evoheat EVO COMFORT Series User manual

Page | 1

Page | 2

Contents

1. Preface .........................................................................................................................................3

2. Information on the Evo Comfort .................................................................................................4

2.1 Evo Comfort Technology ...................................................................................................4

2.2 Running Range ...................................................................................................................4

2.3 Functions ...........................................................................................................................5

2.4 Heat Pump Protection .......................................................................................................5

2.5 Specification Data ..............................................................................................................6

2.6 Unit Dimensions ................................................................................................................ 7

3. Safety Precautions .....................................................................................................................11

4. Installation .................................................................................................................................13

4.1 Transit ..............................................................................................................................13

4.2 Installation Notes.............................................................................................................13

4.3 Water Loop Connection...................................................................................................14

4.4 Location of the Unit .........................................................................................................15

4.5 Water Connection Diagram.............................................................................................16

4.6 Power Supply Connection................................................................................................16

4.7 Cable and Switches..........................................................................................................17

4.8 Inspection Before Trial Operation ...................................................................................18

4.9 Trial Operation.................................................................................................................18

5. Controlling and Operation .........................................................................................................19

5.1 Main Interface Display and Function...............................................................................19

5.1.1 Power On Screen ......................................................................................................19

5.1.2 Start Up Screen.........................................................................................................19

5.2 Wire Controller Usage .....................................................................................................21

5.2.1 On and Off ................................................................................................................21

5.2.2 Mode Switch .............................................................................................................21

5.2.3 Setting Target Temperature .....................................................................................22

5.2.4 Fast Heating..............................................................................................................23

5.2.5 Timer Setting ............................................................................................................23

5.2.6 Fault Interface ..........................................................................................................24

5.2.7 Colour Display Calibration ........................................................................................24

6. Troubleshooting.........................................................................................................................25

6.1 Maintenance....................................................................................................................25

6.2 Malfunction Table............................................................................................................26

6.3 Parameter List..................................................................................................................27

7. Main Controller Terminals.........................................................................................................28

7.1 Wire Control Interface Diagram and Definition ..............................................................28

7.2 The Main Controller Terminals........................................................................................28

7.3 Connection of PCB Illustration.........................................................................................30

7.4 Common Observations ....................................................................................................31

8. Appendix ....................................................................................................................................32

8.1 Caution & Warnings.........................................................................................................32

8.2 Cable Specifications.........................................................................................................33

Page | 3

1. Preface

This manual includes all the necessary information in regard to installation, debugging, discharging

and maintenance of your unit. Ensure the contents of this manual are read carefully before the unit

is opened or maintained.

Read these operation and installation instructions carefully. Positioning, installation and

commissioning must be carried out by trained personnel working in accordance with these

instructions.

If the heat pump is to be installed at a later time, keep it free from damage, rust and abrasion by

using the following methods:

-All access points such as water connections must be sealed correctly

-The unit must be free from sun exposure, and kept in temperatures of under 45°

-Ensure a dust build up does not occur on the unit to avoid dirt reaching the evaporator

It is vital that all instructions are adhered to at all times to keep the warranty. The unit can only be

installed or repaired by a qualified installer and authorised dealer. Maintenance and operation

should be carried out according to the recommended frequency. Only genuine standard spare

musts must be used. Pictures and drawings in this manual are for your information only. The

manufacturer has the right to change or improve the product when required, without prior

notification to the users of this device.

Page | 4

2. Information on the Evo Comfort

2.1 Evo Comfort Technology

The Evo Comfort extracts heat from ambient air and transfers it to water. By circulating the water, the

energy is used to warm the house efficiently. Compared with oil boilers, gas boilers, and electrical heaters,

the heat pump is the best solution by providing high efficiency, safety, and environmental protection.

The Evo Comfort is ideal for luxury domestic and commercial applications that require space heating and

cooling and hot water, offering a unique high efficiency solution to heating, cooling and hot water using the

one heat pump.

The Evo Comfort provides hot water up to 65°C and by combining EVI Technology, features a wide operating

temperature range with stable running performance - even in cold climates. Using Wet Injection Technology

allows the Evo Comfort to work safely with reliability at ambient temperatures as low as -30°C.

