6

lfp battery basics

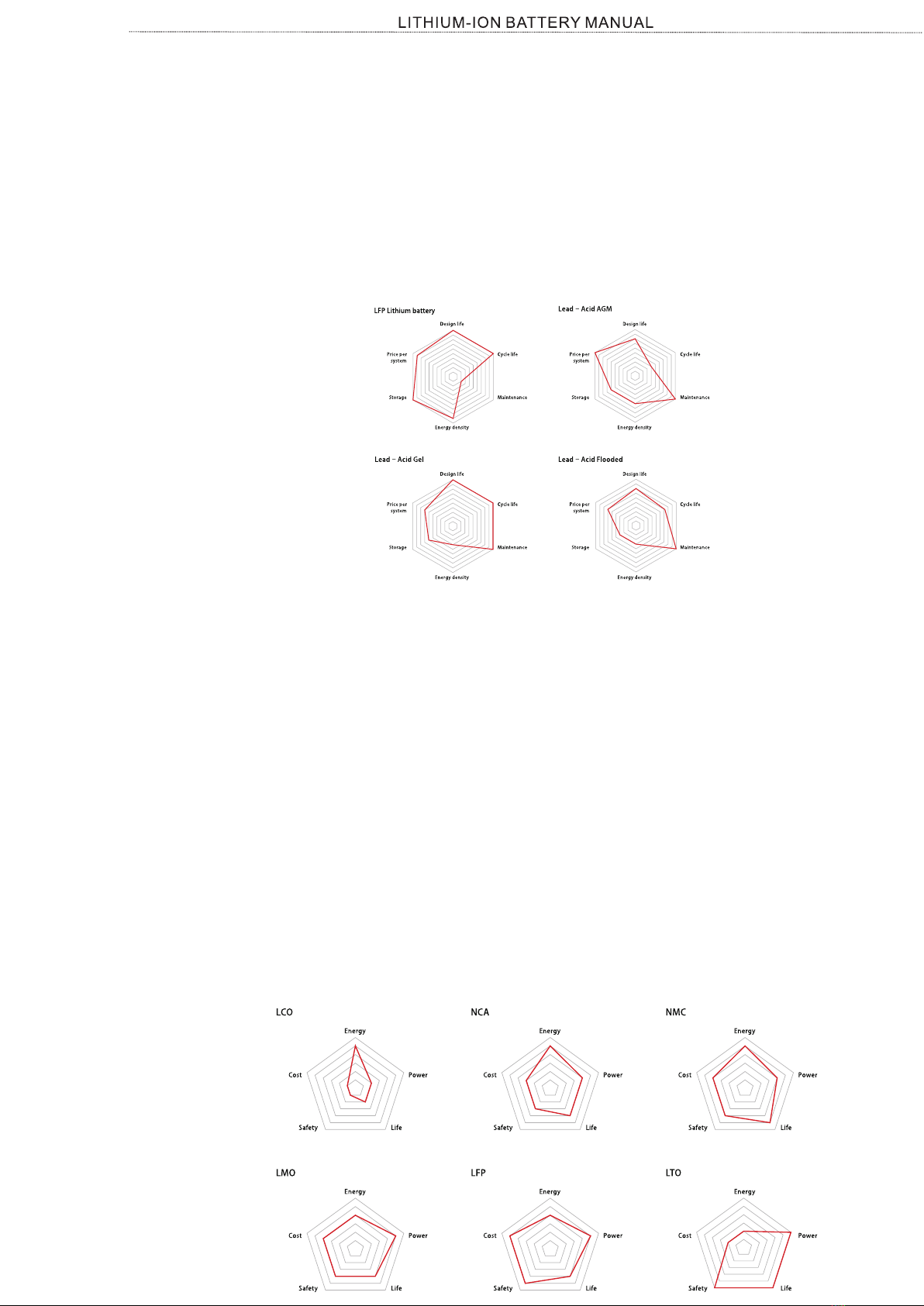

ŸBattery Classifications – Not all batteries are created equal, even batteries of

the same chemistry. The main trade-off in battery development is between power

and energy: batteries can be either high-power or high-energy, but not both.

Often manufacturers will classify batteries using these categories. Other

common classifications are High Durability, meaning that the chemistry has been

modified to provide higher battery life at the expense of power and energy.

ŸC- and E- rates – In describing batteries, discharge current is often expressed as

a C-rate in order to normalize against battery capacity, which is often very

different between batteries. a C-rate is a measure of the rate at which a battery is

discharged relative to its maximum capacity. a 1C rate means that the discharge

current will discharge the entire battery in 1 hour. For a battery with a capacity of

100 Amp-hrs, this equates to a discharge current of 100 Amps. A 5C rate for this

battery would be 500 Amps, and a C/2 rate would be 50Amps. Similarly, an E-rate

describes the discharge power. A 1E rate is the discharge power to discharge the

entire battery in 1 hour.

