Evector EV-97 EUROSTAR SL MICROLIGHT User manual

EV-97 EUROSTAR SL

MICROLIGHT

G-

MAINTENANCE MANUAL

GEN/EUR/04

Light Sport Aviation Tel. Office: 01494 524020

Hangar 1 Web: www.lightsportaviation.org.uk

Booker

Marlow

Buckinghamshire

SL6 3DP

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 2

Amendment Record

Issue

Details of Change

Date

Authorised

1

First Issue

12/05/14

2

Changes to electrical circuit diagrams (Appendix 5)

15/07/14

Change to trim tab deflection (pages 29 and 42)

15/07/14

3

Change to cockpit instruments (page 9 sect 2.12)

01/09/14

4

Change to weight and balance record (appendix 3

page 44)

18/12/15

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 3

Table of Contents

1. Introduction...............................................................................................................................5

2. Aircraft Technical Description...................................................................................................5

2.1 General..............................................................................................................................5

2.2 Dimensions – Drawings......................................................................................................5

2.3 Basic dimensions...............................................................................................................6

2.4 Weight................................................................................................................................6

2.5 Centre of Gravity................................................................................................................6

2.6 Wing...................................................................................................................................7

2.7 Horizontal Tail Unit.............................................................................................................7

2.8 Vertical Tail Unit.................................................................................................................7

2.9 Landing Gear.....................................................................................................................7

2.10 Wheels...............................................................................................................................7

2.10.1 Wheel Brakes..............................................................................................................8

2.11 Tyres..................................................................................................................................8

2.12 Cockpit...............................................................................................................................9

2.13 Additional Equipment List...................................................................................................9

2.14 Control Systems.................................................................................................................9

2.15 Flap Control .....................................................................................................................10

2.16 Elevator Trim....................................................................................................................11

2.17 Power Plant......................................................................................................................11

2.18 Engine Operational Limits................................................................................................13

2.19 Engine Mount...................................................................................................................13

2.20 Engine Cowlings ..............................................................................................................13

2.21 Fuel System.....................................................................................................................15

2.22 Cooling System................................................................................................................15

2.23 Cockpit Heating System...................................................................................................15

2.24 Ventilation........................................................................................................................16

2.25 Electrical System..............................................................................................................16

2.26 Pitot-Static System...........................................................................................................16

2.27 Galaxy Balistic Rescue System GRS 6 473 SD B2..........................................................16

2.28 Stall Warner.....................................................................................................................17

3. Aircraft Assembly and Disassembly of Major Parts.................................................................17

3.1 Wing.................................................................................................................................17

3.2 Horizontal Tail Unit (HTU)................................................................................................19

3.3 Vertical Tail Unit...............................................................................................................19

4. Inspections and Scheduled Maintenance ...............................................................................19

4.1 Pre-Flight Inspection ........................................................................................................19

4.2 Post-flight inspection........................................................................................................20

4.3 Periodic inspections.........................................................................................................20

4.3.1 Periodic inspection intervals ......................................................................................20

4.3.2 Periodic maintenance and inspection work sheets.....................................................20

4.3.3 Periodic Maintenance and Inspections......................................................................21

5. Maintenance Procedures........................................................................................................28

5.1 Rotax 912 UL engine .......................................................................................................28

5.2 Oil ....................................................................................................................................28

5.3 Oil Draining......................................................................................................................28

5.4 Oil Filter Replacement......................................................................................................28

5.5 Coolant ............................................................................................................................28

5.6 Brake System...................................................................................................................29

5.6.1 Fluid Type..................................................................................................................29

5.6.2 Brake fluid refilling .....................................................................................................29

5.6.3 Brake fluid emptying..................................................................................................29

5.6.4 Brake Pad Replacement............................................................................................29

5.6.5 Bleeding ....................................................................................................................30

5.7 Control Surface Deflection Setting ...................................................................................30

5.7.1 Aileron.......................................................................................................................32

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 4

5.7.2 Flap ...........................................................................................................................32

5.7.3 Elevator.....................................................................................................................32

5.7.4 Rudder.......................................................................................................................33

5.7.5 Trim Tab....................................................................................................................33

6. Fueling ...................................................................................................................................33

6.1 Filling – Precaution...........................................................................................................33

6.2 Fuel emptying ..................................................................................................................34

7. Lubrication..............................................................................................................................34

7.1 Engine..............................................................................................................................34

7.2 Airframe...........................................................................................................................34

7.3 Lubricating Points.............................................................................................................35

7.4 Access Holes for Lubricating & Inspection .......................................................................35

8. Bolt Tightening .......................................................................................................................36

9. Rudder ...................................................................................................................................36

