EWC Controls ULTRAZONE MRK Installation and operating instructions

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-635-8646 E-Mail- [email protected]

Contents:

(1) MA-ND3 Motor Actuator

(1) ND/ND2 Anti-Rotation Bracket

(1) URD/RDN

(1) Shaft Adaptor

(4) 11/32 hex nuts

(2) #8 x 1/2” self tap screws

(2) Flat washers

(4) #6 phillips screws

Tools Required:

1/4” Nut Driver

5/16” Nut Driver

11/32” Nut Driver (ND/ND2)

3/32” Allen Wrench (RDN)

Medium Phillips Screwdriver

Precision Pocket Screwdriver

Anti-Rotation Bracket

(1) ND3 Anti-Rotation Bracket

The New & Versatile MRK Damper Motor

Replacement Kit is compatible with original ND &

ND2 Rectangular Dampers. It also works with any

URD damper ever produced, including RDN style

dampers.

P/N 090376A0152 REV. E Copyright C EWC Controls 2004All Rights Reserved -- AN-152

Installation and service should be performed by

qualified personnel only. Follow all local &

national, mechanical & electrical codes &

ordinances.

BEFORE YOU BEGIN

-Read all instructions and figures pertaining to the

model actuator you are replacing.

-Gather the necessary tools to complete the

replacement.

-Disconnect 24vac power supply.

-Tag and remove low voltage wires from existing

actuator.

