Exmark ARX481CKA30000 User manual

STAND-ON

AERATOR

ForSerialNos.

315,000,000&Higher

PartNo.4502-175Rev.A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

(CPRC)Section4442touseoroperatethis

engineonanyforest-covered,brush-covered,

orgrass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilar

laws.

Toacquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

Thissparkignitionsystemcomplieswiththe

CanadianstandardICES-002.Cesystèmed’allumage

parètincelledevèhiculeestconformeàlanorme

NMB-002duCanada.

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2014ExmarkMfg.Co.,Inc.

2101AshlandAve

Beatrice,NE683102

Contactusatwww.Exmark.com.

PrintedintheUSA

AllRightsReserved

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkAerator.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

aerator.

BEFOREOPERATINGYOURAERATOR,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyouraerator,

maintainitsmaximumefciency,andpromotesafe

operation.

Important:Tomaximizesafety,performance,

andproperoperationofthismachine,itis

essentialthatalloperatorscarefullyreadand

fullyunderstandthecontentsoftheOperator’s

manualprovidedwiththeproduct.Safe

operationofExmarkequipmentisessential.

Failuretocomplywiththeoperatinginstructions

orreceivepropertrainingmayresultininjury.

Gotohttp://www.Exmark.comforadditional

safeoperationinformation,suchassafetytips,

trainingmaterials,andOperator’smanuals.

Ifadditionalinformationisneeded,orshould

yourequiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

3

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals......................10

Specications........................................................15

ModelNumbers.............................................15

Systems..........................................................15

Dimensions....................................................16

TorqueRequirements.....................................16

ProductOverview.................................................17

Operation..............................................................17

Controls.........................................................17

Pre-Start.........................................................19

OperatingInstructions...................................19

Transporting..................................................21

Maintenance..........................................................23

RecommendedMaintenanceSchedule(s)............23

PeriodicMaintenance........................................24

CheckEngineOilLevel..................................24

CheckBatteryCharge.....................................24

CheckTines...................................................26

CheckSafetyInterlockSystem........................26

CheckforLooseHardware.............................27

ServiceAirCleaner.........................................27

ChangeEngineOil.........................................27

CheckAuxiliaryHydraulicOilLevel................27

CheckHydraulicTransmissionOil

Level..........................................................28

CheckTirePressures......................................28

CheckConditionandTensionOf

Belts...........................................................28

CheckConditionOfChains............................28

CheckConditionOfSprockets.......................28

LubricateChains............................................28

LubricateGreaseFittings................................28

LubricateCasterWheelHubs.........................29

CheckSparkPlugs..........................................30

ChangeAuxiliaryHydraulicReservoirFluid

andFilter....................................................30

ChangeHydraulicTransmissionFiltersand

Fluid..........................................................30

CheckTransmissionOutputShaftNut

TorqueSpecication...................................31

CheckWheelHubNutsTorque

Specication...............................................31

CheckWheelLugNutsTorque

Specication...............................................31

CheckSparkArrester(ifequipped)..................31

ThreadLockingAdhesives..............................32

Adjustments......................................................33

AuxiliaryPumpDriveBeltAdjustment...........33

TransmissionDriveBeltTension....................33

JackshaftDriveChainTension

Adjustment................................................33

DriveWheelChainTension

Adjustment................................................33

TineDriveChainAdjustment.........................34

AdjustingtheParkingBrake............................34

AdjustingtheBrakeSwitch.............................34

MotionControlLinkageAdjustment..............35

CasterPivotBearingsPre-Load

Adjustment................................................35

Cleaning............................................................36

CleanEngineandExhaustSystem

Area...........................................................36

RemoveEngineShroudsandClean

CoolingFins...............................................36

CleanDebrisFromMachine...........................36

WasteDisposal...............................................37

Troubleshooting....................................................38

Schematics............................................................40

4

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

SafetyAlertSymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Indicatesanimminentlyhazardous

situationwhich,ifnotavoided,Willresultindeathor

seriousinjury.

WARNING:Indicatesapotentiallyhazardous

situationwhich,ifnotavoided,Couldresultindeath

orseriousinjury.

CAUTION:Indicatesapotentiallyhazardous

situationwhich,ifnotavoided,Mayresultinminor

ormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readthismanualitistheowner’sresponsibilityto

explainthismaterialtothem;otherlanguagesmay

beavailableonourwebsite.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

anaerator,andevenmatureteenagersshouldhave

adultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator's

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

aeratorwithouttakingrisks.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,andhearingprotection.Do

Notoperatewhenbarefootorwhenwearingopen

sandals.Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

5

Safety

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengine

oremissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoradd

fuelwhenengineisrunningorwhenthe

engineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Do

Notuseanozzlelockopendevice.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperatorpresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

6

Safety

Operation

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscanoccur

oncontactanddebris,suchasleaves,grass,

brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,to

coolbeforetouching.

