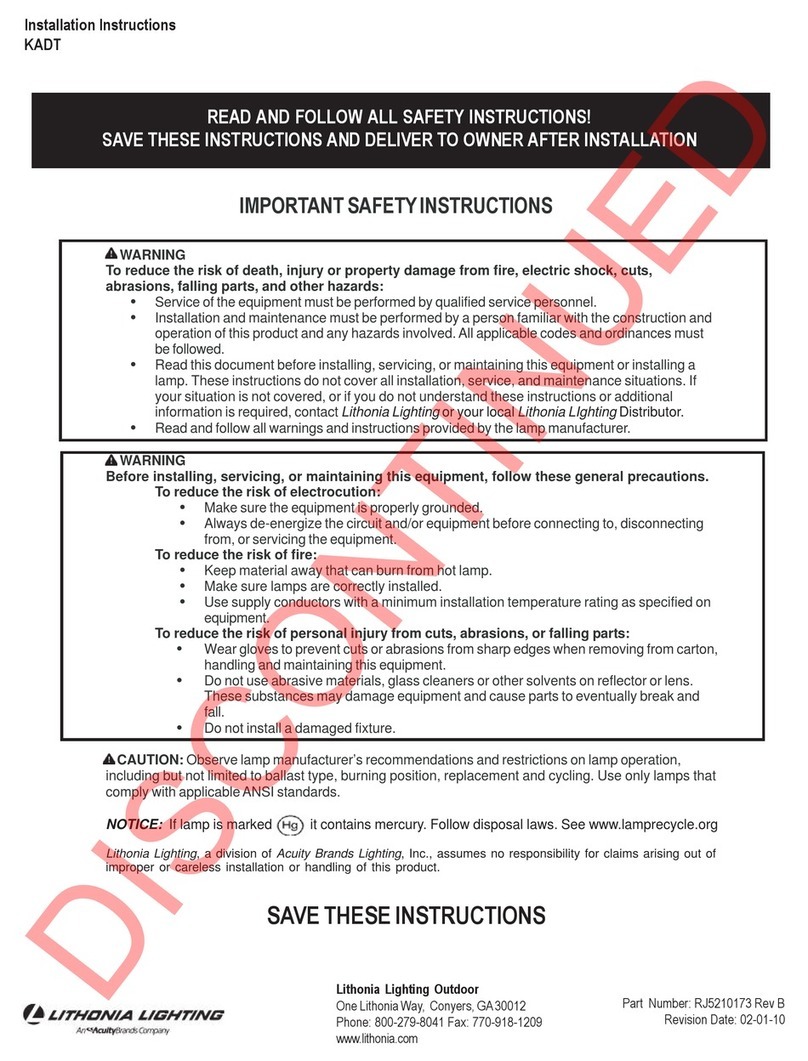

Installation Instructions

Lithonia Lighting Outdoor

One Lithonia Way, Conyers, GA 30012

Phone: 800-279-8041 Fax: 770-918-1209

www.lithonia.com

TM

Part Number: RJ5210203 Rev B

Revision Date: 5/31/10

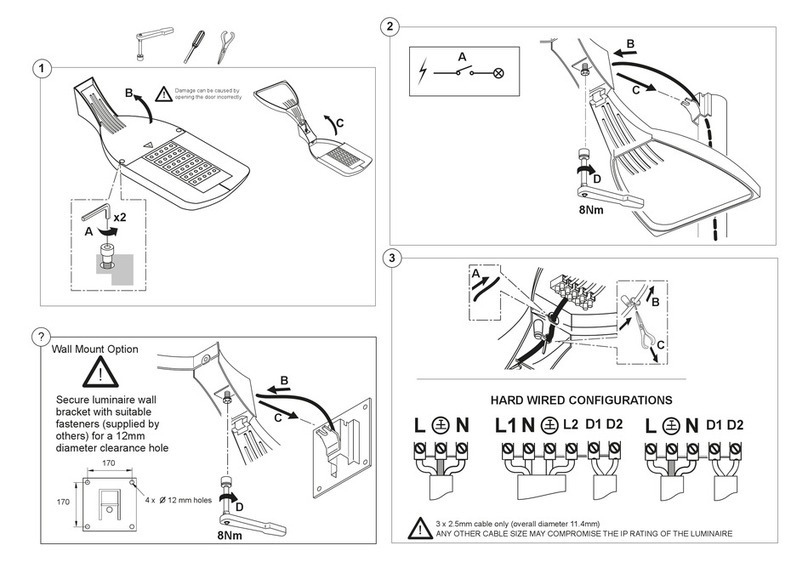

Tools Required: 9/16" socket wrench with extension. 3/16" allen wrench.

