Everest TWIN LOBE User manual

DO NOT OPERATE WITHOUT

READING MANUAL

WARNING Publication No. OMM_Everest Blowers

Rev 3, September 2017

INSTALLATION | OPERATION | MAINTENANCE

TWIN LOBE

& TRI LOBE

PD BLOWERS

EVEREST ROTARY BLOWER INSTRUCTION MANUAL

© Everest Blowers www.everestblowers.com 1

Contents Pg. No.

To Get The Most From Your Everest Blower

Safety Precautions

Working Principle

Introduction - Your Key To Trouble Free Service

Equipment Check & Storage

2

3

4

6

7

Installation 8

Instruction Manual

INDEX

Drive Installation 9

Recommended Layout For Multiple Blowers Installation 10

Auxiliary Equipment 11

Accessories Layout For Everest Blowers 14

Lubrication 15

Special Note for Water Cooled & Gas~Biogas Blowers 18

Orientation of Blowers

18

19

24

27

Spares & Consumables

Blower Startup Checklist

Fault Chart

Everest Wants To Know What You Think - Feedback Form

Notes

Trouble Shooting 21

23

20

Instruction Manual

TO GET THE MOST FROM YOUR “EVEREST” BLOWER

1.0 Make sure proper oil levels are maintained in the gear end and grease/oil in the drive

end.

2.0 Check oil level and grease every 40 hours of operation. Loss of oil or grease should be

replenished.

3.0 First oil change should be done within the first 100 operating hours and thereafter

every 1000 hours or more often, if oil gets dirty.

4.0 Check belt tension every fortnight. Too tight belts would cause premature bearing

failure while too loose belts would cause overheating of belts and pulleys.

5.0 Check regularly for any knocking or abnormal sound. High frequency sound indicates

bearing trouble. Knocking sound indicates rotor timing upset. Contact “Everest” for

necessary adjustments.

6.0 Clean air filter every fortnight by reverse airflow. Chocked filter would result in

excessive power consumption and overheating of blower. Replace filter every three

months or earlier.

7.0 Check and clean air silencer every month.

© Everest Blowers 2

www.everestblowers.com 2

CAUTION

Everest Blower is shipped without oil.

Before operating, put the required amount of oil into the reservoirs as per

instructions under lubrication.

Do not fill oil reservoirs until blower is mounted in its operating location.

NOTICE

Everest Blowers are meant for indoor installation or should be protected

from direct rain and sunlight, if installed outdoor.

WARNING

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 3

SAFETY PRECAUTIONS

Safety is everybody’s business and is based on your good use of common sense. All situations or

circumstances cannot always be predicted and covered by established rules. Therefore, use your

past experience, watch out safety hazards and be cautious. Some general safety precautions are

given below.

DANGER

Failure to observe these notices could result in injury or death of personal.

Keep fingers and clothing away from blower inlet and discharge ports, revolving

belts, pulleys, drive coupling etc.

Do not use the air discharged from this unit for breathing - not suitable for human

consumption.

Do not loosen or remove the oil fill plug, drain plug, covers or break any

connections, etc., in the air or oil system until the unit is shut down and the air

pressure has been relieved.

Electric shock can and may be fatal.

Open main, disconnect switch, tag and lockout before working on the control.

Disconnect the Blower unit from its power source, tag and lockout before

working on the unit.

Failure to observe these notices could result in damage to equipment.

Stop the unit if any repairs or adjustments on or around the Blower are required.

Disconnect the Blower unit from its power source, tag and lockout before

working on the unit.

Do not operate unit if safety devices are not operating properly. Check

periodically. Avoid bypassing safety devices.

