Everest EGC 50 A User manual

VALID FOR UNITS PRODUCED SINCE SEPTEMBER/2015

ICE CUBE MACHINES

EGC 50 A EGC 75 A EGC 100 A / 150 A EGC 150 MA

EGC 150 MA / 140 EGC 150 MA / 250 EGC 300 MA / 250

SINCE 1966

TECHNICAL MANUAL

MARÇO/2017 REV.170331

INDEX

INTRODUCTION/TECHNICAL FEATURES................................................................................................................

MODELS AND POSSIBLE SETTINGS.......................................................................................................................

IMPORTANT INFORMATION..................................................................................................................................

EQUIPMENT INSTALLATION.................................................................................................................................

TYPICAL INSTALLATION DIAGRAM.......................................................................................................................

MAIN COMPONENTS..........................................................................................................................................

OPERATING PRINCIPLE.........................................................................................................................................

1 - CLEANING CYCLE............................................................................................................................................

2 - ICE FORMATION CYCLE...................................................................................................................................

3 - ICE FORMATION CYCLE...................................................................................................................................

4 - OPERATION OF THE TANK THERMOSTAT..........................................................................................................

SCHEDULED MAINTENANCE.................................................................................................................................

NAME OF MAIN COMPONENTS...........................................................................................................................

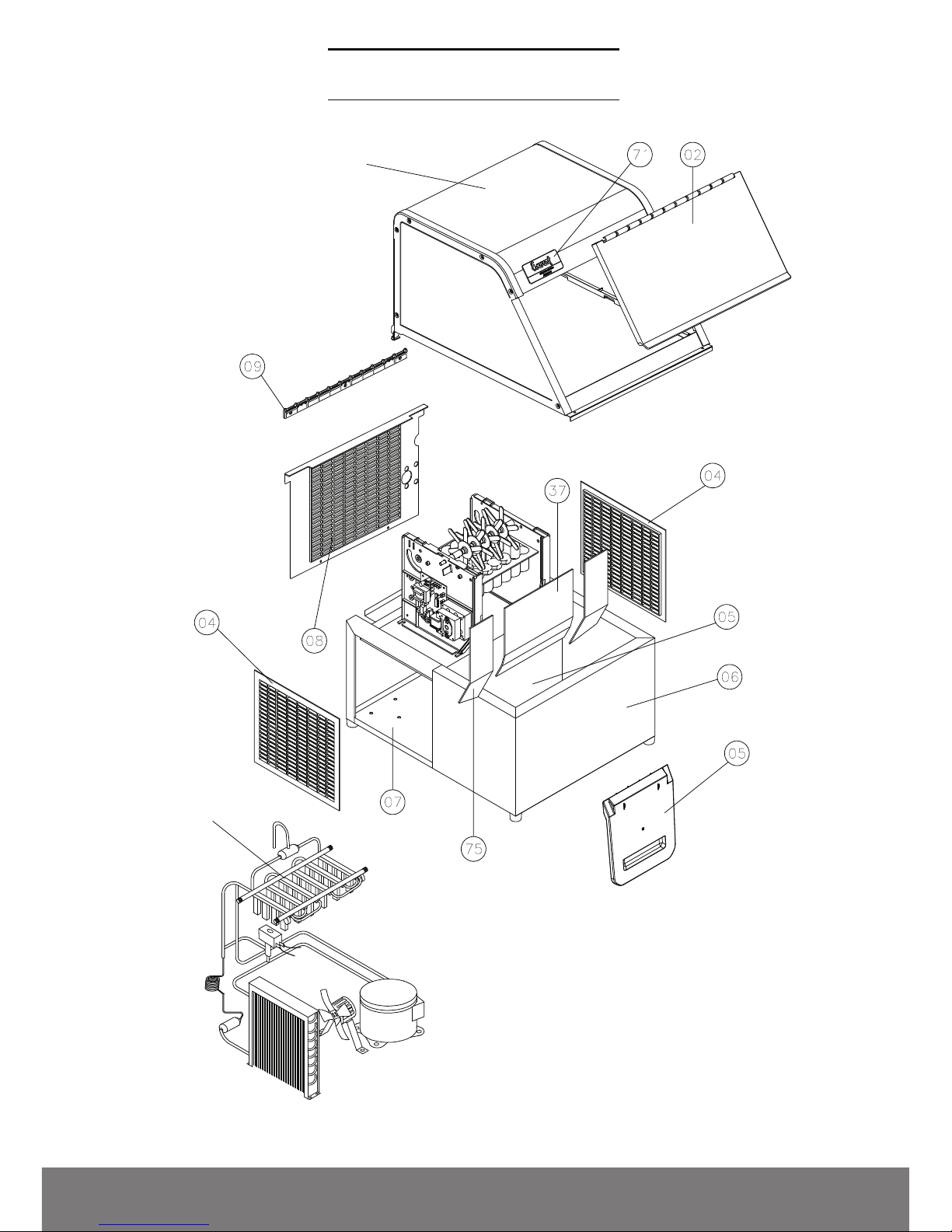

OVERVIEW EGC-50A...........................................................................................................................................

OVERVIEW EGC-75A, EGC-100A AND EGC-150A.................................................................................................

OVERVIEW EGC-150MA......................................................................................................................................

