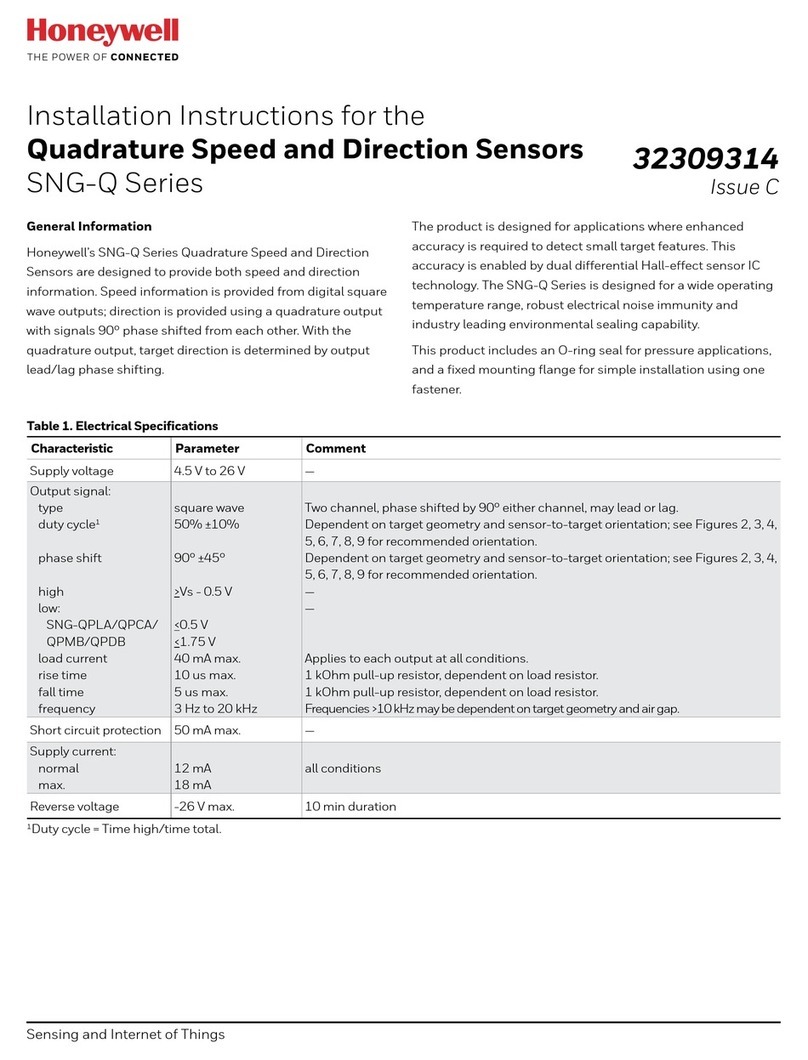

FIGURE 3. FEATURES OF THE PTIR DETECTOR

Base Alignment Notch

Infrared

Light

Pipe

Magnet Test Point

Thermistors

Infrared

Light

Pipe

LEDs

C2050-00

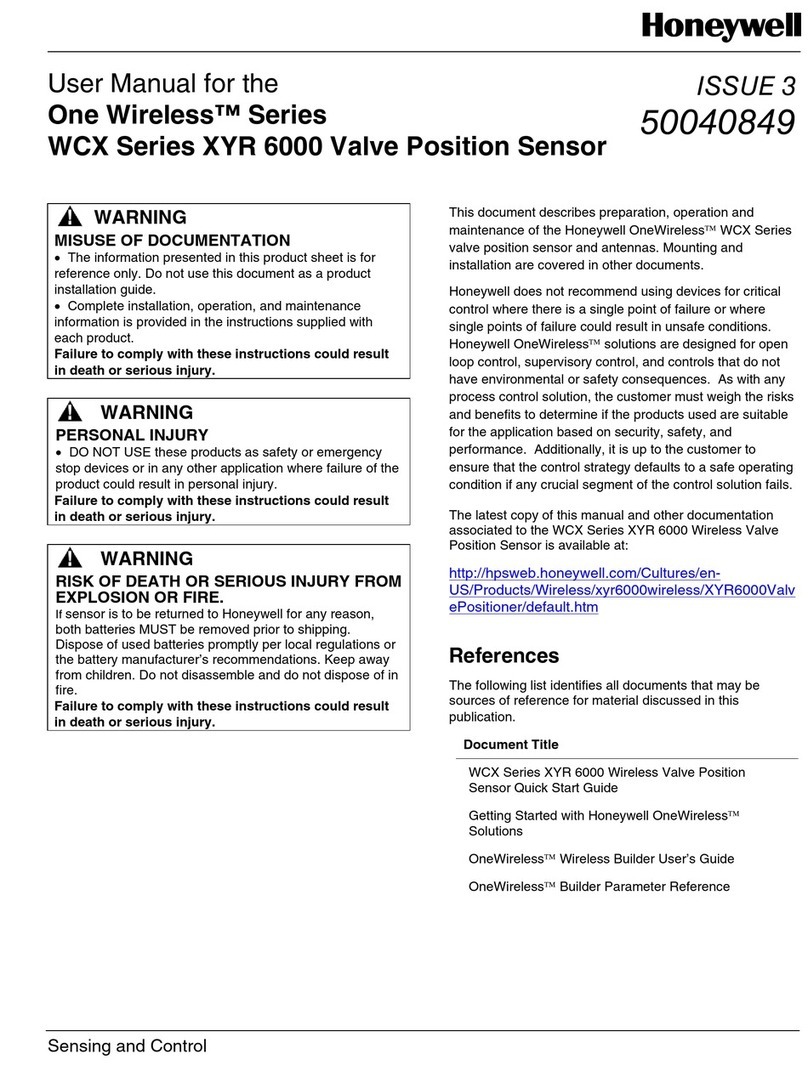

FIGURE 4. CLEANING THE PTIR DETECTOR

Cover

Removal

Tabs

Sensor Cover

Sensing Chamber

Cover and Screen

Infrared

Light

Pipe

Thermistors

Sensing

Chamber

}

C2044-00

Dust covers provide limited protection against airborne dust particles dur-

ing shipping. Dust covers must be removed before the sensors can sense CO.

Remove sensors prior to heavy remodeling or construction.

TAMPER RESISTANCE

Models AD365 and AD365-IV include a tamper-resistant capability that pre-

vents removal from the base without the use of a tool. Refer to the base man-

ual for details on making use of this capability.

TESTING

Before testing, notify the proper authorities that the system is undergoing

maintenance, and will temporarily be out of service. Disable the system to

prevent unwanted alarms.

All sensors must be tested after installation and periodically thereafter. Test-

ing methods must satisfy the Authority Having Jurisdiction (AHJ). Sensors

offer maximum performance when tested and maintained in compliance with

NFPA 72. Sensitivity readings are available through the FACP. Refer to the

manufacturer’s published instructions for proper use.

The sensor can be tested in the following ways:

A. Functional: Magnet Test (P/N M02-04-01 or M02-09-00)

This sensor can be functionally tested with a test magnet. The test magnet

electronically simulates smoke in the sensing chamber, testing the sensor

electronics and connections to the control panel.

a. Hold the test magnet in the magnet test area as shown in Figure 3.

b. The sensor should alarm the panel.

Two LEDs on the sensor are controlled by the panel to indicate sensor

status. Coded signals, transmitted from the panel, can cause the LEDs to

blink, latch on, or latch off. Refer to the control panel technical documen-

tation for sensor LED status operation and expected delay to alarm.

NOTE: The magnet test initiates an approximately 10 minute period when

the detector's signal processing software routines are not active.