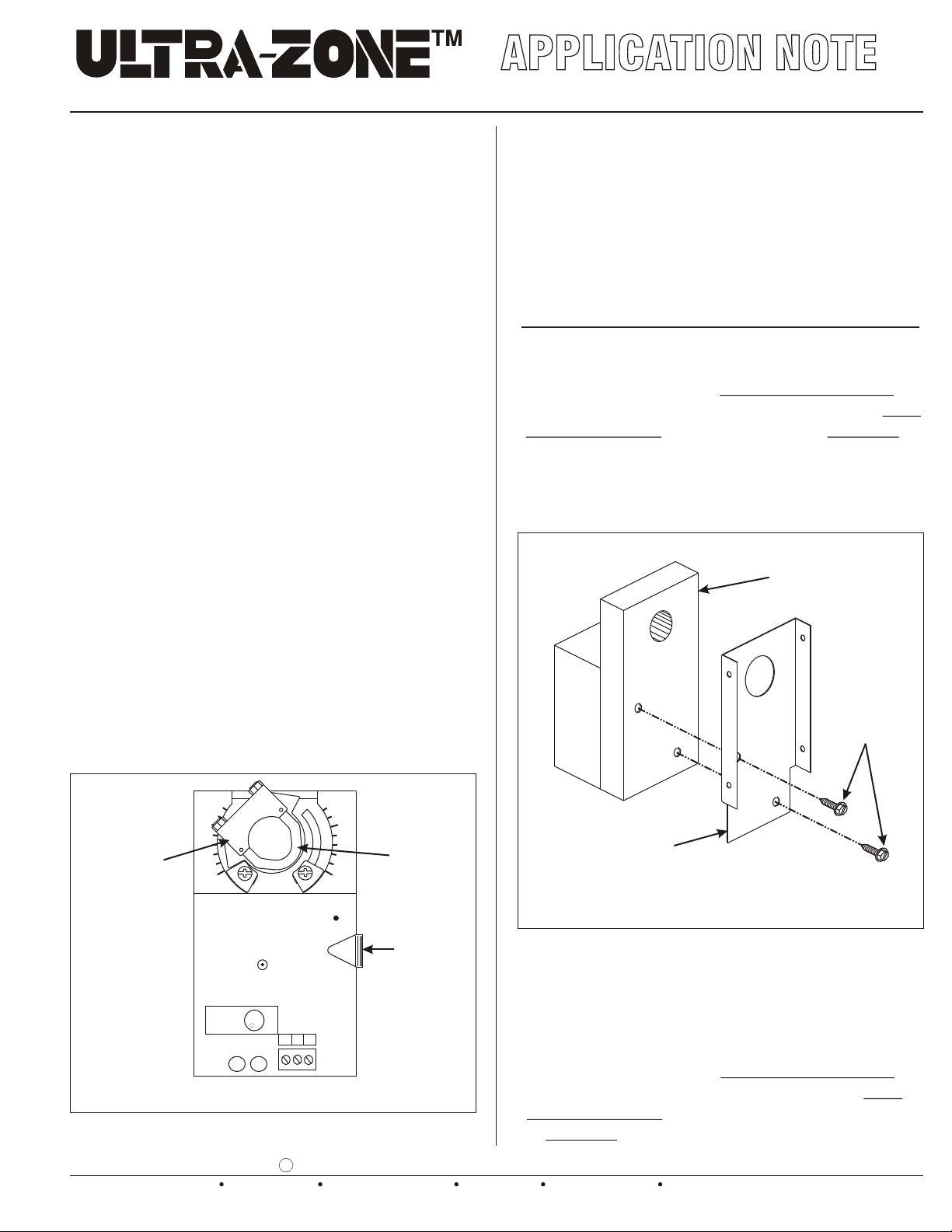

MODEL URD & RDN STYLE DAMPERS

(Figure 2)

-

-Using 1/4” nut driver, Insert 1/2” self-tapping

screws into proper holes and tighten.

Keeping the folds on the Anti-Rotation Bracket

away from the Motor Actuator, align holes on Anti-

Rotation Bracket with holes on rear of MA-ND3.

-Follow instructions for Replacing Motor

Actuator for URD or RDN on pages 2 and 3.

CONTROLS INC.

C

EW

Excellence Without Compromise

MANUAL

GEAR

RELEASE

MA-ND3

CLOSED OPEN

UL

R

CUS

LISTED

94D5

TEMP.IND.&

REG.EQUIP.

CLASS 2 SUPPLY

17 in-lb (2Nm)

30...45s

1 4 6

24VAC

50/60Hz

3.5VA 2W

COM PO PC

ACTUATOR

CLAMP

V-BOLT

MANUAL

GEAR

RELEASE

Figure 1: New MA-ND3 Motor Actuator

Figure 2: URD/RDN Anti-Rotation Bracket Assembly

MA-ND3

URD/RDN

ANTI-ROTATION

BRACKET

1/2” SELF-

TAP SCREWS

MODEL ND & ND2 STYLE DAMPERS

(Figure 3)

-Lay motor actuator on a bench with the back plate

facing up.

-Place one (1) washer over the two (2) lower

mounting holes.

-Keeping the folds on the Anti-Rotation Bracket

towards the motor actuator, align holes onAnti-

Rotation Bracket with holes and washers on rear

of MA-ND3.

ATTACHING BRACKET TO ACTUATOR

AN-152 - Model MRK - Motor Actuator Replacement Kit

1

MA-ND3

WASHERS

Figure 3: ND/ND2 Bracket AssemblyAnti-Rotation

(Continued from previous page)

-Using 1/4” nut driver, Insert 1/2” self-tapping

screws into proper holes and tighten.

-Follow instructions for Replacing Motor

Actuator for ND/ND2 on Page 3 and 4.