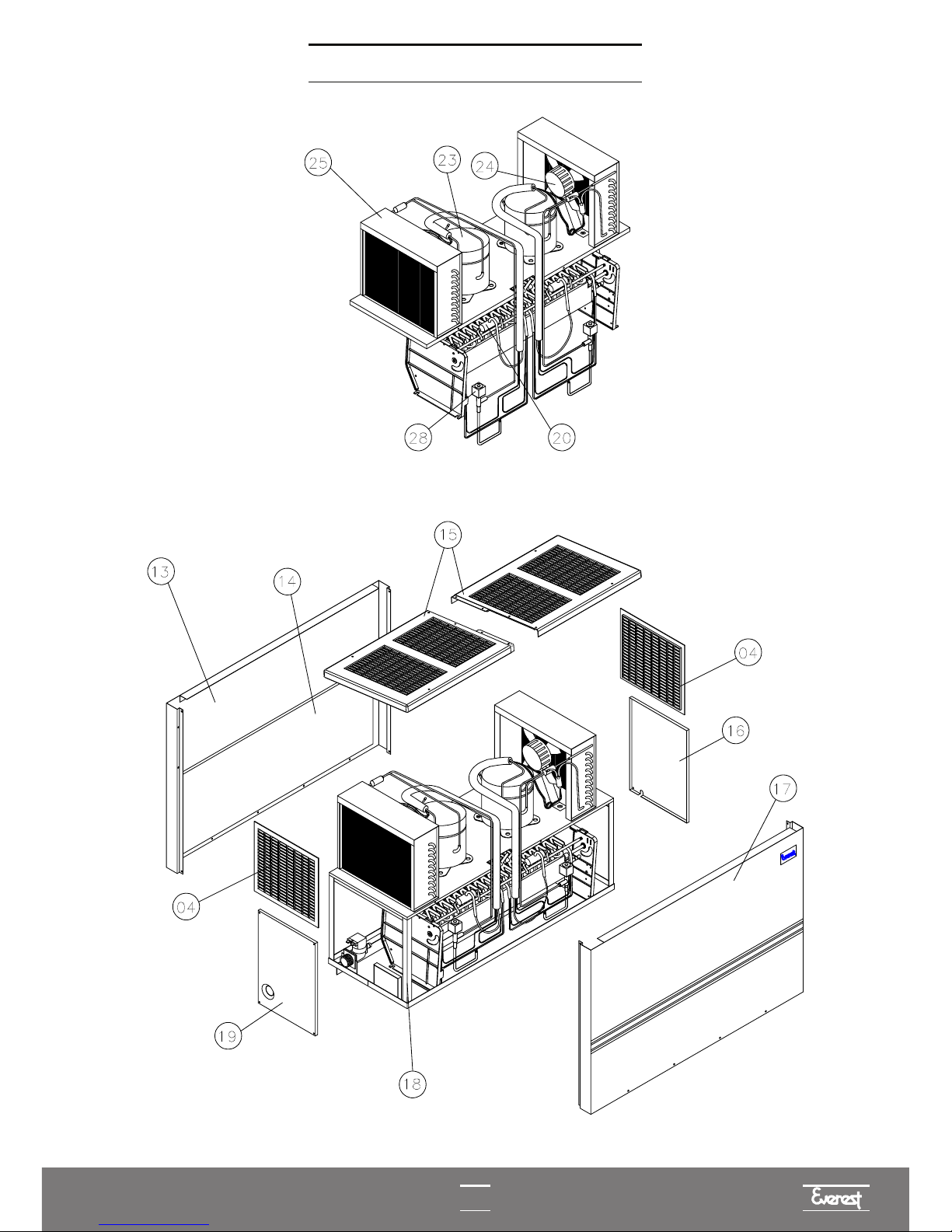

COOLING SYSTEM EGC-50A, EGC-75A, EGC-100A AND EGC-150A......................................................................

COOLING SYSTEM EGC-150MA...........................................................................................................................

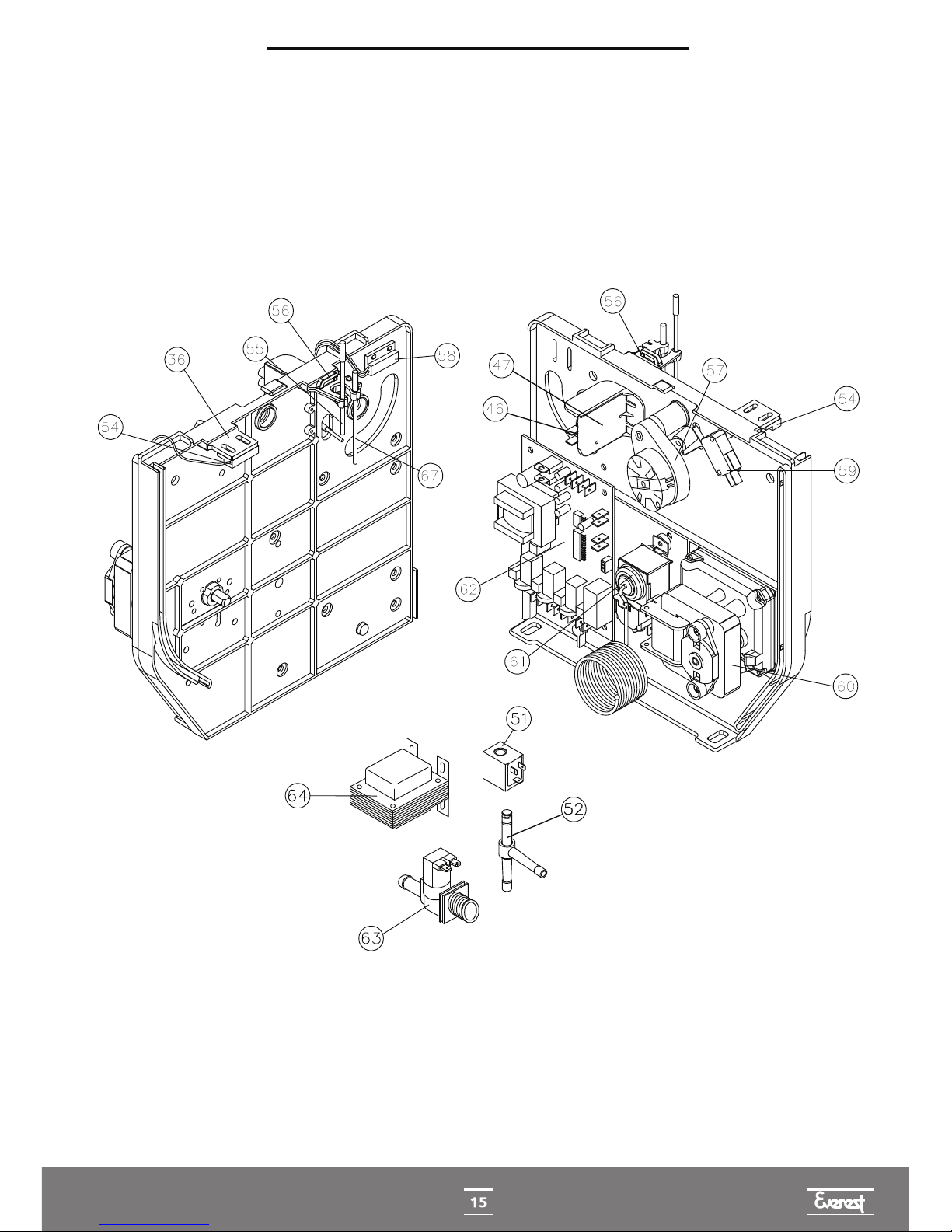

ELECTRICAL ELECTRONIC PART............................................................................................................................

