EURO-Jabelmann V2400 User manual

Operating Instructions and

Spare Parts List for

Conveyor

Type: V2400; V2400K; V2900; V2900K V4000; V 4000K

Wilsumer Straße 29

D-49847 Itterbeck

Tel. 0049(0)5948-9339-0

Fax 0049(0)5948-9339-25

info@euro-jabelmann.de

www.euro-jabelmann.de

Ordering Spare Parts

Tel. 0049(0)5948-9339-26

Fax 0049(0)5948-9339-27

et-dienst@euro-jabelmann.de

2

Prior to the start-up of the machine, any person handling the

machine must carefully read the manual.

Number Contents Page

Declaration of Conformity 3

1Introduction 4

2Purpose of machine 5

3Technical Data 5

4Safety Informations 5

5Scope of Supply 5

6Handling 5

7Assembly and Start-up 6

8Maintenance and Repair 6

9Warranty / Guarantee 7

10 Ordering Spare Parts 7

11 Spare parts list 7

12 Photos as attachment 7

13 Diagrams for machine without frequency regulator 10

14 Diagrams for machine with frequency regulator 12

3

EG-Konformitätserklärung nach Maschinenrichtlinie 2006/42/EG Anhang II 1.A

Der Hersteller / Inverkehrbringer

EURO-Jabelmann Veurink GmbH

Wilsumer Straße 29

D-49847 Itterbeck

erklärt hiermit, dass folgendes Produkt

Produktbezeichnung: EURO-Band

Seriennummer: _____________________________________

Serien-/Typenbezeichnung: V1ALPHA, V2400, V2400/K, V2900, V2900/K, V4000, V4000/K

Beschreibung:

Die Bänder dienen zum dazu, Knollengewächse, wie Kartoffel oder Zwiebeln, waagerecht

oder schräg zu befördern.

allen einschlägigen Bestimmungen der oben genannten Richtlinie sowie den weiteren ange-

wandten Richtlinien (nachfolgend) - einschließlich deren zum Zeitpunkt der Erklärung gelten-

den Änderungen - entspricht.

Folgende harmonisierte Normen wurden angewandt:

EN 620:2002+A1:2010 Stetigförderer und Systeme - Sicherheits- und EMV-

Anforderungen an ortsfeste Gurtförderer für Schüttgut

EN ISO 12100:2010 Sicherheit von Maschinen - Allgemeine Gestaltungsleitsätze -

Risikobeurteilung und Risikominderung (ISO 12100:2010)

EN ISO 13857:2008 Sicherheit von Maschinen - Sicherheitsabstände gegen das Er-

reichen von Gefährdungsbereichen mit den oberen und unteren

Gliedmaßen (ISO 13857:2008)

Name und Anschrift der Person, die bevollmächtigt ist, die technischen Unterlagen zusam-

menzustellen:

EURO-Jabelmann Veurink GmbH

Herr Bosmann

Wilsumer Straße 29

D-49847 Itterbeck

Itterbeck, __________________ ________________________________________

(Unterschrift)

4

1. Introduction

General

1.2 Before the first start-up, please read the

operating instructions for the machinery/plant. It is only

careful compliance with the provisions and information set out below that guarantees trouble-free and

accident-free use and a long life cycle.

Symbols and definitions used on the machine:

Read the operating instructions before start-up

Warning hazard area

Disconnect from the mains before carrying out repair work

Other symbols and definitions for your safety:

When working with the machine, wear suitable safety shoes or boots

When working with the machine, wear suitable personal protective equipment (safety goggles, ear protec-

tion, gloves)

5

2. Purpose of Machine

The EURO-Conveyor is to be used only for transporting potatoes, onions, apple and beetroot.

Any other use of the machine is prohibited.

If the machine is used with other materials, the warranty/guarantee immediately becomes null and void.

3. Technical Data

As an option, it is possible to get a frequency converter with remote operation and a 10 metre cable for all

feed belts. This means that the belt speed can be regulated smoothly. The frequency converter can be or-

dered from EURO-Jabelmann for an additional charge.

4. Safety Information

Never reach into the machine whilst it is operating.

Never open or remove safety devices when the machine is operational.

Disconnect the machine from the mains before carrying out any work.

Do not remove any material from the machine whilst it is operational.

Use the machine only with the contact pressure mat.

Repairs should be carried out by professionals.

Keep the surrounding environment tidy (to prevent trip hazards, etc.).

Always wear personal protective equipment.

Never leave the machine unattended when it is operational (children, pets).

Always let the machine run empty before switching off.

5. Scope of Supply

The EURO-Conveyor is delivered in proper working condition following a thorough final inspection. The

delivery includes the complete conveyor and a motor circuit breaker (permanently attached) with cable and

CEE 16A mains plug.

IMPORTANT

Upon receipt of the machine, please check for any transport damages and report these to the carrier or sup-

plier immediately!!

6. Handling

The machine is mounted on wheels so that it can be moved. In the event that you want to integrate a hoist-

ing machine (forklift truck) into the machine, use the ropes or chains provided for this purpose. Put stress

on these evenly.

