Evinrude & Johnson ICON 764909 User manual

Outboard Engines

Printed in the United States.

© 2009 BRP US Inc. All rights reserved.

TM, ® and the BRP logo are registered trademarks of Bombardier Recreational Products Inc. or its affiliates.

DSS09392I REV 1 1 of 20

EVINRUDE®ICON™ BINNACLE MOUNT REMOTE CONTROL KITS

P/N 764909 / 765381, 764910 / 765382, 764911 / 765383, 764912 / 765384, 764913 / 765385

APPLICATION

Use this instruction sheet when installing the above remote control kits on 2008 and newer Evinrude

E-TEC®outboards, equipped with the ICON system. DO NOT install on any other models.

SAFETY INFORMATION

The following symbols and/or signal words

may be used in this document:

Indicates an instruction which, if

not followed, could severely damage engine

components or other property.

These safety alert signal words mean:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

For safety reasons, this kit must be installed by an

authorized Evinrude®/Johnson®dealer. This

instruction sheet is not a substitute for work

experience. Additional helpful information may be

found in other service literature.

DO NOT perform any work until you have read and

understood these instructions completely.

Torque wrench tightening specifications must

strictly be adhered to.

Should removal of any locking fastener (lock tabs,

locknuts, or patch screws) be required, always

replace with a new one.

When replacement parts are required, use

Evinrude/Johnson Genuine Parts or parts with

equivalent characteristics, including type, strength

and material. Use of substandard parts could result

in injury or product malfunction.

Always wear EYE PROTECTION AND

APPROPRIATE GLOVES when using power tools.

Unless otherwise specified, engine must be OFF

when performing this work.

Always be aware of parts that can move, such as

flywheels, propellers, etc.

Some components may be HOT. Always wait for

engine to cool down before performing work.

If you use procedures or service tools that are not

recommended in this instruction sheet, YOU

ALONE must decide if your actions might injure

people or damage the outboard.

This instruction sheet may be translated into other

languages. In the event of any discrepancy, the

English version shall prevail.

TO THE INSTALLER: Give this sheet and the

operating instructions to the owner. Advise the

owner of any special operation or maintenance

information contained in the instructions.

TO THE OWNER: Save these instructions in your

owner’s kit. This sheet contains information

important for the use and maintenance of your

engine.

DANGER

Indicates a hazardous situation which, if

not avoided, will result in death or serious

injury.

WARNING

Indicates a hazardous situation which, if

not avoided, could result in death or seri-

ous injury

CAUTION

Indicates a hazardous situation which, if

not avoided, could result in minor or mod-

erate personal injury.