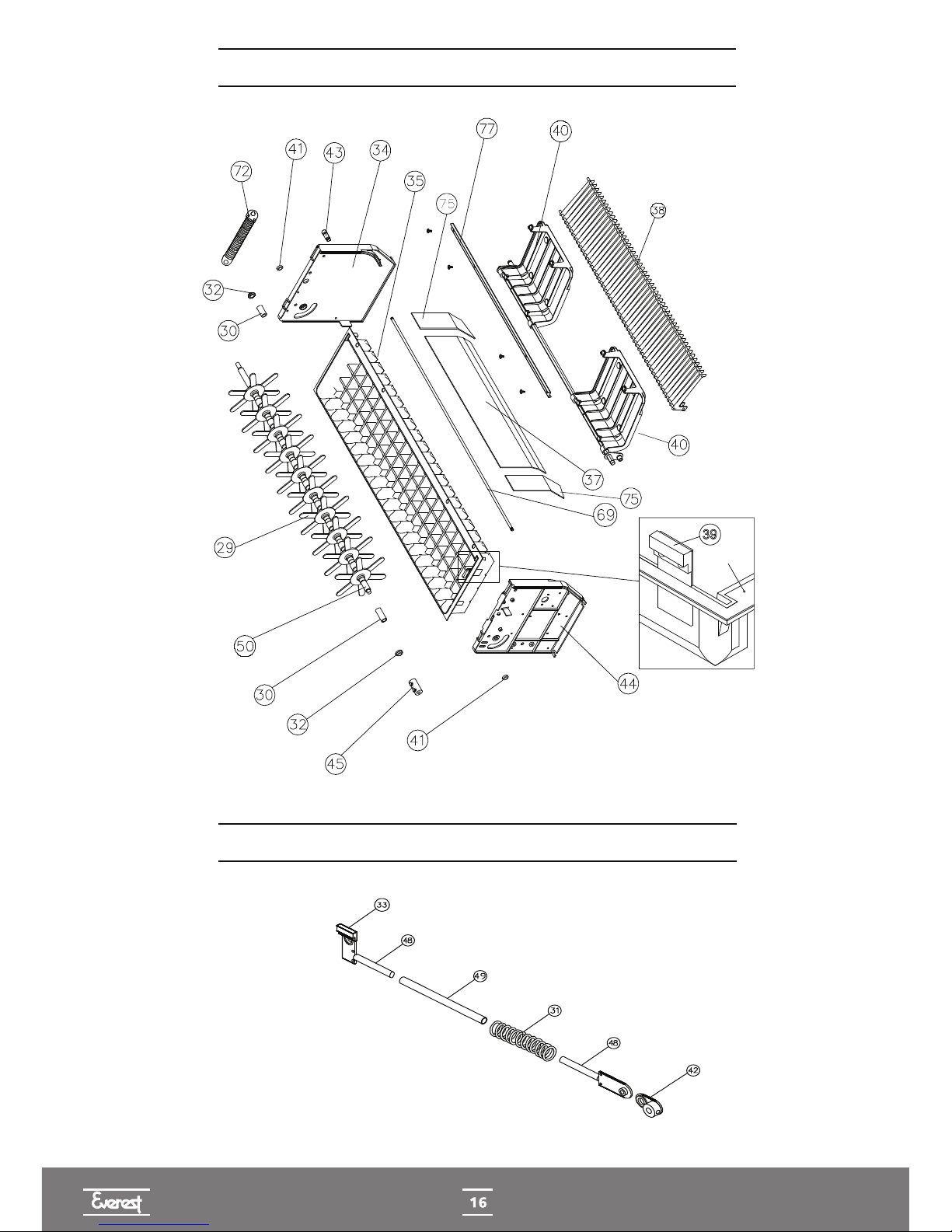

TROUGH DISPLACEMENT SYSTEM.......................................................................................................................

DISPLACEMENT ARM ASSEMBLY.........................................................................................................................

WIRING DIAGRAM EGC-50A, EGC-75A, EGC-100A-220V.....................................................................................

ELECTRICAL DIAGRAM EGC-150A-220V..............................................................................................................

ELECTRICAL DIAGRAM EGC-150MA-220V...........................................................................................................

WIRING DIAGRAM EGC-50A, EGC-75A, EGC-100A-127V.....................................................................................

WIRING DIAGRAM FOR TECUMSEH COMPRESSORS.............................................................................................

WIRING DIAGRAM FOR TECUMSEH COMPRESSORS.............................................................................................

1 - EQUIPMENT FAILURE MANAGEMENT...............................................................................................................

1 - SYMPTOM: WATER SHORTAGE OR LOW WATER FLOW RATE.............................................................................

2 - SYMPTOM: PLASTIC TROUGH DO NOT DESCENDS...........................................................................................

3 - SYMPTOM: TROUGH (35) DESCENDS BUT DOES NOT REACH THE LOWEST POINT..............................................

4 - SYMPTOM: BY-PASS CYCLE OVER 2 MINUTES...................................................................................................

5 - SYMPTOM: TROUGH (35) IS SUSPENDED, BUT DOES NOT REACH THE LOWEST POINT.......................................

6 - SYMPTOM: TROUGH (35) IS SUSPENDED, BUT DOES NOT REACH THE HIGHEST POINT......................................

7 - SYMPTOM: THROUGHOUT THE WATER INLET, THE TROUGH (35) DOES NOT STAY AT THE HIGHEST POINT..........

2 - ANALYSIS OF DEFECTS.....................................................................................................................................

2.1 - MACHINE DOES NOT WORK.........................................................................................................................

2.2 - WATER SHORTAGE OR LOW WATER FLOW....................................................................................................

2.3 - WATER TROUGH GOES UP AND DOWN CONTINUOUSLY...............................................................................

2.4 - CONTINUOUS ENTRANCE OF WATER IN THE TROUGH...................................................................................

2.5 - LOW ICE PRODUCTION.................................................................................................................................

2.6 - MACHINE WORKING BUT DOES NOT PRODUCE ICE.......................................................................................

2.7 - CUBES DO NOT DETACH FROM THE EVAPORATOR ........................................................................................

3 - ADJUSTMENT AND REPLACEMENT OF MAIN COMPONENTS.............................................................................

3.1- DISPLACEMENT SYSTEM AND TROUGH.........................................................................................................

3.2 - ADJUSTMENT OF WATER LEVEL AND HEIGHT OF ICE.....................................................................................

3.3 - AXIS UNSETTLED.........................................................................................................................................

3.4 - CIRCUIT BOARD...........................................................................................................................................

3.4 - CIRCUIT BOARD DOES NOT CONTROL ANY COMPONENT..............................................................................

3.4.1 A - COMPONENTS THAT SENDS INFORMATION TO THE BOARD....................................................................

3.4.1 B- COMPONENTS CONTROLLED BY THE ELECTRONIC BOARD.......................................................................

3.5 - INOPERATIVE WATER VALVE.........................................................................................................................

3.6 - GAS CHARGE/REPLACEMENT OF THE COOLING COMPRESSOR......................................................................

2

4

5

5

6

7

8

8

8

8

8

9

10

11

12

13

14

14

15

16

16

17

17

17

18

18

18

19

20

21

21

22

22

23

23

24

24

24

25

25

25

26

26

26

27

27

28

29

30

30

31

32

33

DEAR USER:

Everest Refrigeração Indústria e Comércio Ltda, congratulates you for choosing to purchase your

Automatic Ice Cube Machine. In our industry, everything was done to make sure that your

machine will have the best performance for many years to come. Your collaboration is required by,

first reading this manual carefully, and then using it as recommended below.

In all of the AUTOMATIC ICE CUBE MACHINE models, improvements were made in mechanics

and electronics that resulted in a 40% reduction in the consumption of waste water,

improvements on the physical appearance of the ice and the ability to identify anomalies in

equipment operation, working to correct and/or protect the equipment, preventing damage to

the main components.