•Removeaccumulateddebrisfrommuferand

enginearea.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcankill

you.

DoNotrunengineindoorsorinasmallconned

areawheredangerouscarbonmonoxidefumes

cancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

DoNotoperatethemachine;seekshelter.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkmachineonlevelground.Stopengine,wait

forallmovingpartstostop,removekeyand

engageparkingbrake:

–Beforechecking,cleaningorworkingonthe

machine.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemachinefor

damageandmakerepairsbeforerestarting

andoperatingthemachine).

–Beforeclearingblockages.

–Wheneveryouleavethemachine.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesinplace

andworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•NEVERcarrypassengers.DONOToperate

themachinewhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.

•Raisethetines,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemachinetoandfromthework

area.

•DoNotoperatethemachineundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremewhenaeratingand/orturningon

slopesaslossoftractionand/ortip-overcouldoccur.

Theoperatorisresponsibleforsafeoperationon

slopes.

7

Safety

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.Wheelsdroppingover

edges,ditches,steepbanks,orwatercancause

rollovers,whichmayresultinseriousinjury,

deathordrowning.

•DoNotoperateonslopeswhengrassiswet.

•DoNotoperateneardrop-offsornearwater.

•DoNotoperateonslopesgreaterthan15

degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

•Reducetinedownpressuretopreventthedrive

tiresfromraisingoffthegroundandtoprevent

thefronttiresfromraisingoffoftheground

whileaeratinguphill.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobeaerated.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromtheworkingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenaeratinguphillbecause

themachinemaytipbackwards.Themachineis

morestablegoinguphillwiththetinesdisengaged.

•Beawarethatoperatingonwetgrass,acrosssteep

slopesordownhillmaycausethemachinetolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithattachments.Thesecan

changethestabilityofthemachineandcauseloss

ofcontrol.

MaintenanceandStorage

•Raisethetines,settheparkingbrake,stopengine

andremovekeyordisconnectsparkplugwire.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Keepengineandengineareafreefromexcessive

greaseoroilandotherdebriswhichcan

accumulateintheseareas.Thesematerialscan

becomecombustibleandmayresultinare.

•Letenginecoolbeforestoringanddonotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevel,hardground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingandservicingtines.Wrap

thetine(s)orweargloves,andusecautionwhen

servicingthem.Onlyreplacedamagedtines.

Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

DANGER

Chargingorjumpstartingthebatterymay

produceexplosivegases.Batterygasescan

explodecausingseriousinjury.

•Keepsparks,ames,orcigarettesaway

frombattery.

•Ventilatewhenchargingorusingbattery

inanenclosedspace.

•Makesureventingpathofbatteryis

alwaysopenoncebatteryislledwith

acid.

•Alwaysshieldeyesandfacefrombattery.

8

Safety

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldeyes,and

rubberglovestoprotectskinandclothing

whenhandlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwith

waterandcalladoctorimmediately.

CAUTION

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagementof

components.Sparkscouldcauseanexplosion

ormovingpartscouldaccidentallyengage

causingpersonalinjury.

Besureignitionswitchisinthe“OFF”

positionbeforechargingthebattery.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,traction,

andsafetyofthemachine.Failuretouseoriginal

Exmarkpartscouldcauseseriousinjuryor

death.Makingunauthorizedchangestothe

engine,fuelorventingsystem,mayviolateEPA

andCARBregulations.

Replaceallpartsincluding,butnotlimitedto,

tires,belts,tines,andfuelsystemcomponents

withoriginalExmarkparts.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemay

result.

•Ifequipped,makesureallhydraulicuid

hosesandlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretohydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,to

ndhydraulicleaks.

•Beforeperforminganyworkonthehydraulic

system:

–Safelyrelieveallpressureintheground

drivehydraulicsystembyplacingthemotion

controlleversinneutralandshuttingoffthe

engine.

–Safelyrelieveallpressureintheauxiliary

hydraulicsystembyshuttingofftheengine,

turningtheignitionswitchtothe“ON”

position,andpressingthetineground

engagementswitch.Oncethetineshave

loweredtotheground,releasethetineground

engagementswitchandturntheignition

switchtothe“OFF”position.

9

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialaerator.

