium provide a “Stratum 1” 10 megahertz

reference signal. This signal stabilizes the GPS receiver so that the clock will operate at

the highest possible precision when a GPS signal is not present. The cesium CSAC is

accurate to 1x10-11, which translates to less than a millisecond per year.

Silicon Receiver and Clock

An independent electronic clock is incorporated which utilizes a silicon real-time-clock

(RTC) chip to provide time in case the GPS signal is unavailable and the CSAC atomic

clock fails or runs out of power. The RTC chip contains a temperature-compensated

quartz oscillator accurate to within a few minutes per year. The RTC chip will operate

independently from all the other systems by means of a lithium cell for several years.

It’s time and date are displayed on the display panel, which panel must be powered on,

at least temporarily, to read the time).

Hamilton 21 Marine Chronometer

Before the advent of radio time signals and portable quartz clocks, ships at sea utilized a

highly precise mechanical clock known as a chronometer to ascertain the ship’s

longitude. Chronometers sufficiently accurate to provide navigational time at sea were

first developed in the late eighteenth century by John Harrison. Over many years the

design of marine chronometers advanced, culminating in the Hamilton Model 21 Marine

Chronometer, developed during World War II by the Hamilton Watch Company in

Lancaster, Pennsylvania. The Hamilton chronometer was an improvement of

chronometers manufactured in Switzerland.

The US Navy and US Army used these chronometers until 1985, when they were

replaced by quartz instruments. The Hamilton 21 has a typical rate stability of one part

per million, equivalent to less than a minute per year. Generally marine chronometers

are provided to the user with data on when it was set to correct time and how much the

time can be expected to vary per day (the rate error). For navigational use, the user

must calculate the actual current time using the rate error and the number of days since

the chronometer was set to correct time.

The TTC contains a servo mechanism which provides a mechanical twisting motion to

the chronometer once per second to keep the chronometer synchronized with the GPS

timing receiver (which in turn is stabilized by the cesium CSAC). Thus, the GPS clock, the

cesium frequency reference, and the Hamilton chronometer are kept in resonance, and

the chronometer will remain as accurate as the GPS and atomic references.

The Hamilton 21 chronometer in the TTC is equipped with an electronic winding system

that winds the chronometer each hour to a consistent state of winding.

In order that precise time could be calculated from the Hamilton chronometer even if

the GPS and atomic references are not functioning (for example, if electrical power has

been lost for longer than the backup batteries will maintain operation), the natural rate

of the chronometer is measured once per day for a period of thirty minutes (at

midnight), and the deviation of the mechanical clock from the GPS and atomic

references is measured and printed out on the external printer. The user will thus have

the best possible knowledge of the rate error of the chronometer, and the precise

navigational time can be calculated from the number of days since it was last

synchronized and the average rate error per day.

Figure 1: Hamilton 21 Marine Chronometer

GPS and Silicon Clock Display Panel

The TTC has an electronic display panel which indicates the UTC time, date, latitude, and

longitude from the GPS clock as well as UTC time and date as maintained by the silicon

RTC clock.

Figure 2: GPS and RTC Display

UTC Navigational Time

There are many standards for time and date. Besides the standard local time zones,

there is a basis time known as Coordinated Universal Time (UTC). UTC is defined as the

time at the zero meridian which passes through Greenwich, UK. It is regulated by an

international committee, the International Time Bureau. Periodically, leapseconds are

added (or subtracted) from UTC in order to keep it more or less synchronous with

Earth’s rotation relative to the stars. Since UTC is always within one half second of the

Earth’s rotation, it is the preferred time standard to be used for navigation. For that

reason, the TTC uses UTC in all its displays and on the Hamilton chronometer.

Origin of the TTC

How Did This Project Begin?

After discovering and rebuilding the Time Viewer originally constructed by Leonardo; da

Vinci, the present inventor saw the need for a navigational clock for time travelers. It

may be true that Leonardo traveled to America in the 1940s, that he wanted to return

to Milano in 1478, and that he built the Time Viewer in order to learn the future

technology needed to construct a time-traveling machine. We know that Leonardo did

remain in Italy for the rest of his life. Could it be that he couldn’t navigate in time

anymore, since he lacked a chronometer? If the present inventor is ever able to build a

time-traveling machine, he would want to carry with him the most reliable possible

chronometer. So, first things first: the inventor turned his efforts to creating that

timekeeper.

Figure 3: Leonardo’s Time Viewer

Why Do You Need a Time Traveler’s Clock?

Imagine you’re traveling in time and space. Just like navigators of old, you’ll want to

have some “bearings” back home, so you can return or go to a new destination. Time

will essential to navigation, and we can assume that UTC will always be a good time to

know.

