EWS TS Series User manual

2www.ews-tools.de

EWS TOOL SHUTTLE/TOOL CARRIER

iGeneral notes:

In order to maintain the high quality of your tool shuttle / tool carrier for as long as possible,

there are some important points to consider.

If you have any questions, you are also welcome to contact our sales and service staff.

Dear customers,

By purchasing the tool shuttle / tool carrier from EWS, you have made a good choice and we want

to thank you for your trust.

Our tooling systems and accessories are designed according to the machine specifications and

manufactured with high precision using state-of-the-art production units.

Operating instructions

Please carefully read through and follow the operating instructions. Keep the documentation permanent-

ly at the place of use of the tool shuttle / tool carrier for the entire service life of the product. Use these

operating instructions to familiarise yourself with the product, its correct use and the safety instructions.

Ensure that all persons involved with the tool shuttle / tool carrier are aware of this documentation.

Intended use

The tool shuttle/tool carrier may only be used for the transport or storage of tool holders.

It must not be used for any other purpose, is delivered in assembled condition and can be used directly in

combination with the appropriate tool palette(s).

Danger

The user is liable in the event of improper use.

3www.ews-tools.de

1. Safety

2. Basic structure

3. Properties

4. Commissioning and operation

5. Care, maintenance and service

6. Storage, transport and disposal

7. Service / warranty

8. Technical specifications

4-6

7- 9

10

10

11

11

12

13

CONTENTS

4www.ews-tools.de

1. SAFETY

DANGER

Imminent danger that will absolutely lead to serious bodily injury or death.

CAUTION

Dangerous situation that may result in minor to moderate bodily injury.

WARNING

Imminent danger that can lead to serious bodily injury or death.

NOTE

Important information as a requirement, the observance of which is necessary for the correct

use of the product and the safety of the operator.

Children and young people under the age of 16 as well as persons who are not familiar with these

operating instructions must not use the product. Persons with reduced physical or mental abilities

may only use the product if they are supervised or instructed by a competent person. Never use the

product when tired, ill or under the influence of alcohol, drugs or medicines.

General safety and information labelling

In addition, of course the general accident prevention regulations, legal requirements, the duty to exercise

care when handling the tool shuttle / tool carrier, as well as the observance of environmental protection,

also apply.

5www.ews-tools.de

WARNING Tool shuttle

Risk of injury from:

Running over the feet

Flinging away other persons

Crushing the feet and body

Crushing of other persons against a fixed resistance

(e.g. wall, machine, vehicle)

- Careful and safe handling of the tool shuttle.

- Only use in industrial indoor areas on dry, solid and level floors.

- Release the parking brakes on the transport castors only for transport, then actuate

them again immediately.

- Wear suitable work clothing/safety shoes.

- Persons must not be transported with the tool shuttle under any circumstances.

- Avoid tipping the tool shuttle at all costs.

- Keep transport routes clear.

- Push at walking speed.

- Observe maximum load.

WARNING Tool carrier

Risk of injury from:

Insufficient stability

Tool carrier falling over/falling off the work table or tool holders falling to the floor dur-

ing removal/insertion

- Careful and safe handling of the tool carrier.

- Place the tool carrier securely on a table top.

- Only use in industrial indoor areas on a work table with sufficient load-bearing capacity.

- Wear suitable work clothing/safety shoes.

- Avoid tilting the tool carrier at all costs.

- Observe maximum load.

6www.ews-tools.de

WARNING

Danger from use of the tool shuttle / tool carrier in an unsuitable environment.

Ambient conditions: clean, dry, frost-free, non-EX, industrial area

NOTE

Structural changes to the tool shuttle / tool carrier may not be made without the written

consent of EWS Weigele GmbH & Co. KG.

WARNING Tool shuttle/tool carrier

Risk of injury from:

Tools clamped in the tool holder (e.g. drills)

- Always use protective caps over tools to avoid abrasions.

- If necessary wear suitable personal protective equipment (PPE).

Slipping, tripping or falling over elements such as pipes, tubes or other elements in the

movement space

- Lay and fix cables, hoses or other elements outside the movement space.

Misuse

- Read the operating instructions before use and keep them available at all times.