ECO FRIENDLY

HIGHLY EFFICIENT AND MONEY SAVING

SAFE TO USE AND LONG UNIT LIFE

EASY OPERATION

2.2 Running Range

Evo Comfort 19 / 37 / 50 / 100

Page | 5

Running Ambient Temperature Comparison

2.3 Functions

•Heating/Cooling

•Smart Defrost

•Auto Protection

•Multiple Module Control

•Automatic Reset for Partial Failure

•Auto Alert

•Remote Control

2.4 Heat Pump Protection

•Water flow protection

•Compressor overload, discharge air temp protection

•Discharge air pressure over high protection

•Suction air pressure over low protection

•Water (out) temperature over high protection

•Water (out) temperature over low protection

•Suspend anti-freezing protection in winter

•Compressor frequent switching protection

Page | 6

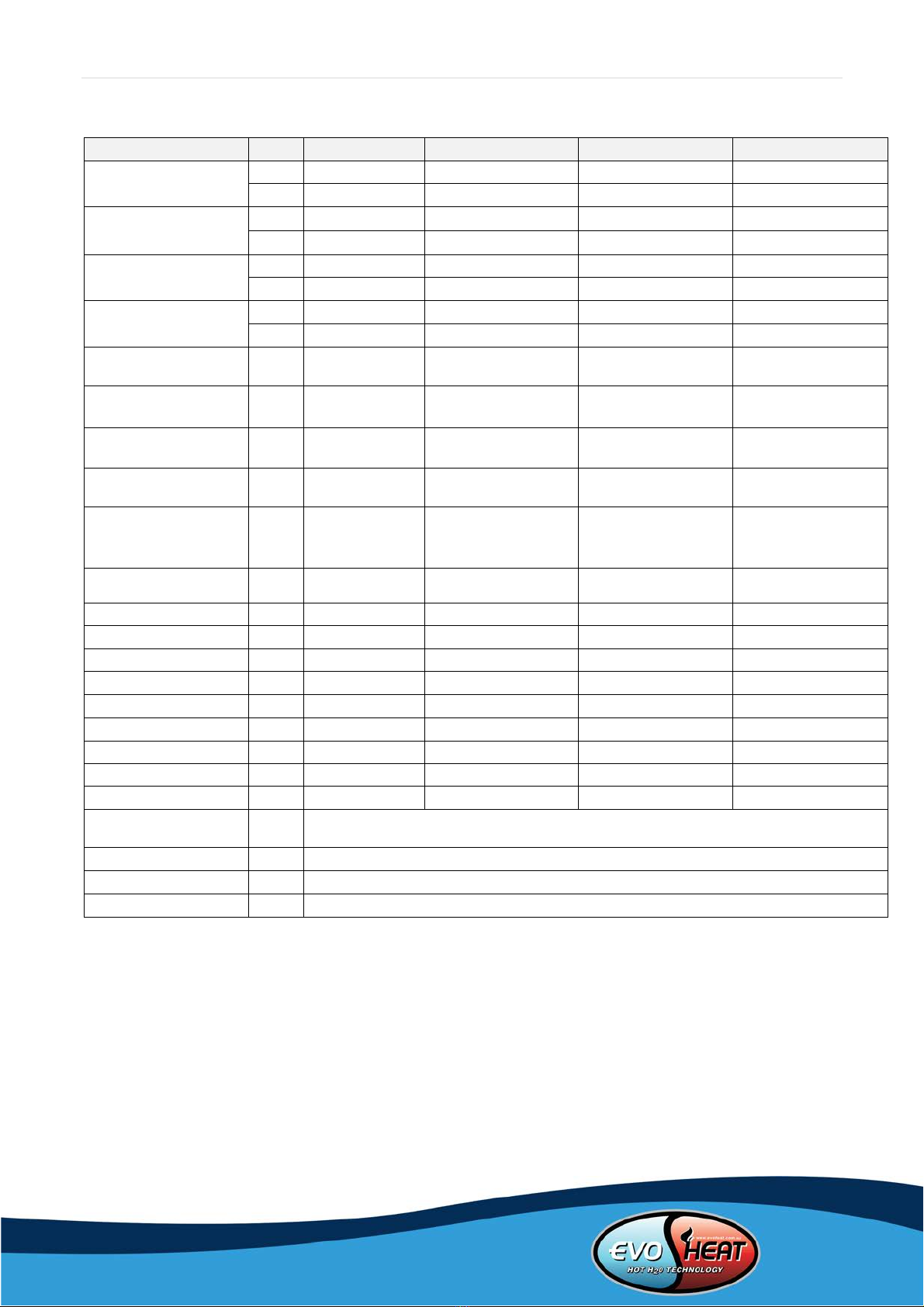

2.5 Specification Data

1. *Hot Water: outdoor temperature DB/WB20°C/15°C , outlet water circulation from 15°C to 55°C;

2. **Heating: outdoor temperature DB/WB7°C/6°C , outlet water 55°C, inlet water (return) 50°C;

3. ***Heating: outdoor temperature DB/WB7°C/°6C , outlet water 35°C, inlet water (return) 30°C;

