EverExceed uXcel Series User manual

uXcel series charger

user manual

Everexceed Corporation

1

Thank you for using the products of EverExceed.

Please strictly follow all safety instructions and instructions in the manual before using the

machine. In the absence of complete reading. Please do not operate this machine until some

safety instructions and instructions have made.

Please take good care of this product manual so that you can check it later.

Due to the continuous updating of the technical system, some contents of this manual may

be changed, and The company reserves the right to improve the technology without prior

notice.

Please keep this manual to the end operator and maintenance personnel.

Safety Precautions

Please do not install, operate, maintain or examine the equipment before reading the

user manual, service materials carefully and using it correctly.

Danger!!

Incorrect operating may cause the hazardous situation which will result in death or

serious injury

Notice!!

Incorrect operating may cause the hazardous situation which will result in minor or

moderate injury, or direct economic loss, or hardware damage of equipment. Notice: the

matter of “notice” may also result in serious consequences depending on different

situation. Please follow the two precautions for they are important to the person

concerned.

2

Safety Instructions

1).Avoid electric shock

Danger!!

Please do not touch any part of the battery or the frame, electrolyte, cooling water of

the battery by hand when the equipment charging up the battery. Operator shall wear

insulative waterproof rubber shoes and gloves to operate the battery, or may result in

electric shock injury accident.

Please do not operate the equipment when opening the door of equipment, or may

touch the high voltage terminal and result in electric shock accident.

Keep the equipment off-position when connecting the battery, or may result in electric

shock or injury.

Please do not open the equipment when powering on or operating, or would get an

electric shock.

Please do not approach nearby ground when the equipment is on-position because in

the process of charging, the output positive and negative side would in high pressure

and the ground would have leakage current from the frame. The ground nearby would

in high pressure.

Please do not touch the DC output end in high pressure state, or may result in electric

shock.

When Wiring or examining, power shall be disconnected and 10 minutes later,

detecting the residual voltage disappearing by multimeter, or may result in electric

shock accident.

Please do not maintain the equipment when the DC output end still connecting the

battery even though the power is at a off-position state. Please maintain without

connecting the battery, or may result in electric shock accident for the battery voltage

attaches to the equipment through output cable and the equipment still in high

pressure.

The equipment shall use third-level or above grounding method.

Please do not change the fuse when charging with electricity, or may result in electric

shock.

Please do not change the fuse when the equipment outputting and connecting the

battery.

Please do not operate the switch by wet hand to avoid electric shock.

The operation including wiring and examination shall be conducted by professional

technician.

Please do not damage, stress, clamp or make the input and putout cable carry heavy

objects, or may result in electric shock.

The battery rack or frame shall use third-level or above grounding method.

3

2).Avoid fire

Caution!!

The equipment shall be installed in ventilated situation. Keep the around distance of the

equipment 0.5 meters or more and the top and bottom vent shall not be blocked by

objects. Do not install near the flammable and explosive objects, or may result in

Please disconnect the power supply wiring and output battery wiring when the

equipment breaking down. The keeping flowing high current may result in fire.

Please use the fuse of prescribed specification or with the same performance. Using the

fuse of different model or different performance may result in fire.

3).Avoid Injury

Caution!!

The voltage of each terminal shall be the regulated voltage to avoid bursting and

damaging

Always ensure that the output positive and negative poles of the equipment are

connecting correctly with the positive and negative pole of the battery to avoid bursting

and damaging the battery.

Do not touch the equipment when connecting or just disconnecting the power supply

for the temperature of the equipment is high which results in scalding.

The input and output cable shall be connected according to the user manual. Orit may

result in bursting and injuring accident.

4

Other Precautions

Please pay attention to the following precautions to avoid accident, injury and electric shock

etc.

1).Transition and Installation

Notice!!

Please use accurate lift appliance when transiting the product to avoid injuring.

Please make sure the place could stand the weight of the equipment to avoid injuring

resulted by the problem of weight.

Please do not operate when the equipment injuring or lacking components.

Please transit by the bottom other than by the lifting padeyes, or may result in

injuring or falling off.

Please check the left and right vent of the equipment not blocking by objects.

Please keep the screw, the debris of cable or other conductive body or oil

combustible out off the equipment.

Please use in the following conditions.

Conditions

Ambient temperature

-100C to 40℃no freezing

Ambient temperature

90%RH no condensation of moisture

Storage temperature

-20℃to 60℃

Environment

Indoor(no corrosive gas, combustible gas, oil

pollution)

Altitude

under 2km

2). Wiring

Notice!!

Please correctly connect the positive and negative poles to the battery. In corrective

connection may injury the battery.

Please correctly connect the input and output cable according to the requirement of

the following drawing.

3). Trial Run

Notice!!

Please trial run according to the operation specification.

5

4). Operation

Notice

Please operate according to the operation specification.

Please take relevant measures to radiate the equipment, or the equipment may be

overheating and damaged because of the increasing ambient temperature.

Please check the nominal parameter values of the equipment when changing the

trigger board or touch panel. The mismatched nominal parameter could result in

abnormal charge and damage the battery.

Please trial run after maintaining the equipment.

The equipment unused for a long time shall keep away from dampness and keep in

seal. It must be checked and trial run before being used.

Power supply network shall have sufficient capacity.

5).Maintenance, check and components change

Notice!!

The setting parameters shall be the same with the nominal parameters of the

equipment when changing the touch panel.

The substituted components shall be the same prescribed specification or the same

performance.

The equipment shall be checked by professional.

6

Content

Safety Instructions..................................................................................................................... 2

Other Precautions ..................................................................................................................... 4

1. Overview................................................................................................................................ 7

2.Technical Parameters ............................................................................................................. 7

2.1. Product model and implication .................................................................................. 7

2.2. Working condition ...................................................................................................... 7

2.3. Performance parameters ........................................................................................... 8

3.Systematic principle ............................................................................................................... 9

3.1、System operating principle....................................................................................... 9

3.2、Circuit schematic diagram ........................................................................................ 9

4.Installation............................................................................................................................ 10

4.1. Safety precautions.................................................................................................... 10

4.2 Installation instructions............................................................................................. 10

5. Operating instructions......................................................................................................... 10

5.1 Panel display and description.................................................................................... 10

5.2 Touch panel operating............................................................................................... 12

5.3 Start-up debugging

...................................................................................................... 20

6. Trouble shooting

................................................................................................................... 21

7. Maintenance

......................................................................................................................... 22

7.1 Routine inspection and regular inspection

................................................................... 22

8.Warranty service

.................................................................................................................... 23

Attachment: control panel diagram and description.............................................................. 23

7

1. Overview

This manual makes comprehensive introduction of uXcel charger series, presenting the

working principle, systematic structure, usage and maintenance of the chargers in detail.