INTRODUCTION

2

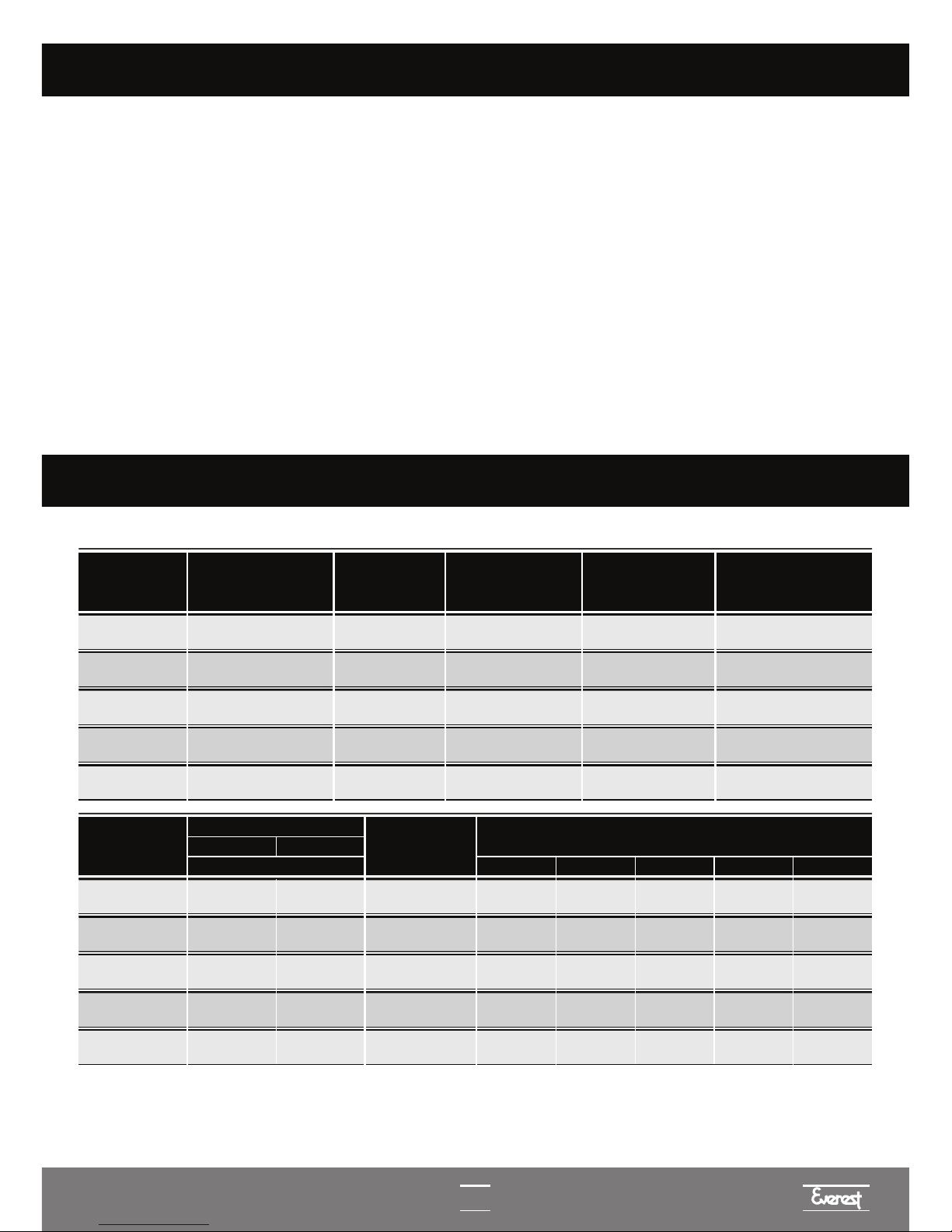

GENERAL TECHNICAL CHARACTERISTICS

MODELO DIMENSÕES

(A/L/P) cm

COMPRESSOR

(HP NOMINAL)

MASSA DO

APARELHO GÁS

(HFC) MASSA DO GÁS

REFRIGERANTE

EGC

75A

EGC

150A 111 x 89 x 54 78 kg 2 x 1/3 R-134a 2 x 225 g

MODEL DIMENSIONS

(A/L/P) cm

COMPRESSOR

(NOMINAL HP)

DEVICE

WEIGHT GAS

(HFC)

WEIGHT OF

REFRIGERANT GAS

EGC

50A

EGC

75A

EGC

100A

EGC

150A

EGC

150MA

61 x 45 x 54

111 x 57 x 54

111 x 89 x 54

111 x 89 x 54

63 x 93 x 35

32 kg

49 kg

61 kg

76 kg

60 kg

1/4

1/3

1/3

2 x 1/3

2 x 1/3

R-134a

R-134a

R-134a

R-134a

R-134a

175 g

220 g

350 g

2 x 225 g

2 x 220 g

MODELO DIMENSÕES

(A/L/P) cm

COMPRESSOR

(HP NOMINAL)