4. Cooling: outdoor temperature DB/WB35°C/24°C , outlet water 7°C, inlet water (return) 12°C.

Evo Comfort Model

19

37

50

100

*Heating Capacity

kW

19.0

36.5

50

100

kcal/h

16337

31384

42992

85984

**Heating Capacity

kW

15.9

31.4

43

86.0

kcal/h

13672

26999

36973

73947

***Heating Capacity

kW

15.7

31.1

42

84.0

kcal/h

13500

26741

36114

72227

Cooling Capacity

kW

11.5

18.0

27.3

59.0

kcal/h

9888

15477

23473

46948

*Power Input for

Heating

kW

4.1

7.8

10.8

22.0

**Power Input for

Heating

kW

5.3

10.6

14.5

29.0

***Power Input for

Heating

kW

3.47

7.4

10

20.0

Power Input for

Cooling

kW

4.0

7.5

10.6

21.9

Running Current

(*Heating/**Heating/

***Heating/Cooling)

A

7.1/8.2/6.0/6.9

13.5/18.4/12.8/13.0

19.2/25.8/17.8/18.8

46.7/61.5/42.4/46.5

Power Supply

380-415V/3N~/50Hz 380-415V/3N~/50Hz 380-415V/3N~/50Hz 380-415V/3N~/50Hz

Compressor Quantity

1

2

1

2

Compressor Type

EVIScroll

EVIScroll

EVIScroll

EVIScroll

Fan Quantity

2

2

1

2

Fan Power Input

W

140x2

300x2

1100x1

1100x2

Fan Rotate Speed

RPM

850

875

900

900

Noise

dB(A)

60

65

68

73

Water Connection

inch

1

1.5

1.5

DN80 Flange

Water Flow Rate

M3/h

2.6

5.2

8.5

17

Water Pressure Drop

kPa

60

53

60

65

Unit Dimension

(L/W/H)

mm

(Subject to drawings of the heat pump)

Packing Size (L/W/H)

mm

(Subject to data on the package)

Net Weight

kg

(Subject to data on the nameplate)

Gross Weight

kg

(Subject to data on the package)