Hope it would be convenient for the user.

The product applies to the charging of all kinds of lead-acid batteries, alkaline batteries and

the power supply of DC load. The charger has reasonable and compact configuration. Under

the digital IC, the operation of the charger is convenient and reliable with the charging mode

of constant voltage, constant current and cycling. When operating, the operation panel

works out the procedure in advance. After working out, it starts charging. The whole

charging process is auto-complete. The important component, transformer, adopts

high-durable enameled wire, which could reach H-level insulation grade. The power

component adopts aluminum profile and high-power SCR component of cake shape. The

product has superior performance and stable operation. In addition, it has long-distance

centralized controllable function, which could arrange real time monitoring management for

system by computer and mobile phone.

2.Technical Parameters

2.1. Product model and implication

uXcel □V / □A

Rated current

Rated voltage

Product series

The rated DC Output current: 20A, 40A, 50A, 80A, 100A, 160A, 200A, 250A, 315A, 400A etc.

The rated Output voltage: 24V, 48V, 110V, 200V, 220V, 300V, 400V, 500V, 600V etc.

Note: the particular specification could customize.

2.2. Working condition

Input power: three phase AC400V 50Hz the allowable voltage fluctuation range of

power grid is ±10%.

Equipment power: 16.5KW

The rated DC Output voltage: 330V

The rated DC Output current: 50A

(Note: The rated DC Output voltage means the max charge voltage. If the input AC voltage of

the line is lower than the nominal voltage. The DC output current means the max charge

current.)

8

Charging functions: constant current, constant voltage, current limiting, voltage limiting and

cycling.

The accuracy for constant current: the accuracy for constant current is less than ±1% when

the rated value ranges from 20% to 100%

The accuracy for constant voltage: the accuracy for constant voltage is less than ±1% when

the rated value ranges from 20% to 100%.

The running mode for the main circuit: Three- phase full-bridge controlled rectifier.

Communication interface and protocol: RS232 interface (support standard MODBUS-

RTU protocol)

Ambient temperature: range from 0℃to 40℃

Ambient humidity: not higher than 90%

Altitude: less than 2KM.

2.3. Performance parameters

Control mode:

The charge-discharge process of all kinds of batteries could be set and the parameters are

automatically controlled, which could reserve the charge formula.

Running mode:

Constant current charging, constant voltage and limiting current charging, constant current

and limiting voltage discharging, cycling, etc.

Protection:

Reserving data when there is over-current, over-voltage, current-cutting and power off. It

could automatically recover when power on and provide phase break protection.

Phase transformation:

Setting time, voltage, current etc.

Record:

Recording the charging data, voltage-current curve, wrong information and operation record.

Rectifying mode:

Three- phase full-bridge controlled rectifier

Cooling mode:

Self cooling or air cooling

The accuracy for stable current and voltage: the accuracy for stable current and voltage is less

than ±0.5%

The accuracy for time: <30S/24h

Operating mode instructions:

Constant current charging: setting charging current. Transition has two modes: time and

voltage

Constant voltage and limiting current charging: setting controlled current value and

controlled voltage value. Transition has two modes: time and current

Cycling: setting the charging steps from one to five. Inside could loop and nest.

Note: please find the specific setting modes in the chapter of touch panel operating

instruction.

9

3.Systematic principle

3.1、System operating principle

The main circuit adopts triangle-like or star-like transformer and three- phase full-bridge

controlled rectifier to make charging circuit. When the charger working, the trigger board

controls the conducting angle of silicon controlled rectifier and changes the voltage level and

current magnitude. The fast acting fuse is installed on the output terminal, which could cut

off the DC circuit quickly to protect the battery and SCR components if there is short circuit in

DC output or battery.

The specific controlling process is: when controlling the charger, the human-computer

interface would send the procedure which establishes in advance to touch panel. Then touch

panel begins to control according to the procedure and rectifier controller would output the

charging mode, current and voltage required. Measuring the present current and voltage

uninterruptedly when the touch panel is working and comparing with the current and voltage

required by the procedure. Adjusting the output if necessary. The virtual current and voltage

should in line with the requirement of the procedure. If the operating data reaches the value

rated by the procedure when it changes and finishes, touch panel would stop the operation

to switch the mode according to the requirement of the procedure. The next stage of

operation or ending would begin.

On the human-computer interface, operator could monitor the details about the current,

voltage and the time mode when the charger is working and control the system by sending

the stage commands of operating, stopping and switching to touch panel.

3.2、Circuit schematic diagram

The charging machine consists of the main circuit and the control circuit. The main circuit

diagram is shown in Figure.3-1.

Figure

3-1

10

4.Installation

4.1. Safety precautions

Please keep the vertical direction when installing and carrying, or may result in the damage

of the equipment.

Please make sure the installing place could stand the weight of the equipment.

Please install in the place that not liable to shake violently.

Avoid installing in the environment with acid fog, or may result in strong corrosion of

components, wire and cabinet.

Avoid installing in the high temperature and high humidity environment and direct sunlight.

Good ventilation condition and installing air-conditioning if possible.

Making sure that the inlet cable and power grid capacity could make the equipment work at

full capacity regularly.

4.2 Installation instructions

When taking out the controller cabinet from the packing box, please open the front and

back door to check the nameplate whether the charger specification in line with the order

form and the cabinet has no apparent damage. Removing the fixed screw and holder to

check whether each component and wire loose or short out or not.

The equipment shall be installed vertically. The max. incline angle shall be less than

50.Making sure that the place for the equipment is enough. Cooling air could move from the

bottom and outgo from the top.

The equipment must be installed in ventilated situation. Keep the around distance of the

equipment more than 0.5 meters. The ambient temperature could make big difference to

the service life of the equipment. When installing, the ambient temperature shall not over

the rated range. Please avoid the high temperature, high humidity and the place with direct

sunlight.

Please choose the suitable input and output wire according to the electric atlas provided by

the equipment.

Making sure that the power grid has sufficient input power according to the power

parameters provided by the equipment.