But, you never know—you might end up in the past when there was no GPS (the atomic

CSAC will keep you navigating); or, you might end up before there was electricity (you

can always wind your chronometer manually, and use the printed data to know the

corrections you’ll need to apply to the time that the chronometer displays). You might

travel to a time near the present when you can find electricity, but the GPS system isn’t

operational. You might travel to the future when the time standards and navigational

systems are completely different from what we have now (but you’ll be able to find

some form of electricity to keep your batteries charged to maintain your GPS internal

clock and your atomic-stabilized chronometer.

Eventually, the sands of time may cause the GPS and CSAC systems to fail, but you’ll be

left with your silicon RTC clock. And, in the end, you’ll still have your Hamilton marine

chronometer that you can keep winding for a long time (they have proven to be very

reliable for many years of operation). Make sure you wind it every day.

What if Time Travel is Impossible

It’s possible that time travel, either to the past or the far future won’t turn out to be

possible. So, the discerning individual would want to be able to navigate by land, sea, or

air via GPS, or using a sextant and their atomic clock, or a backup silicon chip clock, or

even just their mechanical chronometer. The TTC has you covered for any imaginable

eventuality. (And, if you’ve spent a lot of money on your yacht or aircraft, you’d

certainly want to have the absolute, ultimate, most-reliable timekeeper available.)

History of Prototypes

Cesium Breadboard Prototype

The first experimental design was constructed with a Hamilton 21 chronometer, a

Microchip/Jackson Labs cesium chip-scale atomic clock (CSAC) (later used in the MCB

Prototype), a ublox GPS evaluation kit (EVK-M8T), a Maxim DS3231 real-time clock (RTC)

chip, and a servo mechanism to rotate the chronometer by a small amount (about one

half degree of arc) following the seconds pulses from the GPS and CSAC.

This prototype was used to determine if it was possible to resonate a mechanical

chronometer, how much motion would be required, and to refine the displays for time

from the GPS and the RTC. A circuit was incorporated to allow re-setting the RTC from

the GPS whenever desired.

Additional problems to be worked out were an automatic winding system, a backup

battery array, and the rotational suspension system for the Hamilton chronometer. The

circuits were constructed using multiple Arduino Nano microcontrollers, breakout

boards, and solderless breadboards. The gimbals of the Hamilton chronometer were

mounted to a cradle mounted on a large, thin ball bearing and rotated using a high-

torque digital servo motor. Solutions to most of these problems were worked out,

though reliability problems persisted with power supplies and the winding system. In

addition, the full-circle ball bearing prevented the chronometer being rotated upward

for convenient manual winding.

Figure 4: Cesium Time Traveler’s Clock Breadboard

Winding Mechanism

The mechanism which continually winds the chronometer required considerable

development. Winding the chronometer requires substantial torque.The state of wind

must be periodically measured to determine if winding is required. As the chronometer

runs down, the winding input stem must be allowed to rotate backwards, so the

chronometer may continue operation. Finally, provision must be made for manually

winding the chronometer.

The successful winding mechanism uses a titanium-geared radio-control servo motor

fitted with a drive pinion. The drive pinion is driven alternately clockwise and

counterclockwise by the servo motor. The Servo Drive Pinion is constantly meshed with

the Winding Rack, which is driven back and forth by the Servo Motor. The Winding Rack

engages a Winding Gear. The Winding Gear rides on the Sinding Spindle, which has a

square opening on its upper end to engage the winding stem of the chronometer.

In order that the back-and-forth motion of the Winding Rack does not force the Winding

Spindle backwards (which would damage the chronometer), a One-way Clutch is

pressed into the Winding Gear and rides on the hardened surface of the Winding

Spindle. When each winding cycle is completed, the Winding Rack is returned to its

“home” position. In the home position, the rack has a portion of its teeth removed to

disconnect it from the Winding Gear, allowing it to turn backwards as the chronometer

unwinds.

The State-of-wind Potentiometer, coupled to the Winding Spindle by a timing belt,

measures the degree to which the chronometer is currently wound. Complete winding

requires approximately eight turns, so a 10-turn potentiometer is used to follow the

Winding Spindle in a 1:1 ratio.This potentiometer is read by a microcontroller which

controls the winding process.

The bottom end of the Winding Spindle has a 3mm square shaft protruding to allow the

user to apply a manual winding key.

Every hour, the condition of the State-of-wind Potentiometer is measured by the

microcontroller and the Servo Motor is actuated back-and-forth until the chronometer

is fully wound.

