exeltec X CERK HE User manual

Installation , use and maintenance

manual

Gas fired radiant strips heating systems

Technoparc Saône

Vallée Est

-

215 Rue Marie Curie

-

01390 Civrieux en Dombes

Tel : 04 78 82 01 01 Fax : 04 78 82 01 02

www.exeltec.fr – info@exeltec.fr

X-CERK HE EVO 4 -2022-11--Iss1-0-EN

X CERK HE

/ X CERK HE

-

Jr

pr

e

-

mix

burner EVO4

This equipment has been manufactured to work for the intended purposes, without risk, provided

that the following indications are observed:

• Installation, use and maintenance are carried out according to the instructions in the present

manual;

• Power supply and working conditions comply with the product plate data.

IMPORTANT:

PLEASE READ THE INSTRUCTIONS CAREFULLY BEFORE PROCEEDING

WITH THE INSTALLATION AND USE OF THIS EQUIPMENT.

KEEP THE MANUAL FOR FUTURE REFERENCE.

This booklet has been prepared and printed by EXELTEC SAS. Reproduction, even in part, is forbidden without prior

permission.

Constant development in search of product improvement may lead, without advance notice, to changes or

modifications of the contents and descriptions herein

Contents

1 INTRODUCTION ................................................................................. 3

2 WARNINGS ........................................................................................ 4

2.1 Special warnings ................................................................................. 5

2.2 Disposal ............................................................................................ 5

2.2.1 Information to users ........................................................................... 5

2.3 General description ............................................................................. 6

2.4 Symbols and terminology used in the manual .......................................... 7

2.4.1 Terminology ...................................................................................... 7

2.4.2 Symbols ........................................................................................... 8

3 INTENDED USE .................................................................................. 9

3.1 General description and intended use ..................................................... 9

3.2 Identification data of the machine........................................................ 10

4 TECHNICAL DATA ............................................................................ 11

4.1 Technical data in accordance with regulation (EU) 2015/1188 – DIRECTIVE

2009/125 / EC (ErP) ....................................................................................... 12

4.2 Dimensions of thermal units SX (left version) ........................................ 14

4.3 Dimensions of thermal units DX (right version) ...................................... 16

4.4 Radiant ducts dimensions in millimetres ............................................... 18

4.5 Thermal unit components ................................................................... 19

4.6 Radiant ducts components.................................................................. 20

5 INSTALLATION ................................................................................ 21

5.1 Functional and surrounding spaces for the thermal unit ........................... 21

5.2 Distance between radiant ducts and combustible material ....................... 22

5.3 Transport, handling and lifting ............................................................ 23

5.3.1 Handling the thermal unit using eye-bolts (only mod. HE) ....................... 24

5.4 Mounting of thermal unit .................................................................... 26

5.5 Installation of the thermal unit over roof ............................................... 34

5.6 EXHAUST PIPE.................................................................................. 35

5.6.1 Water drain in the flue ....................................................................... 36

5.7 Installation of the radiant modules ....................................................... 36

5.7.1 First and second module .................................................................... 36

5.7.2 Installation of the next modules .......................................................... 38

5.7.3 Expansion joints ............................................................................... 44

5.8 Connections to gas net ...................................................................... 45

5.9 Electrical connections ........................................................................ 47

5.9.1 Thermal overload and short circuit protection ........................................ 47

5.9.2 Grounding ....................................................................................... 47

5.9.3 Protection from indirect contacts ......................................................... 47

5.9.4 Connection terminal board ................................................................. 48

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 2

5.9.5 Connection diagram for sensors and EU-CM300 user interface .................. 49

5.9.6 Electrical diagram for mod. HE ............................................................ 51

5.9.7 Electrical diagram for mod. HE-Jr ........................................................ 52

5.9.8 Electrical panel on board the machine (mod. HE / HE-Jr) ......................... 54

5.9.9 EU-SP300 programmable power board ................................................ 55

5.9.10 Local operation and via EUBus network with EU-NET (with EU-Qbo100) and

EU-VISION (with EU-Qbo 300) configurations ........................................ 55

