109-4198 Rev. A

Page 7 of 9

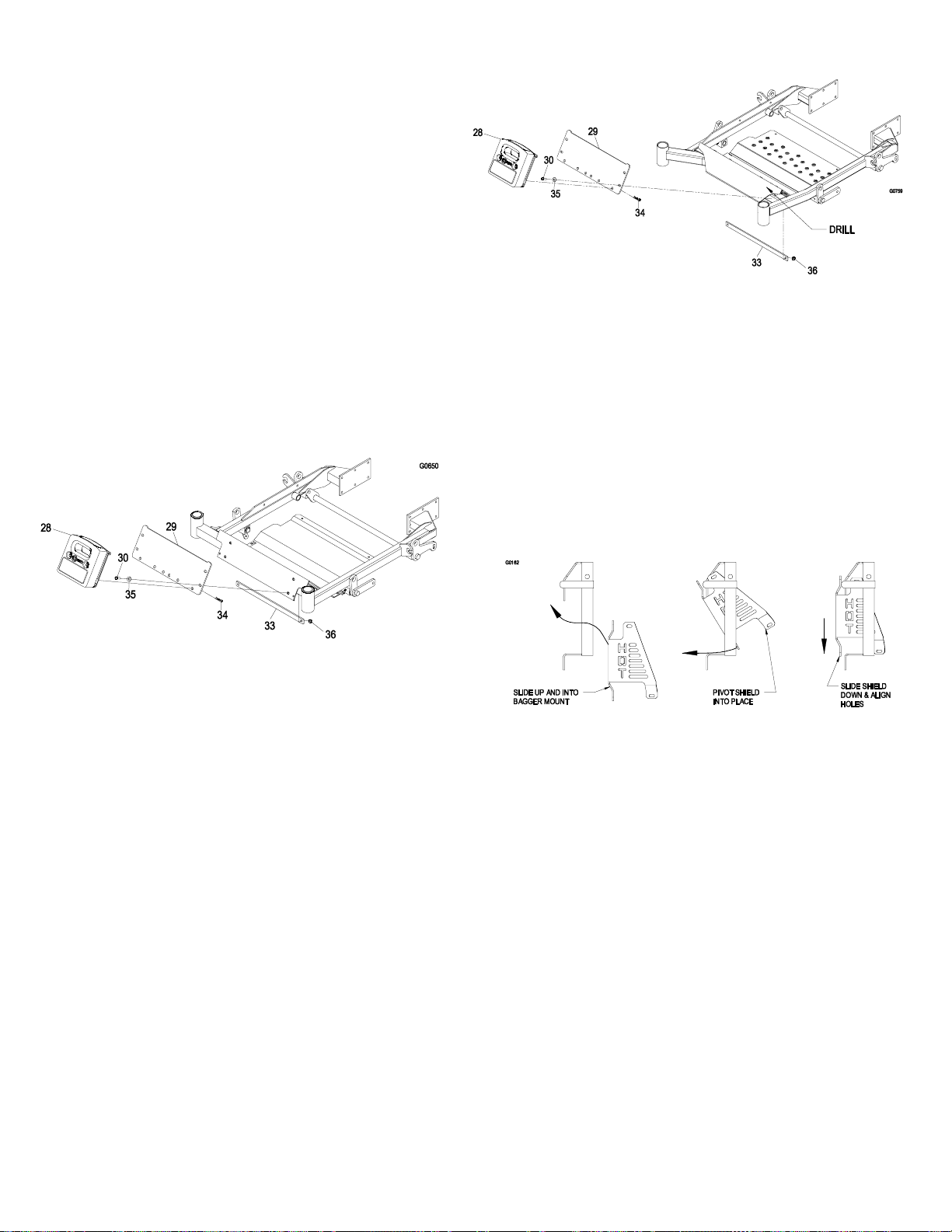

Install Weight Assembly

For units with SN 440,000 to 599,999 (also

required for units with SN 439,999 and lower

with a 2 post ROPS installed):

1. Remove the hardware from the front of the floor

pan. Discard the screws and retain the washer

and whizlock nuts.

2. Assemble the weight mounting plate (Item 29) to

the floor pan using (4) 5/16-18x1 Hex Head

Screws (Item 30) and the (4) washers and (4)

whizlock nuts removed in step 1.

NOTE: Some 52” units have a standard weight

plate bolted to the front of the floorpan. Use the

(4) 5/16-18 x 1.50” Hex Head Screws (Item 30) for

this application and the (4) washers and (4)

whizlock nuts removed in step 1.

3. Hook the weight plate assembly (Item 28) over

the top of the weight mounting plates and secure

with two hairpins (Item 34).