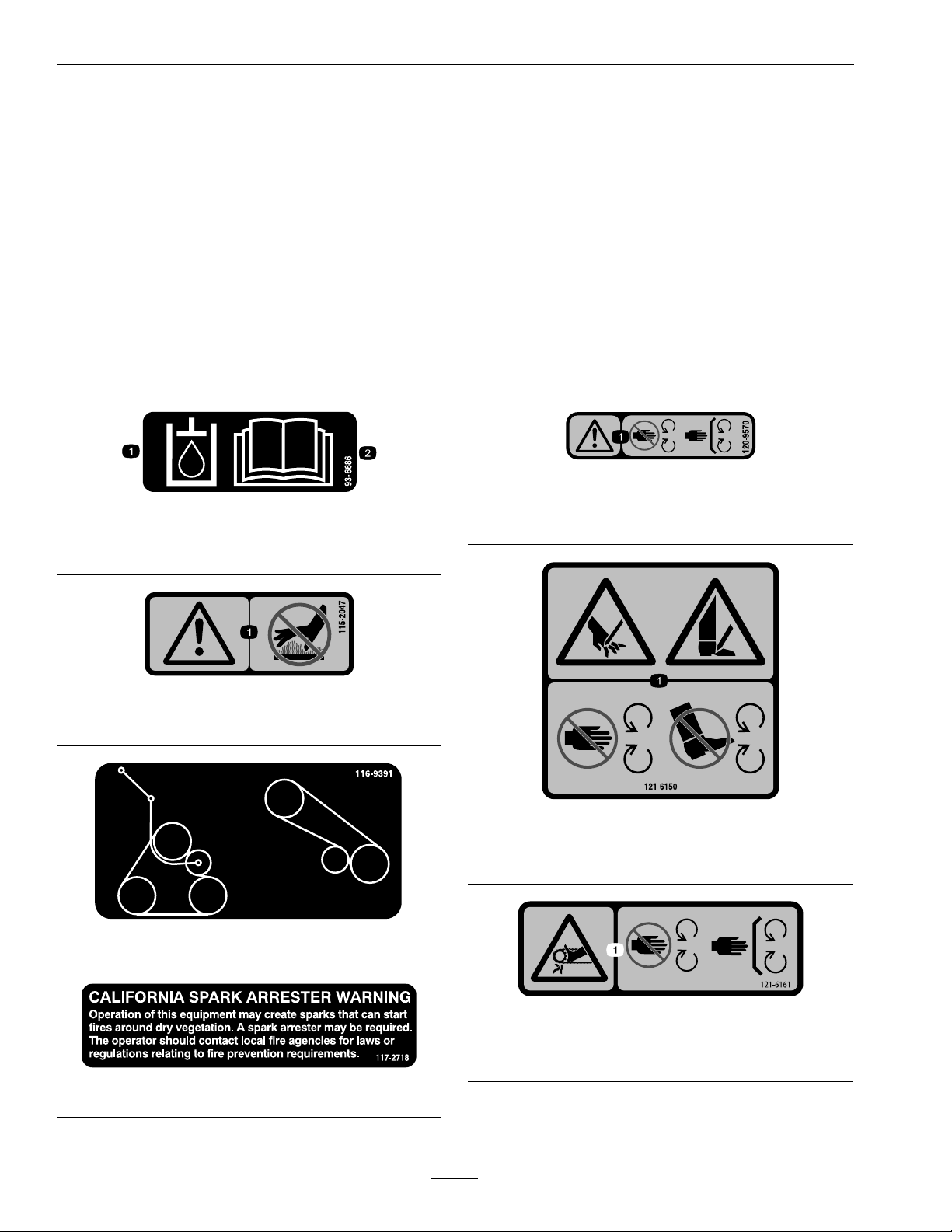

93–6686

1.Hydraulicoil2.ReadtheOperator's

Manual.

115-2047

1.Warning—donottouchthehotsurface.

116-9391

117–2718

120-9570

1.Warning—stayawayfrommovingparts,keepallguards

andshieldsinplace.

121-6150

1.Cuttinghazardofhandandfoot–stayawayfrommoving

parts.

