Everpower Electronics SD700 Mounting instructions

Variable Speed Drive

Programming and Software Manual

Freemaq FR Series

Variable Speed Drive

Programming and Software Manual

AFE_R1.0

Edition: February 2015

SD7FRMTSW01DI Rev. D

SD700FR SERIES

POWER ELECTRONICS

2

POWER ELECTRONICS

SD700FR

3

SAFETY SYMBOLS

Always follow safety instructions to prevent accidents and potential hazards from occurring.

Edition of February 2015

This publication could present technical imprecision or misprints. The information here included will be

periodically modified and updated, and all those modifications will be incorporated in later editions.

To consult the most updated information of this product you might access through our website

www.power-electronics.com where the latest version of this manual can be downloaded.

WARNING

This symbol means improper operation may results in serious personal

injury or death.

CAUTION

Identifies shock hazards under certain conditions. Particular attention should

be given because dangerous voltage may be present. Maintenance

operation should be done by qualified personnel

Identifies potential hazards under certain conditions. Read the message and

follow the instructions carefully.

Identifies shock hazards under certain conditions. Particular attention should

be given because dangerous voltage may be present.

SD700FR SERIES

POWER ELECTRONICS

4

Revisions

Date Revision Description

27 / 11 / 2012 A First Edition-Software version A.002

03 / 06 / 2013 B Software version A.006

28 / 02 / 2014 C Software version R1.0

19 / 02 / 2015 D Misprints correction

POWER ELECTRONICS

SD700FR SERIES

INDEX

5

INDEX

SAFETY INSTRUCTIONS........................................................................................................... 7

1. DISPLAY UNIT AND CONTROL KEYPAD.......................................................................... 11

1.1. Keypad Unit Description............................................................................................. 11

2. STATUS MESSAGES .......................................................................................................... 14

2.1. List of Status Messages............................................................................................. 14

2.2. List of Warning Messages.......................................................................................... 15

3. VISUALIZATION AND STATUS PARAMETERS. GROUP G0 ........................................... 16

3.1. Parameters SV.1 –Motor Visualization...................................................................... 16

3.2. Parameters SV.2 –Drive Visualization ...................................................................... 17

3.3. Parameters SV.3 –External Visualization.................................................................. 17

3.4. Parameters SV.4 –Internal Visualization................................................................... 18

3.5. Parameters SV.5 –Programmable Parameters......................................................... 18

3.6. Parameters SV.6 –Registers..................................................................................... 19

3.7. Parameters SV.7 –Rectifier....................................................................................... 19

3.8. Parameters SV.9 –Diagnostic................................................................................... 19

4. DESCRIPTION OF PROGRAMMING PARAMETERS ........................................................ 20

4.1. Group 1 –G1: Options Menu ..................................................................................... 20

4.2. Group 2 –G2: Motor Nameplate Data ....................................................................... 22

4.3. Group 3 –G3: References......................................................................................... 23

4.4. Group 4 –G4: Inputs.................................................................................................. 24

4.5. Group 5 –G5: Acceleration and Deceleration Ramps ............................................... 32

4.6. Group 6 –G6: PID Control......................................................................................... 34

4.7. Group 7 –G7: Start / Stop Mode Configuration ......................................................... 35

4.8. Group 8 –G8: Outputs............................................................................................... 37

4.9. Group 9 –G9: Comparators....................................................................................... 41

4.10. Group 10 –G10: Limits.............................................................................................. 45

4.11. Group 11 –G11: Protections ..................................................................................... 46

4.12. Group 12 –G12: Auto Reset...................................................................................... 48

4.13. Group 13 –G13: Fault History ................................................................................... 49

4.14. Group 14 –G14: Multi-references.............................................................................. 50

4.15. Group 15 –G15: Inch Speeds ................................................................................... 50

4.16. Group 16 –G16: Skip Frequencies............................................................................ 50

4.17. Group 17 –G17: Brake.............................................................................................. 51

4.18. Group18 _ G18 : Encoder ......................................................................................... 51

4.19. Group 19 –G19: Fine Tuning .................................................................................... 52

4.20. Group 20 –G20: Communication Buses.................................................................... 55

4.21. Group 21 –G21: Networks ........................................................................................ 58

4.22. Group 22 –G22: Rectifier .......................................................................................... 60

5. MODBUS COMMUNICATION.............................................................................................. 62

5.1. Supported Modbus Function Codes........................................................................... 62

5.2. Addressing Modes ..................................................................................................... 63

5.3. Remote Control Functions ......................................................................................... 64

5.4. Summary of Modbus Addresses ................................................................................ 65

6. FAULT MESSAGES. DESCRIPTION AND ACTIONS ........................................................ 78

6.1. Description of Fault List.............................................................................................. 78

7. COMMONLY USED CONFIGURATIONS............................................................................ 85

7.1. Start / Stop Commands and Speed Reference by Keypad ........................................ 85

7.2. Start / Stop Commands by Terminals and Speed Reference by

Analogue Input........................................................................................................... 85

7.3. Start / Stop Commands by Terminals and Speed Reference by

Motorized Potentiometer............................................................................................ 87

7.4. Start / Stop Commands by Terminals and Seven Speed References

Selectable by Digital Inputs........................................................................................ 88

8. CONFIGURATION REGISTER ............................................................................................ 90

SD700FR SERIES

POWER ELECTRONICS

6

INDEX

POWER ELECTRONICS

SD700FR SERIES

SAFETY INSTRUCTIONS

7

SAFETY INSTRUCTIONS

IMPORTANT!

