Sub-menu M3 – 4 – Chrono week-end

It is used to enable/disable and to set the chronothermostat functions on weekends (days 6 and 7, i.e. Saturday and Sunday). To enable, press the P1 and

P2 buttons. Setting the times Start 1 and Stop 1 sets the operating period for Saturday, while Start 2 and Stop 2 are used to set the stove operation for

Sunday.

DATE AND TIME

Use this function to set current time and date. The control board is equipped with a lithium battery guaranteeing the time clock 3/5 year-long autonomy. Set the

current date by pressing OK and the respective arrows to increase or decrease the selected values.

LANGUAGE

Use this command to select one of the languages available. To move to the next language press P1 (increase) to go back, press P2 (decrease) and to confirm

press P4.

SETTINGS

This menu includes:

BUZZE MODE: this is the buzzer on the board. This sub-menu can be used to activate or deactivate the buzzer

ET OILLUMINAZIONE ON: duration of remote control lighting

POWE ON: time the display stays on

LUMINOSITA’: on or off

CONT ASTO: display contrast adjustment

TONI TASTI: activation/deactivation of the remote control key beep

INITIAL LOAD

This function is only available when the stove is OFF and is used to load the auger when the stove is started for the first time when the pellet hopper is empty. After

selecting the menu, press P1. The exhaust blower switches on at the maximum speed and the auger tube (auger tube LED on) starts working. They will switch off

once the period of time indicated on the display has elapsed or after pressing the P3 button.

STATE STOVE

Enter the STOVE STATUS menu, after pressing the P4 button, the display scrolls the status of a number of variables during operation of the stove at work.

USER SETTINGS

This menu permits the pellet drop due to pellet change by a preset percentage to be increased or decreased.

TECHNICAL MENU

This menu item is reserved for the stove installer.

STAND- Y

In this menu it is possible to activate or deactivate the automatic stand-by of the stove. When selected, if the room temperature exceeds the set temperature by

2°C, the stove will automatically switch off and then switch on again when the room temperature drops below 2°C with respect to the set temperature.