Exclude any other type of use or misuse.

Always comply with the relevant specifications.

Do not exceed the maximum permissible total load.

Do not expose to knocks, impacts or heavy loads.

7www.ews-tools.de

Terms

Tool shuttle = TS (tool shuttle/EWS T-Shuttle)

Tool carrier / table stand = TC (tool carrier)

Tool palette = TP (tool palette)

Storage tray = TT (tool tray)

Three basic models of the storage and transport system are offered by EWS.

Tool shuttle TS-400

3 tool palettes TP and one

storage tray TT

or

4 tool palettes TP

Tool carrier/table stand TC-100

1 tool palette TP

Tool carrier/table stand TC-200

2 tool palettes TP

2. BASIC STRUCTURE

8www.ews-tools.de

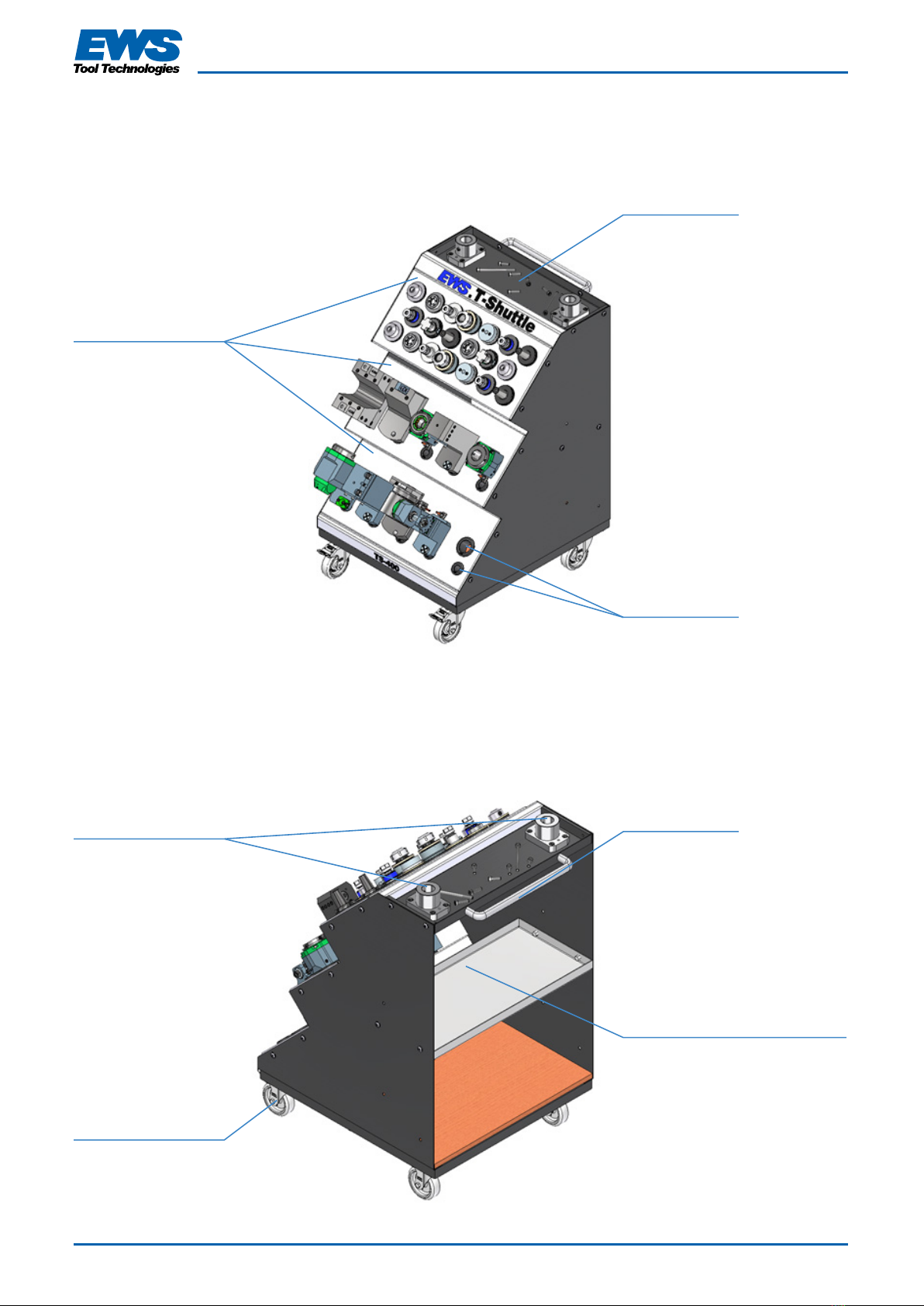

Exemplary EWS tool shuttle TS-400 (EWS T-Shuttle) front side.