Read this manual carefully to maximise the performance of this product and to ensure its safe

use.

Power Electronics accepts no responsibility or liability for any damage resulting from

inappropriate use of the equipment.

In this manual, safety messages are classified as follows:

WARNING

Do not remove the metal cover while the power is applied or the unit is in operation.

Otherwise electric shock could occur.

Do not run the drive with the front cover removed.

Otherwise, you may get an electric shock due to the high voltage terminals or exposure of charged

capacitors.

The drive does not remove the voltage from the input busbars of the drive. Before working on the

drive, isolate the whole drive from the supply.

Do not remove the cover except for periodic inspections or wiring, even if the input power is not

applied.

Otherwise, you may access to the charged circuits and may get an electric shock.

Wiring and periodic inspections should be performed at least 10 minutes after disconnecting the

input power. To remove the front cover check that the DC Link red LED is off, then remove the

terminals metallic cover and check with a multimeter the following measures:

Measure between the output power busbars U, V, W and the cabinet and check that the

voltage is around 0V.

Measure that the DC link terminals +, - and chassis voltage are below 30VDC.

Otherwise, you may get an electric shock.

Operate the switches with dry hands.

Otherwise, you may get an electric shock.

Do not use cables with damaged insulation.

Otherwise, you may get an electric shock.

Do not subject the cables to abrasions, excessive stress, heavy loads or pinching.

Otherwise, you may get an electric shock.

Do not make any insulation or voltage withstand tests on the motor with the drive connected.

SD700FR SERIES

POWER ELECTRONICS

8

SAFETY INSTRUCTIONS

CAUTION

Install the drive on a non-flammable surface. Do not place flammable material nearby.

Otherwise fire could occur.

Disconnect the input power if the drive is damaged.

Otherwise, it could result in a secondary accident or fire.

After stopping the drive, it will remain hot for a couple of minutes. Touching hot parts may result in

skin burns.

Do not apply power to a damaged drive or to a drive with parts missing even if the installation is

complete. Otherwise, you may get an electric shock.

It is not permitted to weld the cabinet; this can damage the electronic sensitive equipment inside.

Do not allow lint, paper, wood chips, dust, metallic chips or other foreign matter into the drive.

Otherwise fire or accident could occur.

WARNINGS

RECEPTION

The SD700FR are carefully tested and perfectly packed before delivering.

In the event of transport damage, please ensure that you notify the transport agency and POWER

ELECTRONICS: 902 40 20 70 (International +34 96 136 65 57) or your nearest agent, within 24hrs

from receipt of the goods.

UNPACKING

Make sure model and serial number of the variable speed drive are the same on the box, delivery

note and unit.

Each variable speed drive is delivered with Hardware and Software technical manuals.

RECYCLING

Packing of the equipments should be recycled. For this, it is necessary to separate different

materials included (plastic, paper, cardboard, wood ...) and deposit them on proper banks.

Waste products of electric and electronic devices should be selectively collected for your correct

recycling company.

EMC

The drive is intended to be used in industrial environment (Second Environment), it achieve

compliance with C3 category defined in IEC/EN 61800-3 standard following the installation

recommendation within this manual.

Select communication and control system according to the drive EMC environment. Otherwise,

systems could suffer from interferences due to a low EMS level.

POWER ELECTRONICS

SD700FR SERIES

SAFETY INSTRUCTIONS

9

SAFETY

Before operating the drive, read this manual thoroughly to gain and understanding of the unit. If

any doubt exists then please contact POWER ELECTRONICS, (902 40 20 70 / +34 96 136 65

57) or your nearest agent.

Wear safety glasses when operating the drive with power applied or the front cover is removed.

Handle and transport the drive following the recommendations within this manual.

Install the drive according to the instructions within this manual and the local regulations.

Do not place heavy objects on the drive.

Ensure that the drive is mounted vertically and keeping the minimum clearances distances.

Do not drop the drive or subject it to impact.

The SD700FR drives contain static sensitive printed circuits boards. Use static safety

procedures when handling these boards.

Avoid installing the drive in conditions that differ from those described in the Environmental

Ratings section.

CONNECTION PRECAUTIONS

To ensure correct operation of the drive it is recommended to use a SCREENED CABLE for the

control wiring.

The motor cable should comply with the requirements within this manual. Due to increased

leakage capacitance between conductors, external ground fault protection threshold value

should be adjusted ad hoc.

Do not disconnect motor cables if input power supply remains connected.

The internal circuits of the SD700FR Series will be damaged if the incoming power is connected

and applied to output terminals (U, V, W).

Do not use power factor correction capacitors banks, surge suppressors, or RFI filters on the

output side of the drive. Doing so may damage these components.

Always check whether the DC Link red LED is OFF before wiring terminals. The capacitors may

hold high-voltage even after the input power is disconnected.