Figure 5: Winding Mechanism

Pyramid Cesium CSACGPSDO Prototype

The next generation of prototypes was built in a pyramidal shape with proportions from

the Great Pyramid of Giza. The bottom of the enclosure was black acrylic with a window

for the electronic displays, and the upper cover was clear acrylic to allow viewing of the

controls and chronometer. The thermal printer to record the natural rate of the

chronometer was added to the rear panel, and backup batteries (Saft thionyl-chloride D

cells) were fitted inside the base. The “tick” signal output from the mechanical

chronometer needed to operate the rating circuit and printer was changed to a simple

contact-closure mechanism which is available in a few of the Hamilton 21 chronometers

which were made in the last century. While only a few of these exist, the mechanical

contact closure is much superior to optical and audio sensors that were evaluated to

pick up the “ticks” of the chronometer.

In the Pyramid Clock, the atomic reference was a Jackson Labs cesium-CSAC GPS

Disciplined Oscillator module, which incorporated a cesium reference oscillator phase-

locked to the GPS chip. A separate display was run from this module to display the date,

time, latitude, longitude, and operational characteristics of its GPS and the CSAC. The

GPS clock was a ublox EVK-M8F module, which provided date, time, longitude, and

latitude independently from that supplied by the CSAC GPS Disciplined Oscillator. The

Maxim RTC system was unchanged except for software refinements.

The gimbal support and servo system were like those on the Cesium Breadboard

Prototype. The problem of not being able to manually wind the chronometer without

disassembling the housing remained and needed to be fixed.

Figure 6: Pyramid Time Traveler’s Clock

It was found that a redundant GPS systems was not needed, because a CSAC GPS

Disciplined Oscillator (either cesium or rubidium) provided date, latitude, longitude, and

time from the atomic reference, maintaining accuracy to a millisecond per year.

Cube Box Rubidium Prototype

The inventor decided that the pyramid enclosure, while having an interesting

appearance, was not very space-efficient, and he decided to go with a more traditional,

cubical, mahogany box, like what has been traditionally used for marine chronometers,

but increased in size (having more internal volume and a smaller footprint than the

pyramid). The cube box had a lower section (about 2/3 of the height) that enclosed all

the circuits, batteries, and chronometer. A display panel was mounted behind the

chronometer, and a row of display lights and switches was placed across the front of the

chronometer. The upper section of the box was hinged and latched to the lower

section, covering the chronometer and controls. It allowed the user to see all the

displays, switches, and chronometer through a clear window. Above the upper section

was a hinged lid and latch to close the box.

In this prototype the atomic reference was a stand-alone rubidium miniature atomic

clock (MAC) from Jackson Labs. This oscillator was calibrated with a GPS-disciplined

reference clock before use. The 10MHz output of the MAC was connected to an input

on the GPS module (a ublox EVK-M8F) to supply the chip with a precision time base to

allow the GPS to maintain accurate time during “holdover”, when a GPS signal is not

available. This simpler design works as well as the cesium CSAC/GPS-Disciplined-

Oscillator module, is less expensive, and is less complicated.

In the Cube Box, the chronometer gimbals were mounted on an aluminum lazy-susan

bearing that was cut away at the rear; this opening allowed the chronometer to be tilted

upward for manual winding. The lazy-susan bearing, however, had too much clearance

between its races, resulting in unstable oscillations of the servo drive.

The chronometer-rate printer was mounted in a separate enclosure and connected by a

cable to the rear panel of the box.

In addition to the GPS Antenna connection on the rear panel, SMA connectors supplied

the MAC 10MHz reference frequency, the MAC 1-pulse-per second (1pps) signal, the

GPS 1pps signal, and the chronometer seconds-tick signal. A push-on connector was

provided for the rate printer.

Refinements needed to this design included improving the reliability of the automatic

winding system, providing a more precise gimbal-support bearing, aesthetics, and

reversion to a cesium-based atomic reference.

Figure 7: Cube Box Traveler’s Clock

Metal Cube Box Final Prototype

The next prototype incorporated a fully-machined anodized aluminum enclosure in

place of the mahogany box following the same design and dimensions. The gimbal-

support bearing was changed from the lazy-susan bearing to a precision V-groove

circular rail with four support bearing rollers; the rear part of the rail was cut away to

allow the chronometer to be rotated for winding. This bearing arrangement was more

precise, so the servo synchronizing mechanism performed much better.

The displays were simplified to two LCD displays: one showing the GPS date, time,

latitude, and longitude and one showing date and time from the RTC. No separate

display was used for the CSAC, as it operates only to supply the 10MHz precision

reference frequency.