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 4

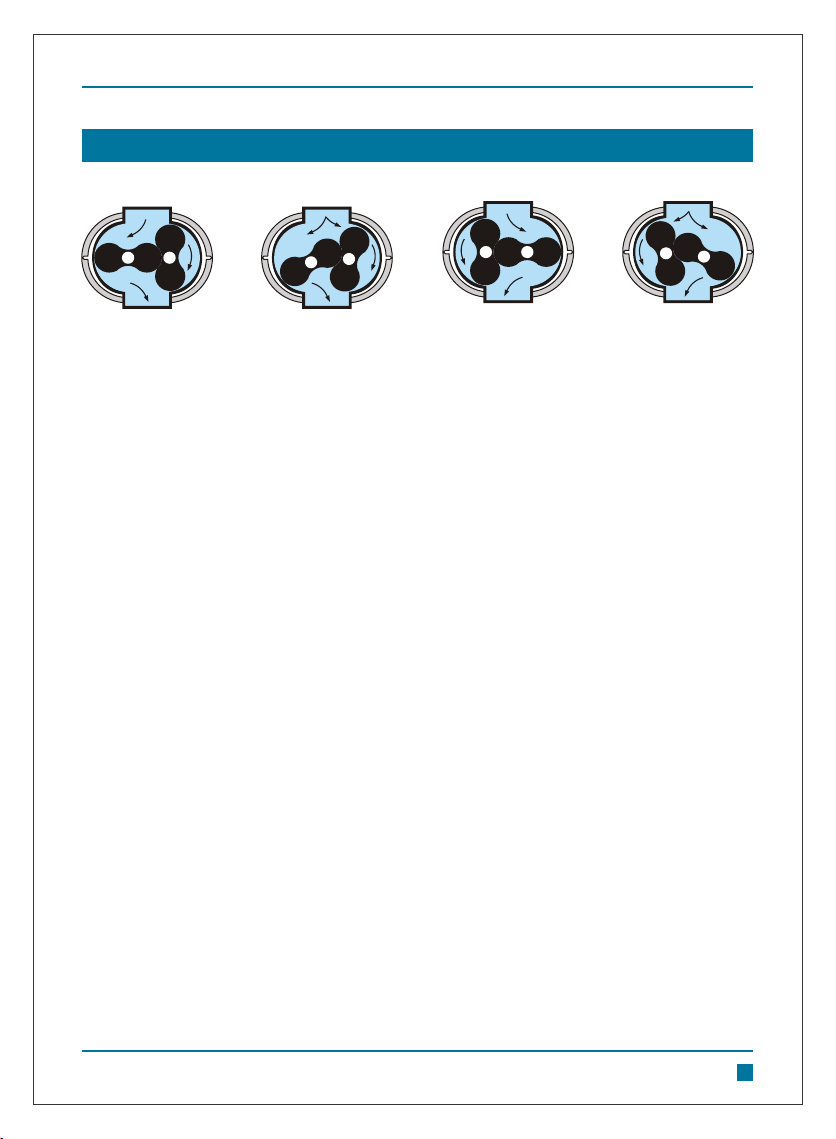

EVEREST TWIN LOBE ROTARY AIR BLOWER WORKING PRINCIPLE

Everest Twin Lobe Rotary Compressors/Blowers are positive displacement units, whose pumping

capacity is determined by size, operating speed and pressure conditions. It employs two Twin

Lobe impellers mounted on parallel shafts, rotating in opposite direction within a casing closed at

the ends by side plates. As the impellers rotate, air is drawn into one side of the casing and forced

out of the opposite side against the existing pressures. The differential pressure developed,

therefore, depends upon the resistance of the connected system. The Blowers, being positive

displacement type, do not develop pressure within the casing but the discharge pressure depends

upon the system resistance / back pressure. Effective sealing of the compressor inlet area from

the discharge area is accomplished by use of very small operational clearance, eliminating the

need of any internal lubrication of the lobes. A pair of accurately machined alloy steel, hardened

and ground timing gears maintain clearances between the impellers, during rotation. The air, thus

delivered, is 100% OIL FREE.

The pumping capacity of a lobe compressor, operating at constant speed remains relatively

independent of inlet and discharge pressure variations. These Blowers are constant volume

machines, which deliver a fixed discharge against the system back pressure. It is, therefore,

essential to ensure that minimum pipeline restrictions, at the inlet and discharge, are imposed.

Adequate size piping and large radius bends ensure minimum line losses resulting in higher

efficiency and low power consumption. Sudden change in pipeline cross section should also be

avoided.

To change capacity, it is necessary either to change speed (energy saving) or vent some of the air

into atmosphere (not energy saving). The air must not be recirculated from the discharge to

suction as it may result in over heating. No attempt should ever be made to control the capacity of

compressor by means of throttle valves in the intake or discharge piping. This increases the power

load on the motor and may seriously damage the compressor. There is an increase in the

discharge air temperature due to heat of compression. As a thumb rule the discharge air

o 2

temperature increases @ 10 C for every 0.1 Kg/cm of ∆ P above the inlet temperature.

POSITION-1 POSITION-2 POSITION-3 POSITION-4

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 5

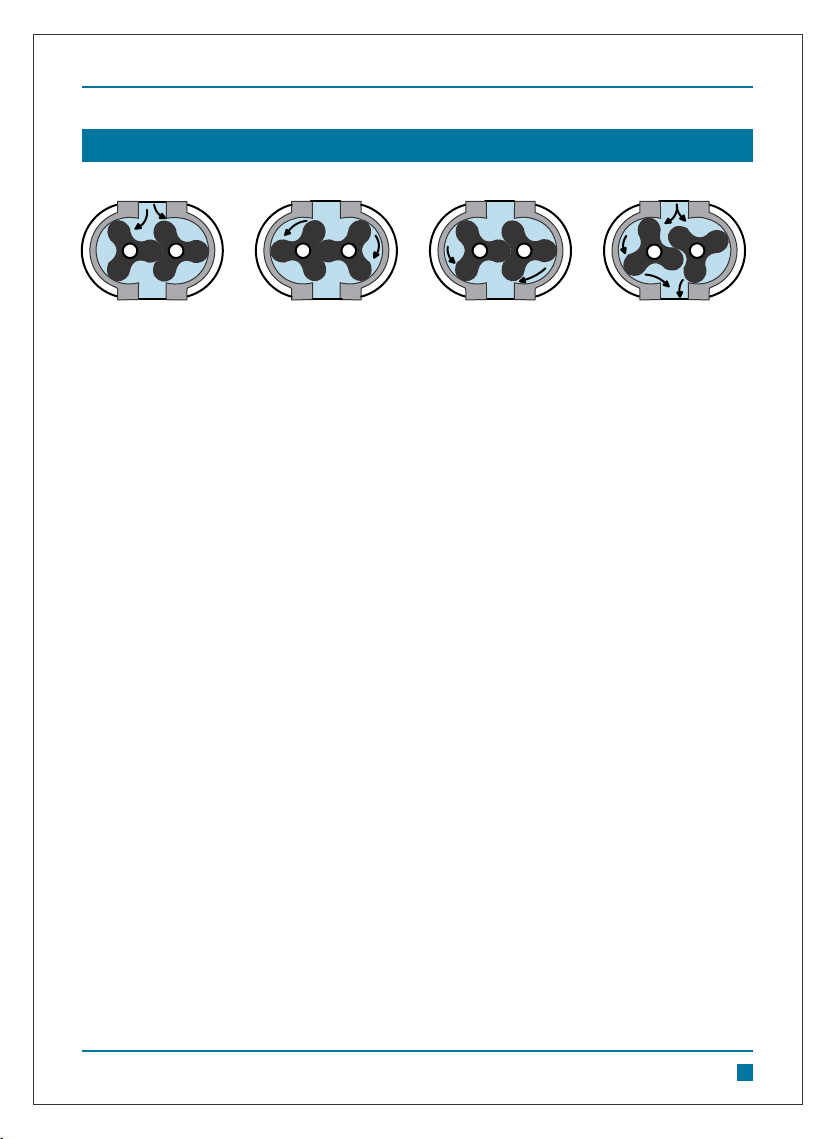

EVEREST TRI LOBE ROTARY AIR BLOWER WORKING PRINCIPLE

Everest Tri-lobe Rotary Compressors/Blowers are positive displacement units, whose pumping