Fixture is IP65 with lens down; damp location with lens up.

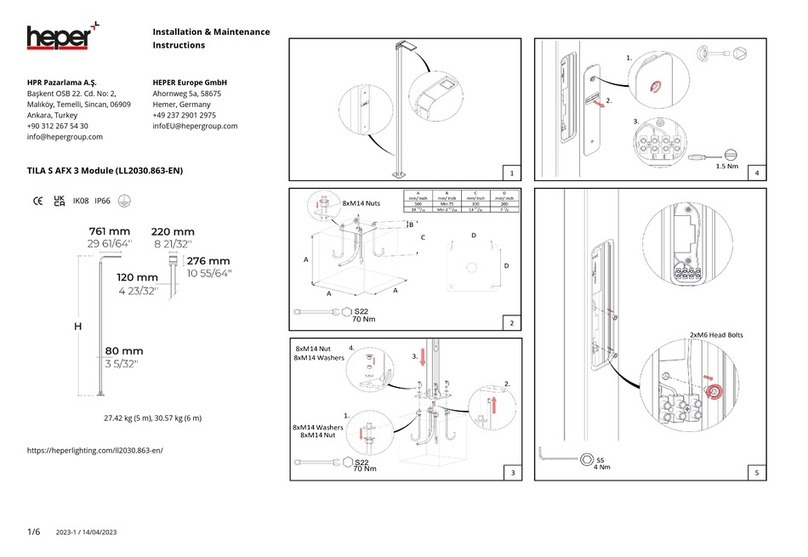

1. Attach mounting block to the pole by placing the flat bar stock with the 3 holes, two of which are threaded, inside the pole, aligning with the Aeris drill pattern. Place

the cast aluminum block on the outside of the pole, with the word “Up” towards the top of the pole and facing outward or away from the pole. Thread the (2) 3/8" diameter

hex head bolts through the block and pole into the threaded bar stock. (There is no gasket needed) Check plumb and level of the block and secure bolts tightly with

9/16" wrench or socket.

2. Open doorframe by loosening the (2) captive doorframe screws using 3/16" allen wrench.

3. Unhook safety-restraining cable. Loosen the 10-24 screw at the neck end of the doorframe 1/2 turn.

4. Remove door by sliding the hinge latch up and away from hinge, close door slightly and lift door assembly off. Set aside for reinstallation.

5. Place the three wires from the fixture through the center hole of the mounting block assembly, pulling them into the pole. Place the fixture onto the mounting block,

being sure the wires are not pinched.

6. Tighten the locking hex head bolt inside the arm with a 9/16" socket to 20-30 ft. lbs. torque. Check the mounted assembly to assure proper placement and secured

mounting has been achieved.

7. Re-install the door assembly by placing hinge of doorframe on fixed hinge rod of fixture. Slide hinge latch on the doorframe over hinge rod. Tighten 10-24 hinge latch

screw. Hook the safety cable to its proper location.

8. Install the lamp as per instructions below. Close the door assembly, and tighten the (2) captive doorframe screws.

US. Patent No. D447,590. Canada Patent No. 94324.

Step 1 Step 2 Step 4 Step 6Step 5

Step 3 Step 7

Delivery: Upon receipt of fixture and accessories (packed separately), throughly inspect for any freight damage. All damage

should be reported to the delivery carrier. Compare the catalog description listed on the packing slip with the fixture label on the

inside of the housing to be sure you have received the correct merchandise.

Troubleshooting: If this fixture fails to operate properly, check to make sure: The proper lamp is installed correctly. • The fixture is wired correctly. • The lamp is

not faulty. • The fixture is grounded correctly. • The line voltage at the fixture is correct. If all these variables have been checked and the fixture still does not

operate as specified, contact your local Lithonia Lighting distributor.