Page | 7

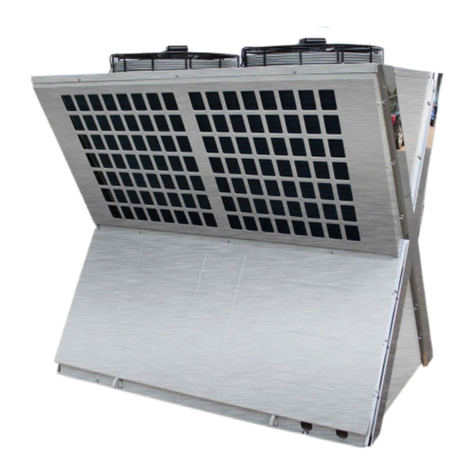

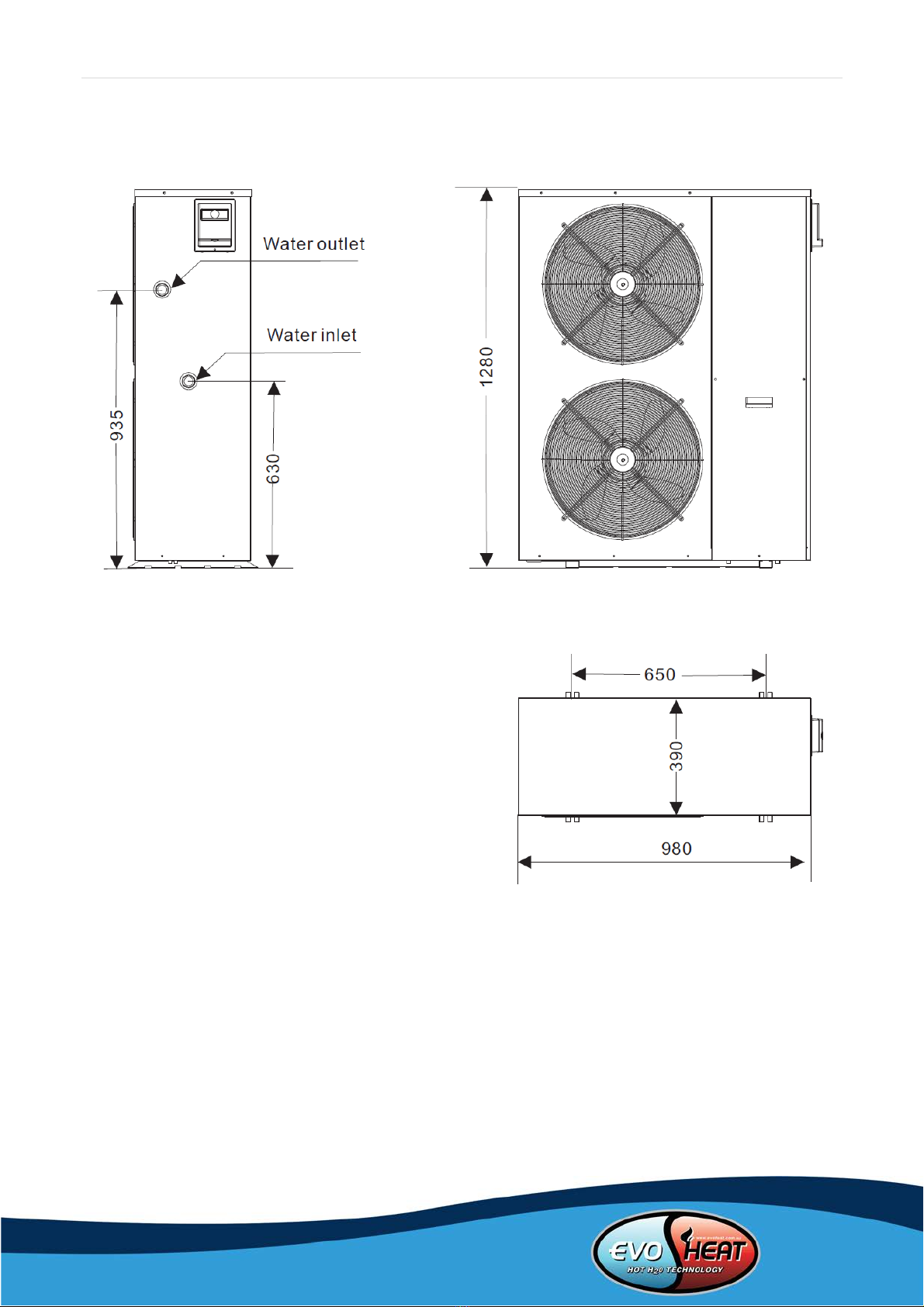

2.6 Unit Dimensions

Evo Comfort 19

Page | 8

Evo Comfort 37

Page | 9

Evo Comfort 50

Page | 10

Evo Comfort 100

Page | 11

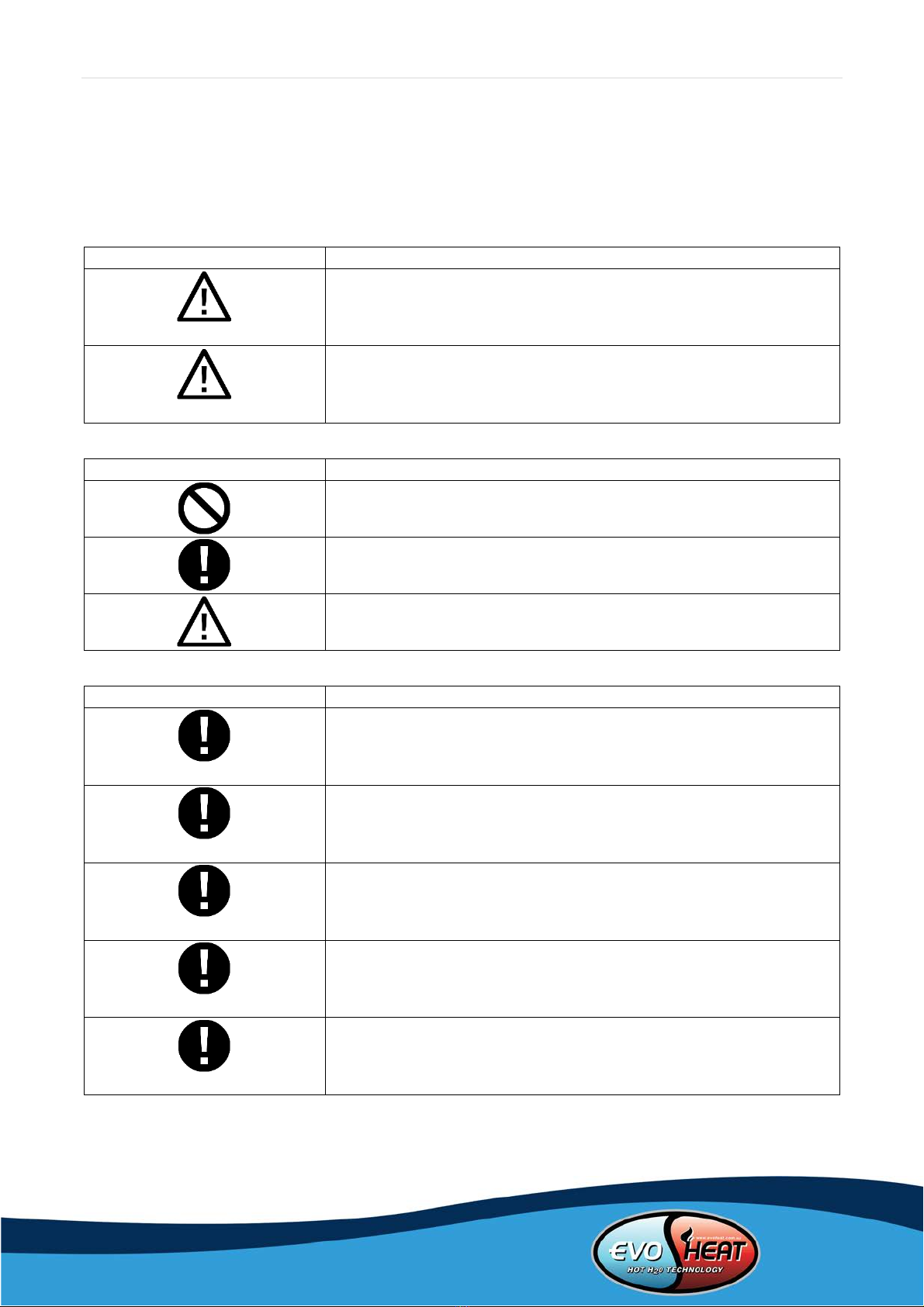

3. Safety Precautions

To prevent personal injury and avoid causing damage to the unit, be sure to read the information

documented below.

The piping connection and wiring should be installed according to the local legislation and regulations as well

as the professional standard.

Mark

Meaning

WARNING

Wrong operation may lead to death or fatal injury on people.

ATTENTION

Wrong operation may lead to harm on people of loss of life.

Icon

Meaning

Prohibition. What is prohibited will be nearby this icon.

Compulsory implement. The listed action needs to be taken.

ATTENTION (including WARNING)

Please pay attention to what is indicated

Installation

Meaning

Professional installer is required

The heat pump must be installed by qualified personnel to avoid

improper installation which can lead to water leakage, electrical shock

or fire.

Earthing is required

Please make sure that the unit and power connection have good

earthing, otherwise this may cause electrical shock.

Installation Place

The unit CANNOT be installed near a flammable gas. Once there is any

leakage of the gas, fire can occur.

Fix the unit

Make sure that the basement of the heat pump is strong enough to

avoid any falling down of the unit.