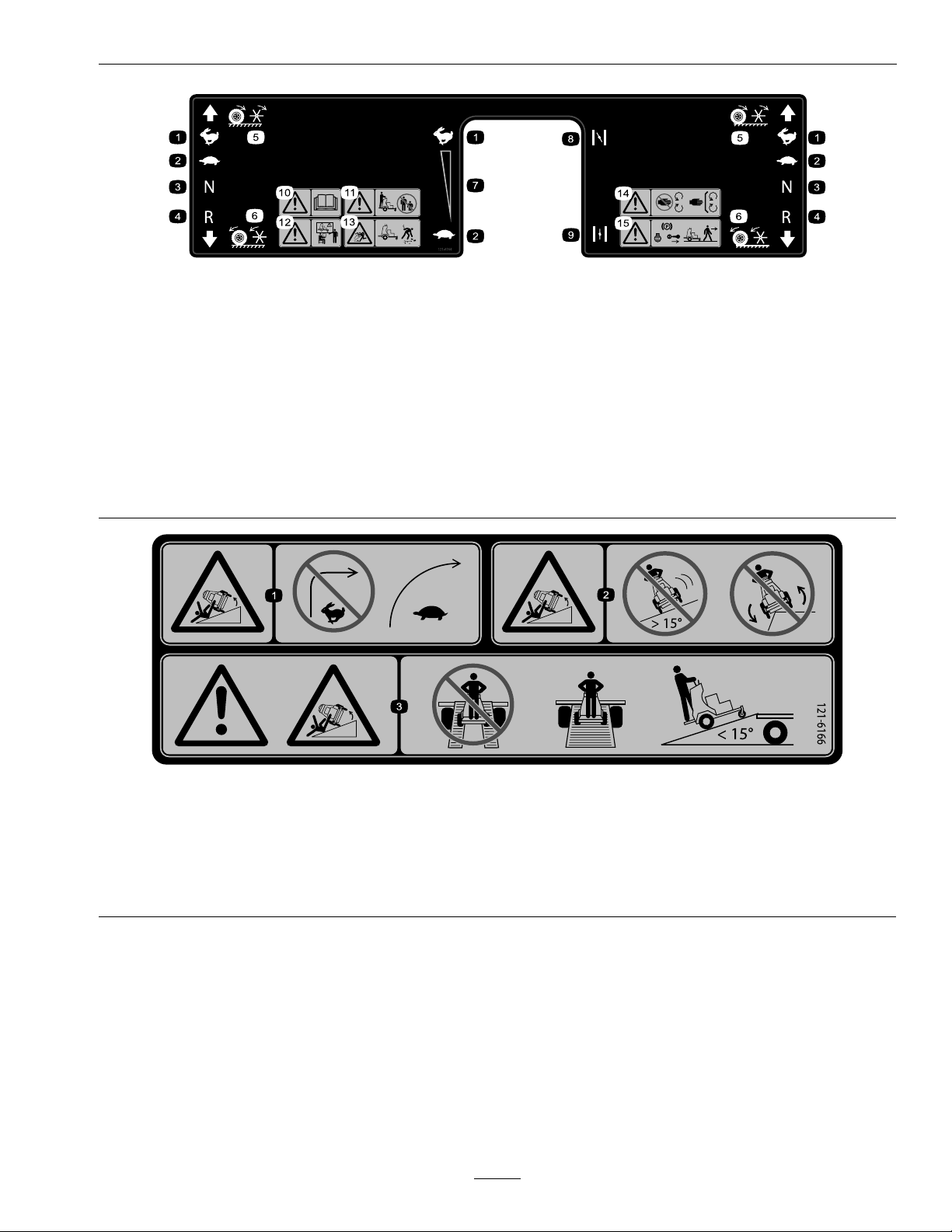

121–6161

1.Entanglementhazard,belt—stayawayfrommoving

parts;keepallguardsinplace.

10

Safety

121–6162

1.Cutting/dismembermenthazardofhandorfoot,

tines—lowerthetinestotheground;readtheOperator’s

Manualfordisassemblyprocedure.

121–6163

1.Presstolowerthetines.2.Releasetoraisethe

tines.

126-2054

1.Wheellugnuttorque95ft-lb(129N-m)(4x)

2.Wheelhubnuttorque235ft-lb(319N-m)

3.ReadandunderstandtheOperator’smanualbefore

performinganymaintenance,checktorqueevery100

hours.

11

Safety

116-9392

1.Readandunderstandtheoperator’smanualbefore

servicingthismachine.

9.Checkauxiliaryhydraulictank(OnlyuseAW-32hydrooil)

every50hours

2.Greasefrontcasterpivots(2x)every100hours10.Greasewheelbearings(2x)every25hours

3.Seeengineowner’smanualforservice11.Greasetineassemblyidlers(2x)every25hours

4.Checkauxiliarypumpdrivebelttensionevery50hours12.Greasetineshaftbearings(4x)every25hours

5.Greasefrontcasterwheelbearings(2x)every100hours13.Checktirepressure-13psi(2x)every50hours

6.Greasecontrolpivots(4x)every50hours14.Cleanandoilchainsandcheckchaintension(2x)every8

hours

7.Greasejackshaftbearings(8x)every25hours15.Greasebeltidlerpivotevery100hours

8.Checkhydraulicoillevel(2x)(Onlyuserecommended

hydrooil)every50hours

12

Safety

121–6164

1.Fast6.Wheelsandtinesrotatewhen

movingbackward

11.Warning—keepbystandersasafe

distancefromthemachine.

2.Slow7.Continuousvariablesetting12.Warning—donotoperatethe

machineunlessyouaretrained.

3.Neutral8.Choke—on13.Thrownobjecthazard—pickup

debrisbeforeoperatingthemachine.

4.Reverse9.Choke—off14.Warning—keepawayfrommoving

parts;keepallguardsinplace.

5.Wheelsandtinesrotatewhen

movingforward

10.Warning—readtheOperator’s

Manual.

15.Warning—stoptheengine,engage

theparkingbreak,andremove

theignitionkeybeforeleavingthe

machine.

121–6166

1.Tippinghazard—donotturnsharplywhiletravellingfast;

slowdownandturngradually.

3.Warning;tippinghazard—donotusesplitramps;usefull

widthrampstoloadaunitfortransport;usealoading

rampatamaximumof15degrees.

2.Tippinghazard—donotoperatethemachineonslopes

greaterthan15degrees;donotoperatethemachinenear

drop-offs.