Battery Basics

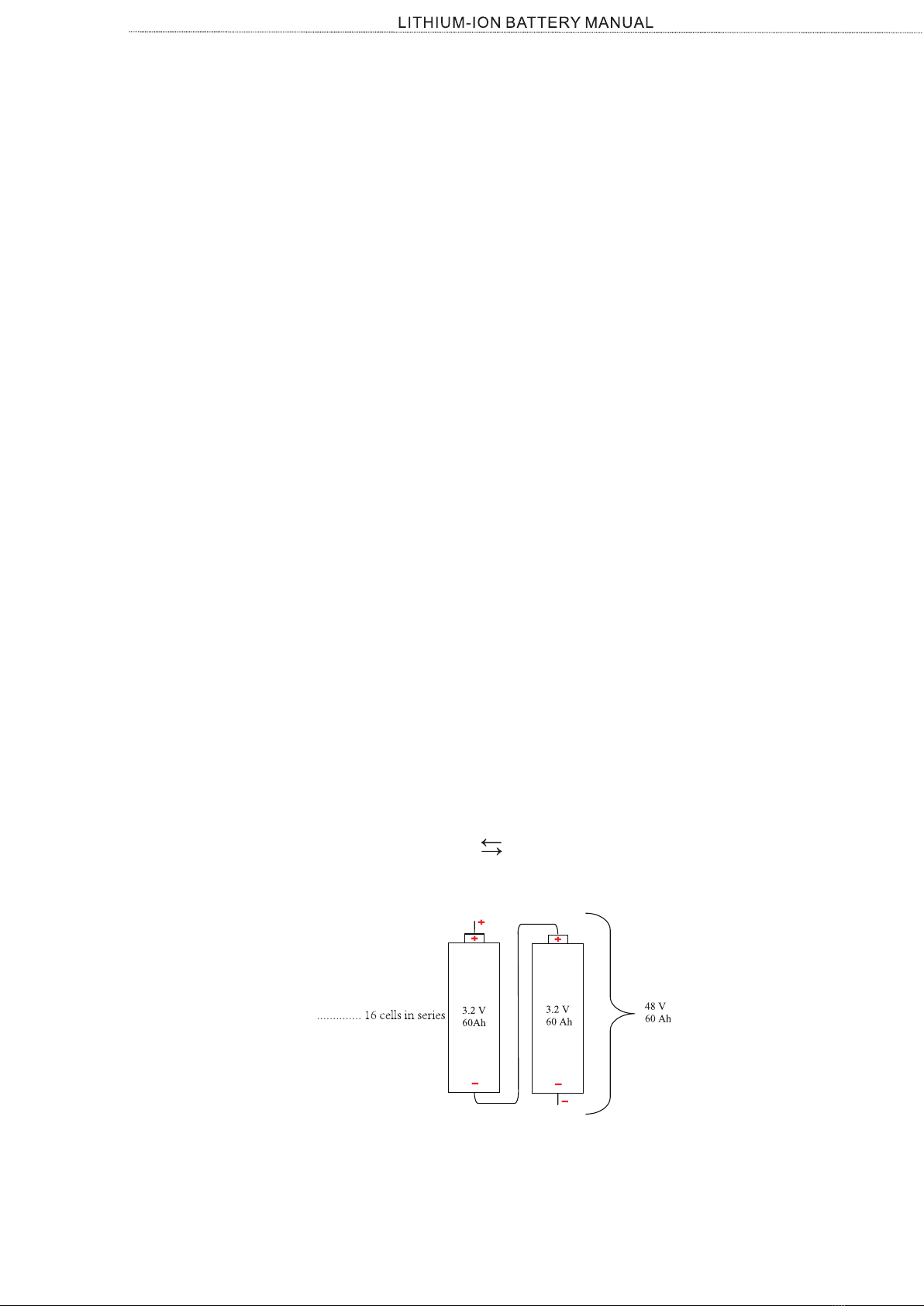

ŸCell, modules, and packs – Electric vehicles have a high voltage battery pack

that consists of individual modules and cells organized in series and parallel. A

cell is the smallest, packaged form a battery can take and is generally on the

order of one to six volts. A module consists of several cells generally connected

in either series or parallel. A battery pack is then assembled by connecting

modules together, again either in series or parallel.

A battery is a device that converts chemical energy into electrical energy and vice

versa. This summary provides an introduction to the terminology used to describe,

classify, and compare batteries for electric vehicles. It provides a basic

background, defines the variables used to characterize battery operating

conditions, and describes the manufacturer specifications used to characterize

battery nominal and maximum characteristics.

Guide to Understanding Battery Specifications

This section describes some of the variables used to describe the present condition

of a battery.