NOTICE

2 of 20

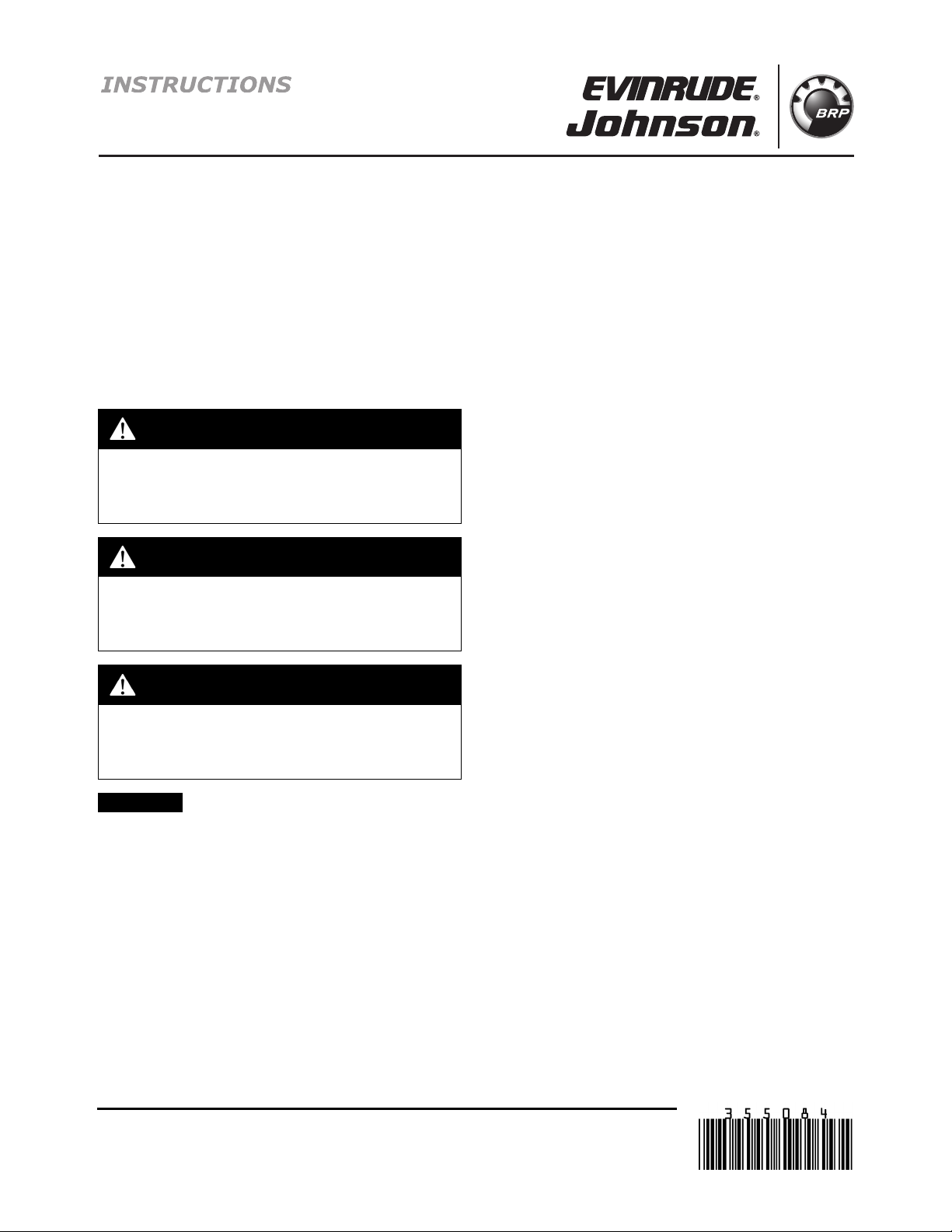

ICON SINGLE LEVER BINNACLE MOUNT REMOTE CONTROL

1

3

5

4

9

10

11

12

16, 17

18, 19, 20 7, 8

6

15

13

2

14

007917

Ref P/N Name of Part Qt

y

Ref P/N Name of Part Qt

y

1 764909 CONTROL, Sin

g

le binnacle - ICON 1 11 ***SCREW, Handle covers 3

2765316 *HARDWARE KIT, Installation 1 12 ***COVER, Inside handle 1

3**STUD, Control mountin

g

313765318**SWITCH, Trim/Tilt 1

4 **WASHER, Mountin

g

314 3011714 ***TERMINAL, Socket 3

5**NUT,Mountin

g

315 765354 *SCREW, Handle 1

6 **SEAL, Control mountin

g

1163011712 *CONNECTOR, 3Socket

p

lu

g

(

Trim sw

)

1

7765355 *CONNECTOR, Switch

p

anel 1 17 3011713*LOCKWEDGE, 3Socket

p

lu

g

1

8765356 *TERMINAL 3183011709 *CONNECTOR, 3Pin Rc

p

t

(

Trim harnes

s

1

9765317 *CONTROL HANDLE AY 1 19 3011711 *TERMINAL, Pin 3

10 765319 **HANDLE GRIP KIT 1 20 3011710 *LOCKWEDGE, 3Pin Rc

p

t 1

3 of 20

ICON DUAL LEVER BINNACLE MOUNT REMOTE CONTROL

1

2

3

5

4

7, 8, 9

10

14

18, 19

20, 21, 22

13

12

10

15

11

13

17

6

12

11

17

13

16

007918

Ref P/N Name of Part Qt

y

Ref P/N Name of Part Qt

y

1 764910 CONTROL, Sin

g

le binnacle - ICON 1 12 ***SCREW, Handle covers 3

2765316 *HARDWARE KIT, Installation 1 13***COVER, Inside handle 1

3**STUD, Control mountin

g

4 14 ***COVER, Starboard lever 1

4 **WASHER, Mountin

g

415765318**SWITCH, Trim/Tilt 1

5**NUT,Mountin

g

4163011714 ***TERMINAL, Socket 3

6 **SEAL, Control mountin

g

117765354 *SCREW, Handle 1

73011715 *CONNECTOR, 12 Socket

p

lu

g

1183011712 *CONNECTOR, 3Socket

p

lu

g

(

Trim sw

)

1

83011714 *TERMINAL, Socket 319 3011713*LOCKWEDGE, 3Socket

p

lu

g

1

93011716 LOCKWEDGE, 12 Socket

p

lu

g

20 3011709 *CONNECTOR, 3Pin Rc

p

t

(

Trim harnes

s

1

10 765317 *CONTROL HANDLE AY 1 21 3011711 *TERMINAL, Pin 3

11 765319 **HANDLE GRIP KIT 1 22 3011710 *LOCKWEDGE, 3Pin Rc

p

t 1

4 of 20

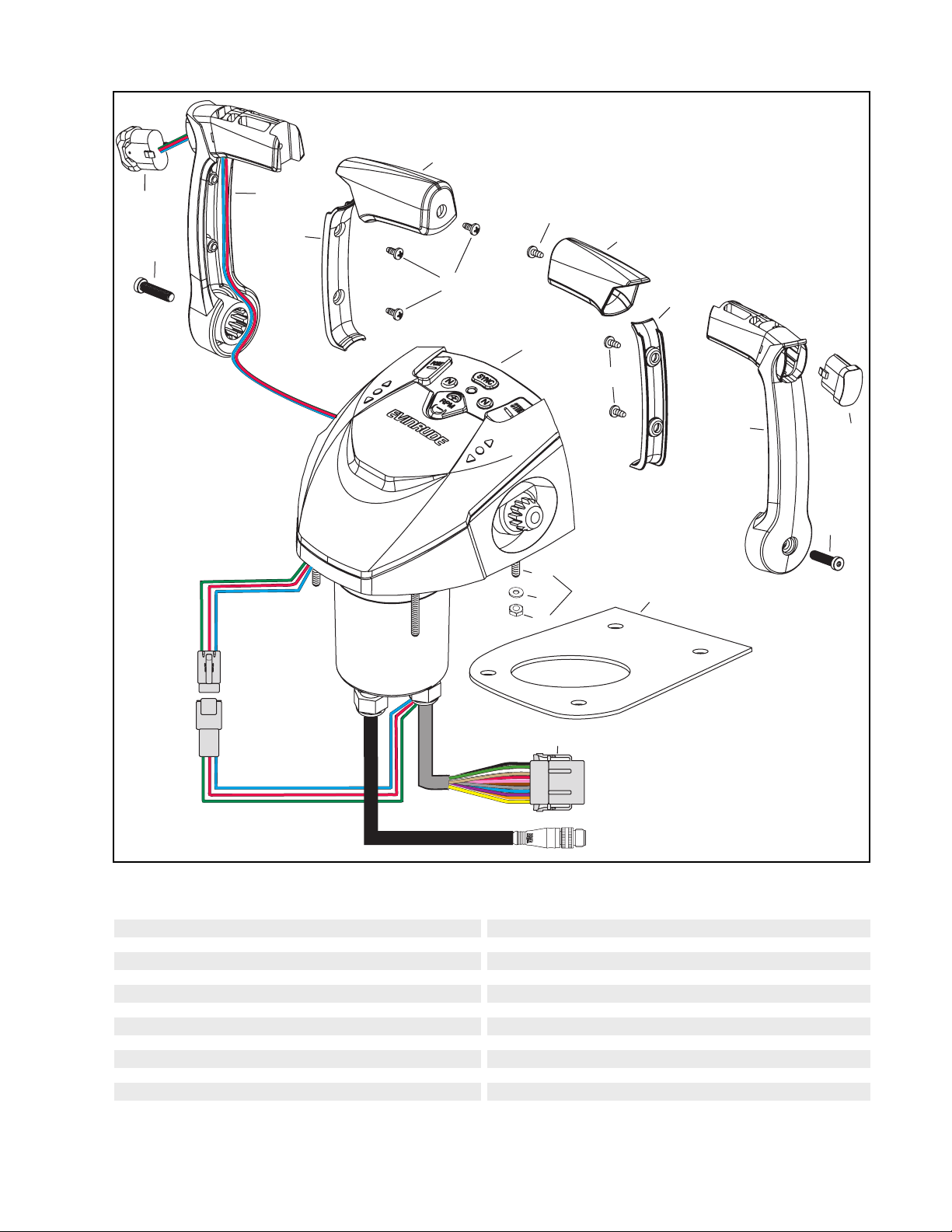

ICON REMOTE CONTROL TRIM PLATES

If upgrading from BRP cable-type binnacle mount remote controls (P/N’s 5006186, 5006184, or