TRIAL RUN

Verify all parameters before operating the drive. Alteration of parameters may be required

depending on application and load.

Always apply voltage and current signals to each terminal that are within levels indicated within

this manual.

OPERATION PRECAUTIONS

When the Auto Restart function is enabled, keep clear of driven equipment, as the motor will

restart suddenly after the fault reset.

The “STOP / RESET” key on the keypad is active only if the appropriate function setting has

been made. Pushing this button the drive will NOT perform a safe stop. It is available STO

optional board, which installed with a separate EMERGENCY pushbutton, will disconnect the

power and will be unable to generate torque in the motor with high reliability.

If a fault is reset with the reference signal still active, the drive will unexpectedly restart. Verify

that it is permissible for this to happen. Otherwise, it may lead to injury to people.

Do not modify or alter internal wiring and spare parts without Power Electronics supervision.

Before programming or operating the SD700FR Series, initialise all parameters back to factory

default values.

SD700FR SERIES

POWER ELECTRONICS

10

SAFETY INSTRUCTIONS

EARTH CONNECTION

Ground the drive and adjoining cabinets to ensure a safety operation and to reduce

electromagnetic emission.

Connect the input PE terminal only to the dedicated PE terminal of the drive. Do not use the

case or the chassis screw for grounding.

Ground the drive chassis through the dedicated and labelled terminals. Use appropriate

conductors to comply with the local regulations. The ground conductor should be connected first

and removed last.

Motor ground cable must be connected to the PE output terminal of the drive and not to the

installation’s ground. We recommend that the section of the ground conductor (PE) should be

equal or greater than the active conductor (U, V, W).

If the user decides to use shielded motor cable, ensure a correct 360º shield bonding in both the

drive cabinet and the motor terminal box.

POWER ELECTRONICS

SD700FR SERIES

DISPLAY UNIT AND CONTROL KEYPAD

11

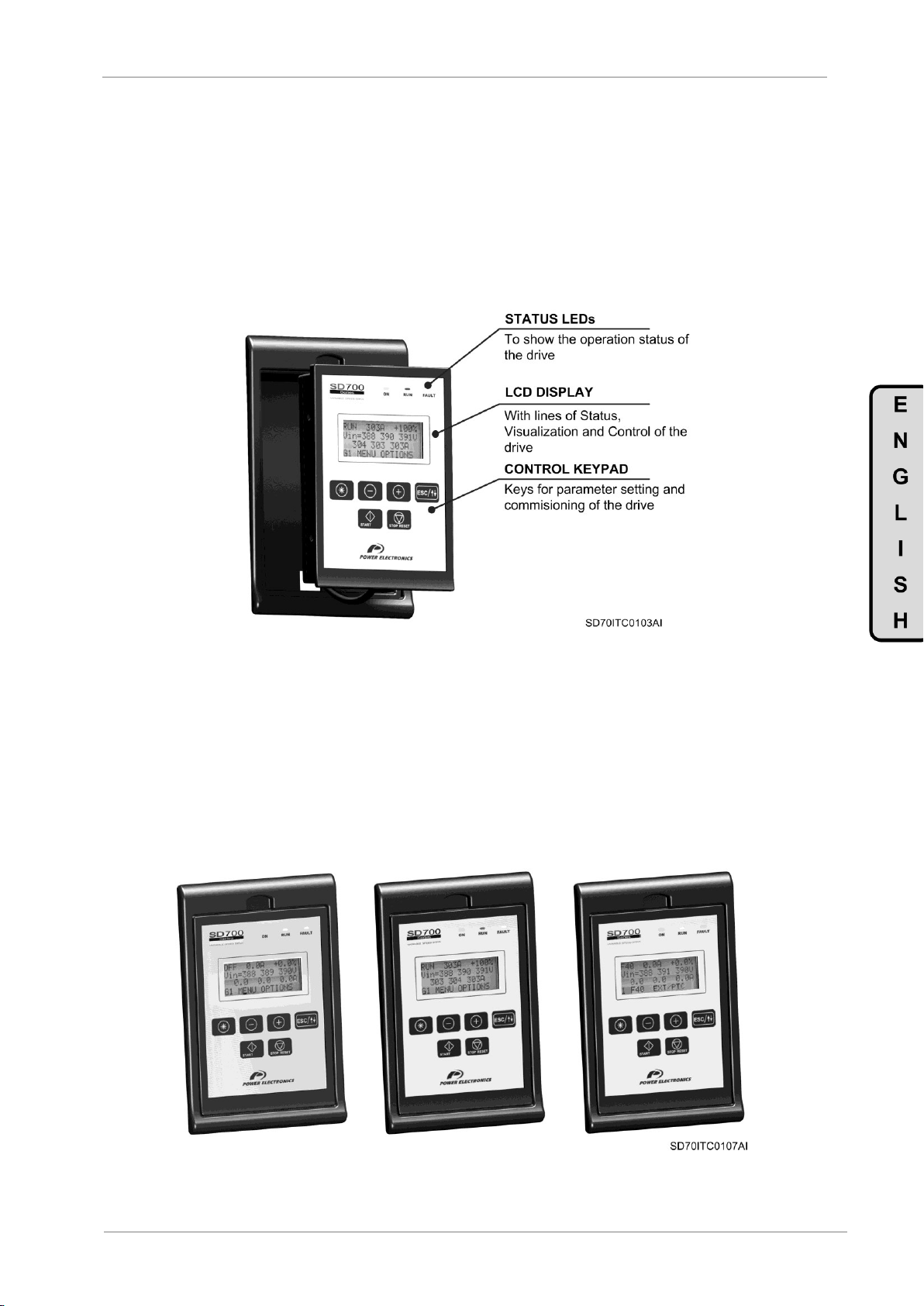

1. DISPLAY UNIT AND CONTROL KEYPAD

1.1.Keypad Unit Description

The display of the SD700FR is removable for remote installation, as the illustration shows. There are