capacity is determined by size, operating speed and pressure conditions. It employs two Tri-lobe

impellers mounted on parallel shafts, rotating in opposite direction within a casing closed at the

ends by side plates. As the impellers rotate, air is drawn into one side of the casing and forced out

of the opposite side against the existing pressures. The differential pressure developed, therefore,

depends upon the resistance of the connected system. The Blowers, being positive displacement

type, do not develop pressure within the casing but the discharge pressure depends upon the

system resistance / back pressure. Effective sealing of the compressor inlet area from the

discharge area is accomplished by use of very small operational clearance, eliminating the need

of any internal lubrication of the lobes. A pair of accurately machined alloy steel, hardened and

ground timing gears maintain clearances between the impellers, during rotation. The air, thus

delivered, is 100% OIL FREE.

The pumping capacity of a lobe compressor, operating at constant speed remains relatively

independent of inlet and discharge pressure variations. These Blowers are constant volume

machines, which deliver a fixed discharge against the system back pressure. It is, therefore,

essential to ensure that minimum pipeline restrictions, at the inlet and discharge, are imposed.

Adequate size piping and large radius bends ensure minimum line losses resulting in higher

efficiency and low power consumption. Sudden change in pipeline cross section should also be

avoided.

To change capacity, it is necessary either to change speed (energy saving) or vent some of the air

into atmosphere (not energy saving). The air must not be recirculated from the discharge to

suction as it may result in over heating. No attempt should ever be made to control the capacity of

compressor by means of throttle valves in the intake or discharge piping. This increases the power

load on the motor and may seriously damage the compressor. There is an increase in the

discharge air temperature due to heat of compression. As a thumb rule the discharge air

o 2

temperature increases @ 10 C for every 0.1 Kg/cm of ∆ P above the inlet temperature.

POSITION-1 POSITION-2 POSITION-3 POSITION-4

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 6

INTRODUCTION - YOUR KEY TO TROUBLE FREE SERVICE

Thank you for investing in Everest quality. The Everest reputation for rugged dependability has

been earned by over 37 years of service in demanding, industrial operations where downtime

cannot be tolerated and efficient blower performance is expected. Your Everest Blower is a

precision-engineered blower that has been carefully manufactured and thoroughly tested at the

state-of-the-art Everest Blowers factory.

As with other precision machinery, there are several relatively simple installation, operation and

maintenance procedures that you must observe for optimum blower performance. There is no

guesswork in the manufacture of your highly advanced Everest Blower and there must be none in

preparing the Blower to get the job done in the field.

The purpose of this manual is to help you properly install, operate and maintain your Everest

Blower. It is essential that you review all sections of this manual in preparation for installing your

blower. Follow the instructions carefully and you will be rewarded with trouble free Everest

service................year in and year out.

WHERE TO CALL FOR EVEREST BLOWER ASSISTANCE:

For prompt professional Everest service always contact your authorized Everest Distributor First.

If you do not know your authorized Everest Distributor, contact the numbers below for immediate

assistance.

EVEREST CUSTOMER SERVICE / FACTORY SERVICE DEPARTMENT

EVEREST BLOWERS PVT. LTD.

B-44 MAYAPURI INDUSTRIAL AREA, PHASE - 1,

NEW DELHI - 110064, INDIA.

Ph : 91 - 11 - 45457740 | Fax: 91-11-45457718

Email : [email protected]

WARNING

Customers are cautioned to provide adequate protection, warning and safety

equipment necessary to protect personnel against hazards involved in installation

and operation of this equipment in the system or facility.

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 7

EQUIPMENT CHECK & STORAGE

EQUIPMENT CHECK:

On uncrating, check the packing slip carefully to be sure all the parts have been received. All

accessories are listed as separate items on the packing slip, and small important accessories

such as relief valves, can be overlooked or lost. After every item on the packing slip has been

checked off, unpack carefully. Register a claim with the carrier for lost or damaged equipment.

STORAGE:

Your Everest Blower was packed at the factory with adequate protection to permit normal storage

for upto three (3) months. If the unit is to be stored under adverse conditions or extended period of

time, the following additional measures should be taken to prevent damage.

1 Store the Blower in a clean, dry area.

2 Make certain inlet and discharge air ports are tightly covered to prevent foreign material from

entering the air box.

3 All exposed, non-painted surfaces should be protected against rust and corrosion.

4 Provide adequate protection to avoid accidental /mechanical damage.

5 In high humidity or corrosive environments, additional measures may be required to prevent

rusting of the Blower internal surfaces.

6 To prevent rusting of gears, bearings etc., the oil reservoirs may be filled with normal

operating oil.

7 Rotate the Blower shaft (10 to 25 turns) monthly during storage. Inspect the Blower shaft

(near shaft seal area) monthly and spray with rust inhibitor if needed.

8 For long-term storage (over six (6) months) contact Everest Customer Care for

recommendations.

REMOVING PROTECTIVE MATERIALS:

The shaft extension is protected with rust inhibitor that can be removed with any standard solvent.

Alternatively the Blower pulley is factory fitted on the shaft extension and it requires no cleaning.

Blower inlet & outlet are temporarily capped to keep out dirt and other contaminants during

shipment. These covers must be removed before start-up. Keep them intact during the period of

storage.