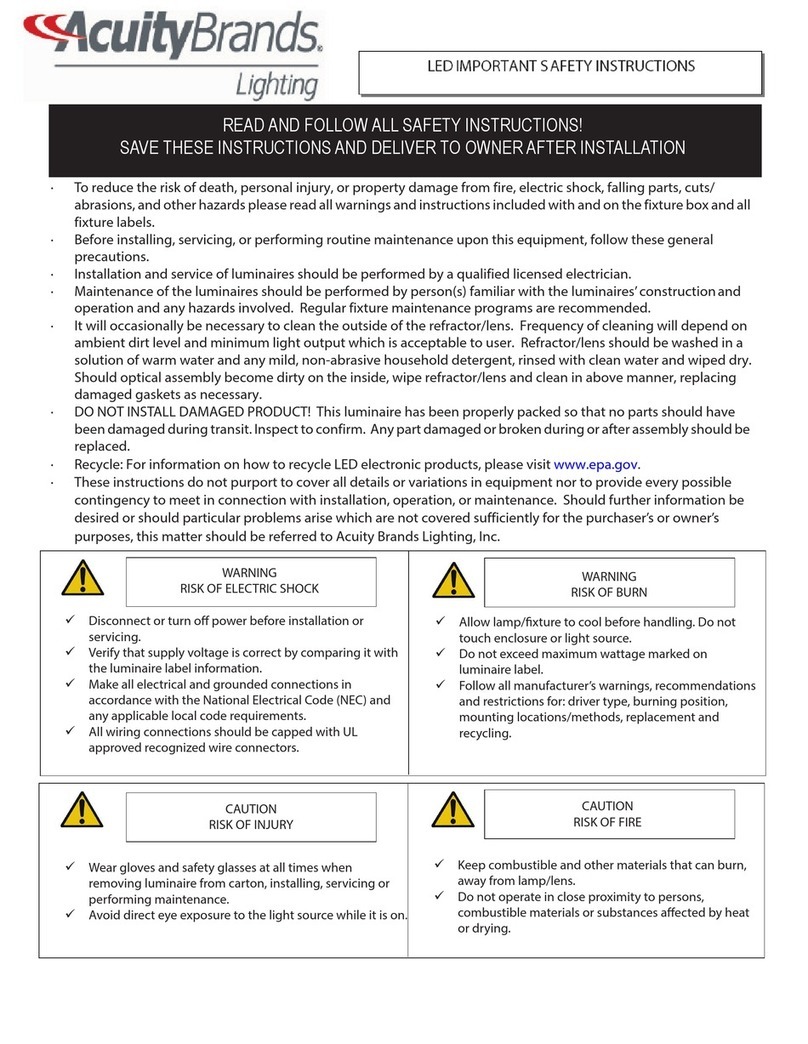

Multi-tap Ballast (TB): The multi-tap ballast will be prewired for 277V at the factory. This option offers multi voltage capability. First determine the correct line

voltage. Then select the corresponding fixture voltage lead, remove the crimped cap and connect to the supply voltage lead. The fixture lead marked COM should

be connected to the neutral supply lead for 120 or 277. For 208 or 240, connect the other incoming hot leg to the fixture lead marked "COM". Be sure to cap off all

unused fixture leads individually.

Cover plate

Gasket

(factoryinstalled)

3/8"screw

Safety chain

Silicone

sealant

(byothers)

(4)1/4"fasteners

(byothers)

Base plate

Figure 1

To wall

Attach to lower bolt

with nut

4. Insert and tighten (4) 3/8" diameter by 1-1/4" stainless steel hex socket head screws into the threaded opening of the cover plate by turning approximately 6-7 full turns.

5. To prepare fixture for installation, refer to the step 2-4 of pole mounting instructions above.

6. Pull the wires from the fixture through the mounting block on the cover plate. Place fixture onto the mounting block, being sure the wires are not being pinched.

7. Follow steps 6-8 of pole mounting instruction above. Attach small eyelet of safety cable to base plate with provided 1/4-20 screw.

8. Slide the entire fixture assembly over the base plate, tighten the top (2) 3/8" x 1-1/4" stainless steel hex socket head screws until 3/8" to 1/4" of the screw is still visible.

Tighten the two bottom hex screws until 3/8" to 1/4" of the screw is still visible. Alternating between the top two and bottom two sets of screws, gently tighten until snug,

(approx one thread showing on each screw).

2. Secure base plate to wall with (4) 1/4" fastener (by others) using the (4)

holes located on the outer corners of the base plate. Check the base plate

to confirm that it is level and plumb in all directions (Fig 1).

3. Prepare the cover plate by attaching the Aeris mounting block to the

cover plate using (2) 3/8" diameter by 1-1/4" bolts with lockwashers by

inserting the bolts and washers into the mounting block through the cover

plate and thread into the threaded steel bar stock. Use a 9/16" socket or

wrench and tighten securely (Fig 2). Place the curved portion of the cover

plate upwards. Ensure the factory installed gasket is in place on the

backside of the cover plate. Place large eyelet of safety cable over the

lower bolt. Secure with nut (provided).