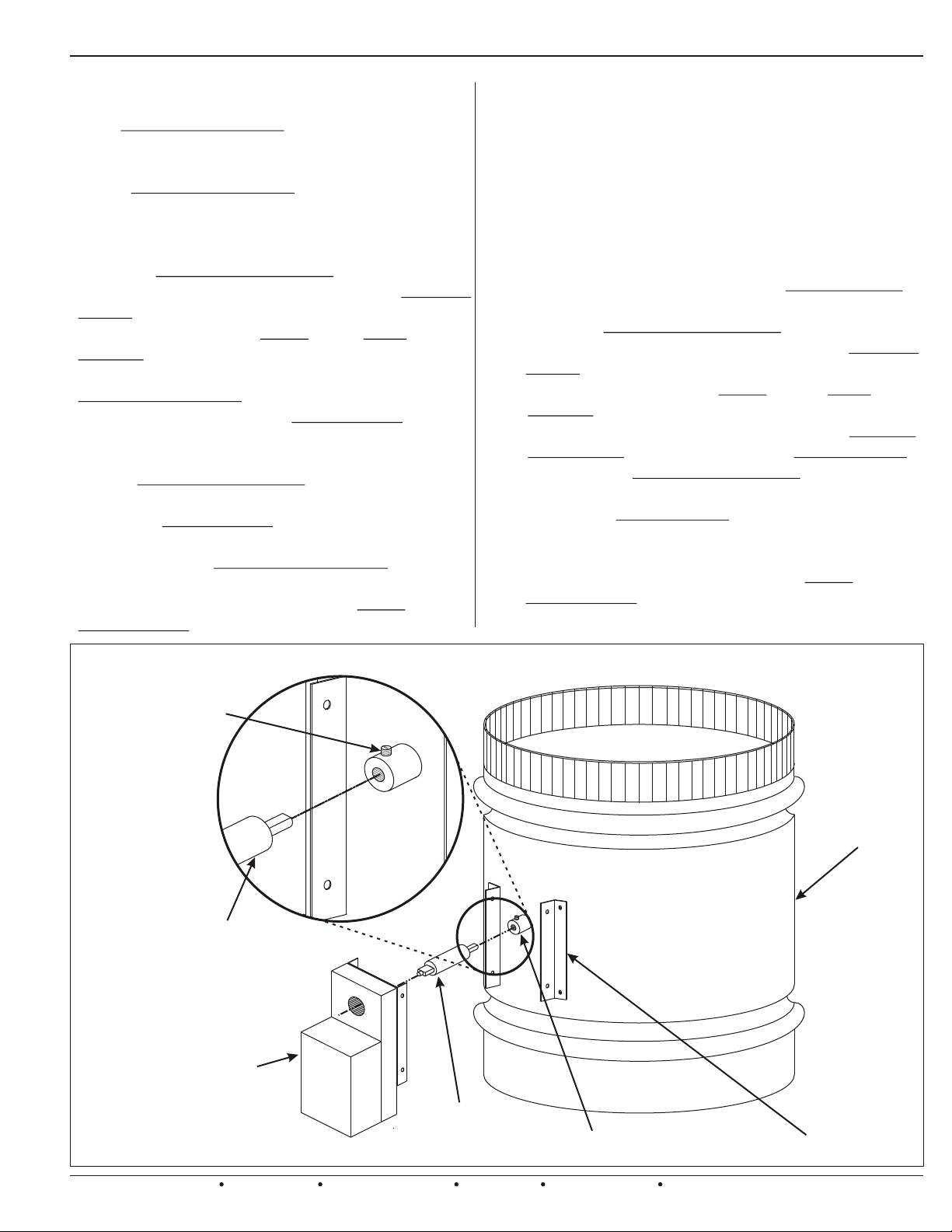

REPLACING MOTOR ACTUATOR

MODEL URD STYLE DAMPERS

(Figure 4)

-Remove the four (4) phillips head screws holding

the existing motor actuator to the damper.

-Pull the existing motor actuator straight off.

-Using the Manual Gear Release on the New

Actuator/BracketAssembly, position the Actuator

Clamp to the far LEFT. (OPEN Position)

-Loosen the nuts on the V-bolt so the Shaft

Adaptor will slide thru easily.

-On the URD damper, position the slot on the

Damper Blade Shaft vertically and insert the

URD/ND mating end of the Shaft Adaptor fully

into the Damper Blade Shaft.

-Align Actuator/Bracket Assembly and mounting

holes with Shaft Adaptor and mounting brackets.

-Insert Philips head screws thru mounting

brackets into the Anti-Rotation Bracket and

tighten.

-Using a 5/16” nut driver, tighten theV-bolt to the

ShaftAdaptor.

-Reconnect wiring.

Figure 4: URD Motor Actuator Replacement Assembly

ACTUATOR/BRACKET

ASSEMBLY

URD

DAMPER

DAMPER BLADE SHAFT

SHAFT

ADAPTOR

POSITION

BLADE SHAFT

SLOT VERTICALLY

SHAFT ADAPTOR-

URD/ND MATING

MOUNTING

BRACKETS

ND/ND2

ANTI-ROTATION

BRACKET 1/2” SELF-

TAP SCREWS

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-635-8646 E-Mail- [email protected]

2

Model MRK - Motor Actuator Replacement Kit

**ACTUATOR CLAMP NOT SHOWN FOR CLARITY

Model MRK - Motor Actuator Replacement Kit

MODEL RDN STYLE DAMPERS

(Figure 5)

-Align Damper Blade Shaft set screw with access

opening on existing motor actuator.

-Using a 3/32” allen wrench, loosen the set screw

on the Damper Blade Shaft.