Everest Blowers are internally and externally treated to protect against normal atmospheric

corrosion. Prior to installation remove covers from Blower inlet and discharge openings and

inspect internals. If the cleaning is required, clean the internals thoroughly using any commercial

solvent (e.g. Kerosene / Diesel). Continue this procedure until the unit is visibly clean. Check the

drive shaft by rotating manually to ensure the impellers turn freely at all points. No internal

adjustment is generally required.

LOCATION:

If possible, install the Blower in a well-lit, clean, dry place with plenty of room for inspection and

maintenance. Protection from direct sunlight and rainwater is required. Effect of location on driver

and accessory equipment must also be considered.

FOUNDATIONS:

For permanent installations we recommend concrete foundations be provided, and the equipment

must be leveled, free of all strains, and anchored so no movement will occur during setting of grout.

After grout has completely hardened, a recheck is necessary to compensate for shrinkage etc. If

required add shims under Blower feet before final tightening of foundation bolts to remove strain

from the Blower housing. Blower assembly can be mounted on Anti Vibration Pads and directly

placed on leveled concrete surface.

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 8

INSTALLATION

WARNING

Rotating components will cause severe injury in case of personal

contact. Keep hands away from blower inlet and discharge ports.

WARNING

Handling of equipment needs to be accomplished with care,

and in compliance with safe practices.

DIRECT DRIVE (COUPLED):

On the direct connected units, alignment and lubrication of couplings to specifications of the

coupling manufacturer is very important. When mounted drives are supplied from the factory,

proper alignment has been established before shipment. However, during shipping, handling and

installation, it is likely that the alignment has been disturbed and final adjustment must be made

before start up. A flexible type coupling should always be used to connect the driver and blower

shaft.

BELT DRIVE:

Belt drives must be carefully aligned. Motor and blower pulleys must be parallel to each other and

in the same plane. Belt tension should be carefully adjusted to the belt manufacturers

recommendation using a belt tension gauge. Check tension frequently during the first day of

operation.

The location of pulley on the Blower shaft greatly affects the stress in the shaft. The optimum

blower pulley positioning is as close as possible to the blower drive shaft bearing cover, to

minimize overhung loads.

PIPING:

Inlet and discharge connections on all blowers are large enough to handle maximum volumes with

minimum friction loss. Reducing the pipe diameter on either inlet or discharge will only create

additional line loss and increase the overall differential pressure and input power.

Pipe threads / flanges (suction and discharge) must meet the blower connections accurately and

connections by springing or cramping the pipe or by forcefully connecting the two may result in

distorting the blower casing and thereby causing serious damage to the Blower. For similar

reasons, piping should be supported near the blower to eliminate dead weight strains on the

blower. A flexible pipe bellow is recommended in the discharge pipeline, close to the blower

discharge, so as to isolate blower and pipeline vibrations.

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 9

WARNING

Misalignment of coupling halves leads to unwarrantable

premature bearing failure and shaft breakage.

WARNING

Over tightened belts lead to heavy bearing loads and shaft

deflections and may result in premature failure of bearings / shafts.

DRIVE INSTALLATION

Avoid sharp bends in the suction and discharge line. Use adequate size pipe with large radius

bends. This would keep pipeline pressure losses to bare minimum. As a thumb rule the line size

should be such that the air velocity is in the range of 20-25 m/sec. Gate valves, nozzles etc. should

be avoided, since they cause turbulence and have not much utility. If at all they must be used,

ensure they are sized properly.

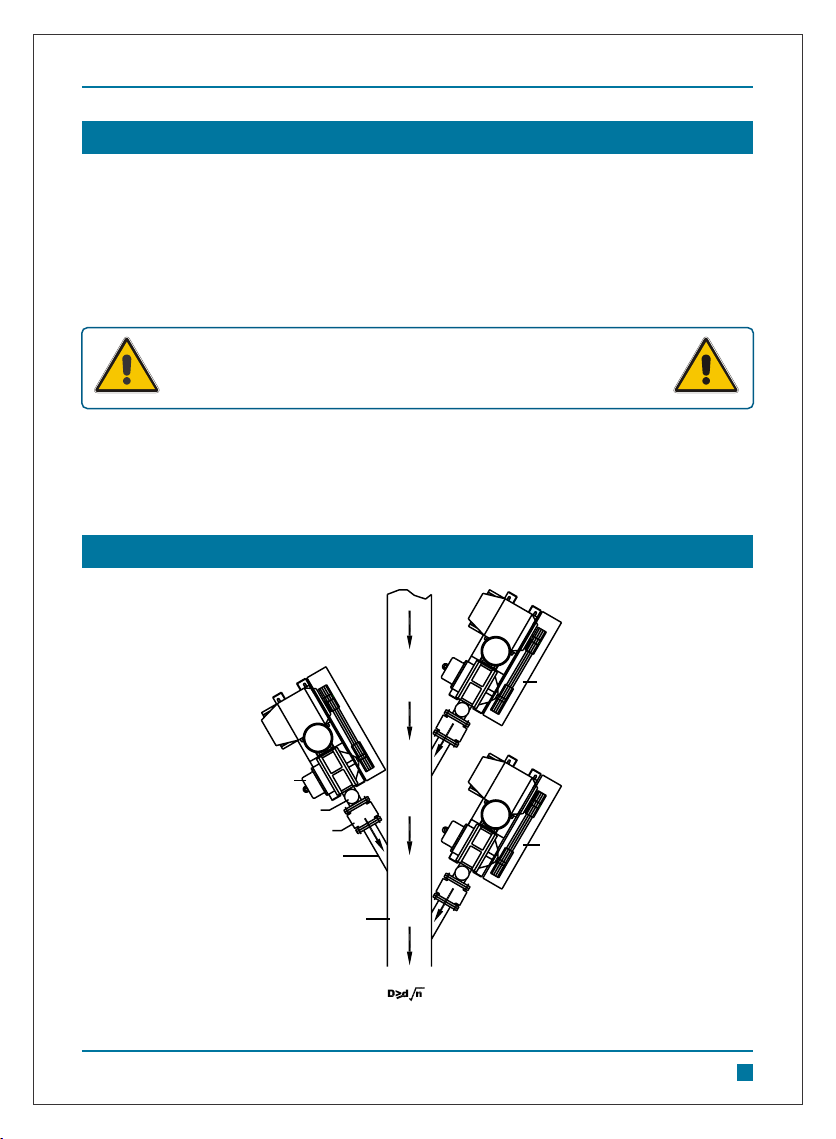

MULTIPLE BLOWER INSTALLATIONS:

When two or more blower are connected to a system through a common header, the line sizes

should be adequately designed to handle the flow rates. Generous line sizes would result in low

line losses and consequently power saving. Refer to proposed layouts as shown below:

EVEREST

BLOWER NO. 2

RELIEF VALVE

NON RETURN VALVE

LINE Ød

COMMON HEADER

LINE ØD

EVEREST

BLOWER NO. 3

EVEREST

BLOWER NO. 1

TO SYSTEM

WHERE D = MAIN HEADER LINE DIAMETER

d = BLOWER DISCHARGE LINE DIAMETER

n = NUMBER OF BLOWERS

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 10

DRIVE INSTALLATION

All system piping must be cleaned internally before connecting

to the Blower

RECOMMENDED LAYOUT FOR MULTIPLE BLOWERS INSTALLATION

WARNING

The auxiliary items that might be required under various operating conditions are:

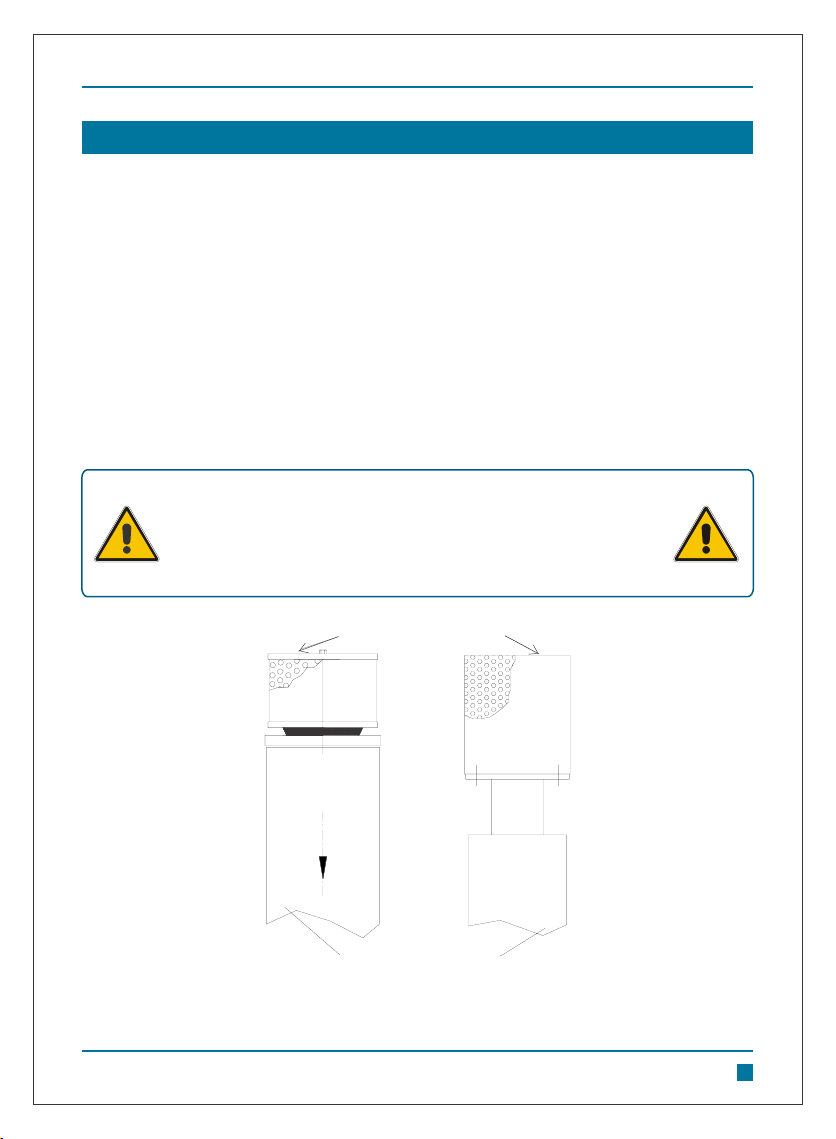

SILENCERS:

The need for silencer depends on Blower speed and pressure as well as sound level requirements

in the general surroundings. Silencers should be mounted as close to the blower as possible.

SUCTION FILTER:

An inlet filter is generally recommended, especially in dusty locations, as it safeguards the

machine against dirt and dust. The filter should be periodically checked for choking. Choking of

filter would result in pressure drop across it thereby increasing the load on the Blower marked by

increase in power intake. The filter element should be regularly cleaned by reverse jet of air. The

pressure drop across the filter should not exceed 100mm WG. Replace filter every three months.

Clean Air Filter every fortnight by reverse air flow. Chocked filter would result in excessive power

consumption and overheating of the blower. Replace filter every three months or earlier, if

inspection so demands. Check and clean Air Silencer every month.

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 11

AUXILIARY EQUIPMENT

Choking of suction filter leads to increased load on the blower.

Replace filter every three months. Servicing the air filter is one of

the most important maintenance operations to be performed

periodically to ensure long blower life.