9.1 Rudder Cable Tension Adjustment...................................................................................36

9.2 Rudder Pedal Adjustment ................................................................................................37

10. Trim Tab Control Cable Tension.............................................................................................37

11. Jacking the Aircraft.................................................................................................................37

12. Puncture Repair .....................................................................................................................37

12.1 Main wheel:......................................................................................................................38

12.2 Nose wheel:.....................................................................................................................38

12.3 Puncture Repair – all tyres...............................................................................................38

12.4 Tyre pressures (for tyre size 14 x 4 or 400 x 6)...............................................................38

13. Small Repairs.........................................................................................................................38

14. Care and Cleaning Recommendations...................................................................................39

14.1 External Paint...................................................................................................................39

14.2 Canopy ............................................................................................................................39

14.3 Upholstery........................................................................................................................39

15. Levelling.................................................................................................................................39

16. Control Surface Deflections....................................................................................................39

17. Permissible Tolerances (Play)................................................................................................40

18. Weighing the Aircraft and Centre of Gravity Calculation .........................................................41

18.1 Empty weight determination.............................................................................................41

18.2 Operating c.g. range calculation.......................................................................................42

Appendix 1 - Levelling Record ......................................................................................................43

Appendix 2 - Control Surface Deflection Record...........................................................................44

Appendix 3 - Weight & Balance Record........................................................................................45

Appendix 4 - Flight Test Record....................................................................................................46

Appendix 5 – Electrical Circuit Diagrams ......................................................................................47

Appendix 6 - Additional Equipment List.........................................................................................48

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 5

1. Introduction

This Maintenance Manual gives recommended procedures for ensuring the continued

airworthiness of the aircraft. Maintenance requirements will depend on aircraft usage and may

need amending accordingly. The operator should always be alert for developing problems and

attentive to ensuring their timely rectification.

2. Aircraft Technical Description

2.1 General

The Eurostar SL airframe is a metal/composite, semi-monocoque construction formed with metal

reinforcements, bulkheads and Duralumin skins. Both pop (blind) rivets and solid rivets are used

for joints. All Metal parts are primary structures. All composite parts, with the exception of the

undercarriage legs, are non-structural (secondary structures).

2.2 Dimensions – Drawings

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 6

2.3 Basic dimensions

Wing span...............................................26.57 ft. 8.1m

Wing area.............................................105.92 sq. ft. 9.84m2

MAC .........................................................4.10 ft. 1.25m

Wing loading (MTOW, 1030 lb, 472.5 kg) 9.72 lb./sq. ft. 48 kg/m2

Aileron area..............................................2.26 sq. ft. 0.21m2

Flap area ...............................................5.60 sq. ft. 0.52m2

Fuselage length......................................19.62 ft. 5.98m

Fuselage width .........................................3.41 ft. 1.04m

Fuselage height........................................7.68 ft. 2.34m

Horizontal Tail Unit (HTU)

Span.........................................................8.20 ft. 2.5m

HTU area................................................20.99 sq. ft. 1.95m2

Elevator area............................................8.61 sq. ft. 0.8m2

Vertical Tail Unit (VTU)

Height.......................................................4.21 ft. 1.28m

VTU area................................................10.93 sq. ft. 1.02m2

Rudder area..............................................4.67 sq. ft. 0.43m2

Landing gear

Wheel track...............................................5.25 ft. 1.6m

Wheel base...............................................4.42 ft. 1.35m

Main wheel diameter................................. 14 in 350mm

Nosewheel diameter................................. 14 in 350mm

2.4 Weight

Empty weight will vary with selection of options and small manufacturing variations. However there

is a maximum limit to the aircraft’s dry empty weight, as shown below.

Empty weight max.(standard equipment) 290.5kg + 0, - 3%

Maximum Take-off weight 472.5kg

Maximum Landing weight 472.5kg

Max. fuel weight, (standard 65 l fuel tank) 47kg

Maximum weight in Baggage Compartment 15kg

NOTE

Actual empty weight is stated on the placard “LOAD LIMITS,“

located on the instrument panel. Empty weight includes 2.9 litres of unusable

fuel.

2.5 Centre of Gravity

Empty weight CG (standard equipment) 18 ±2% Mean Aerodynamic Chord (MAC)

200 – 250mm AoD

Operating CG 20-34% MAC

250 – 410mm AoD

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 7

ANGLE REINFORCEMENT

MAIN LEG

MAIN LEG ATTACHMENT

MAIN LEG ATTACHMENT

2.6 Wing

The rectangular wing has a single, aluminium main spar and rear spar to which are attached

ailerons and flaps. All components are riveted. The composite wing tips are attached by rivets.