5006182), to an ICON remote control, ICON remote control trim plates are available.

Trim plates cover existing mounting holes and provide pre-drilled mounting for the ICON remote

control.

2 31

007919

Ref P/N Name of Part Qty

1 765075 TRIM PLATE, Single binnacle to ICON (white) 1

1 765076 TRIM PLATE, Single binnacle to ICON (off-white) 1

2 765077 TRIM PLATE, Single binnacle with key switch to ICON (white) 1

2 765078TRIM PLATE, Single binnacle with key switch to ICON (off-white) 1

3765079 TRIM PLATE, Dual binnacle to ICON (white) 1

3765080 TRIM PLATE, Dual binnacle to ICON (off-white) 1

5 of 20

INSTALLATION PROCEDURE

Refer to the ICON System Quick Connection

Guide, P/N 764953 for ICON System Diagram.

Disconnect the battery cables at the battery.

Test remote control operation after installation is

complete.

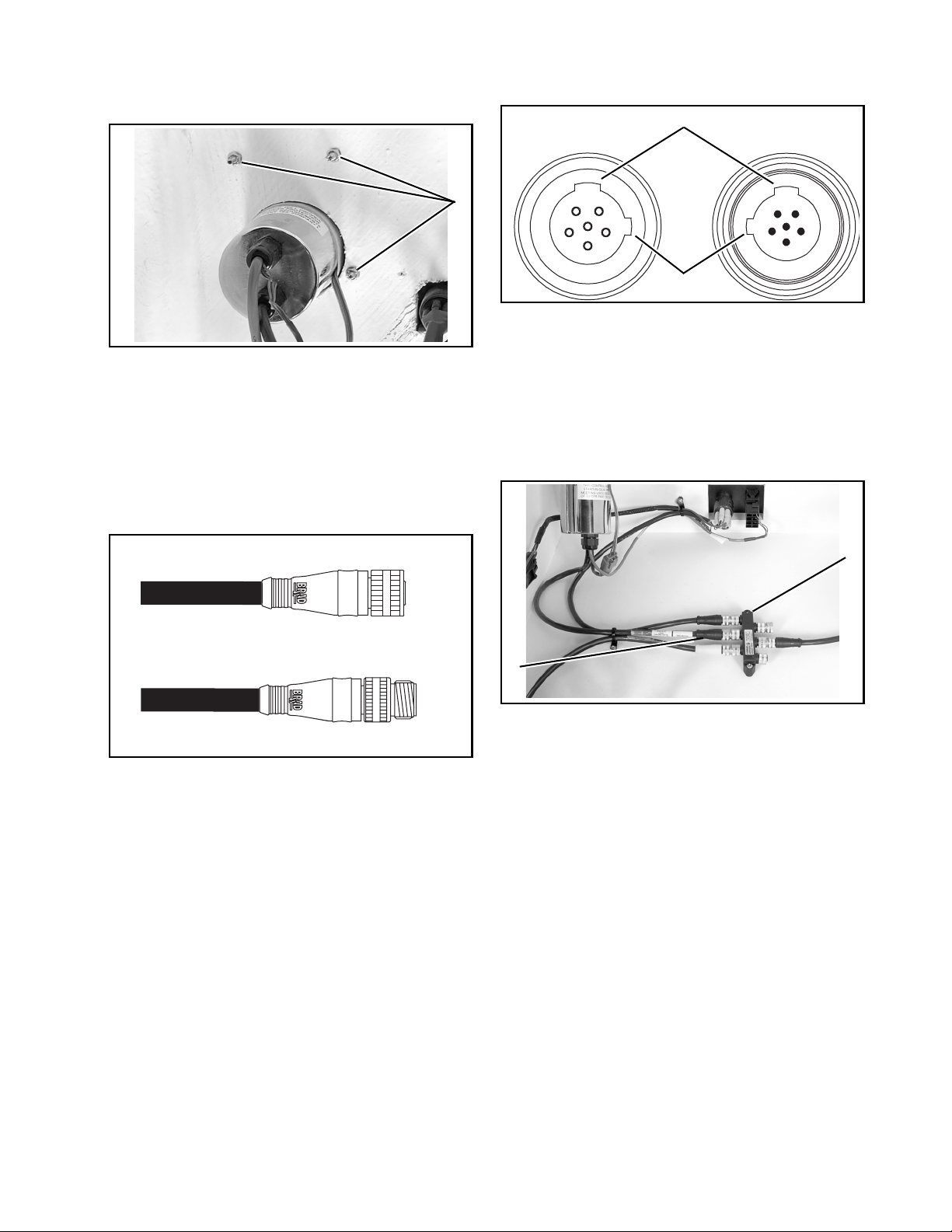

Mounting Location

Select an appropriate location based on the boat

configuration.

IMPORTANT: The mounting location must be a

flat surface and must be strong enough to pro-

vide rigid support. Strengthen mounting surface

as necessary.