three leds on the display which indicate the drive operational status, one LCD screen with 4 lines of

16 characters each and keys for control and parameter setting.

Figure 1.1 Display Unit and Keypad

1.1.1. LEDs for Status Indication

Leds offer an easy method of identifying if the SD700FR is powered up, if the drive is supplying

output voltage, or if the drive has tripped.

Led ON: Yellow colour. When it is lit, indicates equipment is powered up. When it is blinking,

it indicates that the drive gets any warning.

Led RUN: Green colour. When it is lit, indicates the motor is powered by the SD700FR.

When it is blinking, it indicates that only one of the power bridges is switching.

Led FAULT: Red colour. When it is blinking, indicates the equipment is in fault status.

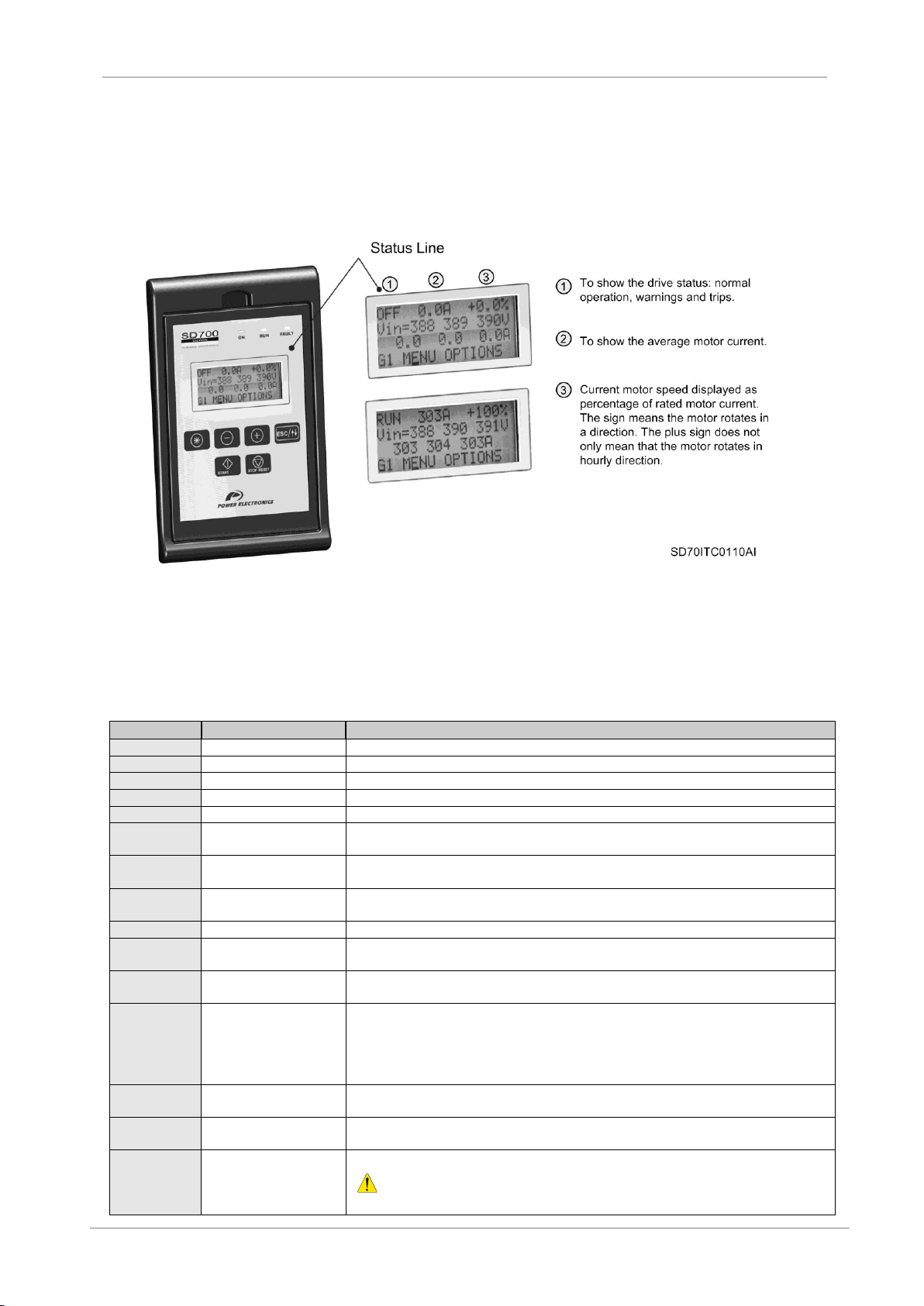

Figure 1.2 Status Visualization

SD700FR SERIES

POWER ELECTRONICS

12

DISPLAY UNIT AND CONTROL KEYPAD

1.1.2. Alphanumeric LCD Display

SD700FR display has a LCD screen of four lines with sixteen characters each (16x4). Each line

has different functions.