2.7 Horizontal Tail Unit

The rectangular HTU comprises a stabilizer and elevator with trim tab. It has a semi-monocoque

construction (i.e. the skins bear part of the load), consisting of Duralumin pressed ribs, spar and

skins. The HTU width of 2.5m permits transport by road without removal.

The stabilizer is attached to the fuselage by two pins at the leading edge and secured with two

screws at the trailing edge.

2.8 Vertical Tail Unit

The trapezoidal VTU comprises fin and rudder. The rudder is attached to the fin by two hinges

consisting of spherical joints bolted into the fin’s trailing edge spar.

A composite fairing is fitted immediately forward of the fin, blending its surface with that of the

fuselage top.

Neither composite tip, nor forward fairing takes significant structural loads.

2.9 Landing Gear

The fixed gear consists of:

•a steerable nose wheel on a leg sprung on a rubber rope suspension. The nose leg is

constructed from steel tube and mounted on the firewall on two bearings. The nose wheel

is steered by two push rods connected to the rudder pedals.

•hydraulically braked main wheels and composite spring legs attached to the fuselage cross

member under the seats. These legs are designed to deflect to reduce landing impact.

The leg’s attachment to the fuselage is shown below:

2.10 Wheels

1

7

°

NOSE WHEEL

CONTROL ROD

FOOT PEDAL

SUSPENSION STOP

NOSE WHEEL LEG

RUBBER ROPE SUSPENSION

FUSELAGE FRAME

WHEEL AXLE

WASHER

E 54-04 21

NUT 765 155

WASHER 765 478

NOSE WHEEL ASSEMBLY

COTTER PIN 4x40

ČSN 02 1781.04

1

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 8

Each wheel consists of a two-part cast alloy rim with tyre and inner tube. The main wheels are

mounted on an axle secured to the composite leg by 4 bolts. Cross sections of the main and nose

wheels and their axles are shown below:

2.10.1 Wheel Brakes

Both wheels on the main landing gear are equipped with hydraulic disc brakes. The brake

system consists of the brake pedals (pilot standard, co-pilot as an option), hydraulic brake

master cylinders, plastic hoses, brake caliper with the hydraulic brake cylinder, brake pads and

the brake disc which is bolted onto the inner part of the rim.

The brakes on both wheels are controlled independently by toe brake pedals mounted on the

pilot’s and the co-pilot’s rudder pedals.

Fig. The brake control with toe brake pedals

1 – ruder pedals, 2 – brake cylinder, 3 – nose wheel steering rod

2.11 Tyres

SAVA 14 x 4 (standard), all three wheels.

NOSE WHEEL LEG

WHEELAXLE

WASHER

E 54-04 21

NUT 765 155

WASHER 765 478

NOSE WHEELASSEMBLY

COTTER PIN 4x40

ČSN 02 1781.04

SCREW 4x40 ČSN 02 1781.04

NUT M16x1.5 ČSN 02 1412.24

WASHER

WHEEL WITH BRAKE

SCREW 5x10 ČSN 02 2150.01

MAIN LEG

2

3

2

1

1

3

1

2

2

1

WARNING

When adjusting the rudder pedals, if the plungers are not fully engaged in one of the

three holes in the plate, the pedal may rotate backwards and prevent rudder movement.

See Brake Pedal Adjustment section 9.2

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 9

2.12 Cockpit

Two side by side seats have between them the levers

for elevator trim and flaps. Floor covering is lightweight

removable carpet and interior trim panels can be

removed for cleaning or access.

The canopy has two parts: a fixed part to the rear and a

forward-opening part at the front. Acrylic (Perspex)

transparencies are used in both parts. Two gas struts

aid opening and a lock is fitted to the top rear of the

opening section. The lock mechanism carries a micro-

switch operating a lamp on the panel showing the pilot

when the canopy is properly locked.

The following electronic or analogue instruments are fitted to the panel:

1. Airspeed Indicator (ASI)

2. Altimeter

3. Compass

4. Vertical Speed Indicator(VSI)

5. Tachometer

6. Cylinder Head Temperature (CHT) gauge

7. Oil temperature gauge

8. Oil pressure gauge

9. Fuel pressure gauge

10. Fuel contents gauge

11. Engine hours indicator.

2.13 Additional Equipment List

See additional equipment list Appendix 6 if applicable

2.14 Control Systems

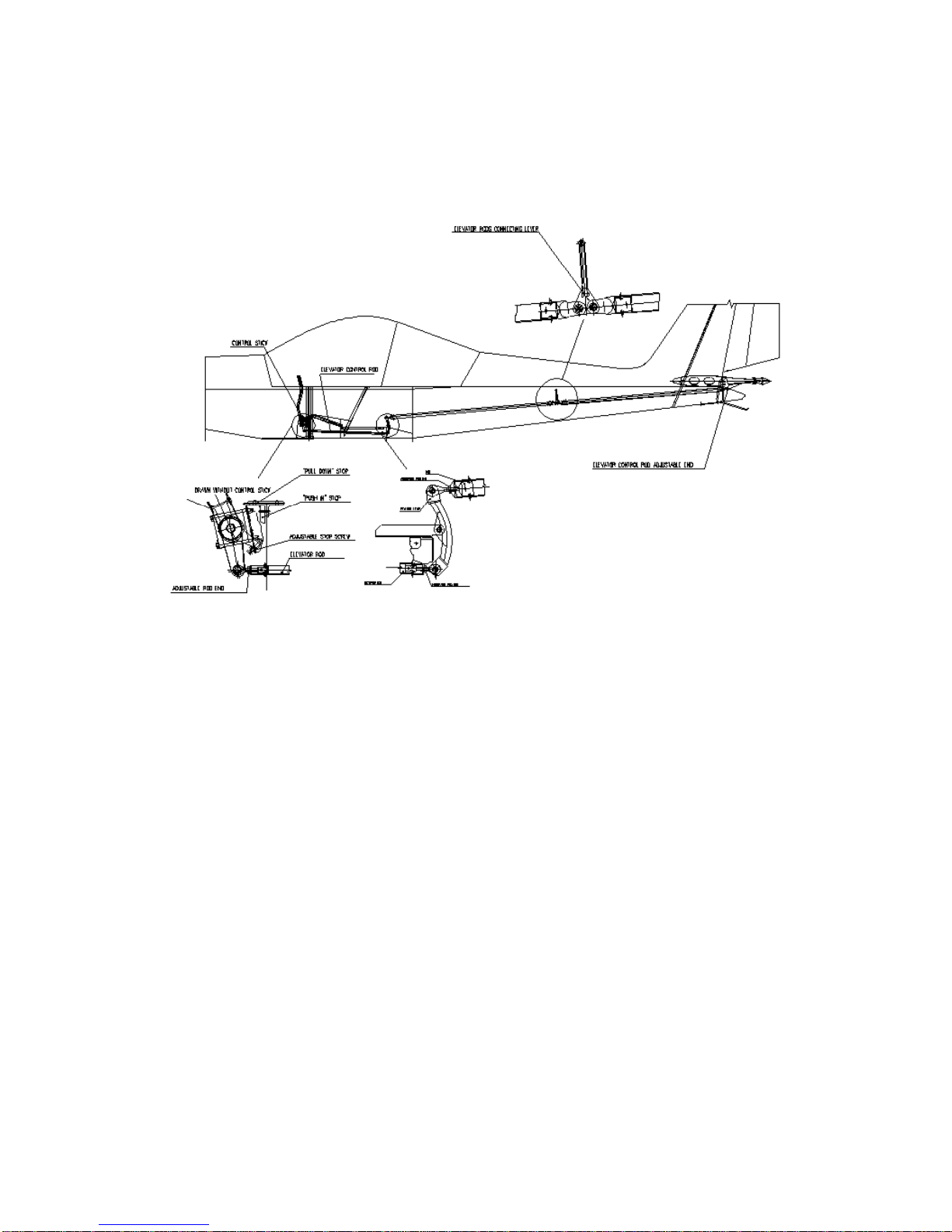

Longitudinal Control (Pitch) – The elevator is controlled by a system of push rods. Movement of the

control stick is passed into a torque tube running along the front of the seats. An arm is attached

to this tube near its centre which connects a push rod to a relay arm mounted beneath the

baggage bay. From here, a second push rod connects to an intermediate relay arm mount half

way along the fuselage rear, and from this point a third push rod connects to the elevator horn; the

system is shown below.

See additional equipment list Appendix 5 if applicable

Elevator trim

Flap lever

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 10

Lateral Control (Roll) – ailerons are also controlled by push rods. Lateral movement of either

control stick is transferred, via a short rod in the cockpit, to a long push rod in the wing,

immediately in front of the main spar. A bell crank, connected to the end of the long push rod,

converts span wise movement to a chord wise one, and a third pushrod terminates on the aileron

horn to deflect it up or down. The short chord wise push rods can be adjusted to achieve the

correct aileron deflections. The control stick base incorporates a stop.

Directional Control (Yaw) – cables, attached to arms at the end of the rudder pedals’ torque tubes,

are guided along the sides of the fuselage to the rudder horn. Stops, in the form of swages

crimped on to the cable, are located at points where the cable passes through fuselage side

stiffeners; adjusters are installed at these points.