-Remove the four (4) phillips head screws holding

the existing motor actuator to the damper.

-Pull the existing motor actuator straight off.

-Using the Manual Gear Release on the New

Actuator/Bracket Assembly, position the Actuator

Clamp to the far RIGHT. (CLOSED Position)

-Loosen the nuts on the V-bolt so the Shaft

Adaptor will slide thru easily.

-On the RDN damper, position the set screw on the

Damper Blade Shaft so it is facing UP and insert

the RDN mating end of the Shaft Adaptor fully

into the blade shaft with the flat side UP.

-Using 3/32” allen wrench, tighten the set screw

on the Damper Blade Shaft.

-Align Actuator/Bracket Assembly and mounting

holes with Shaft Adaptor and mounting brackets.

-Insert Philips head screws thru mounting

brackets into the Anti-Rotation Bracket and

Tighten.

-Using a 5/16” nut driver, tighten theV-bolt to the

Shaft Adaptor.

Figure 5: RDN Motor Actuator Replacement Assembly

ACTUATOR/BRACKET

ASSEMBLY

RDN

DAMPER

DAMPER BLADE SHAFT

SHAFT

ADAPTOR

POSITION

SET-SCREW

FACING UP

ADAPTOR SHAFT-

RDN MATING

FLAT SIDE UP

MOUNTING

BRACKETS

MODEL ND/ND2 STYLE DAMPERS

(Figure 6)

-Remove the two (2) 11/32” actuator mounting

nuts holding existing motor actuator to damper

frame.

-Pull the existing motor actuator straight off.

-For ND2 dampers place one (1) of the supplied

11/32” hex nuts on each existing Mounting Post.

(Not necessary for older ND dampers).

-Using the Manual Gear Release on the New

Actuator/Bracket Assembly, position the Actuator

Clamp to the far LEFT. (OPEN Position)

-Loosen the nuts on the V-bolt so the Shaft

Adaptor will slide thru easily.

-On the damper, position the slot on the Damper

Blade Shaft vertically and insert Shaft Adaptor

fully into the Damper Blade Shaft.

-Align Actuator/Bracket Assembly and mounting

holes with Shaft Adaptor and mounting posts.

-Replace 11/32” hex nuts on mounting posts and

tighten.

-Using a 5/16” nut driver, tighten theV-bolt to the

Shaft Adaptor.

-Reconnect wiring.

-Reconnect wiring. Note: Refer to MA-ND3

Submittal sheet for proper wiring.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-635-8646 E-Mail- [email protected] 3

**ACTUATOR CLAMP NOT SHOWN FOR CLARITY

Figure 6: ND/ND2 Motor Actuator Replacement Assembly

ACTUATOR/BRACKET

ASSEMBLY

ND/ND2

DAMPER

DAMPER BLADE SHAFT

ADAPTOR

SHAFT

ADAPTOR SHAFT-

URD/ND MATING

EXISTING

MOUNTING

POSTS--ND2

EXISTING

MOUNTING

POSTS--ND

11/32” HEX NUTS

(ND2 ONLY)

POSITION

BLADE SHAFT

SLOT VERTICALLY

ACTUATOR

MOUNTING NUTS

Figure 7: Completed URD/RDN Actuator Replacement Figure 8: Completed ND/ND2 Actuator Replacement

Model MRK - Motor Actuator Replacement Kit

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-635-8646 E-Mail- [email protected]

4

**ACTUATOR CLAMP NOT SHOWN FOR CLARITY **ACTUATOR CLAMP NOT SHOWN FOR CLARITY

**ACTUATOR CLAMP NOT SHOWN FOR CLARITY

NOTE: POSITION OF MOUNTING POSTS

MAY REQUIRE THEACTUATOR/BRACKET

ASSEMBLY TO BE ROTATED 180 FROM

POSITION SHOWN

°

This manual suits for next models

1

Other EWC Controls Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Samsung

Samsung AS07A5MA Service manual

Panasonic

Panasonic CW-N1821EA operating instructions

INVENTOR

INVENTOR L5VI32-09WFR user manual

Panasonic

Panasonic CS-KV18UKF-5 operating instructions

Gree

Gree GWH07PA-K3NNA6E Service manual

Olimpia splendid

Olimpia splendid OS-SECFH18EI Instructions for installation, use and maintenance