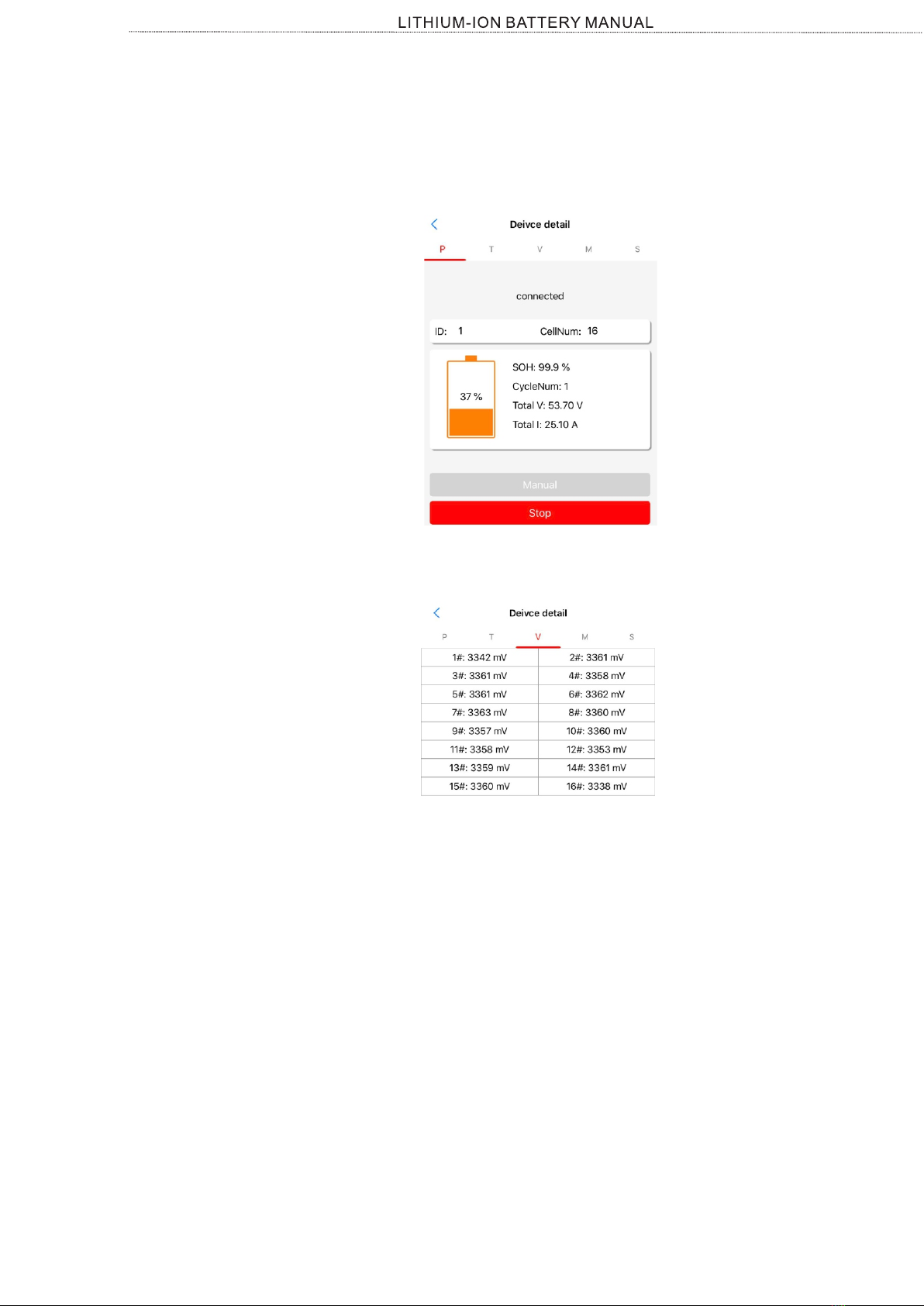

ŸState of Charge (SOC)(%) – An expression of the present battery capacity as a

percentage of maximum capacity. SOC is generally calculated using current

integration to determine the change in battery capacity over time.

Battery Condition

ŸOpen-circuit voltage (V) – The voltage between the battery terminals with no

load applied. The open-circuit voltage depends on the battery state of charge,

increasing with state of charge.

ŸState of Health (SOH)(%) – An expression of the present battery Health(Life

expection/Capacity) as a percentage of maximum life span. SOH is generally

calculated using current/voltage/cell resistance integration to determine the

change in battery life span expectation over time.

ŸDepth of Discharge (DOD) (%) – The percentage of battery capacity that has

been discharged expressed as a percentage of maximum capacity. A discharge

to at least 80 % DOD is referred to as a deep discharge.

ŸInternal Resistance – The resistance within the battery, generally different for

charging and discharging, also dependent on the battery state of charge. As

internal resistance increases, the battery efficiency decreases and thermal

stability is reduced as more of thecharging energy is converted into heat.

ŸTerminal Voltage (V) – The voltage between the battery terminals with load

applied.Terminal voltage varies with SOC and discharge/charge current.