33

Contents

1.0 General information......................................................4

1.1 Information in this manual ...............................................4

1.2 Explanation of symbols and signal words ......................4

1.3 Limitation of liability ........................................................5

1.4 Copyright.........................................................................5

1.5 Spare parts......................................................................5

1.6 Warranty terms................................................................5

1.7 Customer service ............................................................5

2.0 Safety .............................................................................6

2.1 Use ...................................................................................6

2.1.1 Intend ed use ..............................................................6

2.1.2 Unintended Use ........................................................6

2.1.3 Essential performance ..............................................6

2.2 Responsibility of the owner and processor....................6

2.3 Personnel requirements..................................................7

2.3.1 Qualications ............................................................7

2.4 Specic dangers .............................................................7

2.5 Safety equipment ............................................................7

2.6 Safeguard against restart ...............................................8

2.7 Modications of device ...................................................8

2.7.1 Warning labels ...........................................................8

3.0 Technical data...............................................................9

3.1 Ambient conditions .........................................................9

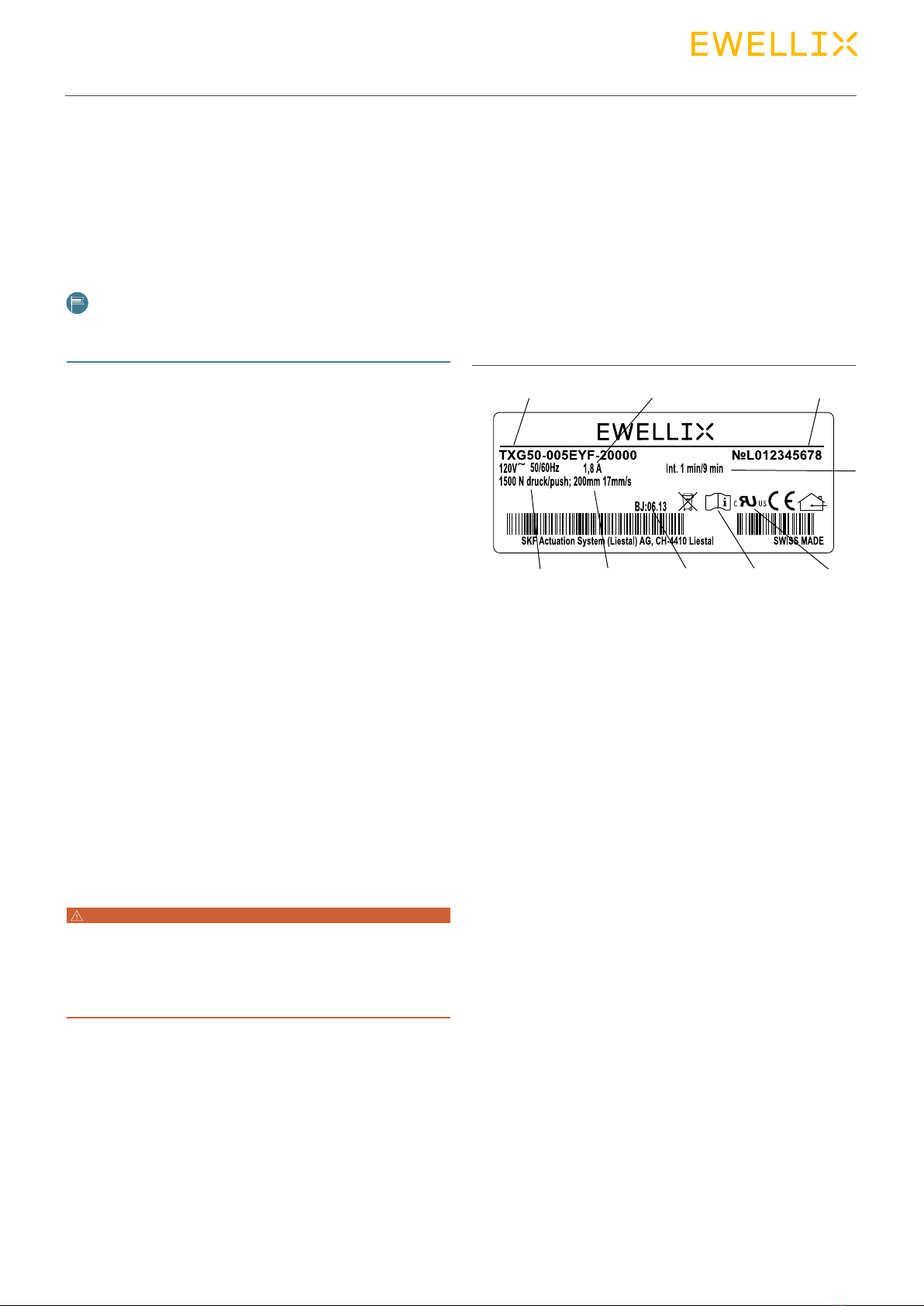

3.2 Product label...................................................................9

4.0 Structure and function...............................................10

4.1 O ver view ........................................................................ 10

4.2 Functional description .................................................. 10

4.2.1 Requirements for third party control (Mandatory in

medical applications)........................................................ 11

4.3 Connections.................................................................. 11

4.4 Operating elements....................................................... 12

4.5 Options.......................................................................... 12

4.6 Accessories................................................................... 12

5.0 Transport, packaging and storage ...........................13

5.1 Safety information for the transport.............................. 13

5.2 Transport inspection..................................................... 13

5.3 Return to the manufacturer........................................... 13

5.4 Packaging...................................................................... 13

5.5 Storage.......................................................................... 14

6.0 Installation and rst operation ................................. 15

6.1 Installation location ....................................................... 15

6.2 Inspections prior to rst operation ............................... 15

6.3 Installation..................................................................... 16