5.9.11 EUBus network connection scheme for EU-NET and EU-VISION configurations

56

6 WORKING SEQUENCE ...................................................................... 58

7 COMMISSIONING, SERVICE AND MAINTENANCE ............................. 59

7.1 Safety requirements .......................................................................... 59

7.2 Access to the thermal unit .................................................................. 60

7.3 Commissioning and start-up ............................................................... 60

7.4 Ordinary maintenance – General indications and prescriptions .................. 61

7.5 Ordinary maintenance operations ........................................................ 62

7.5.1 Thermal unit .................................................................................... 62

7.5.2 Radiant circuit modules ...................................................................... 63

7.5.3 Summary of main ordinary maintenance operation. ................................ 64

8 TROUBLESHOOTING ........................................................................ 66

8.1 Error code identification ..................................................................... 66

8.2 Error removal procedure .................................................................... 67

8.2.1 Errors reset ..................................................................................... 74

8.3 Problems during operation .................................................................. 75

8.4 Operation status and burner cycle diagram ........................................... 76

9 WARRANTY TERMS .......................................................................... 78

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 3

1 INTRODUCTION

This manual contains the description of X CERK HE EVO4 radiant strips heating system operation

and the instructions necessary to correctly perform the main operations concerning installation, use

and routine maintenance.

The information provided is intended for a professional user. This user must have specific

knowledge on the use of the heating unit, be properly instructed and trained and have the necessary

authorization to operate on it.

The use of original spare parts and accessories is recommended. The installation of non-original

spare parts will invalidate the warranty. Furthermore, non-original parts could reduce the useful

life and performance of the heating system, as well as be dangerous.

Special symbols are present on the unit. The heating system manager has the responsibility to

keep them in perfect visual condition and to replace them in case they are no longer legible.

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 4

2 WARNINGS

Carefully read the instructions and warnings contained in this document before starting the system

up, as they provide important information regarding safety, installation, use and maintenance.

1. This manual is an integral and essential part of the product and must be kept in a safe place

and made available to personnel;

2. Give this manual to the new owner and/or installer who will take care of the installation if

the appliance is sold, or transferred. In case of loss, immediately ask EXELTEC for a copy;

3. EXELTEC disclaims any liability for direct or indirect damage to people, animals or objects

arising from errors in installation, use, failure to comply with the instructions in this manual

and in any case with the instructions provided by the manufacturer;

4. The system must be installed in compliance with national and local regulations in force in

the country of installation;

5. This system shall be used solely for the purposes for which it was expressly designed and

built. Any other use is to be considered improper and therefore dangerous;

6. Any contractual or non-contractual liability of the manufacturer for damages arising from

errors in installation, use and in any case from non-observance of the instructions provided

by the manufacturer is excluded;

7. Installation in premises where artisan or industrial activities are carried out or where working

activities and materials may lead to the risk of formation of gases, vapours or dusts likely

to give rise to fires or explosions is not permitted;

8. The installation and start up of the system must be carried out by qualified and authorized

personnel;

9. The packaging elements (nails, staples, plastic bags, polystyrene foam, etc.) must not be

left within the reach of children as they are potential sources of danger, but must be disposed

of in accordance to current legislation.

Check the system every year through a EXELTEC authorised service centre.

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 5

2.1 Special warnings

Check that the heat unit is pre-set to operate with the electrical power and the gas available in the

network by checking what is indicated in the serial data on the unit.

Check the seal of the gas supply installation, check that it has the suitable size for the necessary

capacity and that it is equipped with all safety and control devices according to the laws in force.

The electrical safety of the installation is complete when the installation is correctly connected to

an efficient grounding system that must meet the requirements of the laws in force.

In case of repeated arrests of the thermal unit do not persist in performing manual reset

procedures, but contact the professional, qualified personnel to solve this anomalous issue.

Deactivate the device in case of failure and/or malfunctioning, do not try to fix and/or directly

intervene on it, but promptly contact the authorised customer service. In case of prolonged

inactivity, close the valve of gas interception and power off the system.

If there are works in the place where the radiant circuit is to be installed, avoid accidental impacts

that can damage the seal of radiant pipes.

Should the installation be subject to demolition, respect the laws in force in the country where the

installation is located.

