Euro-Clear Kft.

Water purification and treatment equipment manufacturer and wholesale distributor

Tel: +36 96 544-240 • Fax: +36 96 544-248 • E-mail: sales@euro-clear.eu • Web: www. euro-clear.eu

BlueSoft Industrial Iron and Manganese Remover Page 7.

4. OPERATION OF THE DEVICE

4.1. TYPES OF IRON THAT CAN OCCUR

Iron can be found in three forms in the nature ( Fe; Fe++; Fe+++ ). Manganese can

have 2 forms in the nature ( Mn+; Mn++ ). You can find it in most of volcanic stones,

usually in standstone, in different kinds of clay, and, in smaller extent, it is also part

of carbonate stones. It is important to know in which forms the iron and manganese

to remove can be found, so that you can apply the most economical iron and/or

manganese remover system.

4.2. DESCRIPTION OF THE OPERATION, ITS THEORETICAL BASES

The charges of the removers are usually natural minerals, their main component is

the manganese dioxide. They have been used for more than 75 years in water

treatment. Catalytic filtrating materials to remove iron reduce the water’s iron,

manganese and hydrogene sulphide content. They function as a catalyst and remain

unchanged.

The iron removers’ charges work as follows: H2S, iron and manganese oxidize and

get stuck on the filtrating material. The filtrating material can get cleaned by a simple

backwash. You do not need to dose any chemical, so nothing is going into the

drinking water. The iron removers’ charges have a big capacity even when the

pollution has got low concentration.

In order to ensure the adequate bed expansion and long life, it is very

important to backwash the iron removers’ filter properly as the density is

quite big.

In most cases, dissolved iron in water is usually Fe++. If there is oxygen, in

adequate conditions Fe++ can easily get transformed into Fe+++. ( Fe(OH)3) This is

iron-hydroxide, which gets separated in the form of flaky, red-brown residual and it

gets dissolved in water in a very low extent. Dissolved manganese in water can

usually be found in Mn+ condition. If there is oxygen, in adequate conditions, Mn+

can quickly get transformed into Mn++. ( Mn(OH)2 ). This is manganese-hydroxide,

which gets separated in the form of flaky, blackish-brown residual and gets dissolved

in water in a very low extent. The charge is manganese dioxide on a silicon-dioxide

carrier and it is the catalyzer of the oxidation process. The whole system can be

considered as an oxidizing filter. The manganese dioxide catalyzer increases the

reaction speed between the dissolved oxygen and the Fe++ or the Mn+, and it filters

out the generated residual. During the filtration process, the charge bed gets

saturated with iron residual and after that it needs to be backwashed.

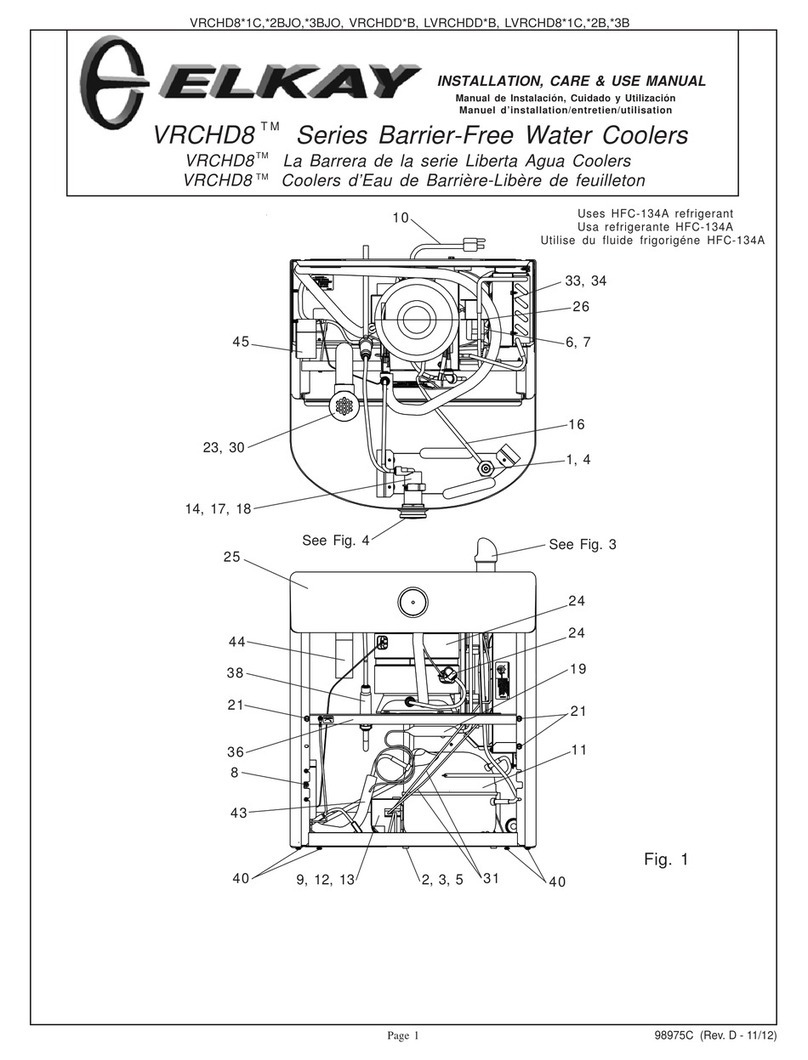

4.3. MECHANICAL OPERATION OF THE DEVICE

While the device is operating, the mechanical operation of the blocked valve ensures

the automatical performance of the water production and regeneration processes.