Status Line: It is the top line.

It is always present and shows the SD700FR

status (STR –Start, STP –Stop, etc…).

It also shows the output current and the

motor speed.

It is not configurable by the user.

Visualization Line 1: It is the second

line of the screen. It is always present

and allows the selection of variables from

the visualization menu.

It is configurable by the user.

Visualization Line 2: It is the third

line of the screen. It is always present

and allows the selection of variables from

the visualization menu.

It is configurable by the user.

Programming Line: It is the fourth line.

It is used to display and / or set different

parameters within the SD700FR. Figure 1.3 Detail of Display Lines

1.1.3. Control Keys

Function keys have multiple uses and can be operated individually or in combination with other

keys:

It allows access to different parameters groups and sub-groups; it displays code

explanations and allows adjustment of parameter values in combination with

other keys. If a group has no sub-groups, it allows direct access to the

parameters of the group.

To modify numeric parameters:

& Simultaneously pushed, the value will increase.

& Simultaneously pushed, the value will decrease.

To modify parameters of numbered options:

Pushing this key, the extended explanation will appear.

& Simultaneously pushed will ascend the user

through the varying options.

& Simultaneously pushed will descend the user

through the varying options.

It allows upward movement through the parameters groups and allows

navigation for different parameters within a parameter group. It also allows the

increase of parameters value.

It allows downward movement through the parameters groups and allows

navigation for different parameters within a parameter group. It also allows the

decrease of parameters value.

POWER ELECTRONICS

SD700FR SERIES

DISPLAY UNIT AND CONTROL KEYPAD

13

When pushed for 2 seconds (approx.) it allows navigation between the

programming line and visualisation lines available to the user. It also offers the

possibility of escaping back to the previous sub-group or group.

To start the drive from the keypad when the control has been set as local

control (check drive configuration).

To stop the drive from the keypad when the control has been set as local

control. In the case of tripping this key can be used to reset the drive, if local

control is enabled. The drive will not perform an Emergency Stop and the drive

will not be disconnected from the power supply.

In the following figure you can see a programming example where you can observe the operation

explained previously.

Figure 1.4 Example of parameters navigation

SD700FR SERIES

POWER ELECTRONICS

14

STATUS MESSAGES

2. STATUS MESSAGES

The upper line of the display corresponds to the status line. In this line we can display the equipment

status, motor current (A) and the motor speed (%). It is always displayed and it is not programmable by the

user.

Figure 2.1 Status Line Description

Note: The user can access to the information displayed in status line via Modbus communication. See section ‘Modbus

Communication’.

2.1.List of Status Messages

Screen

Name

Description

OFF

Deactivated power

Drive power is deactivated.

ON

Activated power

Drive power is activated.

ACL

Accelerating

Drive is increasing the output frequency. Motor increasing in speed, it is accelerating.

RUN

Running

Drive is operating at reference speed. Operation at steady status.

DEC

Decelerating

Drive is decreasing the output frequency. Motor decreasing in speed, it is decelerating.

SPG

Stopping

Drive is decreasing the output frequency due to a stop command. Motor is stopping by ramp

until zero speed is reached.

EST

Free run stop when a

fault occurs

Drive is stopping by free run stop after a fault occurs (emergency stop). Motor stopping time

is determined by inertia as the drive output has turned off.

SPN

Flying start

‘Flying start’ operation must be configured if required. The SD700FR will search for the actual

motor shaft speed once the drive has received a start command.

DCB

DC brake

SD700FR is applying DC current injection to stop the motor.

TBR

DC brake ON delay

Drive is applying a delay time before DC current injection is active. When this time is

elapsed, the DC brake will be active.

DLY

Start Delay Time

When a delay time has been set in order to start the equipment, after the start command has

been activated, this message will be displayed until this time has elapsed.

IN1

Inch speed 1

SD700FR is working according to inch speed 1 command and ‘Start + Inch speed 1' mode is

active. When operated in this mode the "Start + Inch speed 1" command is dominant over

other inputs programmed for "Start" functionality. Therefore if one input is configured as

‘Start’ and it is deactivated; in spite of this deactivated input, the drive will start when ‘Start +

Inch speed 1' command is received. This is also valid for Inch speed 2 and 3.

IN2

Inch speed 2

SD700FR is working according to inch speed 2 command. ‘Start + Inch speed 2' mode is

active.

IN3

Inch speed 3

SD700FR is working according to inch speed 3 command. ‘Start + Inch speed 3' mode is

active.

HEA

Non condensing current

is activated

SD700FR is injecting DC current to prevent moisture condensing within the motor.

CAUTION: Although the motor is not running there is dangerous voltage. Run Led will

be lit during this process. Be careful to avoid damages and personal injury.

