Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onparks,sportselds,caravanparks,cemeteries,and

commercialgrounds.Itisnotdesignedforcuttingbrushor

foragriculturaluse.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyforproductandaccessory

information,helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Themodelandserialnumbersareon

theleftsideoftheframe.Writethenumbersinthespace

provided.

ModelNo.

SerialNo.

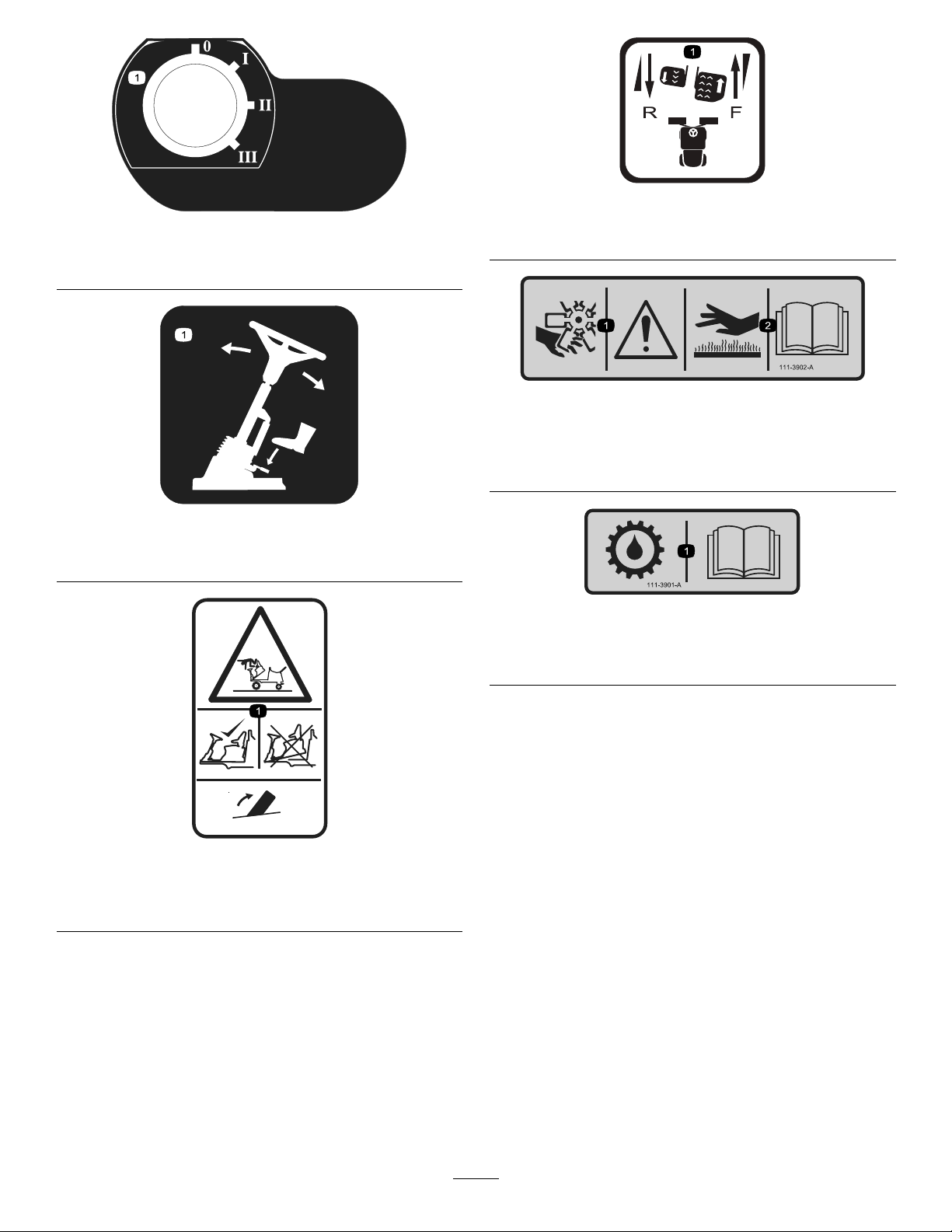

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

g000502

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

GeneralSafety.........................................................3

SafeOperatingPractices...........................................3

ToroRidingMowerSafety........................................6

SafetyandInstructionalDecals.................................8

Setup...........................................................................12

ProductOverview.........................................................12

Controls...............................................................13

Specications........................................................19

Attachments/Accessories........................................19

Operation....................................................................19

CheckingtheEngine-OilLevel.................................19

CheckingtheCoolingSystem...................................20

AddingFuel...........................................................21

CheckingtheHydraulicFluid..................................22

CheckingtheTirePressure......................................23

CheckingtheTorqueoftheWheelNuts.....................23

ThinkSafetyFirst...................................................23

UsingtheOperatorPlatformLatching

Mechanism........................................................23

UnderstandingtheOperatorPresence

Controls............................................................24

StartingandShuttingOfftheEngine.........................24

AdjustingtheCenterCuttingUnitHeight-of-Cut

Correction.........................................................26

ControllingthePositionoftheIndividualCutting

Units.................................................................26

AdjustingtheCuttingUnitAutoLimited

Lift...................................................................26

EngagingtheCuttingUnitDrive..............................26

ClearingtheCuttingUnits.......................................27

UsingWeightTransfer/TractionAssistance................27

FoldingtheROPS..................................................27

LocatingtheJackingPoints......................................28

TransportingMachines............................................29

OperatingTips......................................................29

Maintenance.................................................................31

RecommendedMaintenanceSchedule(s)......................31

DailyMaintenanceChecklist....................................32

PreparingtheMachineforMaintenance.....................33

ServiceIntervalChart.............................................33

Lubrication...............................................................34

GreasingtheBearings,Bushings,andPivots...............34

EngineMaintenance..................................................35

CheckingtheEngineOverheatWarning

System..............................................................35

ServicingtheAirCleaner.........................................35

ServicingtheEngineOilandFilter............................36

FuelSystemMaintenance...........................................37

DrainingtheFuelTank...........................................37

CheckingtheFuelLinesandConnections..................37

BleedingtheFuelSystem.........................................37

ReplacingtheFuelFilter..........................................37

ElectricalSystemMaintenance....................................38

CheckingtheElectricalSystem.................................38

CheckingtheBatteryCondition................................38

ServicingtheBattery...............................................39

DriveSystemMaintenance.........................................39

ChangingtheTransmissionOilFilter........................39

ChangingtheHydraulicReturnFilter........................39

CheckingtheRearWheelAlignment.........................40

InspectingtheTransmissionControlCableand

OperatingMechanism.........................................40

CoolingSystemMaintenance......................................41

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUK

AllRightsReserved