Push rods attached to the inboard rudder pedals connect to either side of the steering yoke of the

front wheel, permitting direct steering via the rudder pedals. Since this system and the rudder

cables form a closed loop, rudder cable tension can be adjusted by changing the lengths of the

steering push rods, using the rod ends screwed into their ends.

Toe Brakes - The brakes are controlled independently by hydraulic toe brake pedals mounted on

the pilot’s and the co-pilot’s (optional) rudder pedals.

2.15 Flap Control

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 11

Wing flaps are controlled by a gated lever located between the seats; the lever is released by

pressing the lock button on the lever’s end.

Push – pull movement of the lever is translated into a longitudinal movement of a push rod by a

quadrant mounted at its base. The other end of the push rod connects to the arm of a torque tube

passing across the fuselage and exiting the wall at each side adjacent to the flap end. An arm on

each end of the torque tube engages in slots in the flap end to deploy or retract the flaps. Where

the arm engages in the flap end, an eccentric is provided to permit fine adjustment and balance of

the flaps’ deflections. The system is shown below:

2.16 Elevator Trim

The elevator’s trim tab is moved by a control lever located between the seats. Movement of the

lever is passed to a pair of Bowden cables which run along the fuselage floor to the elevator trim

tab.

2.17 Power Plant

An 80hp Rotax 912 UL engine drives a 3 blade Woodcomp 170/3/R or a Kievprop 237/1700

propeller via a 2.27:1 reduction drive gearbox. The Rotax 912UL is a 4-stroke, 4 cylinder,

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 12

horizontally opposed, spark ignition engine and has one central camshaft operating push-rods for

the overhead valves. Cylinders are cooled by a combination of oil and ram air; cylinder heads are

liquid cooled.

The engine has a dry sump with pumped lubrication and a dual breaker less capacitor discharge

ignition system which does not require battery power for its operation. The engine is fitted with an

electric starter, alternator and mechanical fuel pump.

Full technical details of the engine can be found in the Rotax Operator’s Manual. Engine

performance and limitations are summarized below. It should be noted that the aircraft

manufacturer places certain limits on engine operation, lower than those given by the engine

manufacturer:

Full details of the propeller can be found in the propeller manufacturer’s Operator’s Manual.

Engine Model: ROTAX 912 UL

Engine Manufacturer: BRP – Powertrain GMBH

Power Max Take-off: 59.6 kW / 80 hp at 5800 rpm, max.5 minutes

Max. Continuous: 56 kW / 75 hp at 5200 rpm

Cruising: 53 kW / 71 hp at 4800 rpm

Engine

speed

Max. Take-off: 5800 rpm, max. 5 min.

Max. Continuous: 4800 rpm

Cruising: 4600 rpm

Idling: ~1400 rpm

Cylinder head

temp. Minimum 60 °C 140 °F

Maximum 120 °C (1) 248 °F

Coolant temp. Maximum 115 ºC (1) & (2) 239 °F

Oil temp. Minimum 50 °C 122 °F

Maximum 140 °C 284 °F

Optimum 90 – 110 °C 194 - 230°F

Oil pressure Maximum 7,0 bar

Minimum 1,5 bar

Optimum

1,5-4,0 bar

Fuel: Premium or super unleaded automobile fuel to EN228, minimum RON 90.

AVGAS UL 91 Certified to ASTM D7547

AVGAS 100LL. The higher lead content in AVGAS can result in wear of valve

seats and increased combustion chamber deposits.

Use AVGAS only if other fuels are not available.

For other suitable fuel types, refer to the engine Operator’s Manual.

Fuel Pressure min. 0.15 bar, max. 0.4 bar

Oil: Automotive engine oil of registered brand with gear additives, but not aircraft oil

(refer to engine Operator´s Manual).

API classification SF or SG. (2)

Propeller

Woodcomp 170/3/R or Kievprop 273/1700

Type

3 Blade ground adjustable pitch, composite

Propeller Pitch 28º at 350 mm radius, however see note 1.

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 13

(1) With 50/50 Ethylene Glycol/water coolant mix.

(2) Service Bulletin SB/EUR/006 Issue 1 is complied with.

WARNING

The Rotax 912 UL has not been certified as an aircraft engine and its failure may occur at

any time. The pilot is fully responsible for consequences of such a failure. Never fly over

an area on to which you cannot safely land in the event of an engine failure.

Note 1: propeller pitch to be set to achieve 4600rpm static at full throttle.

2.18 Engine Operational Limits

Parameter

Minimum

Limit

(red line)

Normal

Operating

(green arc)

Caution

Range

(yellow arc)

Maximum

Range

(red line)

Engine speed

[RPM]

1400 1400-4800 4800-5800 5800

Cylinder Head

Temp.