5. Operating instructions

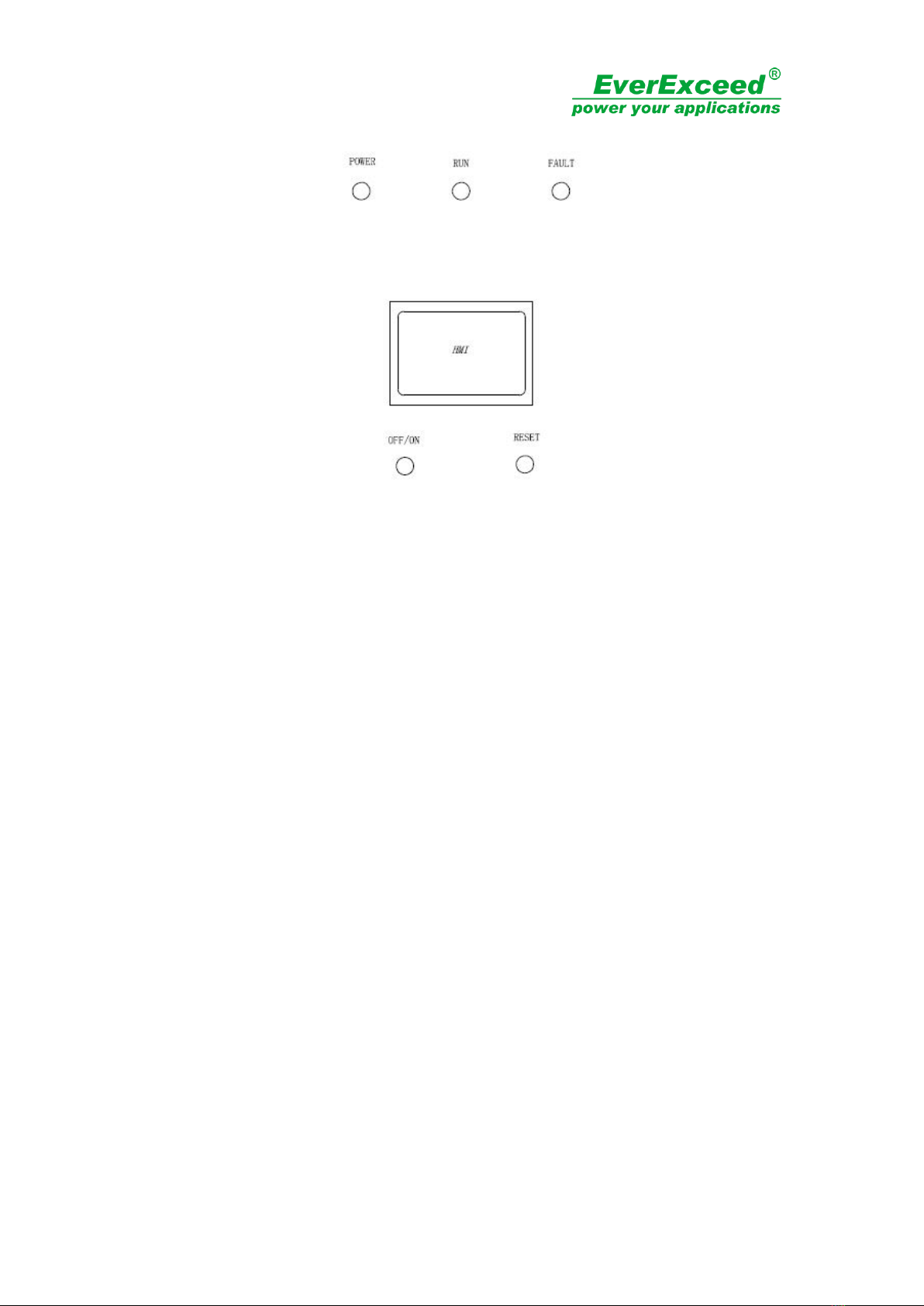

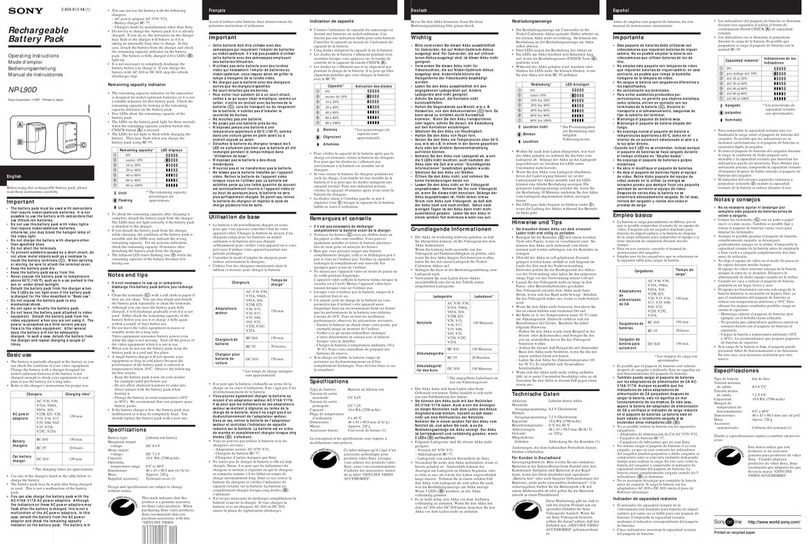

5.1 Panel display and description.

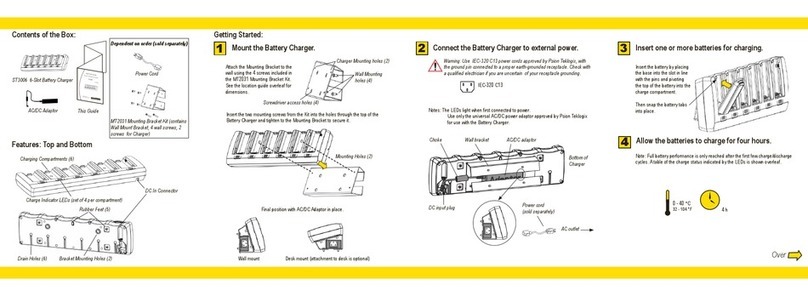

The control cabinet panel of the charger is schematic,

as showed in the figure 5-3.

11

Figure

5-1

The panel includes the operation and display parts of the charging machine control cabinet.

The details are as follows:

Power light ——When the external power supply is energized, the input circuit breaker

and auxiliary circuit breaker are closed. The indicator light is on, indicating that the

power supply is ready.