MASSA DO

APARELHO GÁS

(HFC) MASSA DO GÁS

REFRIGERANTE

EGC

75A

EGC

150A 111 x 89 x 54 78 kg 2 x 1/3 R-134a 2 x 225 g

MODEL POWER

watts

PRODUCTION: kg/24hours

at room temperature

EGC

50A

EGC

75A

EGC

100A

EGC

150A

EGC

150MA

380

630

647

1256

1230

VOLTAGE

5.4 A

9.4 A

9.5 A

-

-

ELECTRICAL CURRENT

127V 220V

32ºC

2,7 A

4.7 A

4.6 A

9.3 A

9.3 A

27ºC22ºC 37ºC 42ºC

485052 42 36

7680

82 70 62

98

108114 84 70

152

160166 140 122

144

158

162 130 101

3

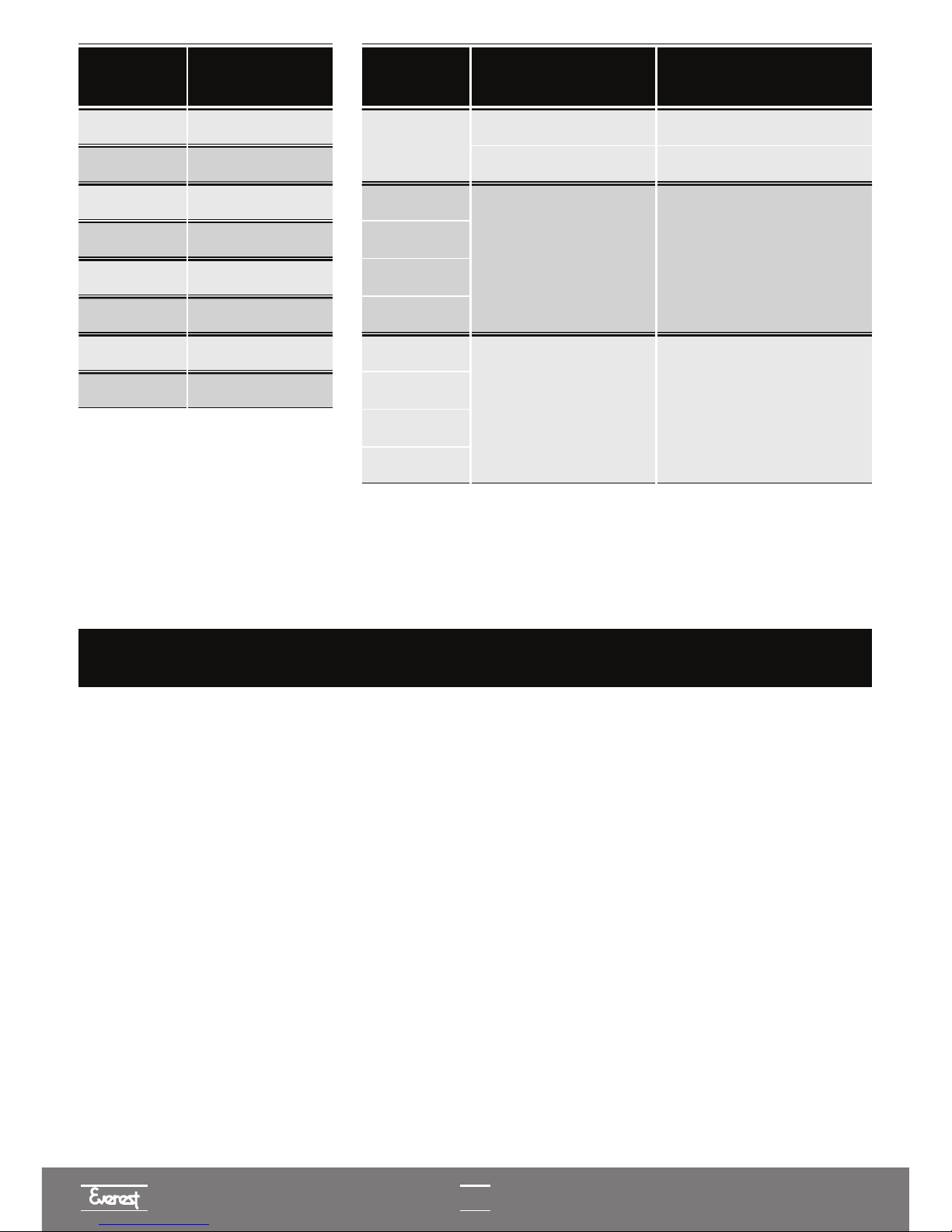

MODELO DIMENSÕES

(A/L/P) cm

MODEL MIN. SECTION OF

THE WIRES (mm2)

EGC

50A - 127V

EGC

50A - 220V

EGC

75A - 127V

EGC

75A - 220V

EGC

100A - 127V

1,5

1,5

2,5

1,5

2,5

EGC

100A - 220V 1,5

EGC

150A - 220V 2,5

EGC

150MA - 220V 2,5

MODEL COMPRESSOR MODEL

EMBRACO FFI 12 HBX

EGC

75A

EGC

100A

EGC

150A

EGC

150MA

TECUMSEH AE4430Y (AE-540)

EMBRACO FFI 8.5 HBK

EGC

50A

TECUMSEH AE4450Y (AE-660)

EGC

75A

EGC

100A

EGC

150A

EGC

150MA

• DEVICE FOR INTERNAL USE (IPX0).

• SUBTROPICAL CLASS DEVICE (CLASS ST)

On the production table, the water inlet temperature should be regarded as 5°C lower than

the room temperature.

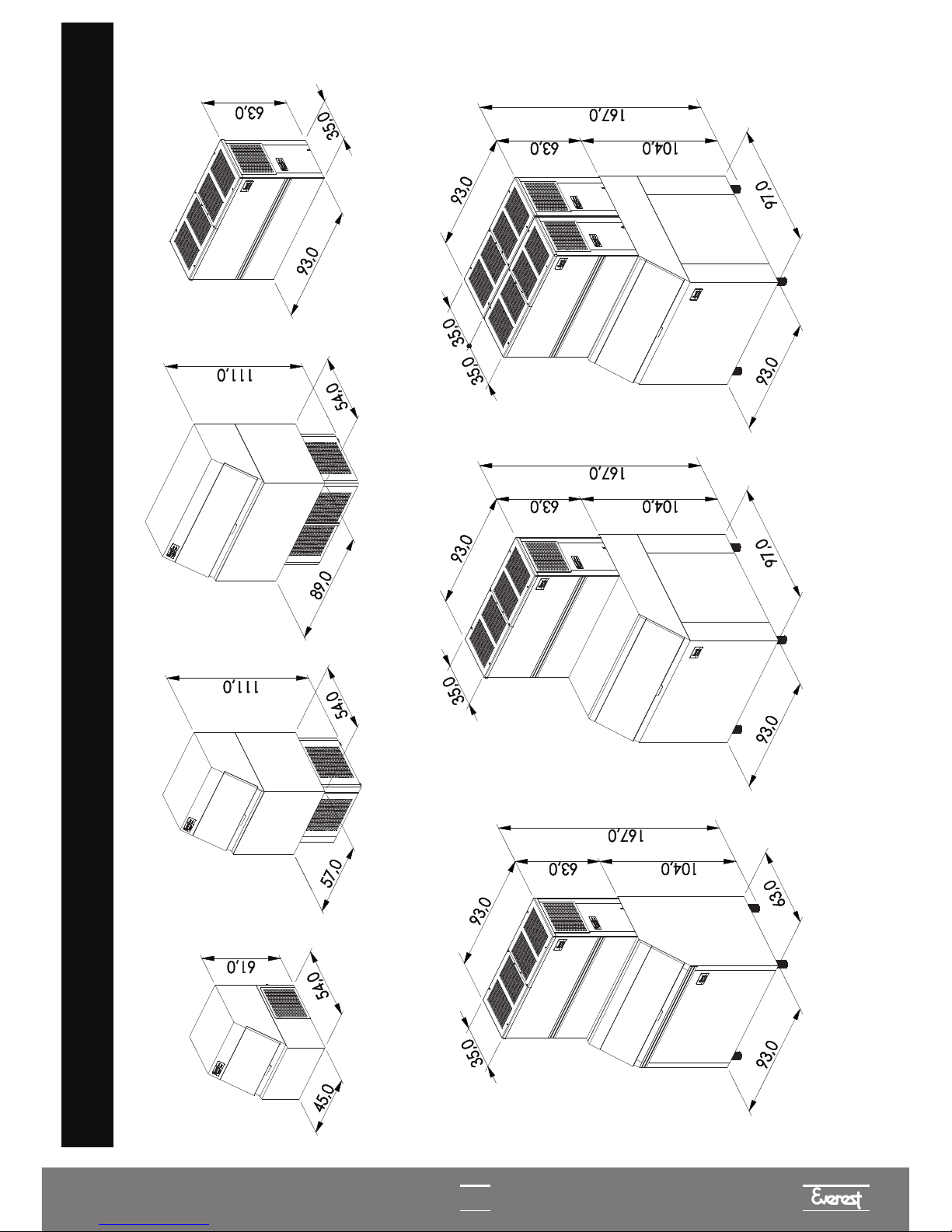

EGC 150 MA / 140 EGC 150 MA / 250 EGC 300 MA / 250

MODELS AND POSSIBLE CONFIGURATIONS

4

EGC 75 A

EGC 100 A / 150 A

EGC 150 MAEGC 50 A

5

I

I

IMPORTANT INFORMATION

Carefully observe the following items upon

equipment receipt:

A • Check for possible damage resulting from

transportation and, should you find any irregularities,

contact your dealer immediately.