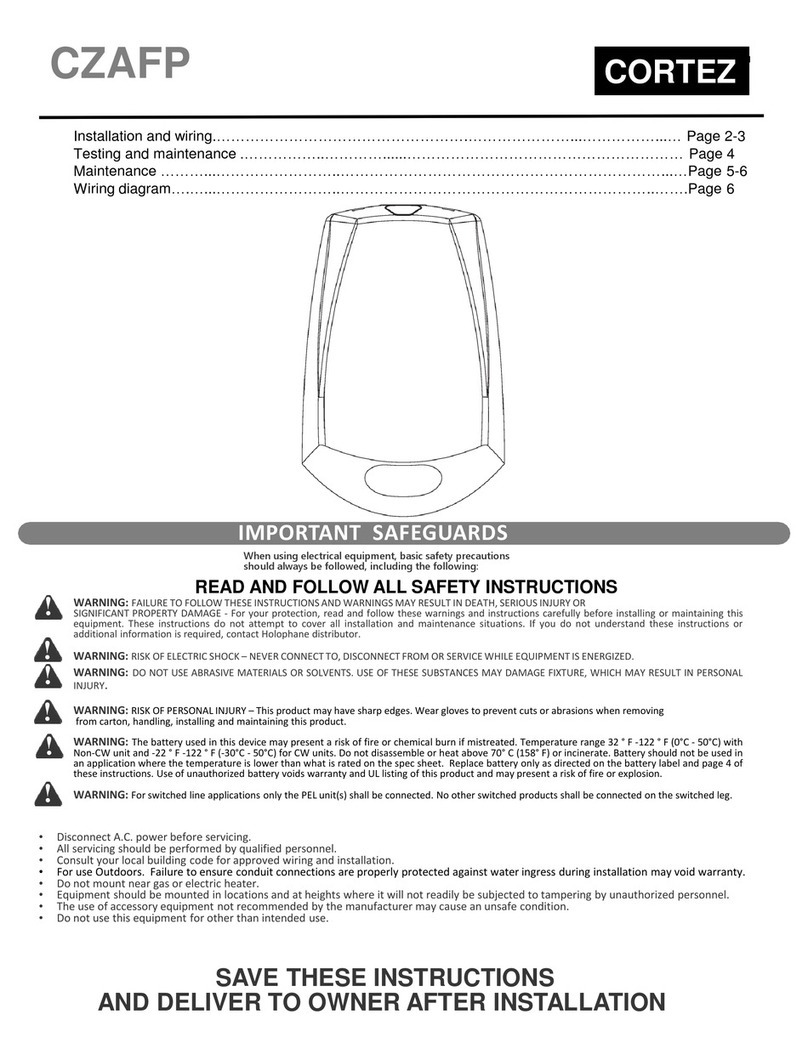

WBA (Wall Bracket lens down only)

1. CAUTION: APPLY A CONTINUOUS BEAD OF WEATHER - PROOF CAULKING BETWEEN MOUNTING PLATE AND WALL TO ENSURE WEATHER - TIGHT INTEGRITY OF ELECTRICAL COMPONENTS

Figure 2

Socket

Head

Screws

Fixture's mounting

block

Threaded

Steel

Bar

Lamp Installation--Open doorframe by loosening the (2) captive screws using 3/16" allen wrench. Prior to installing the lamp, verify that the lamp source and wattage

corresponds with the fixture and ballast label. HID -Screw the lamp securely into the socket, back it out one or two turns, and tighten securely again. This procedure

properly seats the lamp in the socket. Compact fluorescent - Push lamp into socket until the socket retention clips snap secure (you will hear a click). Close

doorframe and tighten the (2) captive doorframe screws using 3/16" allen wrench.

Optical Rotation--Tool-less, in 90° increments. Assure that the unit is NOT energized during this process. To rotate, gently lift the optical assembly away from the

fixture. Once optical assembly is free from its position, rotate to desired direction. Gently place assembly back into the housing, being sure that the holding devices

are aligned with the tool-less spring clips. Make sure no wires interfere with this process. Snap reflector into place. Be sure that the optical assembly has not been

positioned past the seating position on the spring clips. Re-check seating position for secured application. To change optical assemblies, remove the optical

assembly by gently lifting the optical assembly away from the fixture. Once it is free from the seating and spring clips, disconnect socket leads via quick-disconnects.

Connect the quick-disconnects of the new optical assembly with the connector in the unit, rotate and seat as noted in the rotation instructions above.

©2001 Acuity Brands Lighting, Inc.

All Rights Reserved. Rev. 05/10