Running light ——The status indicator of the charger is controlled by the charging

machine, and the indicator light is always on when the charging machine is in normal

operation. When the charging machine stops or fails, the indicator will go out.

Failure indicator light of charger——The charging machine state indicates that the

charging machine is normally extinguished under normal condition, indicating the light

is on when the charger fails.

Change-over switch ——The switch ON the charger, when the switch is ON, the main

circuit of the charging machine is closed, and the charging machine controls the

electricity ON the circuit.

Reset button——The reset button of the charger is used to reset the charging machine.

When the charger fails, press the button to reset the fault.

Control Interface——Responsible for charging process control, man-machine

interaction and data recording.

12

5.2 Touch panel operating

uXcel charger series monitors and controls with 7 inches high-performance screen. The

inside processor of touch panel adopts Cortex-A8 which has quick reaction and high

sensitivity.

The main work of touch panel monitor

(a) Touch panel monitors the operating charging power supply and its present value of

working parameters. Then real-time displaying (mainly includes the present voltage value,

current value, ampere hour, working stage, working mode, charging curve, operated time

value in present stage and the present working condition) and real-time giving an alarm

when it out of order (displaying by screen and judging whether the equipment misfunctions

or not )

(b) Real-time operating and controlling the equipment. The operations to charging power

mainly are operating, pausing, recovering, stopping, leapfrogging(GOTO stage) and

temperature compensating etc.

(c) Including the monitoring function, touch panel also could compile procedure.

Below is the specific operating and displaying screen

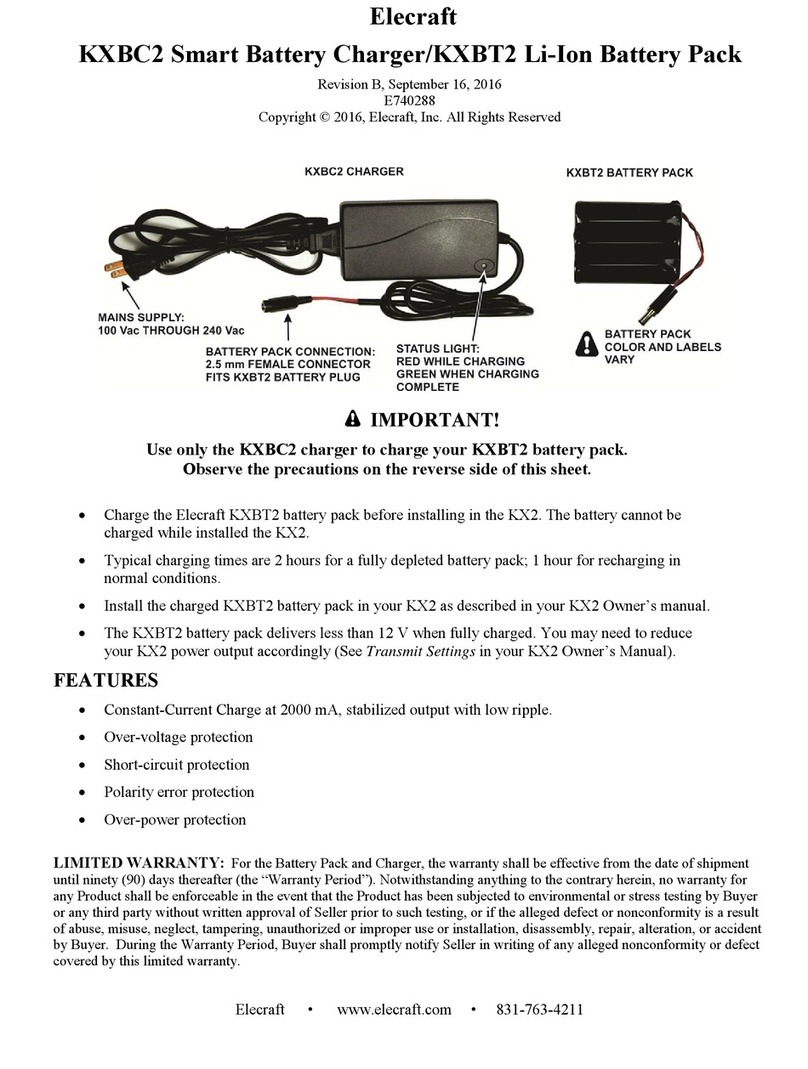

1). Start-up screen

When the charger is turned on, enter a friendly welcome screen.

as showed in the figure 5-2.