B • The water filter, water inlet hose, plastic scoop,

warranty certificate and technical support network can be

found inside the ice storage bin. Notice that the water

inlet hose has a connection that is curved at 90°. This

connection is specific for the machine's water solenoid

valve (63).

C • In model EGC 150M, the items above are inside the

machine.

D • The parts and accessories of the ice bin are inside it.

Warning: Only connect the equipment to the drinking

water supply.

The removable hose set provided with the

ice machine must be connected to the water

network. It is forbidden to reuse the hose or

use a hose from a washing machine.

Do not store explosive substances, such as

aerosol cans containing a flammable

propellant in this device.

This device is dedicated to domestic

use, such as:

• Kitchen areas in stores, offices and other

work environments;

• Farm houses, hotels, motels and other

types of residential environments;

• Environments like hostels;

• Caterers and other non-retail applications.

EQUIPMENT INSTALLATION

Observe the following items carefully when installing the equipment:

A • Check if the place has drinking water.

B • The equipment must be leveled.

C • Check if the fan blades (24) turn freely.

D • Make sure the voltage of the power supply network is in accordance with the one identified on the power

cord of the equipment.

For 127V from 103V to 135V

For 220V from 198V to 242V

E • The plug used allows your equipment to be grounded, thus avoiding the occurrence of electrical

discharges. If the electrical installation (NBR14136) is not in compliance, the installation will be

carried at the user's own risk.

F • The water supply network shall be provided with a specific valve to use the machine. The diameter of the

pipes should be at least V2"(12.7mm), with maximum pressure recommended for use of 0.392 MPa

(4.0kgf/cm2) and the minimum pressure of 0.029 MPa (0.3kgf/cm2).

G • The water is removed using a flexible hose, which should be placed in the sewage entry point below the

machine level, and with the capacity of absorbing at least 3 liters per minute. In the EGC-150MA model, the

sewage entry point should be below the tank level.

This equipment is not intended for use by people - including children - with reduced physical, sensory or

mental capacity, or by people with lack of experience and knowledge, unless they have received instructions

regarding the use of the equipment or they are under the supervision of a person responsible for their safety. It

is recommended that children be supervised to ensure that they do not play with the equipment.

6

I

TYPICAL INSTALLATION DIAGRAM

1) Ice cube machine.

2) Female electrical outlet.

3) Water supply valve.

4) Water filter.

5) Hydraulic connection filter / water inlet hose.

6) Flexible water inlet hose.

7) Flexible water outlet hose (for sewage entry point).

Notes:

1 • Diagram for installer's guidance only.

2 • Items 2 and 3 of the installation diagram are not an integral part of the equipment.

3 • The buyer is responsible for installing the equipment.

4 • For the EGC-50A machines, provide a minimum space of 15cm at the sides, rear and top part for

ventilation.

5 • For the EGC-75A, EGC-100A, EGC-150A and EGC-150MA machines, provide a minimum space of

20cm on the sides and rear for ventilation.

7

I

A • Evaporator (20): Made of copper with nickel finishing, it has vertical cube makers around which

the ice cubes are formed.

B • Gear motor (60): It moves the plastic trough (35).

C • Micro gear motor (57): It moves the finned axis in order to stir the water, improving the ice

quality. Triggers the end of cycle microswitch.

D • End of cycle microswitch (59): It sends a signal to the circuit board signaling the end of the ice

formation cycle.

E • Upper reed switch (54): Positions the trough at the highest point.

F • Lower reed switch (58): Positions the trough at the lowest point.

G • Mobile water sensor (55): Determines the water level, which defines the ice cube's height.

H • Tank's thermostat (61): Turns the machine off when the tank is filled with ice and turns it on again

when the ice is consumed.

I • Gas solenoid valve (28): Allows the hot coolant gas to enter the evaporator directly, causing the ice

to detach therefrom.

J • Water solenoid valve (63): Its function is to fill the water trough at the beginning of each cycle.

K • Plastic Trough (35): Container for water storage where the ice cubes are formed.

L • Micro switch of the fan (46): Turn off the fan when the trough is lowered to perform by pass,

improving the detachment of ice cubes.

M • Compressor (23): Compresses the refrigerant gas, which is designed to work under medium and

high return pressure, necessary characteristics for an ice machine.

N • Circuit board (62): Receives information from the water level sensor, end of cycle microswitch,

upper reed switch, lower reed switch and it also controls the operation of the water solenoid valve, gear

motor, micro gear motor and gas solenoid valve. Sends the signal to the LEDs in case of necessary

maintenance and water shortages.

O • Fan (24): Main component to perform condensation.

MAIN COMPONENTS

OPERATING PRINCIPLES

I

1 - CLEANING CYCLE

I

1.2 - Cleaning of the Plastic Trough (35).

The plastic trough (35) will reach its maximum lower position to discharge the water from the last cycle which was

interrupted by the shutdown of the Machine. This cleaning cycle is necessary due to safety and hygiene reasons,

because we could not quantify the time that the Ice Machine is turned off, with water inside the plastic trough (35).

1.1 - Initialization

Every time the machine is energized (connected to the power grid, switched on again by the tank's thermostat

(61) or after a power surge), the cleaning cycle for the plastic trough (35) and evaporator (20) starts up. The

signaling LEDs - LD1 (maintenance), LD2 (water shortage) - for the circuit board (62) and the LED board (68),

light up for a period of 02 seconds, in order to inform the start-up of the system's operation.

2 - ICE FORMATION CYCLE

2.1 - Formation

After the cleaning cycle, the plastic trough (35) returns to the highest position, the circuit board (62) switches on

the water valve (63) to let water in the the plastic trough (35), the mobile water sensor (55) indicates to the

circuit board (62) when the water level of the plastic trough (35) touches it, and switches off the water valve (63).

With the cooling system in operation, the formation of ice around the cube makers in the evaporator begins (20),

such cubes will grow to a thickness that obstructs the passage of the plastic fins (29) which rotate continuously.

3 - ICE DETACHMENT CYCLE

The purpose of the tank thermostat (61), whose bulb is fixed below the equipment's water draining tray, is to

switch the equipment off when it is filled with ice and turn it back on when the ice level in the tank (6) decreases.

In the EGC-50A model, the thermostat bulb is fixed in the tank. (6)

3.1 - “Quick Stop”

After 45 seconds, the circuit board (62), switches on the gear motor (60) to lower the plastic trough (35) and

discharge the residual water from the ice formation cycle. In this lowering interval, the plastic trough (35) will

perform a temporary stop, this action avoids the residual water - which is close to zero degrees - from reaching

the tank thermostat (61) and switching off the Ice Machine unnecessarily.

4 - OPERATION OF THE TANK THERMOSTAT

8

1.3 - Evaporator Cleaning (20).