The rubidium MAC was replaced with the cesium CSAC used in the Cesium Breadboard

Prototype. Otherwise, the MCB Prototype was like the Cube Box Prototype and used

the same electronic hardware and firmware. The operational scheme remained with

the GPS module being fed a precision 10MHz frequency reference from the CSAC to

ensure long-term accuracy during holdover.

Figure 8: Metal Cube Box Time Traveler’s Clock (rendered with clear case)

How the TTC Works

Marine Chronometer Advantages and Deficiencies

The Hamilton 21 Marine Chronometer represents the height of development of

portable mechanical clocks for navigation. The basic design, developed by several

companies in Switzerland (Zenith, Ulysse-Nardin, Ditisheim, among others) includes a

wooden box, gimbals, chronometer case, and a clockwork which incorporates a fusee

mechanism for near-constant winding force as the mainspring winds down, a detent

escapement, and a temperature-compensated balance wheel fitted with a helical

hairspring.

When the US Navy realized the upcoming need for thousands of such chronometers in

the years prior to World War II, the only company which could fill the need was

Hamilton Watch Company of Lancaster, Pennsylvania. Hamilton could meet the need if

the basic design of a Ulysse-Nardin chronometer was exactly copied, except for the

balance wheel assembly. Hamilton had developed a better way to create a

temperature-compensated balance wheel that would not require the time-consuming

and laborious process of regulation that was required by the Swiss-pattern

chronometers.

Figure 9: Ulysse-Nardin Marine Chronometer, Predecessor to Hamilton 21

By making the balance wheel an unbroken ring of stainless steel supported by a simple

two-spoke arrangement made from Invar (a metal alloy with near-zero change in

dimension with temperature change), a Hamilton could manufacture a balance with

built-in temperature compensation not requiring many days of regulating. Hamilton

produced about 10,000 such chronometers prior to and during the war, and these were

found to be the most reliable and precise chronometers manufactured until that time.

The advantages of a mechanical, manual-wind chronometer are its reliability and

trustworthiness. As long as the chronometer is wound each day, accurate time is

assured. Each instrument could be regulated to keep time within a second per day,

and—more important—its deviation from perfect time would be a very precise value

which would not change over the life of the chronometer. Each chronometer supplied

to the Navy (and, also, to the US Army Corps of Engineers) came with a record telling

when it was set to time as well as its measured error per day. From these data a

navigator could subtract the daily error multiplied by the number of days from the

currently displayed time, resulting in a very accurate “corrected” time for navigation.

Weaknesses of a mechanical chronometer include the need for continual winding; and,

if the instrument is allowed to run down, then all knowledge of time will be lost. Also,

while physically very robust, these instruments have to be handled with great care in

order not to upset the timekeeping. On larger ships the navigator kept two or three

chronometers for redundancy.

During normal operation, the TTC keeps the mechanical chronometer synchronized to

GNSS or atomic precision by means of a servo-mechanical system. It has been found

that a very small rotation of the chronometer every second will quickly cause the

chronometer to become synchronized to that rotation, because the escapement and

balance system in the chronometer become resonant with the applied mechanical

rotation. It is this resonance that affords the chronometer the ability to maintain

“perfect” time as long as the atomic or GNSS signals are present. If those signals are no

longer present, such as if all power is lost for an extended period, the chronometer will

revert to its natural rate. During normal operation, once per day, at midnight UTC, the

servo synchronization is turned off so that the natural rate of the chronometer can be

measured versus the atomic or GNSS standard, and that error is printed on a paper

tape.

Should the electronic clock systems in the TTC be lost, the user can use these historical

measurements to calculate the best time for navigation by applying the daily error to

the time read on the chronometer, as was done in the past, before satellite and atomic

standards.

Figure 10: Hamilton 21 Marine Chronometer

GPS Clock Advantages and Deficiencies

The various global navigational satellite systems (GNSS systems, including the US GPS,

Russia’s Glonass, Europe’s Galileo, and China’s Beidou) rely on very-high precision time

keeping in order to allow a receiver to calculate its own position. Each satellite

broadcasts its current time and its ephemeris (the parameters of its orbit). The receiver

must then compare the times received from multiple satellites, correct for relativistic

timing frame differences, and perform a complex calculation to “multilaterate” its own

position on earth. In the process, the receiver also calculates the current time to a very

high degree of accuracy, on the order of nano- or micro-seconds. A timing-rated

receiver can provide true time accurate to within a few tens of nanoseconds.