Figure 5-2

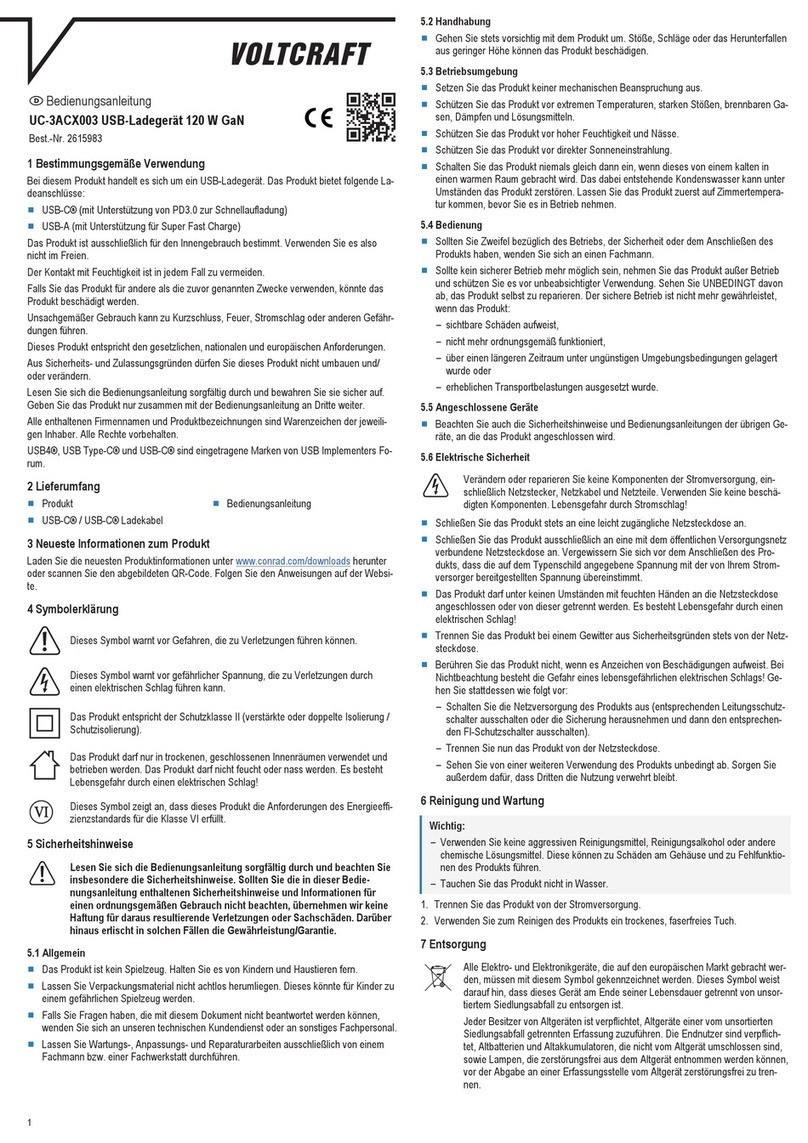

2). Charging state screen

From the charging state screen, operator could start or stop the charger and see the

parameters of the present charging step, charging voltage, charging current, charging time and

charging capacity etc. as showed in the figure 5-3

13

Figure 5-3

3). Charging curve screen

Operator could click the bottom right button of “curve” to enter into the charging curve screen.

From the charging curve, checking the situation of the charging voltage and current that

changed by time. It could save st most charging curve of 7 days. As showed in the figure 5-4.