POWER ELECTRONICS

SD700FR SERIES

STATUS MESSAGES

15

2.2.List of Warning Messages

Screen

Name

Description

MOL

Motor overload

This message will appear when motor thermal model is increasing the estimated motor

temperature.

MOC

Motor over-current

Motor current is higher than the rated current value.

DOC

Drive over-current

This message will appear if the output current is higher than 125% of the nominal current.

ILT

Current limitation

Current limit algorithm has been activated.

TLT

Torque limitation

Torque limit algorithm has been activated.

VLT

Voltage limitation

A high DC Link voltage level has been detected and the voltage limit control algorithm has

been activated to protect the drive.

ACO

Asymmetric current

Asymmetry in output currents of the drive has been detected.

AVO

Output voltage

imbalance

Asymmetry in output voltage of the drive has been detected.

AVI

Input voltage imbalance

Asymmetry in input voltage of the drive has been detected.

OVV

High input voltage

Input voltage of the equipment is reaching a dangerous level. The value is above the set

value (protections settings).

UNV

Low input voltage

Input voltage of the equipment is reaching a dangerous level. The value is below the set

value (protections settings).

S1L

Speed limit 1 reached

Motor speed has reached speed limit 1.

S2L

Speed limit 2 reached

Motor speed has reached speed limit 2.

IPR

Current input protection

Input current has reached the 100% of the rated current.

IIB

Input current imbalance

Inverse input current has reached the 75% of the fault threshold “R19 I IM BIN”.

IGF

Input ground fault

Ground fault current has reached the 75% of the ground fault threshold.”R20 GRND INPUT”.

TRB

Temperature rectifier

bridge

The rectifier’s IGBTs have reached 90ºC.

CCM

CAN communication

module

Some CAN frames from the fiber optics communication have been lost.

FPS

Fan Power Supply

The rectifier’s fan power supply has a failure. The fault “R34 IGBT TEMP” will reduce its

threshold value from 110ºC up to 90ºC, in order to protect the drive components.

PLL

Phase Locked Loop

The rectifier is synchronizing to the grid.

SWM

Software Mismatch

SW version not compatible

DWA

Diagnostic Warning

Active

Some Diagnostic Board is reporting a warning.

LCL

Contactor LCL

The LCL feedback is not correctly.

