01. PRODUCT SAFETY

4

01.2 GENERAL SAFETY PRECAUTIONS

•Use the sto e only as described in this manual. Any other use not recommended by the manufacturer may cause fires or accidents to people.

•Make sure that the electrical power a ailable corresponds to the alue indicated on the data plate (230V~/50Hz).

•This appliance is not a toy. Make sure children are not left unattended and do not use the appliance as a toy.

•This de ice is not intended for use by persons (including children) with reduced physical or mental capacity, or without specific

experience and knowledge, unless super ised or duly instructed on the use of the appliance by a person responsible for their safety.

•Disconnect the appliance from the mains when not in use or during cleaning operations.

•To do so, turn the switch to the O position and disconnect the plug from the socket. Pull the plug, not the cable.

•Ne er block the combustion air inlets and fume outlets.

•As the sto e is fitted with electrical components, do no touch it with wet hands.

•Do not use the appliance in case of damaged cables or plugs. The device is classified as type Y: power supply cable may only be

replaced by a qualified technician. Should the power supply cable be damaged, it can be replaced only by the manufacturer or by

its technical assistance service or by a similarly qualified person.

•Do not place any object on the cable and do not bend it.

•A oid using extension cables as their temperature may increase excessi ely posing fire hazards. Ne er use one single extension cable

to power se eral appliances.

•During normal functioning some parts of the stove may become extremely hot, such as the door, the glass or the handle. Be careful,

especially with children. Do not touch any hot parts if not wearing adequate protective devices.

•ATTENTION! DO NOT TOUC the FIRE DOOR, the GLASS, the ANDLE or the FUME OUTLET DURING FUNCTIONING if not wearing

adequate protective devices since they become extremely hot!

•Keep inflammable materials, such as furniture, cushions, pillows, blankets, paper, clothing, curtains, etc., at least 1.5 m away from the

sto e front and 30 cm from the sto e sides and back.

•The sto e that is co ered by or in direct contact with flammablematerials, including curtains, drapery, blankets, etc., during normal

operation may result in a fire hazard. KEEP T E APPLIANCE AWAY FROM T E MATERIALS MENTIONED ABOVE.

•Do not immerse the cable, plug or any other appliance component in water or other liquids.

•Do not use the sto e in dusty en ironments or where er inflammable apours are generated (e.g. in a workshop or garage).