With the plastic trough (35) at the lowest position, the gas solenoid valve (28) is activated for 45 seconds, cleaning

the evaporator from ice cubes.

3.2 - Ice detachment cycle.

With the plastic trough (35) positioned at the lowest point, the by-pass cycle begins. The circuit board (62)

switches on the gas solenoid valve (28), which allows the hot gas to enter directly into the evaporator (20),

detaching the ice cubes. After 45 seconds of By Pass, the circuit board (62) switches on the micro gear box (57)

for 5 seconds and checks whether the finned axis (50) is still blocked by any ice cube. If the finned axis (50) is

blocked, the by-pass time is increased by 5 more seconds, as often as needed, for up to 2 minutes. In case it is

unblocked, the circuit board (62) switches off the gas solenoid valve (28) and switches on the motor gear (60),

returning the plastic trough (35) to the highest point and restarting a new ice formation cycle.

2.2 - Growing cycle

When the ice cubes grow up to a thickness that prevents the rotation of the plastic fins (57), the micro gear

motor coupled to the finned axis (50) activates the end of cycle micro switch (59), indicating to the circuit board

(62) that the ice formation cycle is completed. In this moment, the circuit board (62), switches off the micro gear

motor (57). The system will wait for 10 seconds with the plastic trough (35) on the highest position, allowing

the residual water from the ice formation cycle to be used, increasing the volume of ice cubes and reducing the

volume of water discharged.

1.4 - The fan (24).

The fan (24) is activated through the micro switch (46). The micro switch (46) is fixated on the left panel of the

cylinder head (44), in a way that its rod is activated by the plastic trough (35). When the trough is lowered, the micro

switch (46) opens and it switches off the fan (24). This action assists the detachment of the ice cubes. When the

BYPASS is finished, the plastic trough (35) is elevated, the micro switch (46) is closed and the fan is switched on (24)

9

SCHEDULED MAINTENANCE

4 • The following items must be checked during scheduled maintenance:

A • Check and clean the screen of the water solenoid (63) valve.

B • Clean the gas condenser (25).

C • Clean the plastic trough (35) and the trough's water sensors (55 and 67).

D • Clean the ice tank (6), checking for incrustation or blocking, both in the draining tray and the tank's drain (6).

E • Check if the machine is leveled.

F • Check if the fan blade (24) rotates freely and if it is well balanced (there should be no vibrations when it is

operating).

G • Check if the finned axis (50) rotates freely , also observing gaps in the finned axis' bearings (41). (see p. 30

item 3.3)

H • Check the water level in the plastic trough (35). The level determines the size of the ice cubes. If you want to

increase or decrease cube size, verify item 3, sub-item 3.2, failure management, p. 30 (Adjustment of water level

and ice cube height) contained in this manual.

I • Check the wear of the sintered bronze bushings (32) on the plastic trough (35).

J • Check the filtering cartridge. When replaced, it should be by the same or similar model, in order to reduce the

corrosive effect of chlorine on the stainless steel, as well as ensuring the best quality of ice produced.

Before starting maintenance, unplug the machine and remove the machine's cover (1), except for

the EGC-150MA model.

For the EGC-150MA model: Remove the right side plate (16), loosen the fixation screws, open the frontal lid or

the right side plate (16).

1 • Maintenance and cleaning schedules are suggested to keep your equipment in good condition. Cleaning

varies especially depending on the location of the installation, water conditions and the volume of ice produced.

We recommend that maintenance be carried out every 6 months.

2 • The replacement of the power cord should only be carried out by the manufacturer. Authorized Technical

Assistance or a qualified professional, in order to avoid risks for the user and damage to your equipment.

3 • Filtering Cartridge Replacement.

Your equipment is supplied with an activated carbon filter. The service life of the filter is 6 months and it

depends on the quantity and quality of water passing through the filter cartridge, which aims at retaining

impurities, reducing chlorine, strange odors and flavors in the water, as well as minimizing the corrosive

effect of chlorine on the stainless steel. The filtering cartridge, which is located inside the filter, does not

allow cleaning after saturation, so it should be changed.

10

COVER

FRONT COVER EGC-50Atf 5A/100A/150A

PLASTIC GRATING EGC-50A/75A/100A/150MA

WATER COLLECTOR OF THE EGC-50A TANK

ICE TANK HOUSING

EGC-50A COOLING UNIT BASE

REAR GRATING EGC-A

COVER'S HINGE

WHEEL

EGC-75A/100A/150A COOLING BASE

EGC-75A/100A/150A COLUMN

EGC-150MA BACK PLATE

BACK PLATE INSULATION EGC-150MA

UPPER GRATING OF THE EGC-150MA

RIGHT SIDE PLATE EGC-150MA

EGC-150MA FRONT PLATE

EGC-150MA STRUCTURE

EGC-150MA LEFT SIDE PLATE

EVAPORATOR

TROUGH STOPPER

EGC-100A/EGC-150A/EGC-150MA

SUPPORT BRACKET OF THE EVAPORATOR

FAN

COMPRESSOR

CONDENSER

GAS FILTER

CAPILLARY TUBE

GAS SOLENOID VALVE (ASSEMBLY)

PLASTIC FIN

PLASTIC SPACER

SPRING

SINTERED BRONZE BUSHING

LOWER MAGNET

PLASTIC TROUGH

RIGHT PANEL CYLINDER HEAD

UPPER REED SWITCH SUPPORT

EVAPORATOR PROTECTION PLATE

LOWERING ICE GRATING EGC-75A EGC-100AE EGC-150A

NAME OF MAIN COMPONENTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

24

23

25

26

27

28

29

30

31

32

33

35

37

34

36

38

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

76

75

PLASTIC TROUGH SUPPORT ASSEMBLY

FINNED AXIS' BEARING

LEVER-ARM REDUCER

SPRING PIN

LEFT PANEL OF CYLINDER HEAD

MICRO GEAR MOTOR CONNECTION BUSHING

FAN MICROSWITCH

MICROSWITCH PLASTIC SUPPORT

MOBILE ARM

SPACER TUBE OF THE EGC-A ARM

FINNED AXIS

BY-PASS OF GAS SOLENOID COIL

BY-PASS OF GAS VALVE HOUSING

UPPER REED SWITCH

MOBILE WATER SENSOR

WATER LEVEL SENSOR SUPPORT

MICRO GEAR MOTOR

LOWER REED SWITCH

END OF CYCLE MICROSWITCH

GEAR MOTOR

TANK THERMOSTAT

CIRCUIT BOARD

WATER SOLENOID VALVE

TRANSFORMER 127/220V - 80VA

FIXED WATER SENSOR

PANEL SUPPORT AXIS

REAR CABINET COVER

FRONT LABEL

SPRING ASSEMBLY

FRONTAL GRATING EGC-A

REAR GRATING EGC-A

SIDE GRATING EGC-75A/100A/150A

RIGHT/LEFT SIDE PROTECTION PLATE

UPPER MAGNET

39

77

78

TROUGH SUPPORT RAIL

FUSE HOLDER

OVERVIEW EGC-50A

COVER

COOLING SYSTEM

OVERVIEW EGC-75A, EGC-100A AND EGC-150A

In the EGC-150A model, there are two compressors and two fans.