SD700FR SERIES

POWER ELECTRONICS

16

VISUALIZATION AND STATUS PARAMETERS. GROUP G0

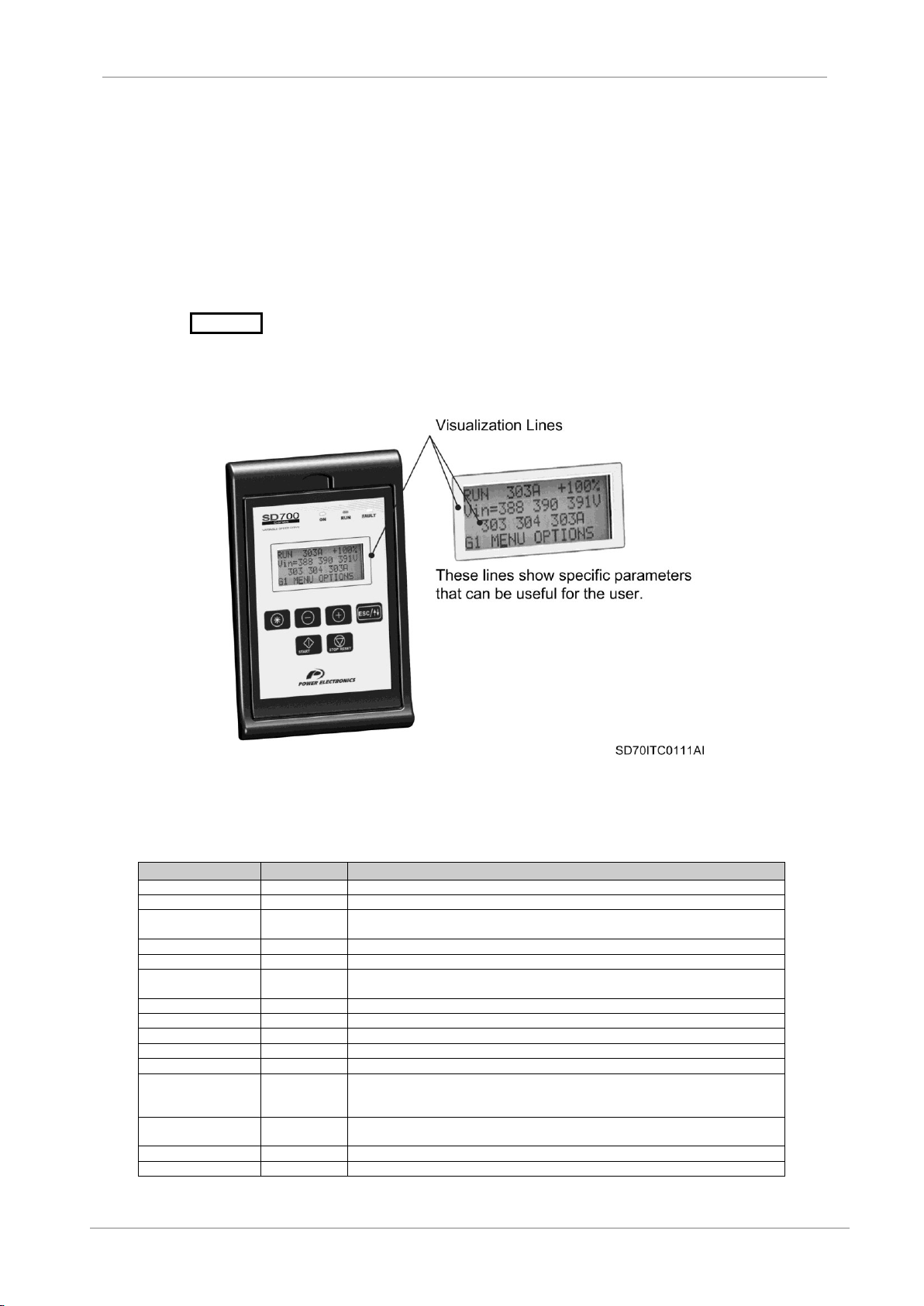

3. VISUALISATION AND STATUS

PARAMETERS. GROUP G0

These parameters constantly indicate the input signal status and dynamic parameter status of the

SD700FR. Visualization lines are the second and the third lines. The user can select the parameter to be

displayed in each line from the different visualization options.

To select a display parameter you should move to the cursor to the second or third line. For this, you need

to press ESC / key for approx two seconds. The cursor moves from one line to the next. Once

located on the second or third line you can navigate like the programming line (line 4) and select the

desired parameter to be displayed. Once selected these parameters are saved into memory. These

parameters are then displayed on lines 2 and 3 whenever the drive is powered up.

Thanks to these lines user can display desired parameters and obtain additional information easily.

Figure 3.1 Visualization Lines Description

3.1.Parameters SV.1 –Motor Visualisation

Screen

Units

Description

Sp Ref = +000%

% motor speed

It shows the present reference value of speed which is applied to the motor.

Mtr Speed = +0rpm

rpm

It shows the motor speed in revs per minute.

Mtr Sp = +0.0%

%

It shows the motor speed in %. It corresponds with the third field of the status line

OFF 0.0A +0.0%

Mtr Freq = +0.0Hz

Hz

It shows the frequency being applied to the motor.

Mtr Vout = 0V

V

It shows the present voltage applied to the motor.

Mtr Iout = 0.0A

A

It shows the present current flowing to the motor. It corresponds with the second field of the

status line OFF 0.0A +0.0%

Mtr Torqe = 0.0%

% motor torque

It shows the present torque applied to the motor.

Mtr Pfactr = 0.0

-

It shows the power factor of the motor.

Mtr Pwr = +0.0kW

kW

It shows the instantaneous power consumption of the motor.

0.0A 0.0A 0.0A

A

It shows the instantaneous current of each phase of the motor (U, V and W).

Vmt= 0 0 0V

V

It shows the instantaneous voltage applied to the motor terminals.

PTC Motor = 0

-

It shows if the motor PTC (temperature sensor) is connected.

X: PTC Connected.

0: PTC Not Connected.

Motor Temp = 0.0%

% Motor heat

It shows the estimated motor temperature. A level of 110% will cause F25 trip (motor

overload).

Enco. Pulso =0

pulses

It shows the encoder pulses.

Clsped = 0 rpm

rpm

Real speed mesured by the encoder.

POWER ELECTRONICS

SD700FR SERIES

VISUALIZATION AND STATUS PARAMETERS. GROUP G0

17

3.2.Parameters SV.2 –Drive Visualisation

Screen

Units

Description

390 390 390V

V

It shows the input instantaneous voltage applied to the drive (RS, ST, RT).

Inp Vol = 390V

V

It shows the average input voltage to the drive.

50.0 50.0 50.0Hz

Hz

It shows the frequency of the input voltage to the drive.

Bus vol = 540V

VDC

It shows DC Link voltage of the drive.

IGBT Temp =+23ºC

ºC

It shows the temperature measured at the power stage of the drive output.

Drive Temp =+26ºC

ºC

It shows the temperature measured inside the electronics chamber of the drive.

3.3.Parameters SV.3 –Visualisation

Screen

Units

Description

ANLG IN1 = +0.0V

V or mA

It shows the value of Analogue Input 1.

AIN1 Refr = +0.00%

% bottom scale

AI1

It shows the value or the PID reference proportional to Analogue Input 1 in percentage.

AIN1 S = +0.00l/s

Engineering

units

It shows the value of sensor 1 associated to the Analogue Input 1.

ANLG IN2 = +0.0V

V or mA

It shows the value of the Analogue Input 2.

AIN2 Refr = +0.00%

% bottom scale

AI2

It shows the value or the PID reference proportional to the Analogue Input 2 signal.

AIN 2 S = +0.00Bar

Engineering

units

It shows the value of sensor 2 associated to the Analogue Input 2.

ANL OUT1 = +4.0mA

V or mA

It shows the value of Analogue Output 1.

AOUT1 Refer = +0.0%

% associated

magnitude

It shows the magnitude value associated to the Analogue Output 1 (speed, current ...).