Need circuit breaker

Make sure that there is circuit breaker for the unit, lack of circuit

breaker can lead to electrical shock or fire.

Page | 12

Operation

Meaning

PROHIBITION

DO NOT put fingers or objects into the fans and evaporator of the unit,

otherwise harm may occur.

Shut off the power

When there is something wrong or a strange smell, the power supply

needs to be shut off to stop the unit. Continuing to run may cause

electrical shortage or fire.

Check the installation basement

Please check the installation basement periodically (monthly), to avoid

any damage on the basement, which may hurt people or damage the

unit

Shut off the power

Please switch off the power for cleaning or maintenance.

Prohibition

It is prohibited to use copper or iron as fuse. The right fuse must be

fixed by an electrician for the heat pump.

Prohibition

It is prohibited to spray flammable gas near the heat pump as it may

cause fire.

Move and Repair

Meaning

Entrust

When the heat pump needs to be moved or installed again, please

entrust the dealer or qualified person to carry it out. Improper

installation will lead to water leakage, electrical shock, injury or fire.

Entrust

When the heat pump needs to be repaired, entrust the dealer or a

qualified person to carry it out. Improper movement or repair on the

unit will lead to water leakage, electrical shock, injury or fire.

Prohibit

It is prohibited to repair the unit by the user himself, otherwise

electrical shock or fire may occur.