13

I

OVERVIEW EGC-150MA

I

14

COOLING SYSTEM

EGC-50A, EGC-75A, EGC-100A AND EGC-150A

I

COOLING SYSTEM EGC-150MA

I

ELECTRICAL/ELECTRONIC PART

TROUGH DISPLACEMENT SYSTEM

DISPLACEMENT ARM ASSEMBLY

TROUGH

ELETRICAL DIAGRAM EGC-50A, EGC-75A, EGC-100A - 127V

ELETRICAL DIAGRAM EGC-50A, EGC-75A, EGC-100A - 220V

ELETRICAL DIAGRAM EGC-150A, EGC-150MA - 127V

FAN

FAN MICROSWITCH

TRANSFORMER

THERMAL

PROTECTOR

PLUG

FUSE HOLDER

TANK

THERMOSTAT

CIRCUIT

BOARD

MICRO GEAR MOTOR

END OF CYCLE

MICROSWITCH

REDUCER

GAS VALVE

WATER VALVE

WATER

LEVEL

SENSOR

RELAY

START-UP

CAPACITOR

START-UP

CAPACITOR

FAN

THERMAL

PROTECTOR WATER

LEVEL

SENSOR

MICRO GEAR MOTOR

END OF CYCLE

MICROSWITCH

CIRCUIT

BOARD

REDUCER

GAS VALVE

WATER VALVE

FAN MICROSWITCH

FUSE HOLDER

TANK

THERMOSTAT

RELAY

FAN THERMAL

PROTECTOR

FAN

START-UP

CAPACITOR

THERMAL

PROTECTOR

START-UP

CAPACITOR RELAY

WATER

LEVEL

SENSOR

CIRCUIT

BOARD

MICRO GEAR MOTOR

END OF CYCLE

MICROSWITCH

GAS VALVE

GAS VALVE

WATER VALVE

TANK

THERMOSTAT

FUSE HOLDER

TRANSFORMER

FAN

MICROSWITCH

REDUCER

18

ELECTRICAL DIAGRAM EGC-150A, EGC-150MA - 220V

ELECTRICAL DIAGRAM FOR TECUMSEH COMPRESSORS

ELECTRICAL DIAGRAM FOR EMBRACO COMPRESSORS

C OF COMPROSSOR

MODEL FFI-12HBX

RELAY START-UP

CAPACITOR

PHASE

PHASE

THERMAL PROTECTOR

PHASE

THERMAL PROTECTOR

PHASE

START-UP

CAPACITOR

RELAY

MODEL AE 4450 Y

THERMAL

PROTECTOR

CIRCUIT

BOARD

MICRO GEAR MOTOR

END OF CYCLE

MICROSWITCH

REDUCER

GAS VALVE

WATER VALVE

WATER

LEVEL

SENSOR

GAS VALVE

THERMAL

PROTECTOR

START-UP

CAPACITOR

START-UP

CAPACITOR

FAN MICROSWITCH

FAN

FAN

RELAY

TANK

THERMOSTAT

FUSE HOLDER

19

EQUIPMENT FAILURE MANAGEMENT

The circuit board (62) is equipped with a program that monitors the operation of the ice machine.

When there is an anomaly in this function, it controls the main components (gear motor (60), micro

gear motor (57), gas solenoid valve (28) and water solenoid valve (63)), in order to resolve the

aforementioned anomaly or protect the equipment in general. Read carefully the items below

related to equipment failure and its probable causes.

This manual suits for next models

6

Table of contents

Popular Ice Maker manuals by other brands

U-Line

U-Line UMCR014-SC01A User guide & service manual

Scotsman

Scotsman Prodigy ELITE MC222 ECC Installation and user manual

Sub-Zero

Sub-Zero Undercounter Ice Machine Installation & operation guide

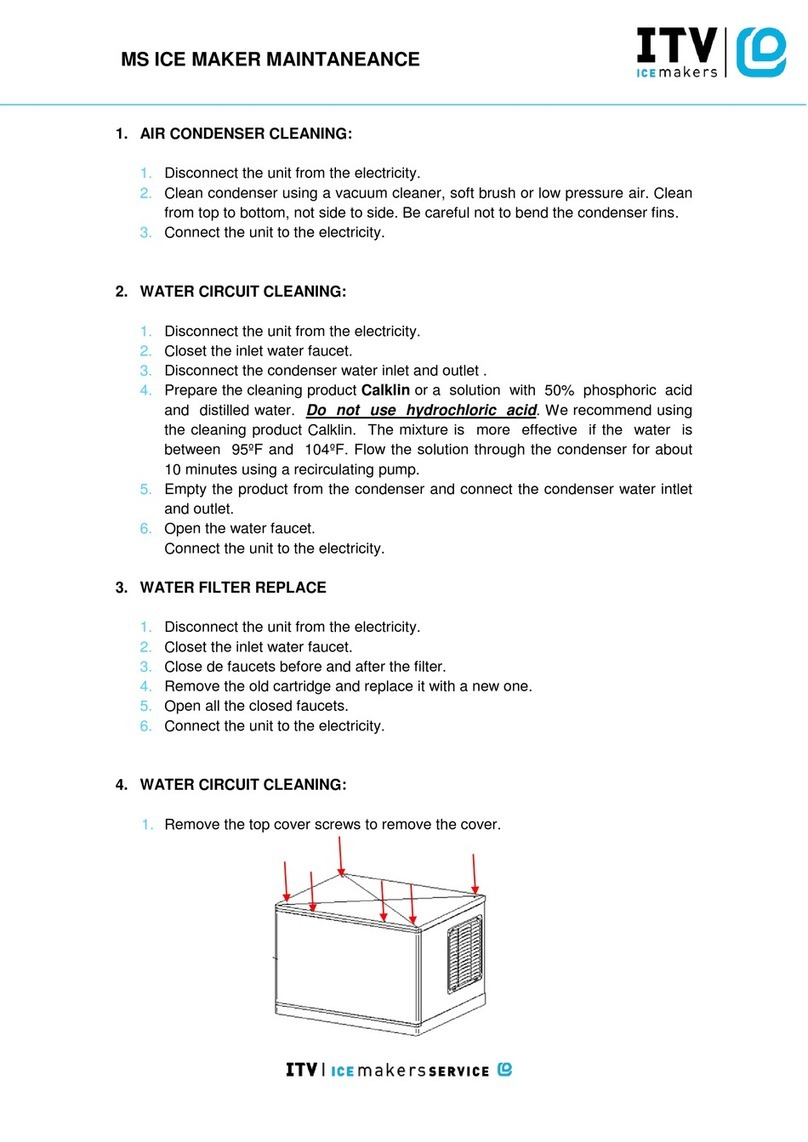

ITV ICE MAKERS

ITV ICE MAKERS MS Series maintenance

Diamond

Diamond ICE90MA Instructions for installation, use and maintenance manual

Hoshizaki

Hoshizaki KM-1601SRH parts list