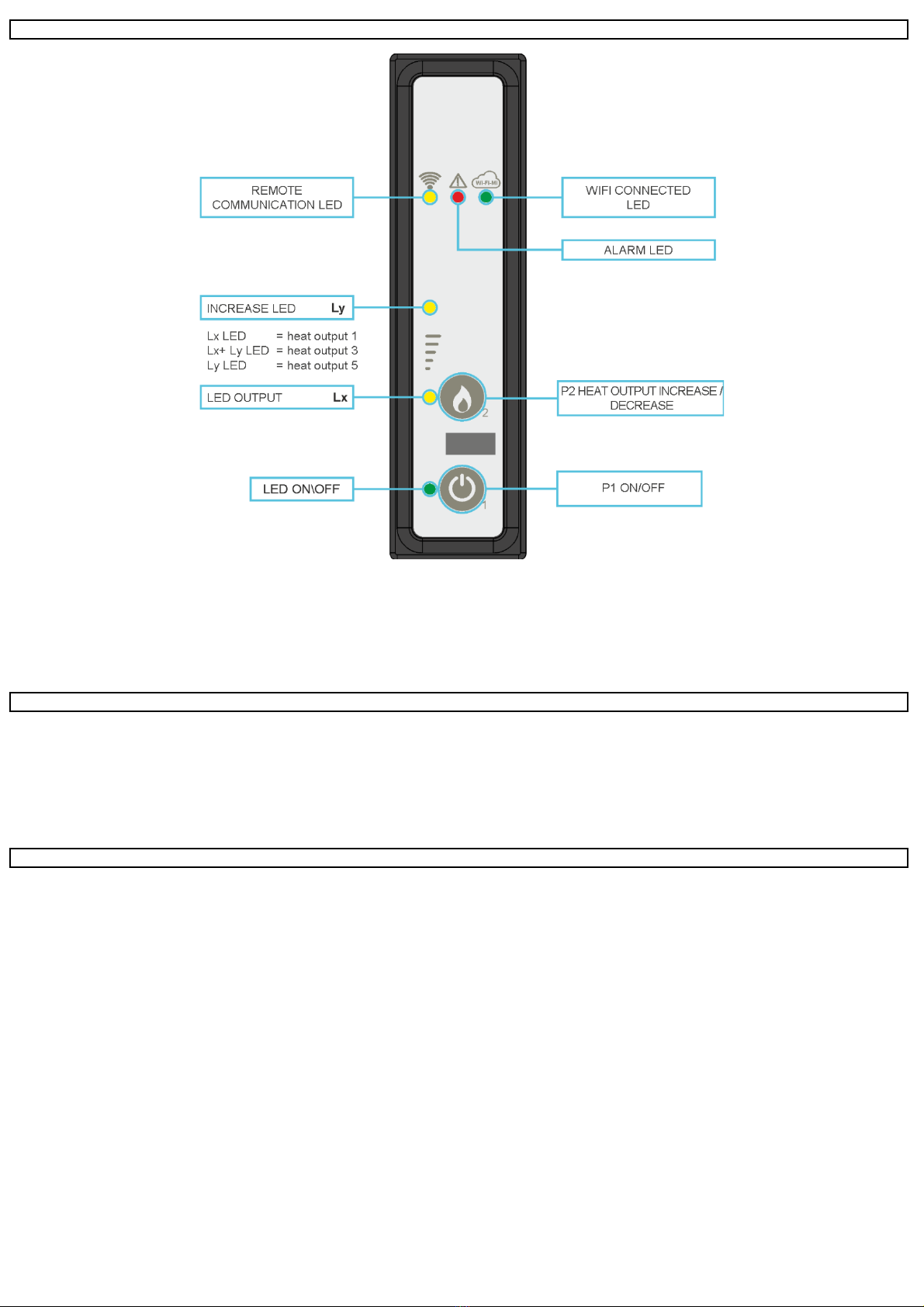

04. USER FUNCTIONS

Standard functioning of a control board properly installed on an air stove is described below with reference to the functions available to users.

Stove ignition

Hold P3 button down for a few seconds to switch on the stove. Ignition is signalled on the display with the wording “CHECK UP”. In these conditions the stove is in

the pre-heating state, the burn pot is cleaned, the glow plug (visible with the glow plug LED) and the fume extraction fan come on.

Any problem detected during the switching-on phase is indicated on the display and the stove goes into alarm status.

Loading with Pellets

After approximately 1 minute, the pellet loading phase begins and the message “LOAD PELLET” appears on the display. During the initial phase, the auger tube

loads the pellets into the burn pot for a fixed amount of time. In the second phase the auger tube turns off, while the speed of the fumes and the glow plug remain

in the previous state. If ignition does not occur after this phase, the auger tube is switched on again and the glow plug remains on.

Fire present

After the temperature of the fumes has reached and exceeded a preset threshold, the system switches to ignition mode and “STABILIZZAZIONE” appears on the

display.

The speed of the fumes is fixed, the auger tube turns on for a fixed time and the glow plug is turned off. Any problem during this phase will cause the control board

to stop and the stove to go into error state.

Stove operational

After the temperature of the fumes has reached and exceeded a given value and has maintained it for at least a predetermined time, the stove goes into work

mode which is the normal working mode. The upper display shows the time and the room temperature and the lower one the set power and the power in which

the stove is found. The heat output can be set by pressing the P2 key and the room temperature can be set by pressing the P1 button. If the fume temperature

reaches a certain set threshold, the air exchanger fan turns on. oom ventilation can be excluded from the BLOWE MODE menu.

After this phase, the stove cleans the burn pot. “Burn pot cleaning” scrolls on the display, the auger is switched on (auger LED on) and the exhaust blower is

switched on. Once the set period of time has elapsed, the stove goes back to the working mode.

Changing set heat output

During normal stove operation (WO K), the heat output can be changed using the P2 button. Press the P2 button again to increase the heat output and the P1

button to decrease it. The display will show the set heat output. To exit the set, wait 5 seconds without performing keyboard operations, or press P3 or P4.

Changing set room temperature

Press P1 button to change the set room temperature. The display shows the set room temperature (SET temperature value). Press P1 (increase) and P2

(decrease) buttons to modify the temperature. The value is saved after approx. 5 seconds and the display goes back to normal. Otherwise, press P3 or P4 to exit.

External thermostat/chrono-thermostat use

If you want to use an external programmable thermostat, connect it to the TE M clamps (connector CN7 pin 7-8).

• External thermostat

• External chrono-thermostat

The stove external thermostat is enabled when the contact is closed with stove on.

Room temperature reaches the set value (SET temperature)

When the set room temperature value is reached, the stove heat output is automatically set to the minimum value. During this phase, “MODULAT-” appears on

the display. If room temperature falls below the set value (Set temperature), the stove will return to “WO K” mode and to the previously set heat output (Set heat

output). If there is an external thermostat and the room temperature has been set to T-e, if the thermostat is open it will begin modulation and if closed, it will return

to the heat output set.