Refer to ICON SINGLE BINNACLE REMOTE

CONTROL PROFILE DRAWING on page 14

and ICON DUAL LEVER BINNACLE REMOTE

CONTROL PROFILE DRAWING on page 15

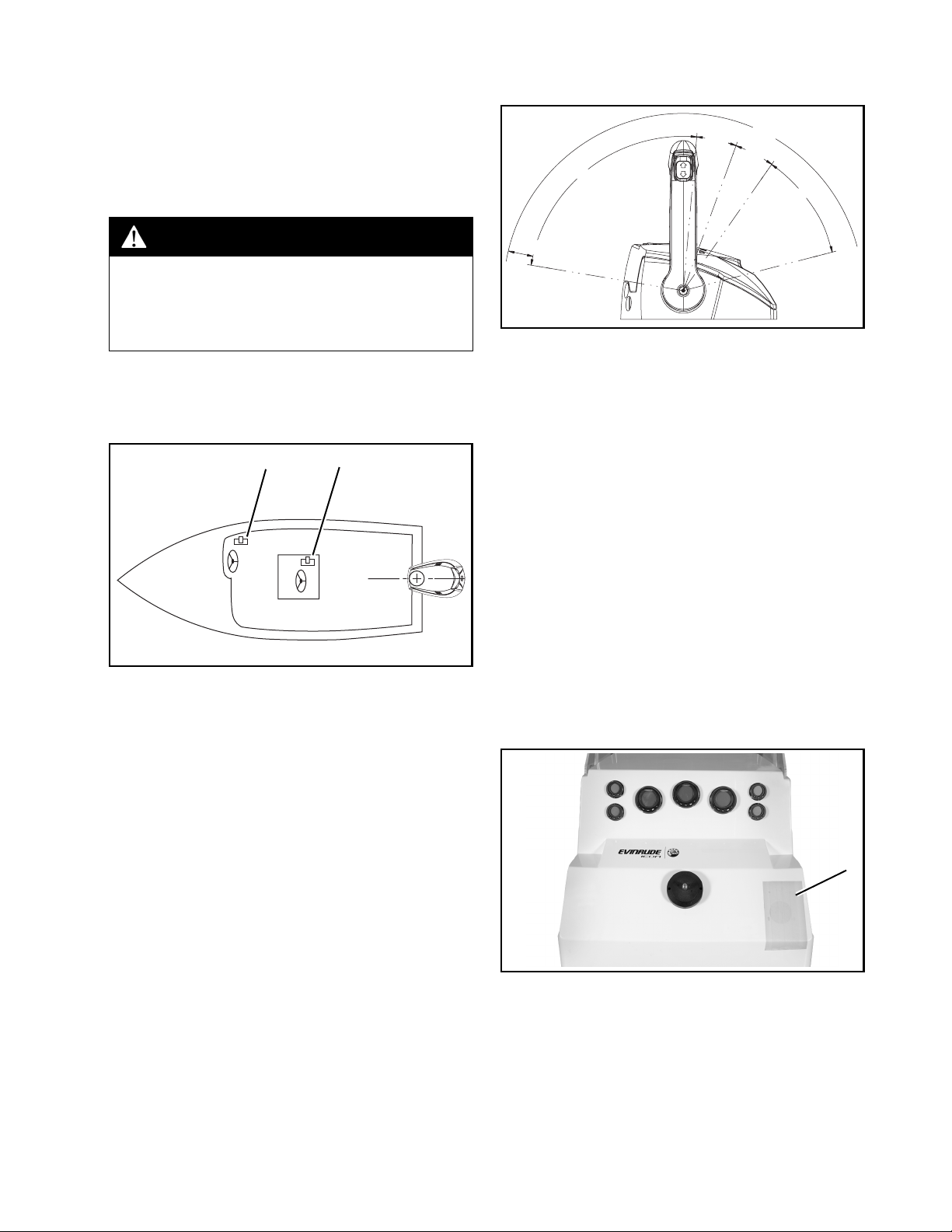

Place remote control at proposed location and

check clearance around remote control lever at

full throttle in FORWARD and then at full throttle

in REVERSE. There must be at least 2.5 in. (64

mm) of clearance between the handle and any

part of the boat throughout the control lever

travel.

There must be at least 5 in. (127 mm) of clear

space below the control for the housing and

network cable routing.

Mounting Holes

Refer to ICON SINGLE BINNACLE REMOTE

CONTROL - DRILL TEMPLATE on page 17 and

ICON DUAL LEVER BINNACLE REMOTE

CONTROL - DRILL TEMPLATE on page 19.

Use appropriate drill template to cut mounting

holes.

IMPORTANT: Make sure the mounting location

has all the required clearances before drilling or

cutting.

Protect mounting surfaces from damage while

drilling. Apply masking tape to fiberglass

surfaces. Use appropriate protection for other

surfaces.

WARNING

Failure to properly install and test remote

control operation may result in remote

control malfunction and the loss of boat

control.

1. Side console

2. Center console

005471

1 2

007920

1. Masking tape 007921

85.5°

FWD

15.0°

15.0°

40.5°

NEUTRAL

REV

2.5 in (64 mm)

1

6 of 20

Position template. Use center punch to mark the

centers of drill locations.

Single Lever Binnacle Mount Controls

Drill three (3) 1/4 in. (6.3 mm) holes at the three

mounting stud locations.

Use a 3 in (76 mm) hole saw to cut out for the

control base.

Dual Lever Binnacle Mount Controls

Drill four (4) 1/4 in. (6.3 mm) holes at the four

mounting stud locations.

Use a 3-1/8 in (79 mm) hole saw to cut out for the

control base.

Mounting Control

Install control on console.

1. Template 007922

1. Three mounting stud locations 007923

1. 3-inch hole saw 007933

1

1

1

1. Four mounting stud locations 007934

1. 3 1/8-inch hole saw 007924

007925

1

1

1

7 of 20

From under console, install washers and #10

locknuts on studs of control. Tighten locknuts to

a torque of 24 to 36 in. lbs. (2.7 to 4 N·m).

IMPORTANT: Make sure remote control as-

sembly is secured to console and does not move

during operation.

ICON Network Buss Cables

ICON network buss cables use a proprietary

6-pin threaded, Molex-type connector.

IMPORTANT: Do not force connectors or lock-

ing rings. Properly aligned connectors should as-

semble easily.

Do not use Electrical Grease on ICON buss

cable connectors.

Align the tabs of the buss cable connectors.

Carefully push connectors together and tighten

locking rings finger tight.