All materials and/or substances must not be dispersed in the environment but reused and/or

disposed of according to current legislation.

The installation contains the following materials:

plastic components;

electrical/electronic components;

single and double insulated electrical wires;

mineral wool insulating material;

glass wool insulating material;

steel, copper and aluminium.

2.2 Disposal

2.2.1 Information to users

Illegal/abusive disposal of products on the part of the user, leads to the application of the

administrative sanctions foreseen by the Italian Legislative Decree 152/2006.

INFORMATION TO USERS according to art. 14 of the Directive 2012/19/EU of the European

Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment (WEEE).

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 6

The crossed bin symbol (Fig. 2.1) on the appliance or on its packaging indicates that the product,

at the end of its operating life, must be collected separately and not disposed together with other

mixed urban waste.

Fig 2.1 Fig. 2.2

The separate collection of this equipment at the end of its life is organized and managed by the

manufacturer. The user who wishes to dispose of the present equipment can therefore contact the

manufacturer and follow the system that this has adopted to allow the separate collection of the

equipment at the end of life, or autonomously select an authorized waste chain for its management.

The adequate separate collection of the disused equipment for the start after recycling, treatment

and environmentally compatible disposal helps to avoid possible negative effects on the room and

human health and favours the reuse and / or recycling of the materials of which it is composed the

equipment.

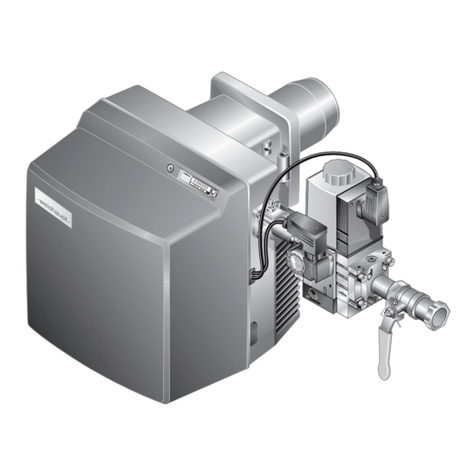

2.3 General description

XCERK HE/HE-Jr is a radiant heating system operating with gas, and it is particularly suitable to

heat medium-large environments. Its design and manufacturing have involved special attention in

order to obtain optimal results in terms of efficiency, safety, temperatures uniformity and reduction

in polluting emissions.

XCERK HE/HE-Jr consists of aluminised steel fixed on the ceiling of the room to heat. The heated

pipes emit infrared rays that heat the environment without creating air movement.

The production of the heat necessary for heating the radiant pipes takes place through a heat unit

equipped with modulating burner. The heat exchange of the combustion chamber to the fluid

present in the pipes is ensured by the continuous recirculation of the same fluid through a

centrifugal fan.

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 7

2.4 Symbols and terminology used in the manual

2.4.1 Terminology

DAMAGE Physical injury or damage to health

GCV Higher calorific value, it is the total quantity of heat emitted by a

fuel mass unit dried till its intrinsic humidity, when this is

subjected to complete combustion in presence of oxygen and

when the products of combustion are back to the original pre-

combustion temperatures; this quantity includes the vapour

condensation heat created by the combustion of the hydrogen

contained inside the fuel.

NCV Lower calorific value, it is the total quantity of heat emitted by a

fuel mass unit containing a proper humidity level, when this is

subjected to complete combustion in presence of oxygen and

when the products of combustion are back to the original pre-

combustion temperatures.

DANGER Potential source of damage, the term danger can be qualified in

order to state its origin (for example electric, danger, mechanical

danger, etc.).

QUALIFIED PERSONNEL Person having the requisites required by the law in force, who

has achieved experience concerning the necessary interventions,

who attended proper specialisation and/or professional training

courses.

USER Person using the product.

INTENDED USE Use of the appliance in conformity to the indications in the

present manual.

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 8

2.4.2 Symbols

SYMBOL

DESCRIPTION

NOTE

Indicates information useful for the correct operation of the system or

behavioural indications.