B. Smoke Entry

Canned aerosol simulated smoke (canned smoke agent) may be used for

smoke entry testing of the smoke detector.

The multi-criteria smoke sensor uses algorithms to process signals re-

ceived from multiple sensors to determine alarm conditions and reduce

false alarms. Therefore, a single burst of canned smoke will not immedi-

ately place the detector into an alarm condition because the detector al-

gorithms correctly determine a burst of canned smoke is not fire. In order

to perform functional testing of the photoelectric sensor, the device must

be placed into test mode. Test mode allows the detector to isolate the indi-

vidual sensors for testing. The device can be placed into test mode through

either of the following methods.

a. Put the device into test mode by holding a test magnet in the magnet

test area as shown in Figure 3 for 6-12 seconds.

NOTE: If the magnet is held in place for too long the fire alarm test func-

tion will be triggered. (See Magnet Test, above.) Reset the panel and pro-

ceed with testing the smoke entry portion of the device.

b. Perform smoke entry testing immediately following the magnet test. The

magnet test initiates an approximately 10 minute period when the detec-

tor’s signal processing software routines are not active.

Once in test mode, test the smoke detector using one of the tested and ap-

proved aerosol smoke products. Refer to the manufacturer’s published instruc-

tions for proper use of the canned smoke agent. When used properly, the

canned smoke agent will cause the smoke detector to go into alarm.

Tested and approved aerosol smoke products include:

Manufacturer Model

HSI Fire and Safety 25S, 30S (PURCHECK)

SDi SMOKE CENTURION , SOLO A10,

SMOKESABRE, TRUTEST, SOLO 365

No Climb TESTIFIRE 2000

Canned aerosol simulated smoke (canned smoke agent) formulas will vary

by manufacturer. Misuse or overuse of these products may have long term

adverse effects on the smoke detector. Consult the canned smoke agent manu-

facturer’s published instructions for any further warnings or caution statements.

C. Direct Heat Method (Hair Dryer of 1000-1500 watts)

A hair dryer of 1000-1500 watts should be used to test the thermistors. Di-

rect the heat toward the thermistor, holding the heat source approximately

12 inches (30 cm) from the detector in order to avoid damaging the plastic

housing. The detector will reset only after it has had sufficient time to

cool. Make sure both thermistors are tested individually.

D. Multi-Criteria Testing

Testifire® by SDi provides testing of the smoke and heat sensors. Consult the

manufacturer’s published instructions for complete usage instructions.

A sensor that fails any of these tests may need to be cleaned as described

under CLEANING, and retested. When testing is complete, restore the system

to normal operation and notify the proper authorities that the system is back

in operation.

CLEANING

Before removing the detector, notify the proper authorities that the smoke

detector system is undergoing maintenance and will be temporarily out of

service. Disable the zone or system undergoing maintenance to prevent un-

wanted alarms.

1. Remove the sensor to be cleaned from the system.

2. Remove the sensor cover by pressing firmly on each of the four removal

tabs that hold the cover in place.

3. Vacuum the screen carefully without removing it. If further cleaning is

required continue with Step 4, otherwise skip to Step 7.

4. Remove the chamber cover/screen assembly by pulling it straight out.

5. Use a vacuum cleaner or compressed air to remove dust and debris from

the sensing chamber.

6. Reinstall the chamber cover/screen assembly by sliding the edge over the

sensing chamber. Turn until it is firmly in place.

7. Replace the cover using the LEDs to align the cover and then gently push-

ing it until it locks into place. Make sure that the thermistors do not be-

come bent under the cover.

8. Reinstall the detector.

9. Test the detector as described in TESTING.

10. Reconnect disabled circuits.

11. Notify the proper authorities that the system is back on line.

SPECIAL NOTE REGARDING SMOKE DETECTOR GUARDS

Smoke detectors are not to be used with detector guards unless the combina-

tion has been evaluated and found suitable for that purpose.

2 I56-6617-001

4/22/2019