The tool holders shown are not included in the scope of delivery.

Exemplary EWS tool shuttle TS-400 (EWS T-Shuttle) Rear side

Tool palettes TP

Mounting

blocks optional

4 lockable

transport rollers

Standard shelf

Handle

Tool inserts

Storage tray TT or alternatively an

additional tool palette TP

9www.ews-tools.de

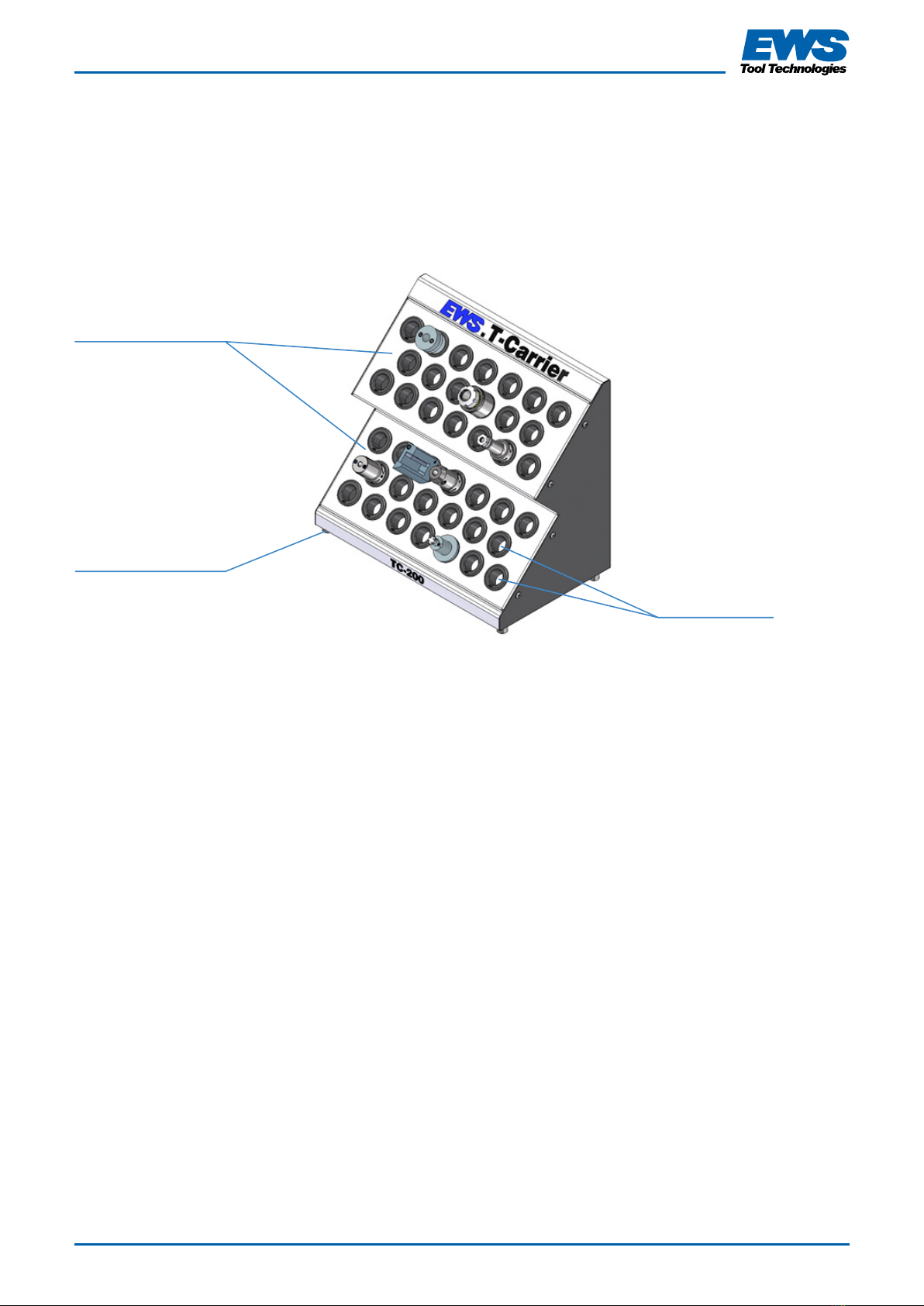

Exemplary EWS tool carrier TC-200 (EWS T-Carrier) as table stand.

The tool holders shown are not included in the scope of delivery.

Tool palettes TP

4 feet

Tool inserts

10 www.ews-tools.de

4. COMMISSIONING AND OPERATION

3. PROPERTIES

■Unpack the tool shuttle / tool carrier, check it for completeness and report any transport damage

immediately to EWS Weigele GmbH & Co. KG.

■Place the tool carrier securely on a stable table top at least 50 mm thick.

■To assemble/replace the TP tool palettes, a size 5 Allen key is required for each of the 4 pan head

screws (not included in the scope of delivery).

■Only insert tool holders into the tool inserts provided.

■Check for damage before each use.

■If damaged, the tool shuttle / tool carrier must not be used.

■Set up near the processing machine.

of the tool shuttle/tool carrier:

■Provision and protected storage of tool holders.

■Depending on the requirements, individual composition of the palettes with the same or different tool

inserts.

■Thenumber of tool inserts on the tool palette varies according to the shank size of the tool holders.

■Tool inserts are available for a wide range of tool holder interfaces.

■Tool palettes fit tool shuttles and tool carriers and are interchangeable.

■Ideal for multi-tasking machines, turning lathes or modular systems.

■Tool-friendly plastic inserts.

■One tool shuttle/tool carrier can be used for several processing machines.

■Time saving with sister tools quickly to hand.

Only from the tool shuttle:

■safe transport due to 4 lockable transport castors.

■Ideal for transport between a central setting and measuring device and the

processing machine.

■Mounting blocks and storage compartments can be integrated (to be ordered separately).