Page | 13

4. Installation

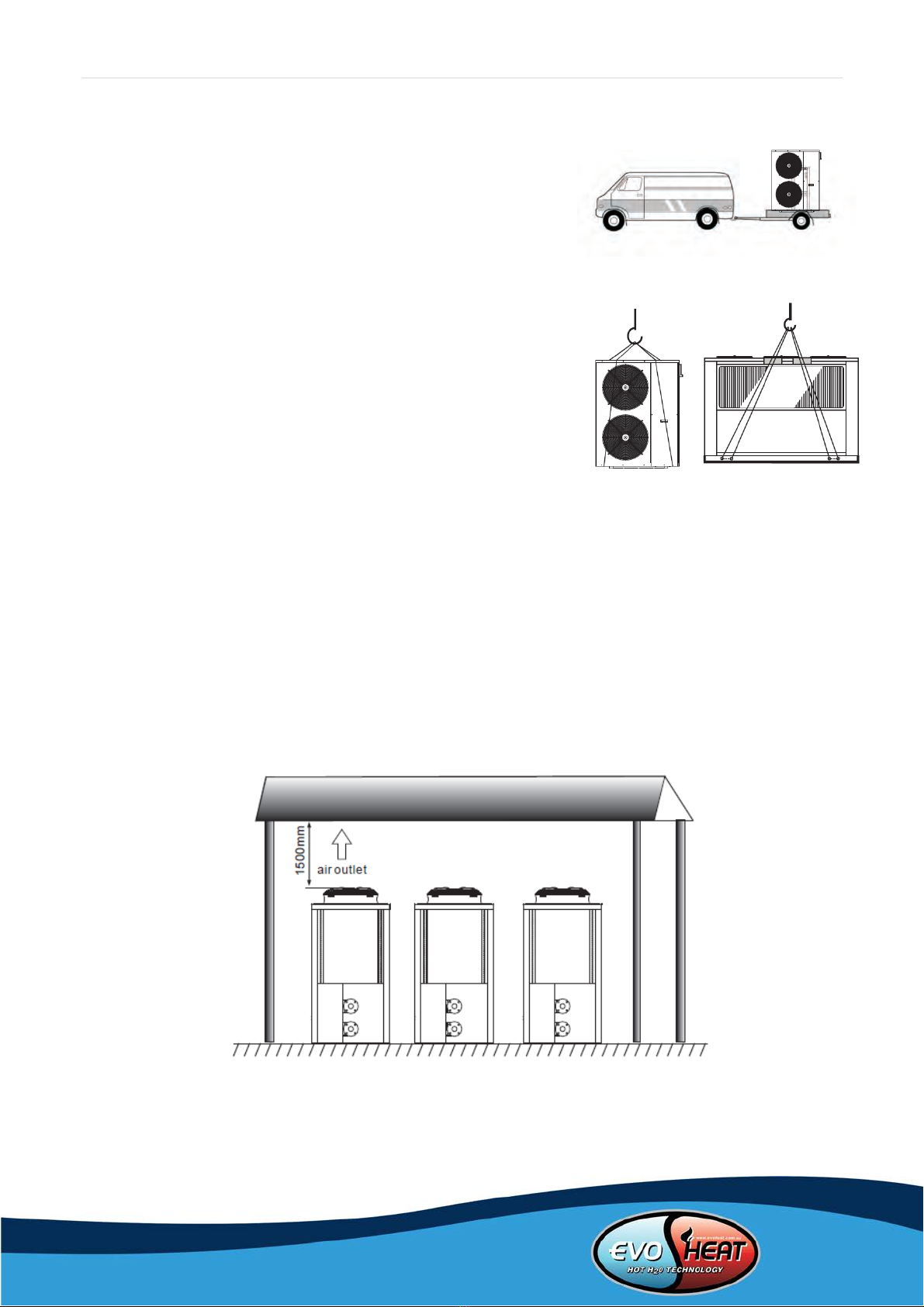

4.1 Transit

When the heat pump is to be transported, please keep the unit

standing upright. The unit cannot be laid down, otherwise inner

parts of the device may become damaged.

If the unit needs to be hung up during installation an 8 metre cable

will be needed to do so. There must be padding of some kind

between the cable and the unit to prevent damage to the heat

pump cabinet.

DO NOT TOUCH THE RADIATING FINS BEHIND THE MACHINE WITH

HANDS OR OBJECTS!

4.2 Installation Notes

-The unit can be installed in any outdoor area which can carry heavy machinery, such as a terrace,

rooftop, the ground etc.

-The location must have adequate ventilation and be free from strong winds.

-The installation location must be free from heat radiation and fire hazards.

-Ensure there are no obstacles near the air inlet and outlet of the heat pump.

-There must be a water channel around the heat pump to drain condensing water.

-Ensure that there is enough space around the unit for maintenance.

-The heat pump can be installed onto the concrete basement using expansion screws, or onto a steel

frame with rubber feet which can be placed on the ground or rooftop. Ensure the unit is placed

horizontally.

A snow shelter is required in areas that receive snow:

Page | 14

4.3 Water Loop Connection

•Try to reduce the resistance to the water from the piping.

•The piping must be clear and free from dirt and blockage. A water leakage test must be carried out to

ensure that there is no water leaking before the installation can be made.

•The pipe must be tested by pressure separately. DO NOT test it together with the unit.

•There must be an expansion tank on the top point of the water loop, and the water level inside the tank

must be at least 0.5meters higher than the top point of the water loop.

•The flow switch is installed inside of the heat pump, check to ensure that the wiring and action of the

switch is normal and controlled by the controller.

•The connection between the heat pump and the construction is best to be of a flexible type to avoid

vibration transfer. The support to the water pipe must be separate, but not rely on the heat pump unit.

•Try to avoid any air from being trapped inside the water pipe, there must be an air vent on the top point

of the water loop.

•There must be a thermometer and pressure meter at the water inlet and outlet for easy inspection

during running.

•There must be drainage on the low points of the water system, and there is already drainage on the

chassis of the heat pump. The water in the system must be drained out during winter if the heat pump is

not to be used.

Page | 15

4.4 Location of the Unit

This map only shows a single heat pump positioning.