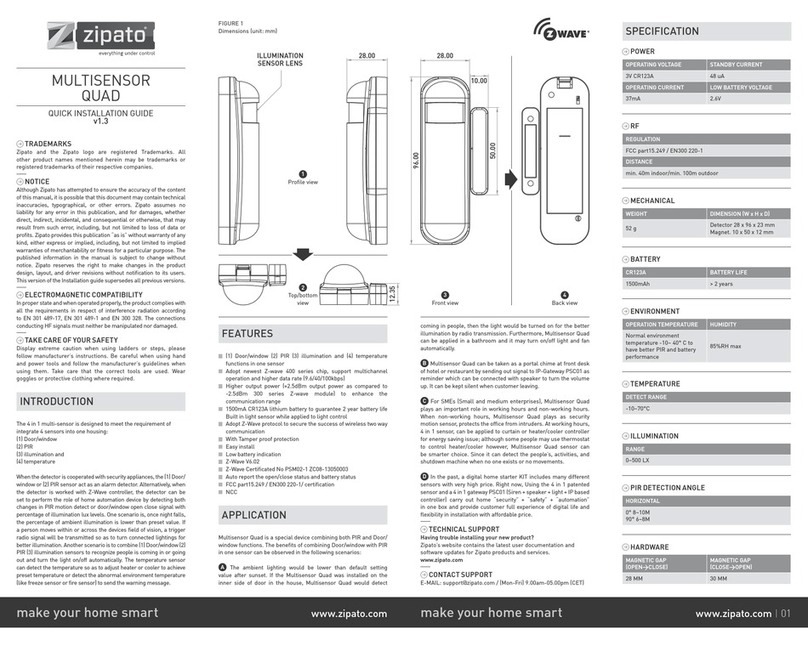

Typ V2400 V2400K V2900 V2900K V4000 V4000K

Belt length 2400mm 2400mm 2900mm 2900mm 4000mm 4000mm

Belt length

horizontal 700mm 700mm 700mm

Overloading

height

1350-

1700

1300-

1800 1900-2300

1800-

2400

1700-

2700

1550-

2800

Belt witdh 400mm 400mm 500mm 500mm 500mm 500mm

Cleat width 320mm 320mm 420mm 420mm 420mm 420mm

Cleat height 60mm 60mm 60mm 60mm 60mm 60mm

Cleat distance 250mm 250mm 250mm 250mm 250mm 250mm

KW 0,37kw 0,37kw 0,55kw 0,55kw 0,55kw 0,55kw

to. / h 5 to 5 to 10 to 10 to 10 to 10 to

Weight 130kg 130kg 190kg 190kg 230kg 230kg

6

7. Assembly and Start-Up

7.1. Assembly of the Machine

Place the machine on a flat and even surface and

the feet to the desired height. The front and back feet must be the same height. Check the screw joints for

tightness.

Before connecting to the electric circuit, check whether the energy grid corresponds with the specification

on the motor’s rating plate.

7.2 Starting Up the Machine

Set the desired discharge height for the feed belt using a winch (photo). Ensure that the belt is always sta-

ble.

Insert the 16 Ampere plug into a suitable socket and switch the belt on using the switch (photo 4).

When starting the machine up, ensure that the belt is running in the right direction.

If the belt is rotating in the wrong direction, the

rotation direction of the motor is to be reconnected on the mains plug.

This is to be done by trained professionals only!

After the belt has started, you can pour the material that is to be transported into the hopper.

Before you finishing working with the machine, it is important that you let the belt run empty and that no

material remains on the belt.

Should the motor circuit breaker trip, this is probably the result of you having put too much material into

the machine.

Reduce the quantity if this happens.

8. Maintenance and Repair

IMPORTANT

Switch off the motor and disconnect from the mains

before any repair or maintenance work is carried out.

8.1. Maintenance and Lubrication

The lubricating points on the bearings are to be lubricated

regularly. This is regardless of how often the machine is used. Switch off the machine and disconnect from

the mains before lubricating the machine.

8.2. Repair work

IMPORTANT

Repair work is only to be carried out by

trained professionals!

8.3. Tension the conveyor belt

Should the belt pull on the protective plates at the side, it is useful to tension the belt.

In addition to this, the thread alignment can be easily

changed.

7

9. Warranty/Guarantee

As agreed, a warranty for material and work applies in accordance with our sales and payment conditions.

The warranty does not cover:

- use that is not in accordance with its intended purpose

- non-compliance with the operating instructions

- use of non-original spare parts

- unauthorised technical modifications

Warranty period: 12 months from delivery

Warranty claims are to be made immediately in writing

with full details of the defect being provided. Photos and/or the defective part are also to be sent, if possible.

10. Ordering Spare Part

Tel. 0049(0)5948-9339-26

Fax 0049(0)5948-9339-27

Mail: et-dienst@euro-jabelmann.de

11. Spare part list

12. Photos as attachment

8

13. Diagrams for machine without frequency regulator

9

10

14. Diagrams for machine with frequency regulator

11

This manual suits for next models

4

Table of contents

Popular Accessories manuals by other brands

Honeywell

Honeywell Fire-Lite Alarms AD365 Installation and maintenance instructions

Hydac

Hydac CS 1000 Series Operation and maintenance instructions

Siko

Siko MSK400 quick start guide

Crivit

Crivit 322422_1901 Instructions for use

Zephyr

Zephyr PRB24C01AS-ADA Use, care and installation guide

Imax

Imax EA/PS user manual