Only from the tool carrier:

■table structure with 4 stable feet.

TIP

Tool palettes with inserts for the tool shuttle/tool carrier are available for many interfaces in the

EWS-ONLINE CATALOGUE. www.ews-tools.de/OnlineCatalogue (Search with item number: TP%)

or contact the EWS sales department. Other tool palettes can also be supplied on request.

Example order: TP-V5-20 Tool palette for Varia V5 with 20 tool inserts

11www.ews-tools.de

5. CARE, MAINTENANCE AND SERVICE

NOTE

Only original parts from the manufacturer are permitted as spare parts and accessories.

Spare parts and accessories not supplied by the manufacturer have not been tested for op-

eration and may impair operational safety. EWS accepts no liability for damage caused by the

use of non-approved spare parts and accessories.

Care: Clean only with a cleaning cloth. Never use compressed air or cleaning agents

so as not to damage the powder-coated surfaces or the plastic inserts.

Maintenance: The tool shuttle/tool carrier is maintenance-free for the user.

Service case: In case of defects of any kind, contact the EWS service staff.

EWS Weigele GmbH & Co. KG

Tel+49(0)7161-93040-700

Fax +49(0)7161-93040-30

E-mail [email protected]

The EWS service department can be reached at:

Always store and transport EWS products in a clean, dry and frost-free place.

Constant vibrations or strong shocks must be avoided.

Proper storage is guaranteed under the following conditions:

Do not dispose of these products with normal household waste.

Please contact our service department or return the tool shuttle / tool carrier to us for disposal

at the end of its service life.

Temperature Humidity

5-40 °C < 65 %

6. STORAGE, TRANSPORT AND DISPOSAL

12 www.ews-tools.de

7. SERVICE / WARRANTY

EWS Weigele GmbH & Co. KG

Tel+49(0)7161-93040-700

Fax +49(0)7161-93040-30

E-mail [email protected]

Services

■Professional, fast repair by our service team

■Competent advice from our service department in the event of faults

NOTE

In the event of a warranty claim, please contact our service department.