DANGER

Indicates a high level of danger. Failure to comply may result in serious injuries

or death

DANGER

Indicates a medium level of danger. Failure to comply may result in medium or

serious injuries

ATTENTION

Indicates a warning. Failure to comply may result in material or functional

damage, even irreversible damage

PROHIBITION

Generic prohibition

PROHIBITION

Do not use screws

PROHIBITION

Do not use sealant

INDICATION

Use sealant

INDICATION

Use screws

Tab. 2.1

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 9

3 INTENDED USE

3.1 General description and intended use

X CERK HE/HE-Jr is a radiant heating system operating with gas, and it is particularly suitable to

heat medium-large environments. Its design and manufacturing have involved special attention in

order to obtain optimal results in terms of efficiency, safety, temperatures uniformity and reduction

in polluting emissions.

X CERK HE/HE-Jr consists of aluminised steel fixed on the ceiling of the room to heat. The heated

pipes emit infrared rays that heat the environment without creating air movement.

The production of the heat necessary for heating the radiant pipes takes place through a heat unit

equipped with modulating burner. The heat exchange of the combustion chamber to the fluid

present in the pipes is ensured by the continuous recirculation of the same fluid through a

centrifugal fan.

Any use of the system other than that indicated above is to be considered

unauthorised and dangerous.

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 10

3.2 Identification data of the machine

Each appliance is identified with a rating plate containing its technical characteristics and serial

number. This label, together with warning ones, are applied on the electrical panel on board of the

unit and they must not be removed.

Below is an example of the aforementioned label.

Fig. 3.1

In case of orders of spare parts or inquiries about procedures for the use and/or

maintenance of the radiant strips heating systems, always indicate exact model

and serial number as shown on the rating plate.

It is absolutely forbidden to remove the rating plate or alter its data.

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 11

4 TECHNICAL DATA

TECHNICAL SPECIFICATION X CERK HE X CERK HE-Jr

Nominal heat output [kW] Heat input [kW]

275.8

114.4

Thermal efficiency NCV 100% [%]

290

120

Thermal efficiency NCV 50% [%]

92.90%

93.10%

Envelope loss factor [%]

95.50%

95.40%

Exhaust gas – thermal loss @ burner ON [%] 2.20% 2.20%

Exhaust gas – thermal loss @ burner ON [%] 4.90% 4.70%

Exhaust gas – thermal loss @ burner OFF [%] <0,1% <0,1%

Useful efficiency NCV 100% [%] 95.10% 95.30%

Useful efficiency NCV 50% [%]

96.60%

96.50%

Exhaust gas temperature @ 100% [°C] (*)

120 ÷ 170

110 ÷ 140

Exhaust gas temperature @ 50% [°C] (*)

70 ÷ 120

60 ÷ 100

Fuel gas – compatibility

G20 - G25 - G31

Heat-transfer fluid

-

Emission system Radiant strip

Power supply [V/Hz/-] 400 / 50 / 3F+N

Installed electric power [kW] 2.7 1.6

Power consumption in stand-by [W] 10 10

Max input current [A] @ 400 V / 50 Hz 4.7 2.7

Inverter presence

YES

Modulation of the recirculation fan for combustion products

YES

Combustion modulation

YES

Evacuation of the combustion products – Type of installation

B22 ; B52

Category

II2H3P

Regulation mode

Modulating

Burner type

Mixing premix blown

Exahust gas - available pression [Pa]

50

10

Exhaust gas – duct max. length [m] (**)

5

8

Flue gas connection [mm]

150

120

Gas supply connection [BSP]

1”

3/4”

Nitrogen oxides emissions [mg/kWh]

27

29

Unit weight [kg]

190

122

Frame weight [kg]

29

20

Lw - Max sound power level [dB(A)]

90

86

Lp - Max sound power level @5m [dB(A)]

73

69

Supply pressure G20 min / max [mbar]

20 / 100

20 / 50

Supply pressure G31 min / max [mbar]

37 / 100

37 / 50

Radiant modules compatibility M8Ø3 – M4Ø3

M12Ø3

M8Ø2

M8Ø3 – M4Ø3

Tab. 4.1

Reference gas G20

*

Variable depending on module type and radiant line configuration

**

Consider that each 90° curve corresponds to 1.5 linear metres of duct.