ICON Remote Control Connection

Connect remote control buss cable to ICON

network hub.

If the installation requires a buss cable

extension, use no more than one extension.

Check operation and movement of control

levers. Make sure remote control shift and

throttle functions operate smoothly. Refer to

REMOTE CONTROL OPERATION TESTS on

page 11.

1. Locknuts 007926

1. ICON buss cable connectors 007882

1

1. Large tabs

2. Small tabs

007883

1. Remote control buss cable connector

2. ICON network hub

007884

1

2

2

1

8 of 20

ICON Remote Control Electrical Connections

After all connections are made, connect the battery cables at the battery.

Single Lever Binnacle Mount Control (Single Station)

Install connector from remote control onto START/STOP switch until latched.

Single Lever Binnacle Mount Control (Second Station)

Install connector from remote control onto START/STOP switch until latched.

AB

M

M

3

2

2

1

007927

1. Connector

2. To ICON network buss cable/hub

3. To gateway module/network power cable

2

1

007929

1. Connector 2. To ICON network buss cable/hub

9 of 20

Dual Lever Binnacle Mount Control (Single Station)

Apply a light coat of Electrical Grease™ onto the seal of the Deutsch connector. Push connectors

together until latched.

Dual Lever Binnacle Mount Control (Second Station)

Apply a light coat of Electrical Grease™ onto the seal of the Deutsch connector. Push connectors

together until latched.

M

M

AB

2

3

3

4

1

007928

1. Seal

2. Connector

3. To ICON network buss cable/hub

4. To gateway module/network power cable

1

3

2

007930

1. Seal

2. Connector

3. To ICON network buss cable/hub

10 of 20

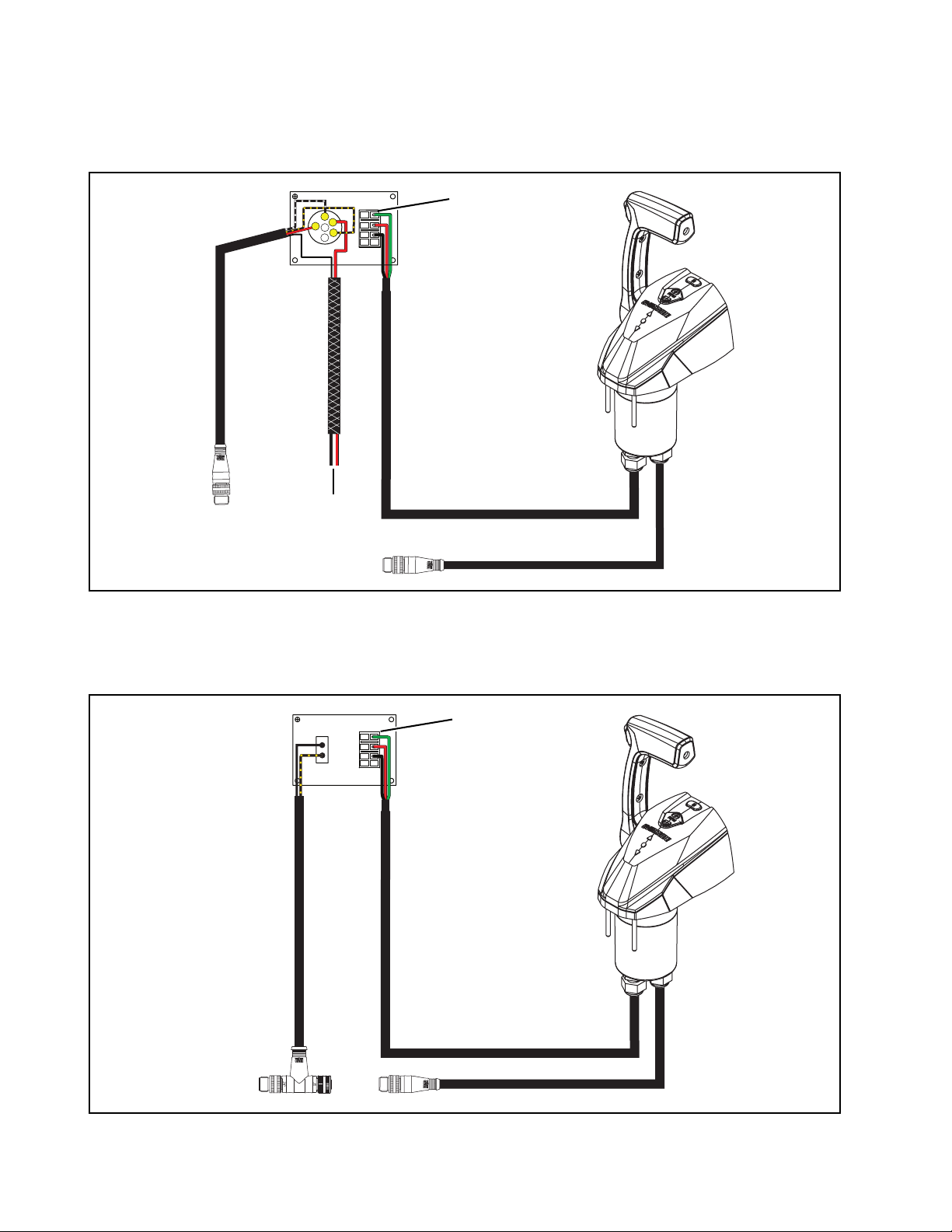

Control Lever Friction Adjustments

Check control lever friction. When properly

adjusted, the control lever(s) should have low

friction to allow easy movement in FORWARD

throttle range, and not allow vibration to change

throttle setting.

Use a flat tip screwdriver to adjust friction

adjustment screws. Turn adjustment screws

clockwise to increase the friction or

counterclockwise to reduce the friction.

Shift Friction

This adjustment is used to increase or reduce the

force required to move the control lever to the

FORWARD and REVERSE gear positions only.

Throttle Friction

This adjustment is used to increase or reduce the

force required to move the control lever through

the throttle range.

SET ENGINE IDENTITY (Instance)

If this kit is being installed on an outboard in a

multi-engine application, the transom position of

the outboard must be identified on the network.