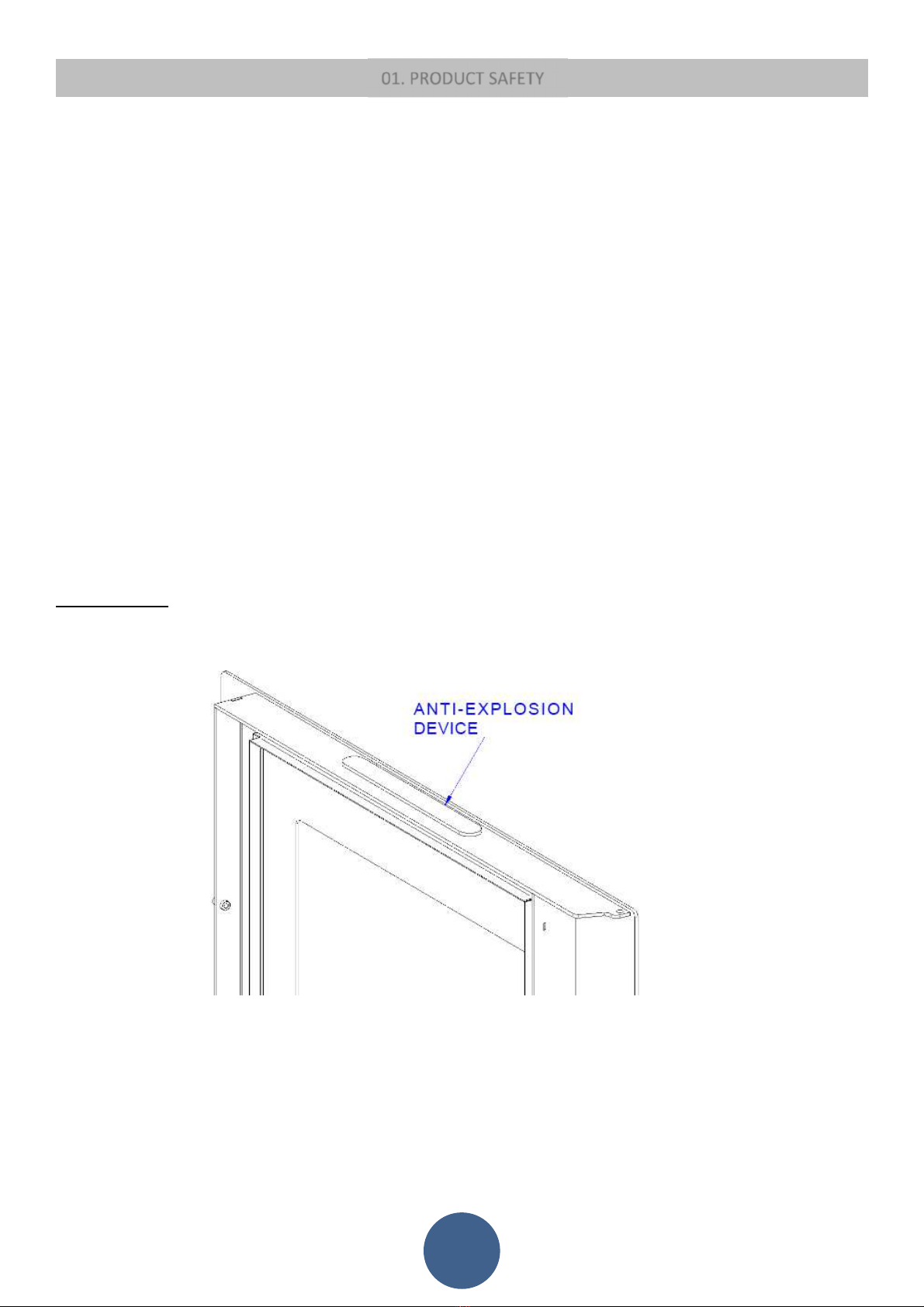

•The sto e contains components that generate arcs and sparks. Do not install the sto e in areas posing a significant fire or explosion

hazard due to a high chemical substance concentration or to a high humidity le el.

•Do not use the appliance close to bathtubs, showers, basins, sinks or swimming pools.

•Do not install the appliance underneath an air ent. Do not install the sto e outdoors.

•Do not repair, disassemble or modify the appliance. The appliance is not fitted with components that can be repaired by users.

•Turn the switch off and remo e the mains plug before performing maintenance and operate only when the sto e is cold.

•WARNING: DISCONNECT T E STOVE FROM T E MAINS BEFORE PERFORMING MAINTENANCE OPERATIONS.

•ATTENTION! These stoves operate exclusively on pellets and possibly also pits if the stove has this option; DO NOT USE OT ER

FUELS: any other material that may be burnt will result in failure and malfunction of the appliance.

•Keep the pellets in a fresh dry place: storing pellets in a place that is damp or excessively cold may reduce the stove potential heat

output. Be careful when storing and handling pellet bags to prevent pellet crushing and consequent sawdust production.

•The fuel consists of small cylinders with 6-7mm diameter and a maximum length of 30 mm. Their maximum moisture content is equal

to 8%. This sto e was designed and calibrated to burn pellets made of arious types of pressed wood in compliance with en ironment

protection legislation.

•The use of different types of pellets may result in a slight, sometimes e en undetectable, change in the sto e efficiency. This change

can be counterbalanced by increasing or decreasing the sto e heat output by only one step.

•Clean the burn pot on a regular basis upon every ignition or pellet refuelling.

•Open the firebox only upon refuelling or remo al of residues to pre ent fumes from escaping.

•Do not turn the sto e on and off intermittently ; it is equipped with electrical and electronic components that could become damaged.