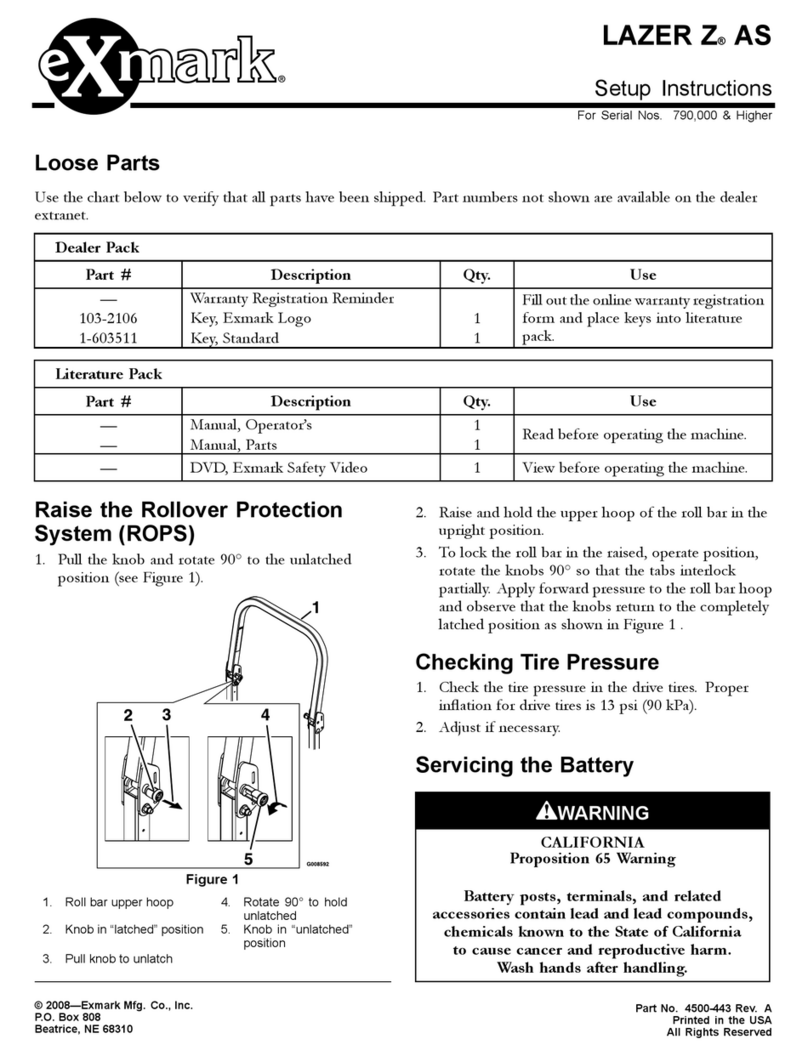

FIGURE 7

For units with SN 600,000 and Higher:

1. Slide mounting strap (Item 33) behind front panel

of floor pan, above the reinforcing bars that are

welded to the front frame. Attach the weight

mounting plate using (2) 5/16-18 x 1.50 hex head

screws (Item 30) (2) washers and (2) Whizlock

Nuts (Items 35 and 36) (See Figure 8).

2. Use the upper mounting holes of the weight

mounting plate to mark the location to drill the

mounting holes in the front panel of the floor pan.

Remove the weight mounting plate and drill 3/8”

upper mounting holes in the front panel of the

floorpan.

3. Permanently mount the weight mounting plate to

the front panel of the floor pan using (4) 5/16-18 x

1.50 hex head screws, (4) washers, (4) whizlock

nuts and the mounting strap (Items 30, 33, 35, 36)

4. Hook the weight plate assembly (Item 28) over

the top of the weight mounting plates and secure

with two hairpins (Item 34).

FIGURE 8

Install Hood Assembly and Bags

44, 46, 48 and 50 inch units

1. Remove the (12) bolts that retain the “HOT”

engine guard shield (Item 1). Discard (8) of

the bolts and retain (4). Keep all (12) nuts for

reuse in Step 3.

2. Working from the front side of the bagger

mount, slide the top end of the engine guard

up and into the mount. Pivot the lower end

through the bagger mount and slide it down

into place until the holes align with the holes in

the bagger mount (See Figure 9).

FIGURE 9

3. Install the Bagger Mount Weldment (Item 2) and

engine guard shield using the (8) 5/16-18 x 1

Screws provided (Item 3) and (8) whizlock nuts

removed in step 1.

4. Align the side holes in the engine guard shield to

holes in the frame on each side of the unit.

Reattach the sides of the engine guard shield

using the (4) bolts and remaining (4) whizlock

nuts retained in step 1. Continue at step 1 of the

All Units section.

52 and 56 inch units

1. Remove and discard the (8) bolts that retain

the rear weight (Item 12). Keep the whizlock

nuts for use in steps 2 and 3.

2. Install the Bagger Mount Weldment (Item 2) to

the rear of the frame using (4) 5/16-18 x 1

screws (Item 3) and (4) 5/16 – 18 whizlock

nuts (Item 15). Use only the bottom four holes

on the Bagger Mount Weldment