Figure 5-4

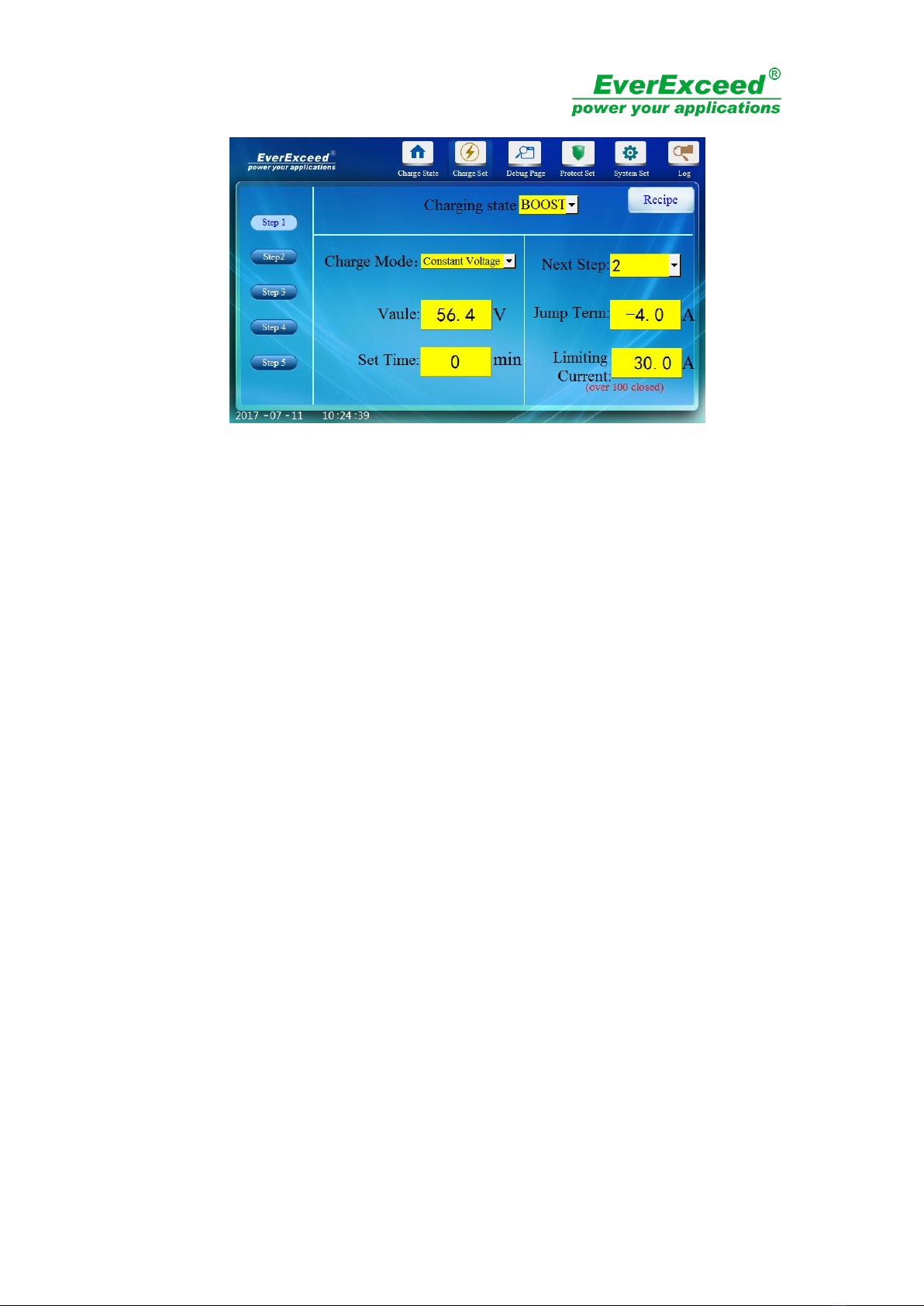

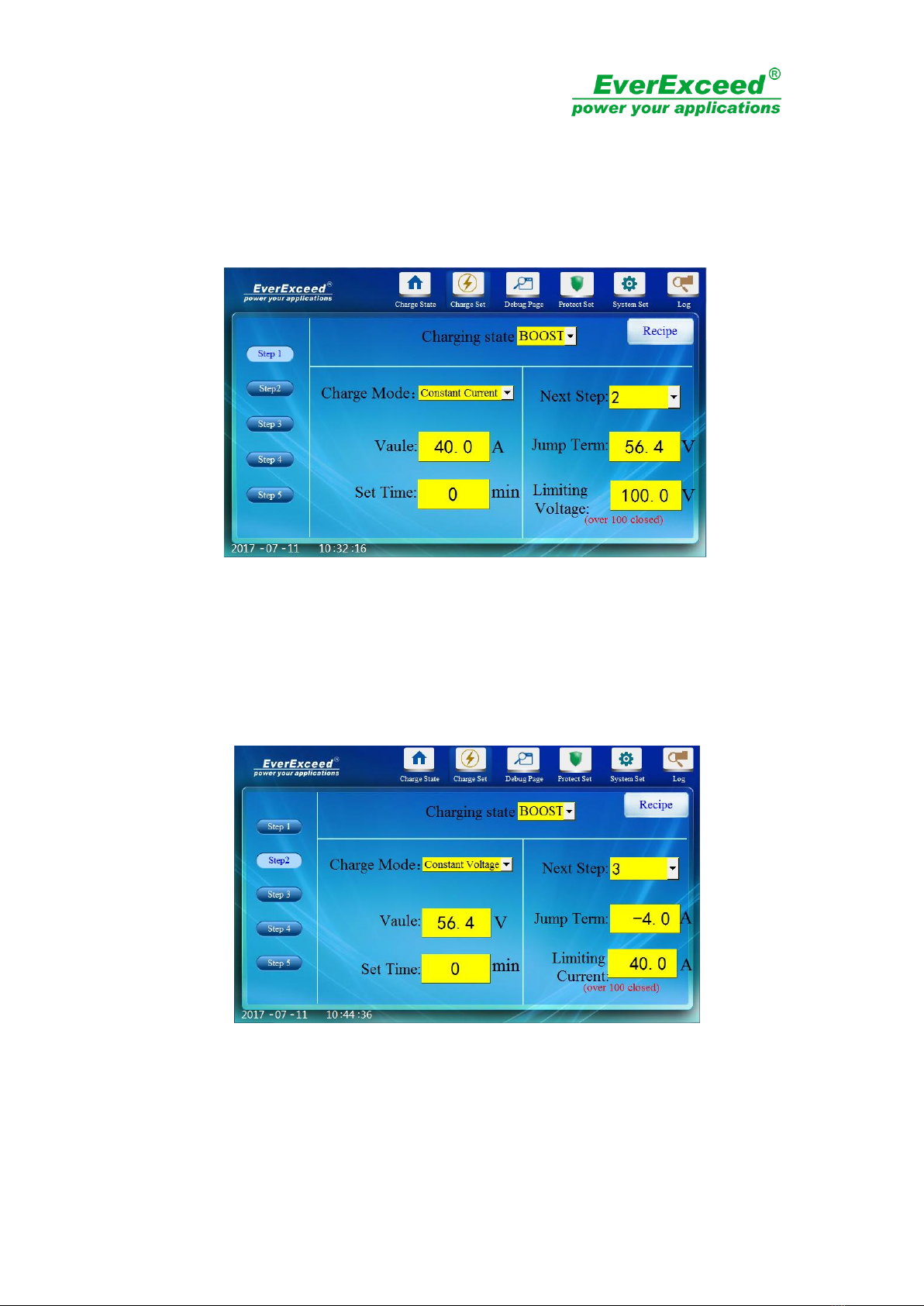

4). Charging setting screen

Operator could click the top button of “charge set” to enter into the charging setting screen. In

this screen, flexibly setting charging step is allowed according to the battery characteristics. as

showed in the figure 5-5.

14

Figure 5-5

The available setting contents are:

Charging state (boost/float): in this case, operator could set the present step as “boost” or

“float”. After setting, it would display in the charging state screen and charger panel.

Charge mode (constant voltage/constant current):

constant voltage mode or constant current

mode could be chosen.

Value:

Setting the voltage value of constant voltage mode and the current value of constant

current mode.

Set Time:

Setting the charging time for the present step.

Next step:

When the "Set Time" or the “Jump Term”meets the condition, then goes on the

"next step" and sets any step from 0 to 5. If sets among 1 to 5, it means the step is what the

value for after meeting the leaping condition. If sets as 0, it means stopping charging when

meets the condition.

Jump Term:

Setting the jump term condition. When charging voltage or current reaches this

adjustment, it would leap and leap to the step of setting “next step”. Minus means leaping if it

is less than the value. No symbol means leaping if it is more than the value.

Limiting current (voltage): if it is a constant voltage charging mode, the term would display as

limiting current, showing the max. current shall not over the rated value. If it is a constant

current charging mode, the term would display as limiting voltage, showing the max. voltage

shall not over the rated value.

The steps of setting charging: charging setting screen could set five charging steps. Each step

could set charging state, charging mode, values, time, next step, jump term, limiting current

(voltage) etc. The five steps could realize the cyclic charging process.

For example, a 48V200AH battery bank firstly needs constant current charging with 40A. when

the voltage reaches 56.4V, constant voltage equalized charging with 56.4V. if the current is less

than 4A, float charging with 54V. if the current is more than 16A, it would leap to the second

step.

15

In this moment, setting three charging steps on the charger:

Step 1: Setting charging state as "boost" and the charging mode as constant current with 40A.

Time could be set as 0min (0 means the jump condition would not affect by time). Setting next

step as 2 and the jump term as 56.4V. The limiting voltage could be set as 100V.