(CHT)

R 912

UL

(80 hp) - - -

-

150 °C

(Evans

coolant)

120 °C

(glycol coolant)

Exhaust Gas

Temp. (EGT) - - - 880 °C

1616 ° F

Oil

Temp. R 912 UL

(80 hp) 50 °C

122 °F 90-110 °C

194-230 °F

50-90 °C

122-194 °F

110-140 °C

230-284 °F

140 °C

284 °F

Oil

Pressure 0.8 bar

12 psi 2 - 5 bar

29 – 73 psi

0.8 - 2 bar

12 - 29 psi

5 – 7 bar

73 – 102 psi

7.0 bar

102 psi

cold engine

starting

2.19 Engine Mount

The engine mount is welded from chrome-molybdenum tube and is attached to the firewall by 4

bolts. The assembly incorporates 4 anti-vibration mounts (Silent blocs).

2.20 Engine Cowlings

Two composite cowlings, upper and lower, cover the power plant. Both cowlings are coated

internally with fireproof paint. The upper cowling is connected to the lower cowling by quarter turn

fasteners and is easily removed for pre-flight inspections. Removal of the lower cowling requires

removal of the screws supporting the radiator to the front of the cowling, then removal of the

screws supporting the lower cowling’s rear edge.

Engine cowlings disassembly and assembly

•The upper cowling: The disassembly and assembly are both easy by releasing

the quick-closing locks (or screws). The upper cowling is usually removed during

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 14

engine pre-flight inspection to check the engine compartment, operating fluids

quantity (oil, coolant) and to check the engine installation.

•The lower cowling: To remove it, un-screw the attachment screws connecting the

cooler to the cowling face side, then remove two air hoses (unscrew sleeves) and

then un-screw the attachment screws connecting the cowling to the firewall

outside edge.

It is highly recommended to protect the removed cowlings so as to prevent them

from inadvertent damage.

The cowling assembly is the reverse of disassembly.

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 15

2.21 Fuel System

A 65 litres fuel tank is installed behind the seat and feeds fuel to a tap located inside the cockpit on

the port side, below the instrument panel. Fuel then passes through a filter to the engine fuel

pump and the carburetors.

The fuel system incorporates a sump and drain

valve to collect water and other contaminants in

the fuel. The drain outlet is located under the

fuselage, near the starboard flap root, and is

accessible when the flaps are fully extended.

(See photo on the right). The tank’s vent also

terminates adjacent to this drain outlet.

A filler cap is installed on the starboard side of

the fuselage.

Fuel quantity is indicated on the panel by a gauge operating from a float sender inside the tank.

The aircraft must be on level ground. It is highly recommended to have accurate knowledge of fuel

load before each flight. Timing fuel burn is also recommended during each flight.

2.22 Cooling System

Two forms of cooling keep engine temperatures under control: cylinder heads are liquid cooled;

cylinders are ram air cooled. A coolant radiator is mounted in the front of the lower engine cowling;

coolant is forced through the radiator to the cylinder heads by a water pump driven from the

crankshaft. Coolant then passes from the top of the cylinder heads to an expansion tank mounted

on top of the engine. This tank allows the coolant to expand and is fitted with a pressure relief cap

and return valve system. Excess coolant passes through the cap into a small plastic overflow

bottle mounted on the firewall.

The coolant level in the expansion tank should be checked before the first flight of the day and

should reach the bottom of the filler neck. Normal coolant level in the overflow bottle is level is ½

to 2/3 up the tank (0.2 litres); minimum level is 25mm from the bottom.

2.23 Cockpit Heating System

One intake air hose routes outside air to the heat exchanger (a jacket around the exhaust), where

the air is heated. It is then led through a valve on the firewall to the mixing chamber on the cockpit

floor. When the valve is closed, the air is exhausted via an outlet air hose exiting under the

fuselage. A second hose feeds outside air directly through the valve on the firewall to the mixing

chamber on the cockpit floor. It is recommended to fit a carbon monoxide detector

Hot air and cold air valves are operated by a Bowden cable running to small control knobs on the

panel.

Demisting/defrosting of the windshield is performed by hot air being fed from the mixing chamber

on the firewall to the internal space of the canopy frame molding and then through a row of holes

along the bottom edge of the tinted plastic canopy.

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 16

2.24 Ventilation

2 eyeball vents mounted

at either side of the

canopy frame provide

fresh outside air. The

vents are connected to

NACA scoops on the

canopy. Turning the rim

adjusts air volume.

2.25 Electrical System

The electrical system uses a single wire supply and chassis (negative) return for all equipment

except avionics units which have their own negative wire returns.

Power for all services except engine ignition is provided by a LiFePO4 (Lithium ion Iron Phosphate)

battery mounted on the firewall and charged via the engine’s alternator and rectifier-regulator. The

battery has its own integrated cell protection and balancing circuits.