WARNING

SUCTION SILENCER

SUCTION AIR FILTER

RELIEF VALVE NORMAL POSITION RELIEF VALVE OVERLOADED POSITION

DISCHARGE PIPE LINE DISCHARGE PIPE LINE

SAFETY RELIEF VALVE

Fig: Relief Valve Operation Illustration

PRESSURE RELIEF VALVE:

A pressure relief valve is necessary in the discharge pipe to protect against any overloading in the

discharge line. In case of discharge line pressure exceeding the set limits, the valve cap pops up,

discharging air into atmosphere.

NON RETURN VALVE (OPTIONAL):

Non-return valve may be fitted close to the discharge port to prevent the compressor from running

in the reverse direction, when switched off under load conditions. In multiple blower installations

when two or more units discharge into a common header, use of non return valves is

recommended. One non-return valve should be located in each blower discharge line. Properly

installed, they will protect against damage from reverse rotation caused by air back flow through

an idle blower.

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 12

AUXILIARY EQUIPMENT

Relief valve should be placed as close as possible to the Blower

discharge. They are not meant to discharge full capacity and

therefore cannot be taken as safefuard against total blockage.

NOTICE

WRONG

RIGHT

MEASURING AND MONITORING DEVICES:

Pressure gauge is supplied along with the supply and it is recommended to connect it to the

discharge pipe line, close to the blower, to ensure that the system pressure is within

the Blower rated pressure. However, U-Tube Mercury manometer may be used for

more accurate observations. Special measuring and monitoring systems can be

connected as per the individual requirement.

CAPACITY CONTROL:

The capacity of the blower can be varied by changing the blower speed, however, confirmation to

the input power and maximum speed must be made prior to doing so. No valves should be put into

the suction / discharge line to regulate the air capacity. One may, however, vary the discharge air

capacity by venting out some of the air into atmosphere. Refer illustration below.

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 13

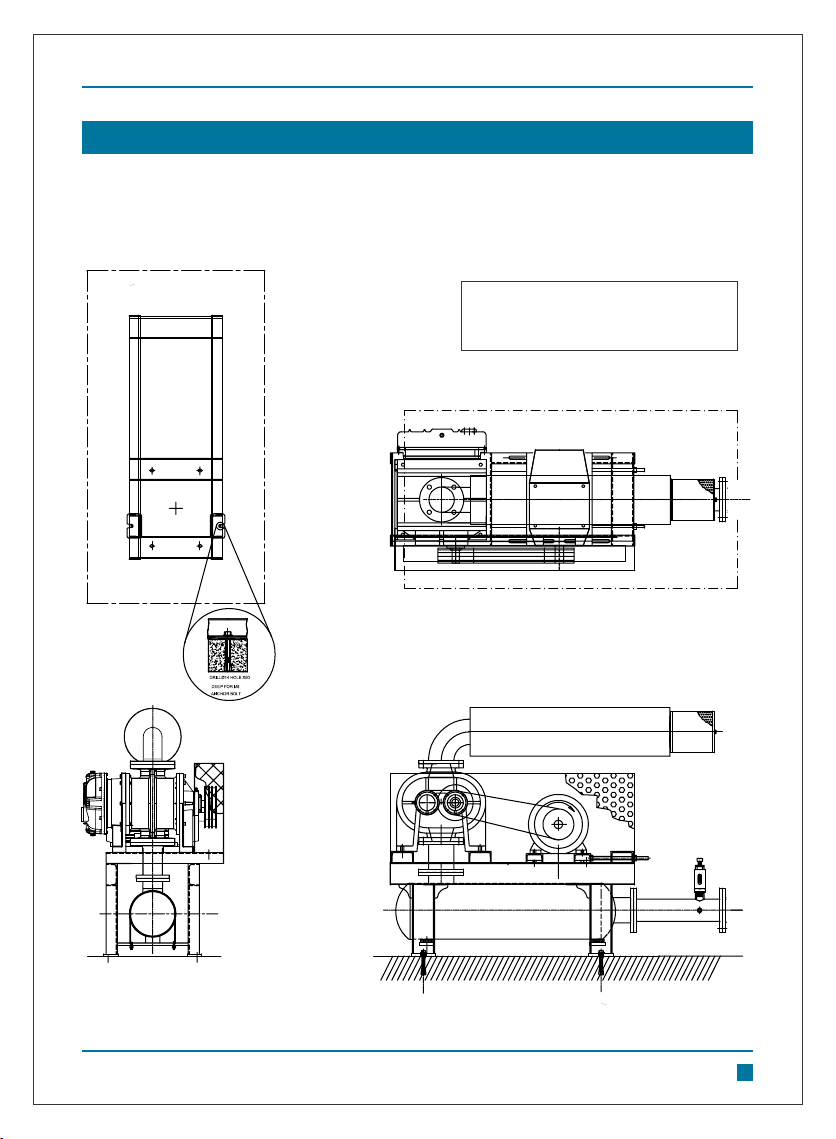

CAPACITY CONTROL

G.A. drawing for a typical Everest Blower. G.A. drawing of your particular Everest Blower was

issued alongwith P.O. Acknowledgment, sectional drawing & bill of material. You may request for

another copy of the same giving reference of P.O. No. & Date and Blower Model & Serial Number.

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 14

ACCESSORIES LAYOUT FOR EVEREST BLOWERS

FOUNDATION

PLAN

MOTOR

BLOWER

ELEVATION

SIDE VIEW

PLAN

Note:

1. Direction Of Rotation Clockwise As Viewed.

2. Protect From Direct Sunlight & Rain.

3. Blower Opening Detail : 100 mm NB

Instruction Manual

© Everest Blowers www.everestblowers.com

LUBRICATION

EVEREST Twin Lobe Rotary Air Blowers have a very simple yet effective lubrication systems. At

the gear end, the timing gear teeth are lubricated by being partially submerged in oil. A good grade

industrial type, rust oxidation and foam inhibited, non-detergent gear oil (of medium viscosity) is

recommended. The oil level indicator is provided at the back of the gear cover to monitor oil level.