6.4 Connect to the control unit ........................................... 17

6.5 Connection to operating element................................. 17

6.5.1 Connect TXG10 (stand alone) to operation element ..

17

6.5.2 Connect TXG (all types except TXG10) to operating

element ............................................................................. 17

6.6 Connect to power supply.............................................. 18

6.6.1 Connect TXG10 (stand alone) to power supply...... 18

6.6.2 Connect TXG (all types except TXG10) to power

supply ............................................................................... 18

6.7 Connect the second actuator “master/slave” (optional)19

6.8 Strain relief .................................................................... 19

7.0 Operation .....................................................................20

7.1 Safety .............................................................................20

7.2 Turn on........................................................................... 20

7.2.1 Turn TXG10 (stand alone) on ...................................20

7.2.2 Turn TXG (all types except TXG10) on ....................20

7.2.3 Turn o ....................................................................20

7.3 Action before use ..........................................................20

7.4 Actions during operation...............................................20

7. 4.1 S t a r t u p .....................................................................20

7.4.2 Instruction for use ................................................... 21

7.5 Disengagement in case of emergency .........................22

7.5.1 Shut down TXG10 (slave or standalone) .................22

7.5.2 Shut down TXG (all types except TXG10)...............22

8.0 Maintenance................................................................23

8.1 Maintenance plan .......................................................... 24

8.2 Maintenance work......................................................... 24

8.2.1 C lea ning .................................................................. 24

8.2.2 Inspections and readings.......................................25

8.2.3 Service log ..............................................................25

8.2.4 Check of visual condition .......................................25

8.3 Measures after completed maintenance......................25

9.0 Malfunctions................................................................26

9.1 Malfunction table........................................................... 27

9.1.1 Only actuators with main power connection (master /

stand-alone)......................................................................27

9.1.2 Only TXG10 (slave or stand alone) ..........................28

9.2 Start of operation after xing malfunction....................28

10.0 Dismantling................................................................29

10.1 Dismantling..................................................................29

10.2 Disposal.......................................................................29

11.0 Appendix ....................................................................30

WARNING

WARNING: read this manual before installing, operating or

maintaining this actuator. Failure to follow safety precautions and

instructions could cause actuator failure and result in seri ous

injury, death or property damage. Keep this manual nearby for

future reference.