Engine identity is set by an Engine Identity Plug

installed in the ESM. Outboards are identified as

Instance 0 through 4, from port to starboard, up

to five engines.

Each identity plug is stamped with its instance

number.

If the outboard is a single engine or the port

engine in a multi-engine application, no changes

are required.

For all other outboards, engine identity must be

set by replacing the original plug (0) with the plug

that corresponds to the outboard’s position on

the transom.

IMPORTANT: The Engine Identity Plug over-

rides any previous EMM instance setting.

1. Shift friction adjustment screws

2. Throttle friction adjustment screws

007931

1

2

1

2

1. Engine Identity plug 007505

Number of

Outboards

Identity Numbers

Port

Port

Center

Center

Starboard

Center

Starboard

10

20 1

3012

40123

5 01234

1

11 of 20

REMOTE CONTROL OPERATION TESTS

DO NOT run outboard without a

water supply to the outboard’s cooling sys-

tem. Cooling system and/or powerhead dam-

age could occur. Be sure the water intake

screens are below the water surface.

Check Start in Gear Protection

Refer to the ICON User’s Guide or outboard’s

operator’s guide for start procedure and remote

control operation.

Start the outboard and shift into FORWARD

gear.

Turn outboard OFF while remote control is in

FORWARD.

Try to restart the outboard. Outboard should not

start.

Shift into NEUTRAL and restart outboard.

Shift into REVERSE gear. Turn outboard OFF

while remote control is in REVERSE.

Try to restart the outboard. Outboard should not

start.

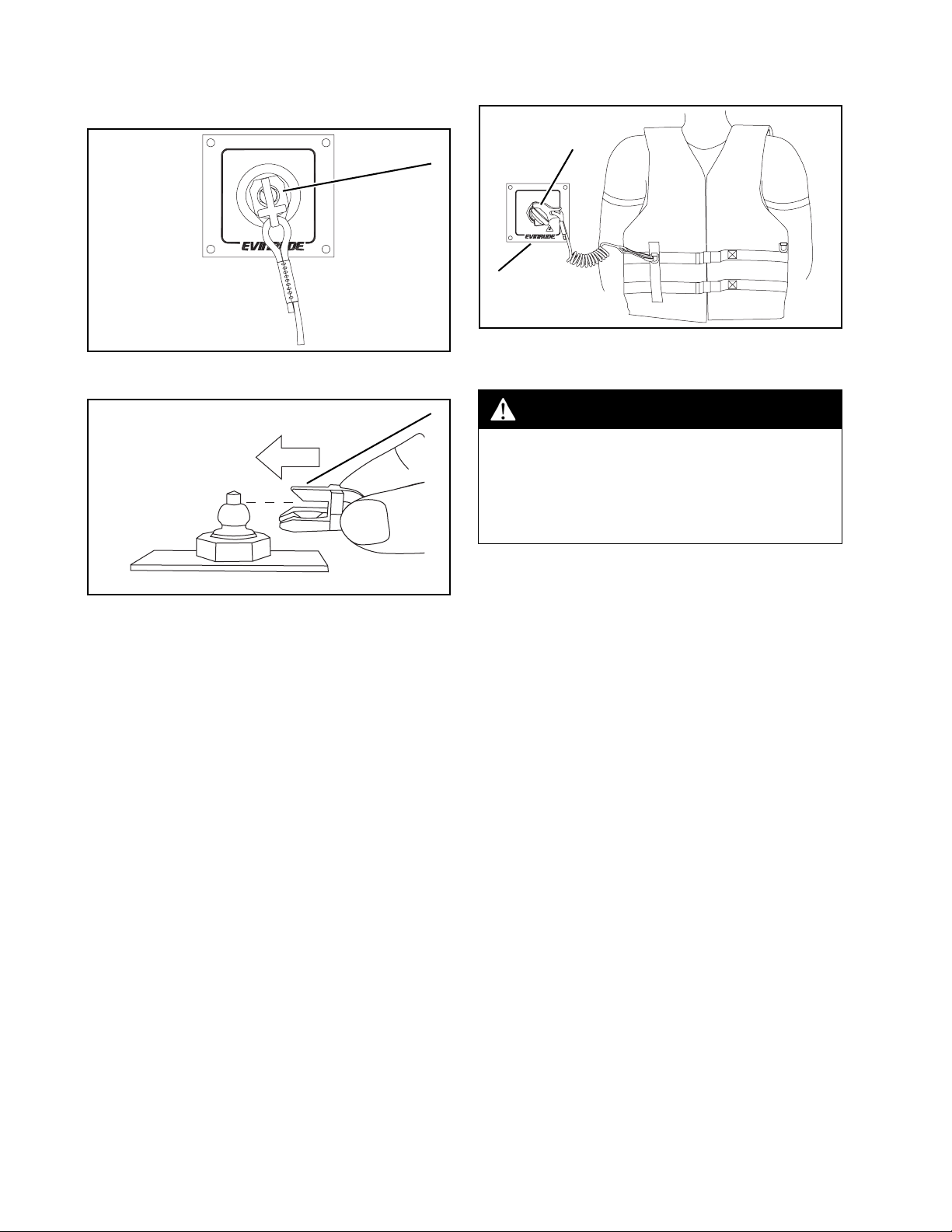

Emergency Stop Test

Main Station

Check emergency stop function. Push clip of

emergency stop lanyard onto master power

switch/key switch.

IMPORTANT: If boat is equipped with an op-

tional second or remote station an emergency

stop lanyard must be installed on the emergency

stop switch of the second station. Engine(s) will

not start without emergency stop clip in place.

Refer to Second or Remote Station.

Start the outboard(s). Refer to ICON User’s

Guide.

With outboard(s) running, remove emergency

stop lanyard. Outboard(s) must STOP. If

outboard does not stop, check master power/key

switch and wiring. Repair as needed.

Reinstall clip on master power/key switch.

WARNING

Make certain starter will not operate when

the outboard is in gear. The start-in-gear

prevention feature is required by the

United States Coast Guard to help prevent

injuries.