Figure 5-6

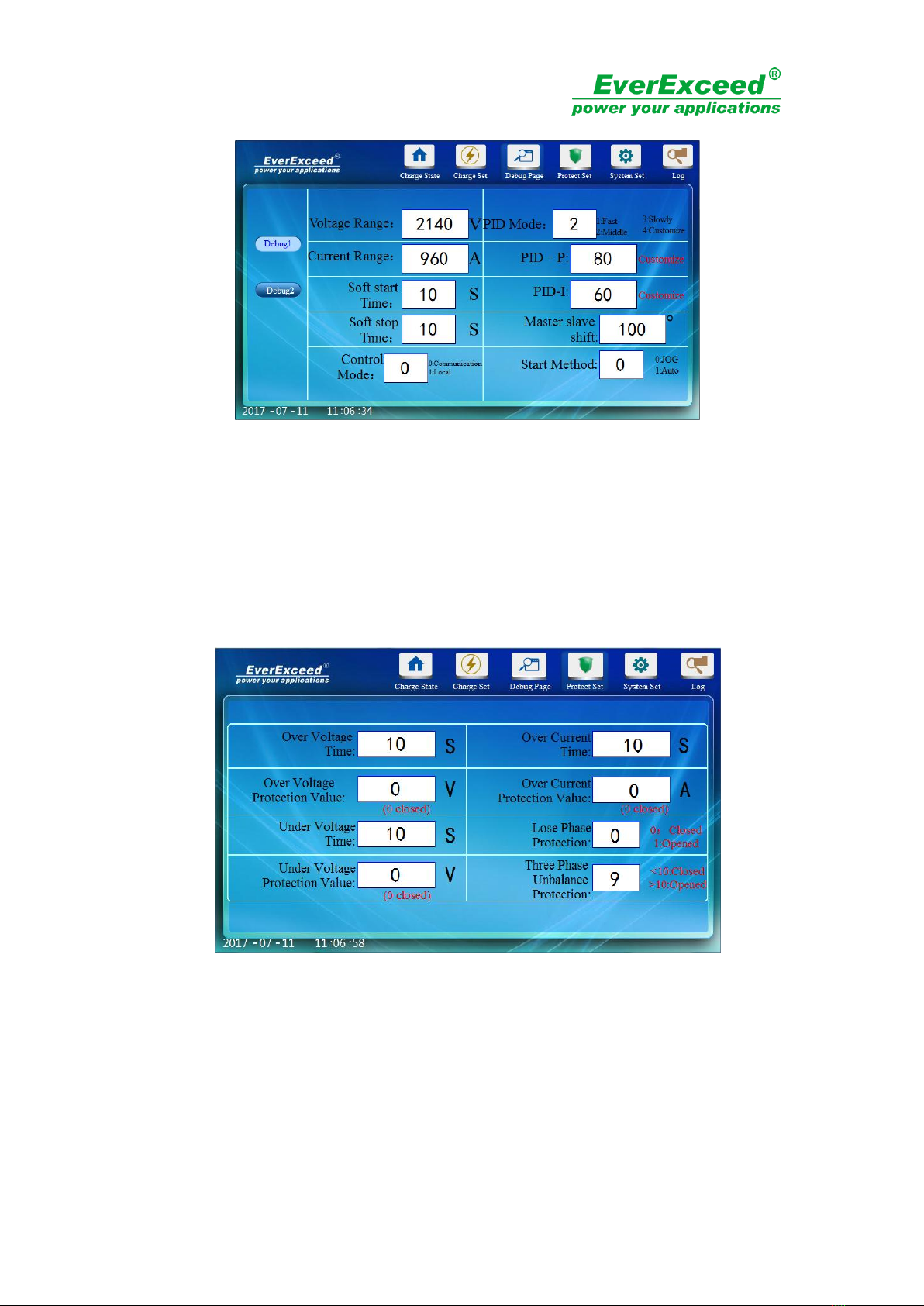

Step 2: Setting charging state as "boost" and the charging mode as constant voltage with 56.4V.

Time could be set as 0min (0 means the leaping condition would not affect by time). Setting

next step as 3 and the jump term as -4A. The limiting current could be set as 40A.

Figure 5-7

Step 3: Setting charging state as “float”and the charging mode as constant voltage with 54V .

Time could be set as 0min (0 means the leaping condition would not affect by time). Setting

next step as 2 and the jump term as 16A. The limiting current could be set as 40A.

16

Figure 5-8

5). Recipe screen

Recipe screen is designed for different batteries with different charging modes. It has five

recipes. All charging steps could be saved in recipe for convenient using. Clicking the "save

parameter" button could save charging step. Clicking "parameter download" button could

download the charging step to changing setting screen. For example, the charging setting of

the 48V200AH battery bank mentioned above has three steps. For convenience, it could save

the whole charging steps to the prescription which no need to inputting the charging steps

again. As showed in the figure 5-9.

Figure 5-9

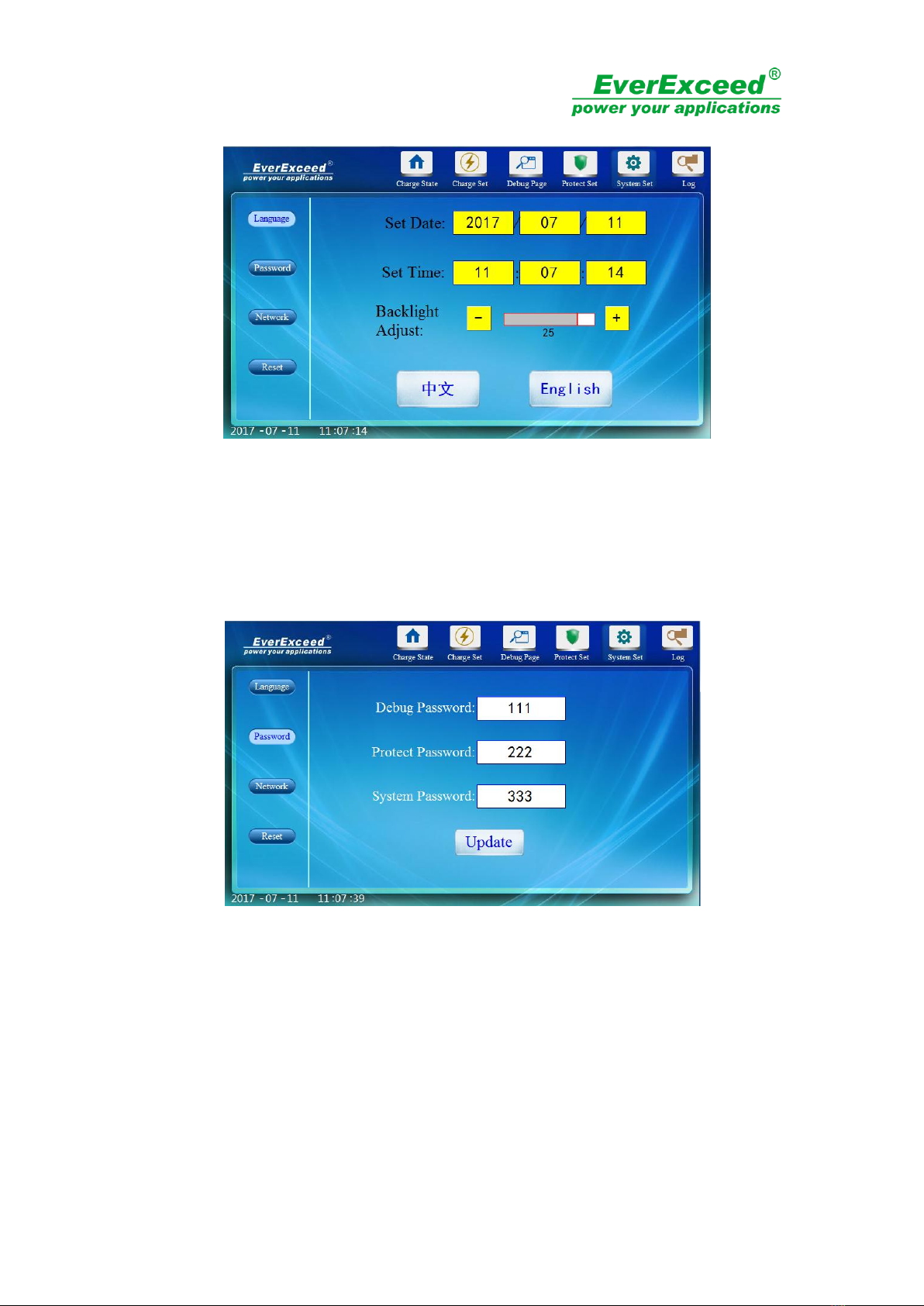

6). Debug page

Debug page is a screen used for debugging the charger before it leaves the factory and it is not

accessible to the user. as showed in the figure 5-10.