The oil should be periodically checked and fresh oil added as required to maintain proper level.

During complete oil change old oil should be drained, gear cover flushed and then new oil added.

The Blower drive end bearings are OIL / GREASE Lubricated.

A weekly check for oil, under normal conditions, ensure longer blower life. Refer Lubrication

diagram as shown below.

First oil change should be done within first 100 operating hours

and thereafter, complete oil change is recommended after about

1000 operating hours or earlier if inspection so indicates.

The recommended oil grade is Shell Spirax S2 G 90 / Indian Oil

Servo Gear HP 90 / Castrol Hypoy EP 90 / HP Gear Oil EP 90 / MAK

Spirol EP 90 / Indian Oil Servo Gear Super 90. Recommended

grease grade is Castrol AP2 / AP3.

LUBRICATION DIAGRAM

CORRECT OIL LEVEL.

BLOWER NOT OPERATING.

LOW OIL LEVEL

2

15

WARNING

WARNING

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 16

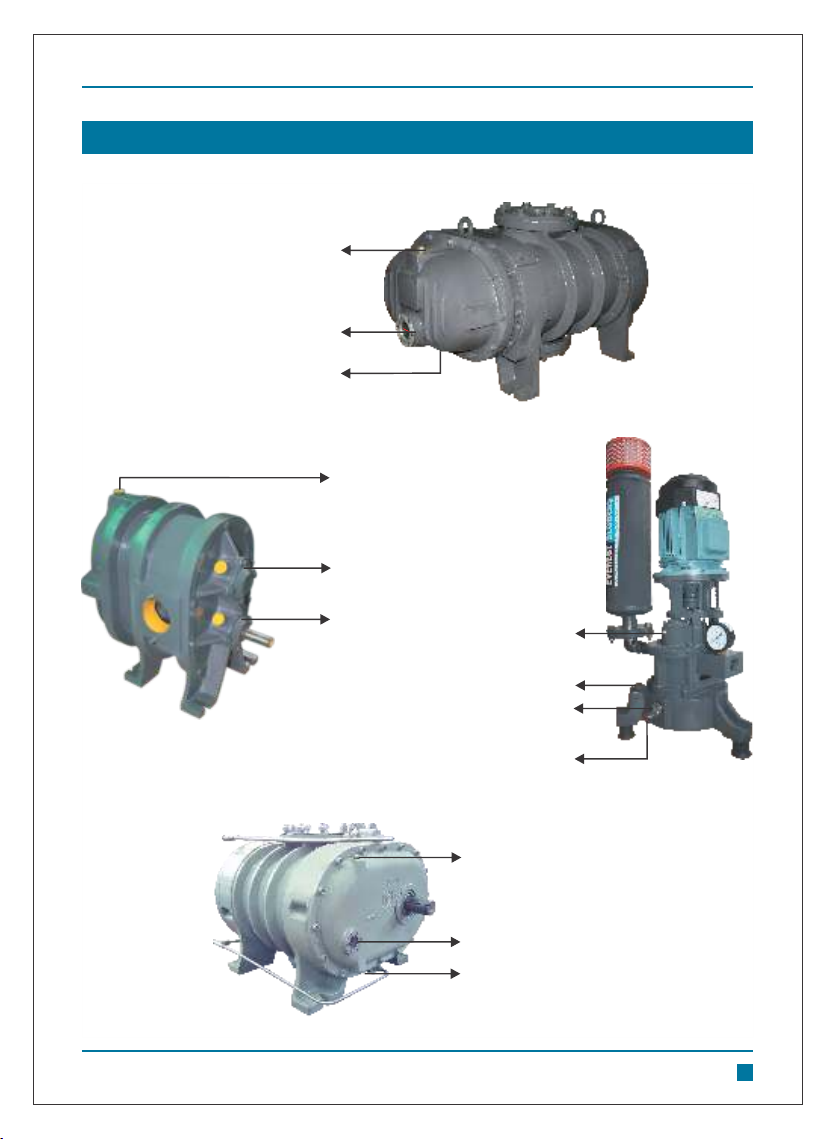

LUBRICATION DIAGRAM

OIL FILL PLUG

OIL DRAIN PLUG

OIL LEVEL INDICATOR

OIL FILL PLUG

GREASE CUP

GREASE CUP

OIL LEVEL INDICATOR

OIL FILL PLUG

OIL DRAIN PLUG

Lubrication points for different blower configurations.

OIL FILL PLUG

OIL LEVEL INDICATOR

OIL DRAIN PLUG

GREASE NIPPLE

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 17

Correct lubrication is probably the most important requirement, other than operating the blower

within its specific rating limits. In a blower there are no moving contacts between the two impellers

or between impellers and the body or side plates. The wear is then, confined to the timing gears,

the bearings and the shaft seals. All are lubricated and wear would be nominal if clean oil of proper

grade is always used.

Timing gears wear should be negligible over the normal period of service. Gear teeth are hardened

and ground to super finish. A reasonable degree of tooth wears, which normally can be

accommodated without permitting contact between lobes.

However, high oil level in the gearbox would cause churning and excessive oil heating usually

indicated by high temperature at the bottom of the sump. If operation is continued under this

condition, gear will wear and tooth clearance will be lost. Rapid tooth wear will then probably

develop, which will eventually produce impeller knocking. From this point serious damage will be

unavoidable if operations are continued. Tooth fracture, brought on by sustained overloading and

shock loads would produce similar results suddenly. Shaft bearings are critical in the service life of

the Blower. Gradual wear may allow shaft position to change slightly until rubbing develops

between impellers and casing or plates. Sudden bearing failure is usually more serious. Since the

impellers shaft assembly is no longer supported and properly located, extensive damage is likely

to occur if operation is continued. It has been observed that main cause of premature sudden

bearing failure is either lack of lubrication or contamination. It is, therefore, strongly advised to take

all the necessary steps to ensure proper, clean lubrication of gears and bearings.