NOTICE

1. Clip of emergency stop lanyard 007895

1. Clip of emergency stop lanyard 007896

OFF

RUN 1

1

2

1

12 of 20

Second or Remote Station

Push clip of emergency stop lanyard onto

emergency stop switch. Restart outboard(s).

With outboard(s) running remove emergency

stop lanyard from second station emergency

stop switch. Outboard(s) must STOP. If outboard

does not stop, check emergency stop switch and

wiring. Repair as needed.

On Water Test

Secure boat to dock to prevent motion. Snap the

emergency stop lanyard to a secure place on the

operators clothing or life vest – not where it might

tear away instead of activating the stop switch.

Push clip of emergency stop lanyard onto master

power switch.

Refer to the ICON User’s Guide for remote

control operation.

Position control lever(s) in the NEUTRAL

position to start or stop outboard.

Turn master power/key switch to RUN position.

Press START symbol of START/STOP switch.

Release switch as soon as outboard starts.

Check shift operation. Check that outboard shifts

into FORWARD gear when control is shifted to

FORWARD, and shifts to REVERSE gear when

control is shifted to REVERSE.

1. Clip of emergency stop lanyard 007897

1. Clip of emergency stop lanyard 007898

1

1

1. Clip

2. Master power switch

005499A

WARNING

Lanyard MUST be securely attached to

operator, and clip MUST be installed on

master power switch. DO NOT operate

outboard with clip removed from switch,

except in an emergency.

OFF

RUN

1

2

13 of 20

MAINTENANCE

Check mounting of remote control. Tighten

locknuts or secure as needed.

If an abnormal condition is found, repair as

needed. Replace all damaged parts.

Check operation and movement of control

levers. Make sure remote control shift and

throttle functions operate smoothly. Refer to

REMOTE CONTROL OPERATION TESTS on

page 11.

Keep remote control clean using a cloth

dampened in fresh water.

CAUTION

Inspection and maintenance must be per-

formed with outboard stopped. Discon-

nect emergency stop lanyard and

disconnect the battery cables at the bat-

tery to prevent accidental starting of out-

board.

14 of 20

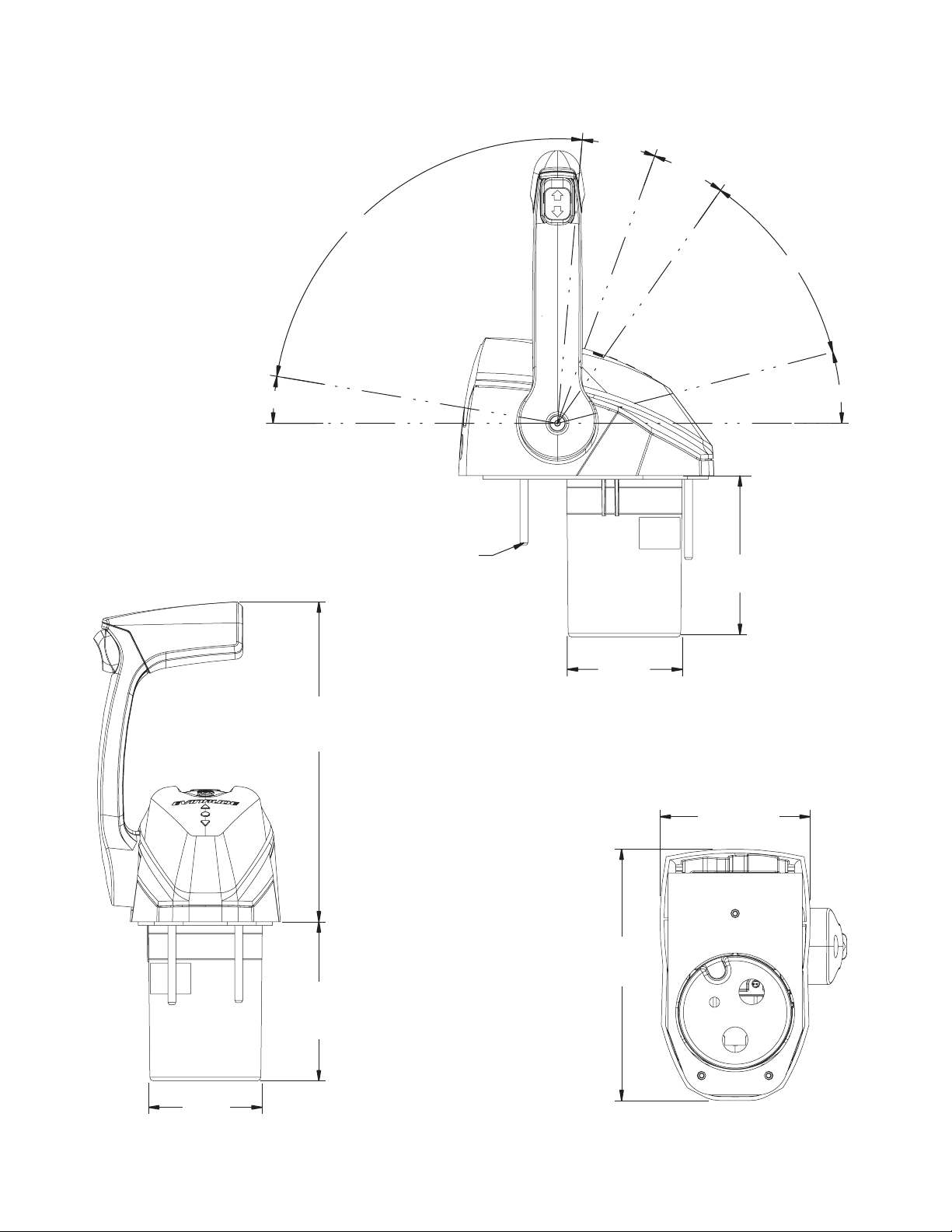

ICON SINGLE BINNACLE REMOTE CONTROL PROFILE DRAWING

Drawing NOT to scale.

FWD

REV

NEUTRAL

15°

15°

40.5°

14.5°

85.5°

9.5°

FWD WOT

REV WOT

#10 - 32 x 2.38 IN (60.45 mm)STUD

3X 3.86 IN

(98.044 mm)

2.76 IN

(70.104 mm)

2.76 IN

(70.104 mm)

3.86 IN (98.04 mm) 7.76 IN (197.10 mm)

3.64 IN

(92.46 mm)

6.10 IN (154.94 mm)

007935

15 of 20

ICON DUAL LEVER BINNACLE REMOTE CONTROL PROFILE DRAWING

Drawing NOT to scale.