13

Safety

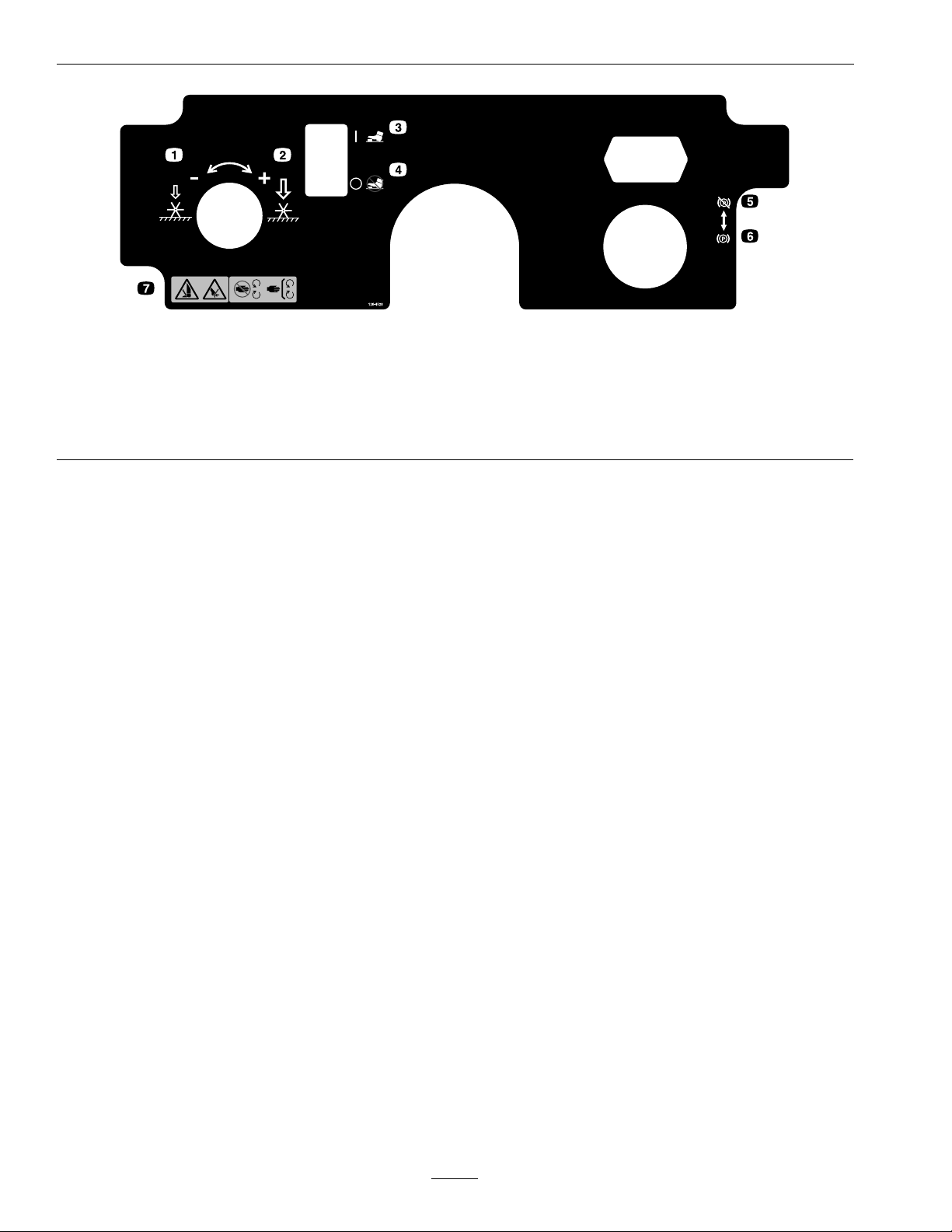

126-4528

1.Rotatecounterclockwisetodecreasepressure5.Parkingbrake-release

2.Rotateclockwisetoincreasepressure6.Parkingbrake-engage

3.On-tinegroundengagementfootswitch7.Cutting/dismembermenthazardofhandorfoot,tines–stay

awayfrommovingparts;keepallguardsinplace

4.Off-tinegroundengagementfootswitch

14

Specications

Specications

ModelNumbers

SerialNos:315,000,000andHigher

ARX481CKA30000

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•EngineOilType:Exmark4–CyclePremium

EngineOil

•RPM:FullSpeed:3600±100RPM(NoLoad)

FuelSystem

•Capacity:5.0gal.(18.9L)

•FuelRecommendations:

–Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

–Oxygenatedfuelwithupto10%ethanolor

15%MTBEbyvolumeisacceptable.

–DoNotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanol

byvolume.Performanceproblemsand/or

enginedamagemayresultwhichmaynotbe

coveredunderwarranty.

–DoNotusegasolinecontainingmethanol.

–DoNotstorefueleitherinthefueltankor

fuelcontainersoverthewinterunlessafuel

stabilizerisused.