Do not overfill. This will cause excessive heating of the gears and

may damage the unit.

WARNING

Ensure Lubrication of Bearings and Gears is regularly maintained.

This avoids premature failure of Blower.

Provide suitable protection / cover to prevent Lubricant getting

contaminated by dust, dirt and water as these render it ineffective.

WARNING

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 18

SPECIAL NOTE FOR WATER COOLED & GAS~BIOGAS BLOWERS

Pressure duty air blowers are not recommended for use in Gas~Biogas and Vacuum duty

applications.

Water cooled blowers are similar to air cooled blowers except for the provision for cooling of end

plates by water circulation in water cooled blowers. Water cooled blowers are recommended for

applications where differential pressure (∆ P) across the blower is high or inlet gas temperature is

high. The objective is to cool the lubricant & bearings and not the discharge gas.

Incase of Gas~Biogas blowers, vacuum switch may be provided at the inlet of the blower, so that

incase the biogas generation falls below the pumping speed of the blower, the blower trips and this

prevents vacuum overloading. Similarly, a pressure switch may be installed on the discharge line

to safeguard the blower against excessive discharge pressures.

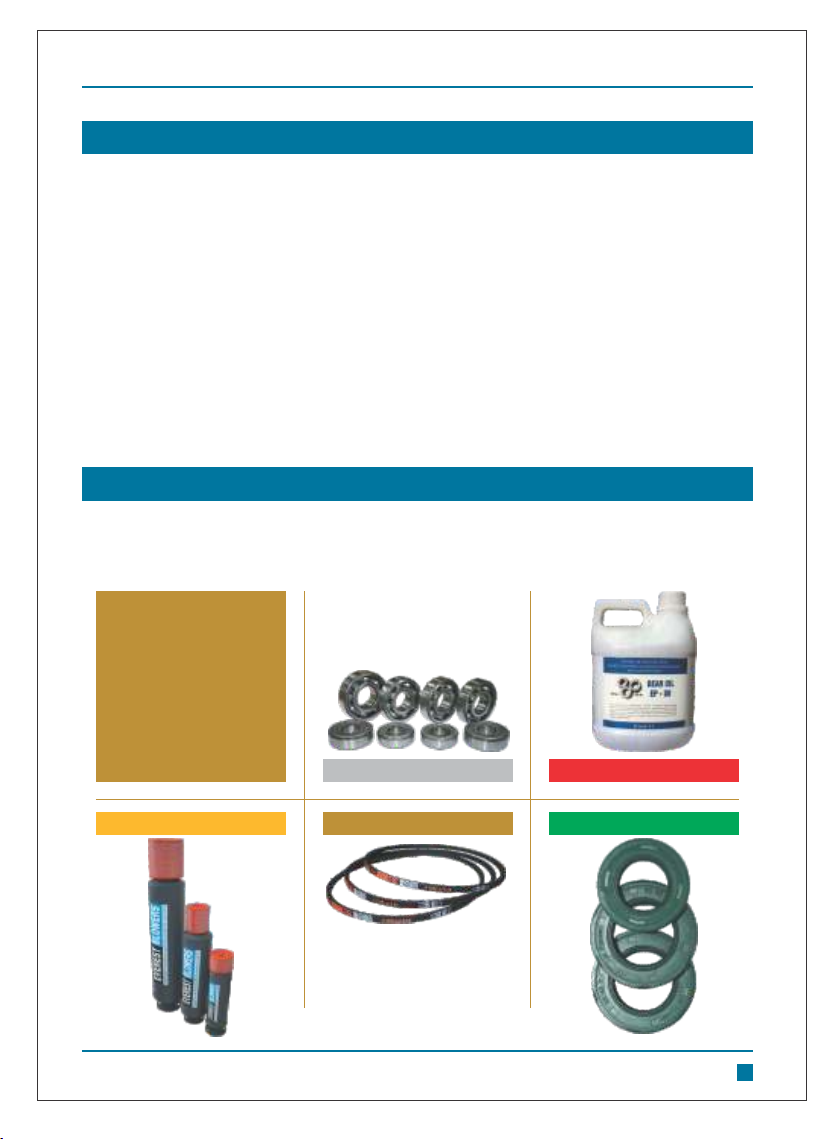

BEARINGS

VEE BELTS

SILENCERS & FILTERS

GEAR OIL

SEALS

Everest

Spares and

Consumables

SPARES & CONSUMABLES

Recommended Spares: Bearings, lip seals/labyrinth seals/piston rings, & gaskets.

Consumables such as filters, vee-belts, lubricating oil & grease do not form a part of spares.

Instruction Manual

© Everest Blowers 2

www.everestblowers.com 19

ORIENTATION OF BLOWERS

All blower models are available in specific orientations (based on direction of flow of air/gas).

Broadly they may be Horizontal flow, Vertical flow or Right Angle Flow.

Suction Discharge

HORIZONTAL FLOW ORIENTATION

VERTICAL FLOW ORIENTATION

Suction

Discharge

RIGHT ANGLE FLOW ORIENTATION

Discharge

Suction

This manual suits for next models

2

Table of contents

Popular Blower manuals by other brands

Lithium Earthwise

Lithium Earthwise LB20024 Operator's manual

EINHELL

EINHELL GE-CL 36 Li E Original operating instructions

EINHELL

EINHELL VENTURRO 18/210 operating instructions

Troy-Bilt

Troy-Bilt 657 Operator's manual

Weed Eater

Weed Eater VS2000BV instruction manual

KRAUSMANN

KRAUSMANN U37020-00 Operation manual