When provided with an external frequency reference, the GNSS receiver can maintain

the time (“holdover”) even if satellite signals are lost. By itself, the uBlox M8F receiver

has a holdover precision of 1 x 10-7, or 8 milliseconds per day. If an atomic reference

signal is supplied, then the holdover precision will be equal to the precision of the

atomic reference signal (in the TTC, 1 x 10-10, equivalent to a few milliseconds per year).

Since these satellite signals are available almost anywhere on earth, the time provided

by a GNSS receiver is the time used for most scientific, civil, and navigational purposes.

Why would a user need to use precise time for navigation, given that he has a GNSS

receiver giving precise latitude, longitude, and altitude data? The answer is that GNSS

systems can be jammed or spoofed, resulting in inaccurate location calculations. By

keeping a reliable clock continually set to known good GNSS time, a navigator may use a

sextant and navigational number tables to calculate his position, even if the GNSS

signals are incorrect or unavailable.

The TTC can be used for navigation because it has multiple time references, including

atomic, quartz, and silicon-based clocks in addition to its mechanical chronometer.

When GNSS time signals are available, the quartz, silicon, and mechanical clocks are

kept synchronized to satellite time.

Silicon Clock Advantages and Deficiencies

One of the redundant clocks contained in the TTC is an integrated-circuit chip (Dallas

DS3231) which contains a temperature-corrected quartz oscillator of its own and an

extremely-low power microprocessor which maintains correct time, even if it’s main

power supply is lost, using a small backup battery. The lifetime of the backup battery is

at least ten years, and it is only used when the normal power supply is not available.

This integrated-circuit clock is not as accurate as an atomic or GPS clock, but it can serve

as a timing reference if all else is lost, and it is a redundant clock to supplement the

other quartz, atomic, and mechanical timekeeping systems. The integrated-circuit clock

in the Dallas DS3231 chip is specified to be accurate to within one minute per year;

DS3231 chips used in the TTC are individually tested and calibrated to achieve

significantly improved timekeeping, on the order of seconds per year.

Figure 11: Real-time Clock with DS3231 Silicon Integrated Circuit

Atomic Reference Advantages and Weaknesses

TTCs use atomic frequency standards based upon the oscillations of cesium or rubidium

atoms. These are the most precise reference standards available that can be used in

portable equipment. The “Miniature Atomic Clock” (MAC) and “Chip-scale Atomic

Clock” (CSAC) technology was developed by Jackson Laboratories.

The current state-of-the-art devices are cesium CSAC modules such as the one used in

the latest MCB version of the TTC. The signal from this module, a 10 MHz reference, is

supplied to the GNSS timing receiver so that if satellite signals are not available, the

receiver will go into “holdover” mode with the precision of an atomic clock. The cesium

CSAC modules have an accuracy of 1 x 10-10, which is equivalent to a few milliseconds

per year. In the TTC, this signal serves as the reference to not only the GNSS receiver,

but also to the mechanical chronometer by way of the servo synchronization system.

Atomic clocks require continuous electrical current to maintain their accuracy.

However, if power is restored after a temporary loss, the atomic clock module will re-

establish its operation according to the last stored tuning data and once again begin to

supply a stable reference signal to the GNSS receiver. During the time that the atomic

reference is lost, the GNSS receiver will revert to its own internal quartz reference,

which is precise to 1 x 10-7, or 8 milliseconds per day.

Figure 12: Cesium Chip Scale Atomic Clock Circuit Board

ServoSync Design Evolution

The conception of the Time Traveler’s Clock includes the means by which a mechanical

chronometer is kept in perfect synchronization with an atomic- or GPS-based time

signal. A very small rotary motion (on the order of +/- 0.5mm) applied to the gimbal-

mounted chronometer will cause the balance wheel and detent escapement to fall into

resonance with that motion. Several design problems needed to be solved in order to

make this system practical. A servo motor of the type used in robots and remote-

control models is driven by a microcontrollers to provide a back-and-forth motion, and

this motion is connected to the gimbals of the chronometer by means of a lever and a

linkage.

Two problems remained: how to mount the chronometer and its gimbals in such a way

that the chronometer can be rotated by this small amount; and, how to provide space

for the chronometer to be tilted forward so it could be manually wound. Three

successive designs were developed.

1. Ring-bearing Design:

The first design developed to impulse the chronometer back and forth in a rotary

direction used a thin-section ball bearing. A servo motor was linked to the rotary

carriage with a simple linkage to transmit the back-and-forth rotary impulse to the

chronometer gimbal rings. This design worked well, but the bearing, being was a

complete circle, would not allow the chronometer to be tilted forward for manual

winding.

Figure 13: ServoSync Mechanism with Thin Ball Bearing Design

Table of contents