–DoNotaddoiltogasoline.

•FuelFilter:ReplaceableIn-line

•FuelShut-OffValve:1/4turn

ElectricalSystem(ElectricStart)

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:Kawasaki:15amps

•BatteryType:BCIGroupU1

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuse:30ampmainfuse

SafetyInterlockSystem

Enginewillnotstartunlesstheparkbrakeisengaged.

OperatorControls

•SteeringandMotionControl

–Separatelevers,oneachsideoftheconsole,

controlspeedanddirectionoftravelofthe

respectivedrivewheels.

–Steeringiscontrolledbyvaryingtheposition

oftheleversrelativetoeachother.

•TineGroundEngagement:Engagesthetines

withtheground.

•ParkingBrakeKnob:Engagestheparkingbrake.

•TineDownPressureControl:Adjuststinedown

pressure.

Transmission

•Twointegratedhydrostatictransmissions:Hydro

GearZT3100.

•HydraulicOilCapacity:78oz.(2.3L)per

transmission

•HydraulicFilterisreplaceablecartridgetype

•Speeds:

–0-7.0mph(11.3km/hr)forward.

–0-2.0mph(3.2km/hr)reverse.

WheelandTineDriveSystem

Drivewheelsandtheoutsideaerationtinesare

driventhroughrollerchainsbythetwohydrostatic

transmissions.

15

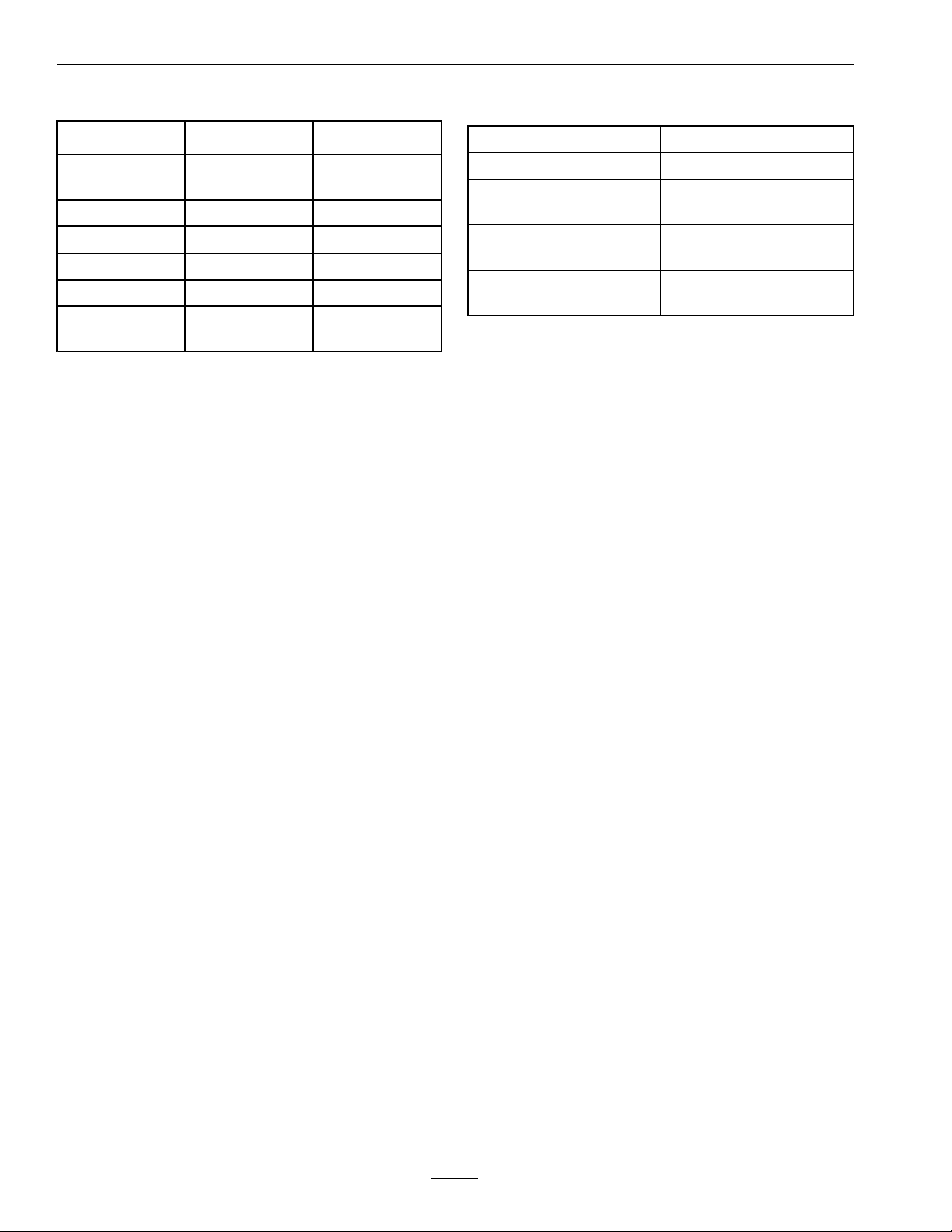

Specications

TiresandWheels

DriveFrontCaster

Pneumatic

(Air-Filled)