ATTENTION

Requirement:

A>1500mm;

B>1000mm;

C>500mm;

D>1000mm.

The size of unit

Parallel model

L(mm)

W(mm)

H(mm)

Two units

2180

3160

2100

Three units

2180

5240

2100

Four units

2180

7320

2100

Five units

2180

9400

2100

The schematic diagram of installation

1

The place for maintenance more than 1500mm

2

The distance between two units more than 1500mm

3

The place for maintenance more than 1500mm

4

The place for maintenance more than 1500mm

5

The place for maintenance more than 1200mm

6

The distance between two units more than 1500mm

Page | 16

4.5 Water Connection Diagram

4.6 Power Supply Connection

-Open the front panel and open the power supply access.

-The power supply must go through the wire access and be connected to the power supply terminals in

the controlling box. Then connect the 3-signal wire plugs of the wire controller and main controller.

-If the outside water pump is needed, please inset the power supply wire into the wire access as well and

connect to the water pump terminals.

-If an additional auxiliary heater is needed to be to be controlled by the heat pump controller, the relay

(or power) of the aux-heather must be connected to the relevant output of the controller.

Page | 17

4.7 Cable and Switches

•The unit should use independent power supply, Wiring required by the corresponding table, Power

supply voltage must in line with rated voltage.

•Power supply circuit must be equipped with an All-pole disconnect device that has at least 3mm contact

opening distance.

•The wiring must be completed by professional technicians in accordance with circuit diagram.

•Power supply circuit must have earth wire, the earth wire of power should be connected with external

earth wire safely, and the external earth wire must be in order.

•The creepage protection device must be settled in accordance with the relevant national technical

standards for electronic equipment.

•The power wire and signal wire should be neatly arranged. High voltage wire and low voltage wires must

be separated and free from any interference, and they must be free from any piping and valves of the

unit.

•When all the wiring is completed, the power can only be connected after a double check.

Power Specifications

Unit Model

Power Supply

Cable

MCB

Creepage

Protector

Evo Comfort 19

380-415V/3N~50Hz

Section area

Earthing wire

40A

30mA less than

0.1 second

4x4mm2

2.5mm2

Evo Comfort 37

380-415V/3N~50Hz

Section area

Earthing wire

80A

30mA less than

0.1 second

5x16mm2

16mm2

Evo Comfort 50

380-415V/3N~50Hz

Section area

Earthing wire

80A

30mA less than

0.1 second

5x16mm2

16mm2

Evo Comfort

100

380-415V/3N~50Hz

Section area

Earthing wire

100A

30mA less than

0.1 second

25x4mm2

25mm2

Page | 18

4.8 Inspection Before Trial Operation

Check the indoor unit, make sure that the pipe connection is done correctly and that the relevant valves are

open.

Check the water loop to ensure that there is enough water inside of the expansion tank, that the water

supply is good and that the water loop has no air in it and is full of water. Make sure there in good insulation

for the water pipe.

Check the electrical wiring. Make sure that the power voltage is normal, the screws are fastened, the wiring

is made in line with the diagram and the earthing is connected.

Check that the heat pump, including all the screws and different parts are in good order. When the power is

on, review the indicator on the controller to see if there are any failure indications. The gas gauge can be

connected to the check valve to see the high pressure (or low pressure) of the system during trial running.

4.9 Trial Operation

Start the heat pump by pressing the ‘Power Button’ key on the controller. Check whether the water pump is

running, if it is running normally there will be 0.2MPa on the water pressure meter.

When the water pump runs for 1 minute, the compressor will start. Hear whether there is a strange sound

coming from the compressor. If an abnormal sound occurs, please stop the unit and check the compressor. If

the compressor runs well, look for the pressure meter of the refrigerant.

Check whether the power input and running current is in line with the manual. If not stop the unit and check

for why this may be occurring.

Adjust the valves on the water loop to make sure that the hot (cool) water supply to each door is good and

meets the requirement of heating (or cooling).

Review whether the outlet water temperature is stable.

The parameters of the controller are set by the factory, the user must not change these.