***

Refer to the specifications indicated in the paragraph 5.8 .

The thermal unit has been designed for an operating temperature between 0 °C

(*) and + 40 °C

(*) With optional electric heater, to be ordered on request, it is possible to extend the operation up

to – 15°C outside temperature.

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 12

4.1 Technical data in accordance with regulation (EU) 2015/1188 –

DIRECTIVE 2009/125 / EC (ErP)

Mandatory information for local space heaters for commercial use.

Model identification: XCERK-HE-

Jr

60

XCERK-HE-

Jr

60

XCERK-HE-Jr

120

XCERK-HE-Jr

120

Heat generator to be installed outside the heated area yes no yes no

Type of heating:

radiant strips

radiant strips

radiant strips

radiant strips

Fuel Natural gas H

Natural gas H

Natural gas H Natural gas H

Fuel Gaseous Gassoso Gassoso Gassoso

Data

Value

Value

Value

Value

Space heating emissions (*)

(NOx ≤ 200 mg/kWhinput)

[mg/kWhinput]

(GCV)

26 26 26 26

Heat output

Nominal heat output

Pnom

kW

57.2

57.2

114.4

114.4

Minimum heat output Pmin kW 28.6 28.6 57.2 57.2

Minimum heat output

(percentage of nominal heat output)

.. % 50 50 50 50

Nominal tube system heat output (if applicable)

Psystem

kW

N.A.

N.A.

N.A.

N.A.

Nominal tube segment heat output (if applicable) Pheater,i

kW N.A. N.A. N.A. N.A.

Number of identical tube segments

n

-

-

-

-

-

Radiant factor

Radiant factor at nominal heat output

RFnom

-

0.6446

0.6446

0.6446

0.6446

Radiant factor at minimum heat output RFmin - 0.5914 0.5914 0.5914 0.5914

Radiant factor of tube segment at nominal heat output

RFi

-

-

-

-

-

Auxiliary electricity consumption

At nominal heat output

elmax

kW

0.500

0.500

0.500

0.500

At minimum heat output elmin kW 0.337 0.337 0.337 0.337

In standby mode

elSB

kW

0.010

0.010

0.010

0.010

Permanent pilot flame power requirement

Pilot flame power requirement

(if applicable)

Ppilot kW N.A. N.A. N.A. N.A.

Useful efficiency (GCV) — tube local space heaters only (**)

Useful efficiency at nominal heat

output (**)

ηth,nom

% 85.8 85.8 85.8 85.8

Useful efficiency at minimum heat

output (**)

ηth,min

% 85.9 85.9 85.9 85.9

Useful efficiency of tube segment at minimum heat

output (if applicable)

ηi % N.A. N.A. N.A. N.A.

Envelope losses

Envelope insulation class

U

W/m2K

0.5

0.5

Envelope loss factor

Fenv

%

2.2%

--

2.2%

--

Heat output control type (select one)

— single stage (ON/OFF)

no

no

no

no

— two stage

no

no

no

no

— modulating yes yes yes yes

Seasonal space heating energy efficiency

(≥74%)

ηS % 85.2 87.5 86.1 88.3

(*) Nox = nitrogen oxides

Tab 4.2

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 13

Model identification:

XCERK-HE 150

XCERK-HE 150

XCERK-HE 300

XCERK-HE 300

Heat generator to be installed outside the heated area

yes

no

yes

no

Type of heating:

radiant

strips

radiant

strips

radiant

strips

radiant

strips

Fuel Natural gas

H

Natural gas

H

Natural gas

H

Natural gas

H

Fuel

Gaseous

Gassoso

Gassoso

Gassoso

Data Value Value Value Value

Space heating emissions (*)

(NOx ≤ 200 mg/kWh

)

input

[mg/kWh

]

inp ut

(GCV)

19

19

19

19

Heat output

Nominal heat output

P

nom

kW

142.7

142.7

275.8

275.8

Minimum heat output

P

min

kW

77.3

77.3

140.1

140.1

Minimum heat output

(percentage of nominal heat output)

..

%

54

54

51

51

Nominal tube system heat output (if applicable)

P

system

kW

N.A.

N.A.