Semi-Pneumatic

Quantity22

TreadSuperTurfSmooth

Size16x6.50-813x5.00-6

PlyRating4

Pressure13psi

(90kPa)

Aeration

AerationWidth:30inches(76.2cm)

Tines:Qty:48

TineDownPressure:0-1200lbs

CoreDepth:2-5inches(5.1-12.7cm)

Holespersquarefoot:4.6

Dimensions

OverallWidth:

47.75inches(121.3cm)

OverallLength:

69.8inches(177.3cm)

OverallHeight:

52inches(132.1cm)

TreadWidth:(OutsidetoOutsideof

Tires,Widthwise)

47.75inches(121.3cm)

CurbWeight:

1015lb(460kg)

TorqueRequirements

BoltLocationTorque

EngineMountingBolts17-23ft-lb(23-31N-m)

WheelLugNuts85-105ft-lb(115-142

N-m)

WheelHubNuts211-260ft-lb

(286-352N-m)

TransmissionOutput

ShaftNuts

211-260ft-lb

(286-352N-m)

16

Operation

ProductOverview

Figure3

1.Platform4.Enginecontrols

2.Parkbrakeknob5.Fuelcap

3.Motioncontrollevers

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

MotionControlLevers

Themotioncontrollevers,locatedoneachsideofthe

topconsole,controltheforwardandreversemotion

ofthemachine.

Movingtheleversforwardorbackwardturns

thewheelonthesamesideforwardorreverse

respectively.Wheelspeedisproportionaltothe

amounttheleverismoved.

Important:Thetinesarerotatingwhenthe

motioncontrolleversaremovedoutofthe

neutralposition.

Figure4

1.LHMotioncontrollever5.Forward

2.RHMotioncontrollever6.Neutral

3.Frontreferencebar7.Reverse

4.Frontofunit

ChokeControl

Locatedonthecontrolconsole(blacklever)(see

Figure5).

Thechokeisusedtoaidinstartingacoldengine.

Movingthechokeleverforwardwillputthechokein

the“ON”positionandmovingthechokelevertothe

rear,tothedetent,willputthechokeinthe“OFF”

17

Operation

position.DoNotrunawarmenginewithchokein

the“ON”position.

Figure5

1.Tinedownpressure

gauge

7.Choke

2.Tinedownpressure

control

8.RHMotioncontrollever

3.On/Off-Tineground

engagementfootswitch

9.Hourmeter

4.LHMotioncontrollever10.Parkbrake

5.Frontreferencebar11.Ignitionswitch

6.Throttle12.Tinegroundengagement

footswitch

ThrottleControl

Locatedonthecontrolconsole(redlever)(see

Figure5).

Thethrottleisusedtocontrolenginespeed.Moving

thethrottleleverforwardwillincreaseenginespeed

andmovingthethrottlelevertotherearwilldecrease

enginespeed.Movingthethrottleforwardintothe

detentisfullthrottle.

ParkBrakeHandle

Locatedontherightsideoftheignitionswitchon

thecontrolconsole(seeFigure5).

Thebrakehandleengagesaparkingbrakeinthe

transmissions.

Toengagethebrake,pullhandleoutandslide

rearward.

Torelease,pushthehandleforwardintothedetent.

Whenparkingonasteepslope,thewheelsmustbe

chockedorblockedinadditiontothebrakebeing

engaged.Theunitmustbetieddownandbrake

engagedwhentransporting.

IgnitionSwitch

Locatedontherightsideofthecontrolconsole.

Theignitionswitchisusedtostartandstopthe

engine.Theswitchhasthreepositions“OFF”,“ON”

and“START”.Insertkeyintoswitchandrotate

clockwisetothe“ON”position.Rotateclockwiseto

thenextpositiontoengagethestarter(keymustbe

heldagainstspringpressureinthisposition).Allow

thekeytoreturntothe“ON”positionimmediately

aftertheenginestarts.

Figure6

1.Off3.Start

2.On

Note:Tostarttheengine,theparkingbrakemust

beengaged.(Itisnotnecessaryfortheoperatorto

beontheplatform.)

HourMeter

Locatedabovetheignitionswitchonthecontrol

console.

Thehourmeterdisplaysthenumberofhoursof

operationthathavebeenloggedonthemachine.

FuelShut-OffValve

Locatedunderthefueltank.

Thefuelshut-offvalveisusedtoshutoffthefuel

whenthemachinewillnotbeusedforafewdays,

18

Operation

duringtransporttoandfromthejobsite,andwhen

parkedinsideabuilding.

Alignvalvehandlewiththefuellinetoopen.Rotate

90°toclose.