All circuits except the starter motor are protected by individual circuit breakers mounted on the right

hand side of the instrument panel. The main battery supply carries a 30A circuit breaker.Circuit

diagrams for each of the systems are given in Appendix 5.

2.26 Pitot-Static System

The pitot static tube, located under the port wing near the aileron root, provides both dynamic and

static pressures to the instruments via flexible plastic hoses.

Moisture and dirt collection reservoirs are installed inside the cockpit, on the left sidewall in front of

the pilot’s seat.

2.27 Galaxy Ballistic Rescue System GRS 6 473 SD B2

The rocket engine and parachute is situated under the front scuttle and is designed to fire through

a break away panel. The parachute is attached at 3 points on the fuselage, the first two being the

port and starboard firewall cross-member, the third point can be found on the port side behind the

pilot’s seat. The red activation handle is easily visible on the lower edge of the instrument panel

next to the throttle.

IMPORTANT

Before working on the aircraft, ensure that the safety locking pin is inserted in the

parachute deployment handle on the panel. If working on or near the parachute itself,

ensure that the transit safety pin is inserted.

Refer to the parachute manufacturer’s maintenance manual for details of maintenance

required.

WARNING

Avoid blowing into the pitot-static system with the collection reservoir covers on - this

may cause damage to the instruments.

WARNING

The battery will be damaged if allowed to completely discharge or if it is jump

started. Only use the recommended charger. See battery manufacturer’s

maintenance manual.

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 17

2.28 Stall Warning Device (SWD)

A stall warner is fitted to the port wing which comprises of a switch in the leading edge of the wing

which is activated by a vane. The switch is connected to a piezo buzzer mounted below the

instrument panel. The buzzer gives a clear and distinct audible warning of an impending stall (10

knots above the stall).

3. Aircraft Assembly and Disassembly of Major Parts

3.1 Wing

Ideally 3 people are needed for the removal and assembly of the wing to the aircraft; however with

care it can be done by 2 people. The following tools are required:

•A rubber or nylon headed hammer to move the wing suspension pins;

•A Pozi-drive screwdriver for the wing root fairings’ screws;

•Spanner to install the rear wing suspension bolts’ nuts.

•For disassembly, a soft metal drift or punch to remove the pins from the wing root attachments.

Wing Removal:

For each wing half, proceed as follows:

1. Remove the wing root fairings.

2. Disconnect the navigation lights’ wiring and pitot-static hoses.

3. Disconnect the aileron control rod.

4. Remove the safety pins from the wing pins.

5. Remove the bolt from its rear wing attachment point, tapping it out gently.

6. Take the load off the lower attachment point by gently lifting the wing tip, then remove

the lower wing pin.

7. Take the load off the upper attachment point by lifting the root, then remove the upper

wing pin, supporting the wing root at the same time.

8. Store the wing in a safe place, taking care not to damage the VG’s.

CAUTION

Take care not to damage the Vortex Generators (VGs) when handling the wing.

IMPORTANT

Check the stall warning device for correct operation before each flight.

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 18

Wing Re-installation:

1. Thoroughly clean and lightly lubricate all the wing supports and bolts with grease

before assembly. Also grease the flap root slot.

2. Have one person hold the wing tip (supporting it on the spar, not the composite tip), a

second person to hold the leading edge wing root and a third person the trailing edge

wing root.

3. Raise the tip to shoulder height.

4. The upper wing suspension should now be carefully inserted into its location in the

fuselage. Take care to avoid damage to the pitot plumbing on the port wing half, and

any navigation light wiring. Insert the pin, with its head facing forward and tap it into

place.

5. Lower the wing tip so that the lower suspension point is aligned; then insert its pin.

6. At the trailing edge, align the flap operating pin in its slot in the flap end. This is

facilitated by moving a wing tip forward a little.

7. Install the bolt into its rear wing attachment point, tapping it home gently.

8. Secure all pins with their safety pins.

9. Connect the aileron control rod and secure their connections.

10. Connect the navigation lights and pitot-static hoses.

11. Attach the wing root fairings.

3.2 Horizontal Tail Unit (HTU)

1. Remove attachment bolts from the HTU-fuselage composite fairing.

2. Disconnect the trim tab control cables (or wire where an electric trim tab is

fitted).

3. Disconnect the elevator control rod.

4. Remove the safety pins securing the castle nuts on the bolts of the stabilizer rear

supports. Remove the nuts and washers.

5. Draw the HTU out of the fuselage.

Re-installation is the reverse of the above procedure. Lubricate the attachment points

before re-assembly. Check elevator and trim tab deflections and adjust as necessary.