The EWS service department can be reached at:

■The warranty period is 1 year.

■The shipping date at EWS is decisive.

■The warranty does not cover wear parts such and any consequential damage caused by them.

■The service life of EWS products depends largely on the corresponding runtime and application.

■The warranty covers all significant defects that can be proven to be the result of material or

production faults.

The warranty shall expire in the event of:

■Conversions / alterations / repairs not carried out by EWS or not approved in writing

■Improper and inappropriate set-up, maintenance and operation

■Force majeure

■Damage due to non-observance of the operating instructions

13www.ews-tools.de

Dimensions (height x width x depth) in standard version:

TS-400: approx. 968 x 613 x 665 mm

TC-100: approx. 292 x 613 x 258 mm

TC-200: approx. 554 x 613 x 364 mm

Empty weight in standard equipment (depending on tool palette or storage tray):

TS-400: from 49 to 55 kg

TC-100: from 8.5 to 10 kg

TC-200: from 10 to 12 kg

Maximum total weight:

TS-400: 455 kg

TC-100: 110 kg

TC-200: 212 kg

Total maximum load capacity:

TS-400: 400 kg

TC-100: 100 kg

TC-200: 200 kg

Maximum load capacity per tool palette:

TS-400, TC-100 and TC-200: 100 kg

Maximum load capacity per tool insert:

20 kg

Maximum angle of inclination:

TS-400: 10°

TC-100: 0°

TC-200: 0°

Operating temperature:

5-40°C

8. TECHNICAL SPECIFICATIONS

NOTE

Observe centre of gravity / tipping safety. The weight of the loaded upper tool palette(s) must

always be less than or equal to the weight of the loaded lower tool palette.

Tooling Systems and Turrets

EWS Weigele GmbH & Co. KG

Maybachstraße 1 · D-73066 Uhingen

Telefon +49(0)7161-93040-100

Telefax +49(0)7161-93040-30

E-Mail: info@ews-tools.de

www.ews-tools.de

WSW Spannwerkzeuge-Vertriebs GmbH

Maybachstr. 1 · D-73066 Uhingen

Telefon +49(0)7161-93040-100

Telefax +49(0)7161-93040-30

E-Mail: contact@wsw-tools.de

www.wsw-tools.de

Command Tooling Systems

13931 Sunfish Lake Blvd NW

Ramsey · MN 55303 USA

Telefon +1-763-576-6910

Telefax +1-763-576-6911

support@commandtool.com

www.commandtool.com

EWS Korea Co. Ltd.

80-101, Golden root-ro,

Juchon-myeon, Gimhae-si,

Gyeongsangnam-do, Korea

Telefon +82 55 -267- 8085

Telefax +82 55-262-3118

E-Mail: info@ewskorea.co.kr

www.ewskorea.co.kr

EWS Ltd.

Krassnaja str., 38

600015 Vladimir

Russland

Telefon +7- 4922-541160

Telefa x +7- 4922-541160

E-Mail: inf[email protected]

www.ews-russland.ru

EWS Tutucu Sistemleri ve

Taretleri Anonim Şirket

Aydınlı mah.Melodi No.2/19 Sk. Bilmo

San.Sit. 18-19

34956 Tuzla / Istanbul

Turkey

Telefon +90-216-593-22-44

E-Mail: mehme[email protected]

www.ews-tools.de

EWS Tool Holder Technologies

(Taicang Co. Ltd)

Beijing East Road No. 88

215400 Taicang · Jiangsu

P. R. China

Telefon +86 512 3306 2600

Telefax +86 512 3306 2601

E-Mail: sales.cnews-tools.de

www.ews-tools.cn

Stand / updated: 04/2022

Tool-Arena GmbH

Maybachstraße 1 · D-73066 Uhingen

Telefon +49(0)7161-93040-100

E-Mail info@tool-arena.com

www.tool-arena.com

This manual suits for next models

3

Table of contents

Other EWS Industrial Equipment manuals