TineDownPressureControl

Locatedontheleftsideofthecontrolconsole(see

Figure5).

Rotatethecontrolcounterclockwisetodecreasethe

pressureandthelengthoftheaerationplug;rotate

clockwisetoincreasepressureandincreasethelength

oftheaerationplug.

On/OffTineGroundEngagement

FootSwitch

Locatedabovethetinedownpressurecontrolonthe

controlconsole.

Pushdownonthetopoftheswitchtoenablethe

tinesgroundengagementfootswitch.Pushdownon

therearoftheswitchtodisablethefootswitch..

TinesGroundEngagementFoot

Switch

Keephandsandfeetawayfromthetines.Make

surethetinesareaisclearofanyobstructions

beforeloweringit.

Locatedontheoperatorplatform(seeFigure5).

Tolowerthetinesintotheground,standonthe

tinegroundengagementswitch.Toraisethetines,

removeyourfootfromtheswitch.

TineDownPressureGauge

Locatedinthemiddleofthecontrolconsole.

Thegaugedisplaysthetinedownpressurewhen

aerating.

Pre-Start

Fillfueltankonlevelground.SeeFuel

RecommendationsintheSpecicationssectionfor

additionalgasolineinformation.

DoNotaddoiltogasoline.

DoNotoverllfueltank.Fillthefueltanktothe

bottomofthellerneck.Theemptyspaceinthe

tankallowsgasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineoremission

system.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

OpentheFuelShut-OffValve

Rotatethevalveandalignwiththefuellinetoopen.

StartingtheEngine

1.Leavethemotioncontrolleversinneutraland

engagetheparkingbrake.

2.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

3.Onacoldengine,pushthechokeleverforward

intothe“ON”position.Onawarmengine,leave

thechokeinthe“OFF”position.

4.Turnignitionswitchtothe“START”position.

Releasetheswitchassoonastheenginestarts.

Important:DoNotcranktheengine

continuouslyformorethantensecondsata

time.Iftheenginedoesnotstart,allowa60

secondcool-downperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor

5.Ifthechokeisinthe“ON”position,gradually

returnchoketothe“OFF”positionastheengine

warmsup.

LoweringtheTines

DANGER

Therotatingtinesundertheenginedeckare

dangerous.Tinecontactcancauseseriousinjury

orkillyou.

DoNotputhandsorfeetundertheunitwhen

theengineisrunning.

1.Setthrottleto“MIDWAY”position.

2.Steponthetinegroundengagementfootswitch

tolowerthetines.Standontheswitchandmove

themotioncontrolleversforwardtoaerate.

19

Operation

Note:Thefootrockerbar,locatedbehindthe

tinegroundengagementfootswitch,canbe

adjustedforoperatorcomfort.Toadjust,loosen

thefootrockerbarhardware,slidethebarforward

orrearward,andretightenhardware.

3.Adjustthethrottlefortheworkingconditions.

AdjustingtheTineDownPressure

Adjusttheplugdepthbyrotatingthetinedown

pressurecontrol.Rotatethecontrolcounterclockwise

todecreasethehydraulicdownpressuretoremovea

shorterplug.Rotateclockwisetoincreasepressure

andpullalongerplug.

Firsttimeuse:setthepressureto350psi(24bar).

Idealplugdepthis3-4inches(7.6–10cm).Rotatethe

plugdepthcontroltoadapttothesoilconditions.

Keepthedrivetiresonthegroundatalltimes.

RaisingtheTines

Toraisethetines,removeyourfootfromthetine

groundengagementfootswitch.

Important:Thetinesarerotatingwhenthe

motioncontrolleverismovedoutoftheneutral

position.

StoppingtheEngine

1.Movethemotioncontrolleversbacktothe

neutralpositionandbringtheunittoafullstop.

2.Liftyourfootoffofthetinegroundengagement

footswitchcontroltoraisethetines.

3.Placethethrottleinthemidwaybetweenthe

“SLOW”and“FAST”positions.

4.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

5.Engagetheparkingbrake.

6.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingtheengine.

7.Closethefuelshut-offvalvewhenthemachine

willnotbeinuseforafewdays,when

transporting,orwhentheunitisparkedinside

abuilding.

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioningone

levertoomuchaheadoftheother.Operatormay

losecontrolofthemachine,whichmaycause

damagetothemachineorinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Important:Tobeginmovement(forwardor

backward),thebrakelevermustbedisengaged

(pushedforward)beforethemotioncontrol

leverscanbemoved.

Figure7

1.LHMotioncontrollever5.Forward

2.RHMotioncontrollever6.Neutral

3.Frontreferencebar7.Reverse

4.Frontofunit

DrivingForward

1.Makesurethemotioncontrolleversareinthe

neutralposition.

2.Releasetheparkingbrake.

3.Tomoveforwardinastraightline,moveboth

leversforwardwithequalpressure.

20

Table of contents