17

Figure 5-10

7). Protect Set

Protect Set page need a password to enter in and the screen could set the parameters of over

& under voltage protection, overload protection, phase-break protection and three-phase

imbalance. as showed in the figure 5-11.

Figure 5-11

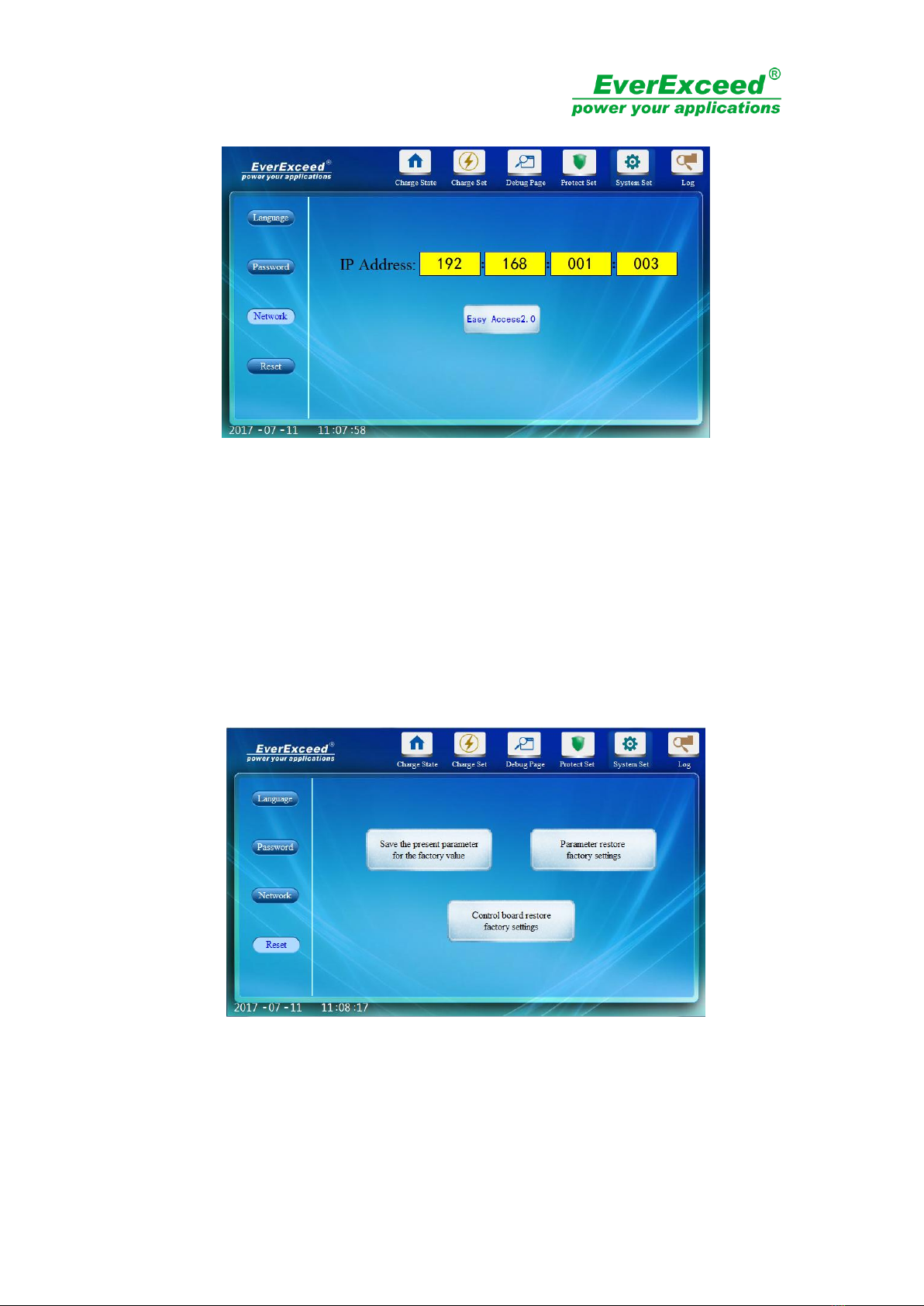

8). System set

①

Language setting----setting the date, time brightness and language. as showed in the figure

5-12.

18

Figure 5-12

②

Password modification----modifying the debugging password, protection password and

system password. as showed in the figure 5-13.

Figure 5-13

③

network setting---- setting the parameters of IP address and remote control for the

charger.(please find the specific entering ways of remote control in remote control chapter). As

showed in the figure 5-14.

19

Figure 5-14

④

Factory reset

Saving the present parameters as factory reset value: saving all the values of charging setting

screen, debugging screen and protection screen as factory reset value.

Parameter factory reset: resetting the charger and the factory reset value shall be the present

value saved.

Charger panel factory reset: when the charger panel out of order or system halted, its function

is to restore the changer panel. as showed in the figure 5-15.

Figure 5-15

9). History log

On this screen, operator could check the history malfunction record and the history charging

record. as showed in the figure 5-16 and 5-17.

Table of contents

Popular Batteries Charger manuals by other brands

Sony

Sony NP-L90D operating instructions

TecMate

TecMate Optimate 3 TM430 Instructions for use

MSTRONIC

MSTRONIC SOL10P12 Series user manual

Intermec

Intermec CN3 Series quick start guide

Myenergi

Myenergi ZAPPI-2H07UB Operation & installation manual

Parkside

Parkside PDSLG 20 A1 Translation of the original instructions