ANL OUT2 = +4.0mA

V or mA

It shows the value of Analogue Output 2.

AOUT2 Refer = +0.0%

% associated

magnitude

It shows the magnitude value associated to the Analogue Output 2 (speed, current ...).

DI: 000000 0

-

It shows whether the Digital Inputs are activated or not, from DI1 to DI6. The final is another

input which shows the status of the motor PTC signal.

X: Active.

0: Not Active.

Relays 1-3: X0X

-

It shows whether the output relays are activated or not.

X: Active.

0: Not Active.

Speed M = +0.000m/s

Depending on

config.

It shows the speed of the motor in engineering units. Pressing key you can access to the

following sub-parameters of configuration:

Screen

Range

Description

Scale ftr=1

0.001 -

10

To set the ratio factor between motor speed and

machine speed.

Units Ma=m/s

m/s

m/m

cm/s

cm/m

v/s

v/m

It allows selection of the units to be displayed

Units

Description

m/s

Meters / second

m/m

Meters / minute

cm/s

Centimetres / second

cm/m

Centimetres / minute

v/s

Turns / second

v/m

Turns / minute

Note: They both are settable during run.

Modbus Traffic=0

0 / X

“X” will be displayed if Modbus communication exists through RS232 or RS485 user port.

Furthermore, “X” will blink at constant frequency while communication is active.

After half second is elapsed without communication, “O” will be displayed.

Display_traffi = 0

-

It shows if the display is connected.

Screen

Description

0

The display is not connected.

1

The display is connected.

SD700FR SERIES

POWER ELECTRONICS

18

VISUALIZATION AND STATUS PARAMETERS. GROUP G0

3.4.Parameters SV.4 –Internal Visualisation

Screen

Units

Description

Actual Fault = 00

-

It shows the present code fault. See fault history G13.

Drive Curr = 170A

A

It shows the drive rated current (maximum current of the equipment at 50ºC).

Drive Volt = 400V

V

It shows the drive rated voltage.

S/W

-

It shows the software version installed into the equipment.

H/W y.y

-

It shows the hardware version of the equipment.

PID R% = +0.0%

% feedback

range

It shows the reference value in PID mode of the equipment standard program.

PID F% = +0.0%

% AI used as

feedback

It shows the feedback value in PID mode of the equipment standard program.

PID Error = +0.0%

% feedback

range

It shows the error value in PID mode that means the difference between the reference value

and the real value of the system feedback signal.

Comparators: 000

-

It shows if comparators are activated or not.

X: Active / 0: Not Active.

FLT.STAT.=NO FLT

NO FLT

---

It shows if the equipment is in faulty status.

If the equipment is in faulty status, it shows the status of the drive before the fault is

produced; when there is not fault, it shows ‘NO FLT’.

Fault Diag.=N

N

Y

When it is set to ‘Y’ (YES), the parameters of groups ‘SV.1 Motor Visualization’ and ‘SV.2

Drive Visualization’ are hold with the last values at the moment of the last fault is produced.

If the user sets the parameter to ‘N’ (NO), or after 135 seconds are elapsed, the parameters

will show the actual values again. The hold values are saved in memory until next fault will be

produced, even if the input power of the drive is lost.

3.5.Parameters SV.5 –Programmable Parameters

This group is not only a display group. Some parameters such as speed, pressure and inch speeds

can be adjusted in this group. These parameters are also available in their corresponding parameter

groups. This is a simple way to allow user adjustment of basic parameters without entering the main

programming groups.

Screen

Units

Description

Local Sp = +100%

% motor speed

It shows the speed reference value in local mode (introduced by keypad). See G3.3 parameter

for additional data.

PID Local = +100%

% feedback

It allows user to select the PID reference in local mode. See G6.2 parameter for additional

data.

Mref 1 = +10.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 1. See G14.1 parameter for

additional data.

Mref 2 = +20.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 2. See G14.2 parameter for

additional data.

Mref 3 = +30.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 3. See G14.3 parameter for

additional data.

Mref 4 = +40.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 4. See G14.4 parameter for

additional data.

Mref 5 = +50.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 5. See G14.5 parameter for

additional data.

Mref 6 = +60.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 6. See G14.6 parameter for

additional data.

Mref 7 = +70.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 7. See G14.7 parameter for

additional data.

Inch Spd1 = 0.00%

% motor speed

It allows user to set the step frequency 1 value. See G15.1 for additional data.

Inch Spd2 = 0.00%

% motor speed

It allows user to set the step frequency 2 value. See G15.2 for additional data.

Inch Spd3 = 0.00%

% motor speed

It allows user to set the step frequency 3 value. See G15.1 and 2 for additional data.

Table of contents

Popular Inverter manuals by other brands

XanLite

XanLite LSBK3SOLARRVB user manual

Mitsubishi Electric

Mitsubishi Electric Freqrol Z024-UL instruction manual

Sunfar

Sunfar V220 Series user manual

Mitsubishi Electric

Mitsubishi Electric FR-D700-SC-EC Safety stop function instruction manual

SG GROUP

SG GROUP 3200W E.START instructions

QRP Labs

QRP Labs Si5351A operating manual