N.A.

N.A.

Nominal tube segment heat output (if applicable)

P

heater,i

kW

N.A.

N.A.

N.A.

N.A.

Number of identical tube segments

n

-

-

-

-

-

Radiant factor

Radiant factor at nominal heat output

RF

nom

-

0.6487 0.6487 0.6487 0.6487

Radiant factor at minimum heat output

RF

min

-

0.5951 0.5951 0.5951 0.5951

Radiant factor of tube segment at nominal heat

output

RF

i

-

-

-

-

-

Auxiliary electricity consumption

At nominal heat output

el

max

kW

0.813

0.813

0.813

0.813

At minimum heat output

el

min

kW

0.485

0.485

0.485

0.485

In standby mode

el

SB

kW

0.010

0.010

0.010

0.010

Permanent

pilot flame power requirement

Pilot flame power requirement

(if applicable)

P

pilot

kW

N.A.

N.A.

N.A.

N.A.

Useful efficiency (GCV) — tube local space heaters only (**)

Useful efficiency at nominal heat

output η

th,nom

%

85.6

85.6

85.6

85.6

Useful efficiency at minimum heat

output η

th,min

%

87.0

87.0

87.0

87.0

Useful efficiency of tube segment at minimum hea

t

output (if applicable)

η

i

%

N.A.

N.A.

N.A.

N.A.

Envelope losses

Envelope insulation class

U

W/m2K

0.5

0.5

Envelope loss factor

F

env

%

2.2%

--

2.2%

--

Heat output control type (select one)

— single stage (ON/OFF)

no

no

no

no

— two stage

no

no

no

no

— modulating

yes

yes

yes

yes

Seasonal space heating energy

efficiency

(≥74%)

η

S

%

87.1

89.3

87.5

89.8

(*) Nox = nitrogen oxides

Tab. 4.3

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 14

4.2 Dimensions of thermal units SX (left version)

Fig. 4.1

1 = Gas

connection

2 = Electrical connection

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 15

DIMENSION X CERK HE-Jr (mm) X CERK HE (mm)

A 1544 1757

B 459 660

C 265 264

D 157 189

E 658 640

F 326 490

G 358 416

H 120 150

I 820 833

J 239 384

K 320 340

L 239 274

M 798 998

N 930 1125

O 824 1023

P 311 372

Q 358 440

R 591 813

S 34 180

T 750 750

U 34 68

V 144 287

W 364 406

X 176 213

Y 528 710

WEIGHT 122 kg 190 kg

Tab 4.4

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 16

4.3 Dimensions of thermal units DX (right version)

Fig. 4.2

1 = Gas connection

2 = Electrical connection

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 17

DIMENSION X CERK HE DX (right version)

(mm)

A

1767

B

660

C

272

D

180

E

630

F

613

G

291

H

150

I

833

J

384

K

340

L

274

M

998

N

1125

O

1023

P

436

Q

469

R

813

S

70

T

750

U

179

V

120

W

406

X

376

Y

710

WEIGHT 190

kg

T

ab.

4.5

Installation manual X-CERK HE EVO 4 -2022-11--Iss1-0-EN

Page | 18

4.4 Radiant ducts dimensions in millimetres

M12Ø3 model weighs 30 kg/m and has the following dimensions:

Fig. 4.3

M8Ø3 model (on the left) weighs 25 kg/m while M4Ø3 model (on the right) weighs 19 kg/m.

Their dimensions are:

Fig. 4.4

M8Ø2 model (M8Ø2-RV with “V” reflector and M8Ø2-ST without reflector) weighs 20 kg/m and

has the following dimensions:

Fig. 4.5

This manual suits for next models

1

Table of contents

Popular Burner manuals by other brands

Grouw!

Grouw! 18002 instruction manual

Kudu

Kudu KU-HP1700-WH instruction manual

Outland Firebowl

Outland Firebowl FMPPC2A-895 owner's manual

Riello

Riello DB 4 SM C03 A0 TC FS1 FB T150 Installation, use and maintenance instructions

Riello

Riello RDB 2.2 BX 12-18 Installation, use and maintenance instructions

Oster

Oster Solid Single burner user guide