85.5°

FWD

15.0°

15.0°

40.5°

14.5°

9.5°

#10-32 x 2.38 IN (60.45 mm) STUD

4X

2.93 IN

(74.422 mm)

3.86 IN

(98.044 mm)

NEUTRAL

REV

REV WOT

FWD WOT

6.78 IN (172.21 mm)

5.78 IN (146.81 mm)

7.33 IN (186.18 mm)

7.76 IN (197.10 mm)

ENGINE TRIM SWITCH

1.56 IN (39.62 mm)

2.93 IN

(74.42 mm)

3.86 IN

(98.04 mm)

007936

16 of 20

17 of 20

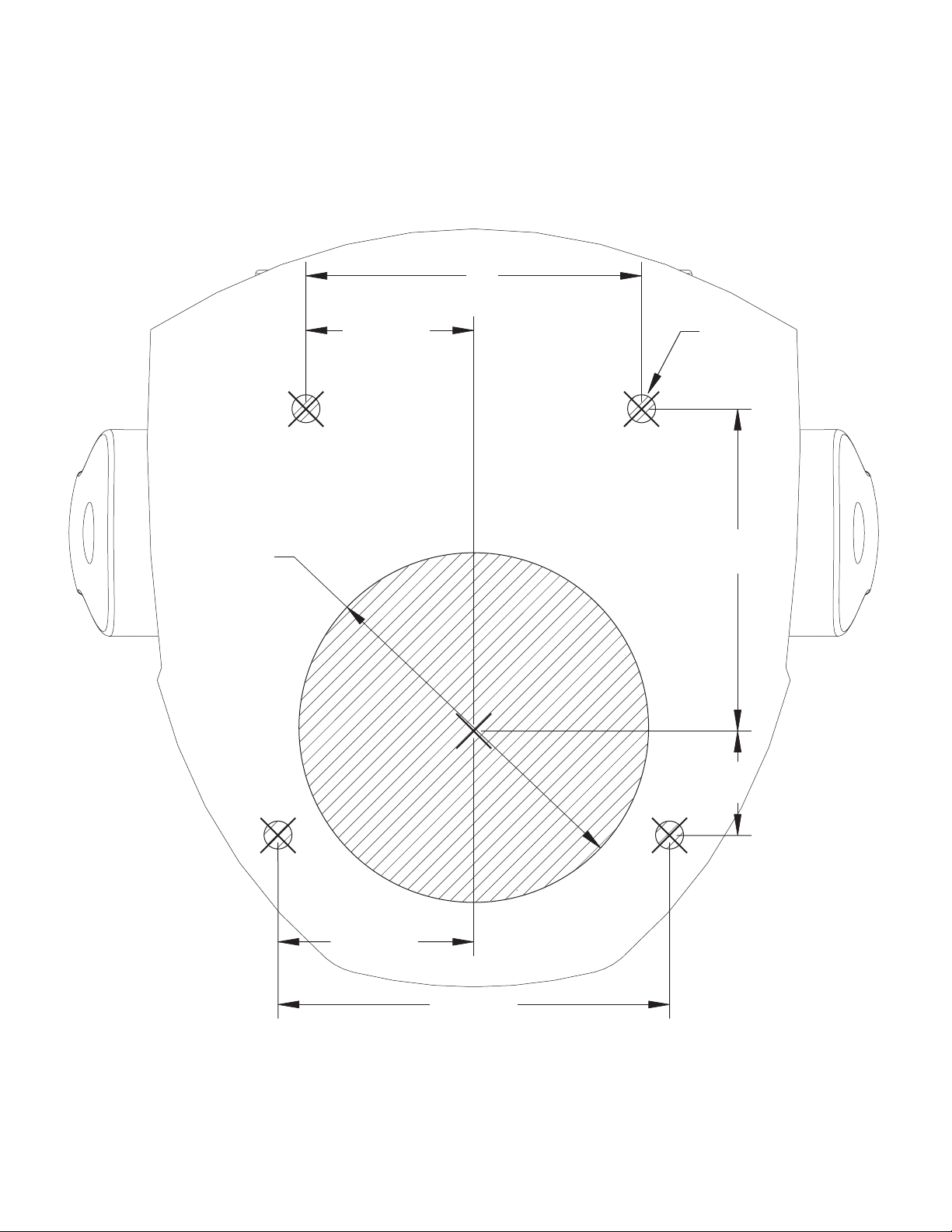

ICON SINGLE BINNACLE REMOTE CONTROL - DRILL TEMPLATE

Drawing to scale.

3X 1/4 IN

3 IN

2 - 13/32 IN

(61.12 mm)

(38.9 mm)

1 - 17/32 IN

1 - 5/8 IN

13/16 IN

(6.35 mm)

(76.2mm)

(41.275 mm)

(20.64 mm)

007937

18 of 20

19 of 20

ICON DUAL LEVER BINNACLE REMOTE CONTROL - DRILL TEMPLATE

Drawing to scale.

3 IN

1 - 1/2 IN 4X

1/4 IN

2 - 7/8 IN

3 - 1/8 IN

15/16 IN

3 - 1/2 IN

1 - 3/4 IN

(6.35 mm)

(38.1 mm)

(38.45 mm)

(88.9 mm)

(79.375 mm) (73.025 mm)

(23.8125 mm)

(76.2 mm)

007938

20 of 20

This manual suits for next models

9

Table of contents

Languages:

Popular Remote Control manuals by other brands

Epson

Epson PowerLite Home Cinema 8350 Installation handbook

Philips

Philips Pronto SBC RU 950 Gebruiksaanwijzing

Magnavox

Magnavox MRU1400 - Universal Remote Control Specifications

Panasonic

Panasonic DMW-RSL1 operating instructions

Leviton

Leviton ZLS0R-RC1 installation instructions

Universal Remote Control

Universal Remote Control Automator URC-200 owner's manual