Page | 19

5. Controlling and Operation

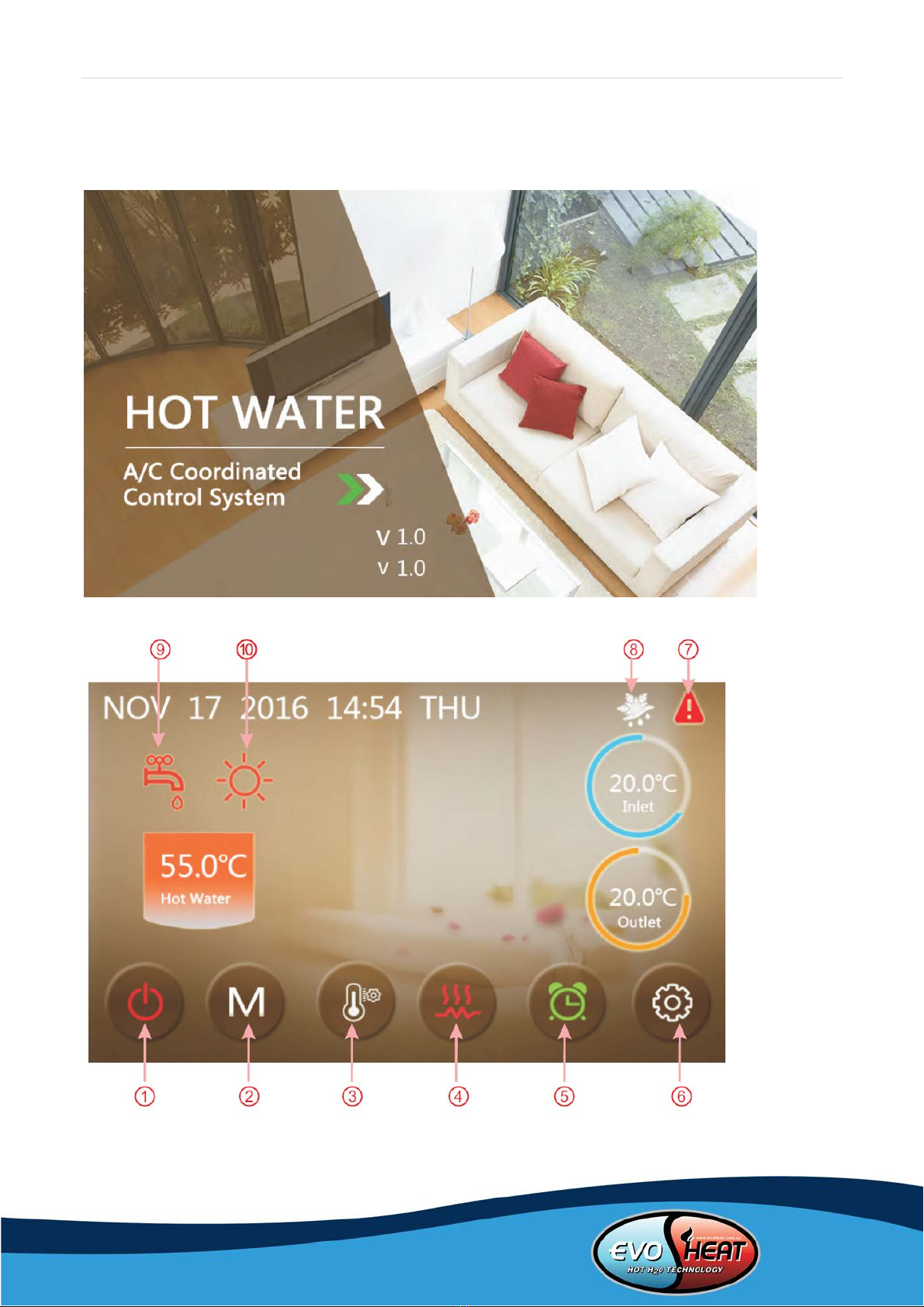

5.1 Main Interface Display and Function

5.1.1 Power On Screen

5.1.2 Start Up Screen

Page | 20

Key Functions

Key No.

Key Name

Key Function

1

On and off

Click this key to switch ON or OFF

Red represents ON, while grey represents OFF

2

Mode key

Hot water mode, heating mode, cooling mode, hot water + heating

mode or hot water + cooling mode can be selected by pressing this key

3

Temperature setting

Click this to set the target temperature

4

Fast heating

Click this key to start rapid heating

This key will be displayed during heating

5

Timer setting

Click this key to set the timer. White represents not enabled, while

green represents enabled

6

Setup key

Click this key to check the unit status, time, factory parameters,

temperature curve, timer setting and mute setting

7

Fault icon

This icon will flash when there is an error occurring, then the display

will enter the failure record interface after tapping this icon

Note:

8is the defrosting icon, the machine is in defrosting mode when this icon is shown

9is the hot water mode icon, this machine is in hot water mode then this icon is shown

10 is the heating mode icon, this machine is in heating mode when this icon is displayed

This manual suits for next models

4

Table of contents

Other evoheat Heater manuals

Popular Heater manuals by other brands

MV Heating

MV Heating MV Airo 2 instruction manual

Honeywell

Honeywell COMFORTTEMP 4 HCE640 Series manual

Linea 2000

Linea 2000 DOMO DO7338H Instruction booklet

Dimplex

Dimplex EPX 500 Installation and operating instructions

Silvercrest

Silvercrest SKD 2300 B2 operating instructions

ARDES

ARDES AR4C05 Instructions for use