3.3 Vertical Tail Unit

1. Disconnect the rudder cables, attaching the ends together to prevent them from

slipping inside the fuselage.

2. Remove the safety pin from the lower hinge bolt; remove the castle nut and washer.

3. Repeat this operation for the upper hinge bolt.

3. Remove the rudder.

Re-assembly is the reverse of the above. If necessary, insert a washer to adjust the lower

hinge clearance. Use tab washers to secure the bolt heads.

4. Inspections and Scheduled Maintenance

4.1 Pre-Flight Inspection

A pre-flight inspection should be repeated prior to each flight even during the same day.

The pre-flight inspection is a visual check of the aircraft for deformations, surface damage, fuel and

oil system leaks, prop damage, insecure locks, covers and cowlings, vortex generators (VGs) etc.

Any damage or failure should be repaired immediately if airworthiness is affected.

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 19

It is important to perform a pre-flight inspection carefully and systematically to prevent anything

from being missed. Refer to the Pilot's Operating Handbook for more details.

4.2 Post-flight inspection

A post-flight inspection is performed at the end of each flight day; the post-flight inspection events

are the same as the pre-flight ones. If possible, failures, damages and malfunctions should be

recorded and repaired immediately. It is recommended to clean and/or wash the aircraft, check for

damage on delicate items such as the Vortex Generators (VG’s) and check that the fuel and oil

consumptions are in the normal range.

Record all hours flown, and other data in the appropriate log book.

4.3 Periodic inspections

4.3.1 Periodic inspection intervals

The periods for overall checks and associated maintenance will depend on operating conditions

and the overall condition of the aircraft. The manufacturer recommends maintenance checks and

periodic inspections at the following intervals.

1) after the first 25 ± 2 flight hours

2) after every 50 ± 3 flight hours

3) after every 100 ± 5 flight hours or annual inspection

Refer to the Rotax 912 Maintenance Manual for engine maintenance.

Refer to the Propeller manual for propeller maintenance.

4.3.2 Periodic maintenance and inspection work sheets

The following Periodic maintenance and inspection Work Sheets are intended for copying and

serve as the Maintenance Records. It is also recommended to include small repairs and damage

and their remedies or replacements. Some parts of the aircraft (engine, propeller, parachute etc.)

may have special time limits - refer to the appropriate manuals.

All maintenance and repair work must be recorded in the appropriate log books by reference to the

above Maintenance Records. The parachute maintenance must be entered into the logbook as a

separate item.

WARNING

Before working on the aircraft, ensure that the safety locking pin is inserted in the

parachute deployment handle on the panel. If working on or near the parachute itself,

ensure that the transit safety pin is inserted.

EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 20

4.3.3 Periodic Maintenance and Inspections.

Model:

S/N: Hours flown: Date of inspection:

EV-97 EUROSTAR

SL MICROLIGHT

Registration: No. of takeoffs: Inspection period: hrs.

Event Event description

Inspection

Carried

out by: Inspected

by:

after the first

25hrs.

every

50

hrs.

every

100

hrs.

or

annually

1.

Prior to the inspection clean and wash the aircraft

surfaces, if needed.

2.

ENGINE see engine manufacturer´s

instructions

3.

ENGINE COMPARTMENT

3.1.

Fiberglass engine cowlings

3.1.1.

Check condition of cowlings and Camlock

Fasteners.

- repair any damage

3.1.2.

Remove engine cowling

3.1.3.

Visually check inside fireproof primer paint

- Repaint if needed

- White color T 50, Norm V1000 N 56582

3.2.

Engine mount

3.2.1.

Visually check condition, attachment, security of

attachment bolts: engine to mount, mount to

firewall. Carefully

check engine mount for

cracks, abrasion and other damage.

3.2.2.

Visually check condition of rubber silentblocks -

replace those cracked or excessively deformed

3.3.

Induction System

3.3.1.

Visually check condition, attachment and security

of air filters on each carburettor inlet.

- clean and oil filter as necesary.

3.3.2.

Visually check condition of carb. rubber adaptors.

3.3.3.

Check carburettor - condition, control cables

attachment, lubricate cables at inlet to the

Bowdens‘ conduits.

3.3.4

Check coolant carb heat system for security and

leaks

3.4.

Battery

3.4.1.

Visually check attachment and security

3.4.2.

Check charging – charge if needed; see note 1

3.4.3.

Visually check condition and attachment of

battery leads

– replace those damaged

3.5.

Wiring

3.5.1.

Visually check condition and integrity of wires,

connections, security of wires

Note 1: The Li-ion battery must only be charged with its dedicated, (constant current) charger. The

use of a normal lead-acid battery charger (constant voltage) may result in damage to the battery

and a reduction in its life.

Table of contents

Other Evector Aircraft manuals