EXOLAUNCH CarboNIX 8 User manual

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

1 / 4

4

Microsatellite separation system

Revision 2.0 |September 2022

CarboNIX

User Manual

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

2 / 4

4

Table of Contents

1. Quick Reference ................................................................................................................................................................. 4

2.

Introduction ...................................................................................................................................................................... 5

2.1 What is CarboNIX............................................................................................................................................................ 6

2.2 Qualification Status.......................................................................................................................................................10

2.3 Components and Features ........................................................................................................................................... 11

2.3.1 S-Ring ..........................................................................................................................................................................12

2.3.2 S-Ring Cable Tie Mounts............................................................................................................................................13

2.3.3 L-Ring .......................................................................................................................................................................... 13

2.3.4 Separation Switch......................................................................................................................................................16

2.3.5 Separation Connector................................................................................................................................................ 16

2.3.6 Separation Switch and Connector Clocking.............................................................................................................17

2.3.7 Harness Routing on the S-Ring ................................................................................................................................. 18

2.3.8 Remove Before Flight (RBF) Elements .....................................................................................................................18

3.

System Description ........................................................................................................................................................20

3.1 Coordinate System ........................................................................................................................................................ 21

3.2 Mass................................................................................................................................................................................ 21

3.3 Mounting Configurations ..............................................................................................................................................22

3.4 Mounting Hole Patterns ................................................................................................................................................ 23

3.5 Keep-Out Dimensions ................................................................................................................................................... 24

3.6 Maximum Loads............................................................................................................................................................. 25

3.7 Stiffness .........................................................................................................................................................................25

3.8 FEM Modeling ................................................................................................................................................................ 26

3.9 Minimum Stiffness Requirements................................................................................................................................ 26

3.10 Separation Velocity .....................................................................................................................................................27

3.11 Rotation Rate...............................................................................................................................................................28

3.12 Separation Shock ........................................................................................................................................................28

3.13 Electrical Interfaces.................................................................................................................................................... 29

3.13.1 DSub-9 Connectors..................................................................................................................................................29

3.13.2 Separation Signal ..................................................................................................................................................... 30

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

3 / 4

4

3.13.3 Grounding .................................................................................................................................................................30

3.14 Thermal Interfaces .....................................................................................................................................................30

4.

Installation and Operation.............................................................................................................................................31

4.1 Installation ..................................................................................................................................................................... 32

4.1.1 Separation Switch Installation ................................................................................................................................. 32

4.1.2 Separation Connector Installation ........................................................................................................................... 33

4.1.3 Installing S-Ring and L-Ring ......................................................................................................................................33

4.2 Operation........................................................................................................................................................................ 34

4.2.1 Tools and Equipment .................................................................................................................................................34

4.2.2 Status at Delivery.......................................................................................................................................................35

4.2.3 Locking the Pusher Arms........................................................................................................................................... 36

4.2.4 Locking S-ring to L-Ring ............................................................................................................................................ 37

4.2.5 Engaging the Lock Mechanism.................................................................................................................................. 38

4.2.6 Functional Tests......................................................................................................................................................... 39

5.

Appendix A Detailed Mass Properties ..........................................................................................................................40

CarboNIX 8 ........................................................................................................................................................................... 41

CarboNIX 15.........................................................................................................................................................................42

CarboNIX 18.........................................................................................................................................................................43

CarboNIX 24.........................................................................................................................................................................44

Version Author Date Changes

1.0 CJP 27 May 2022 Initial release of combined CarboNIX User Manual for all CarboNIX sizes and

configurations.

2.0 CJP 06 Sep 2022 New Document Design

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

4 / 4

4

Quick Reference

Table 1: CarboNIX Characteristics Overview.

Parameter Section C8 C15 C18 C24

Mounting

Pattern

Bolt Circle Diameter [mm]

3.3

203.20 381.00 463.55 609.60

Bolt Circle Diameter [in] 8.00 15.00 18.25 24.00

Number of Fasteners 12 24 28 36

Fastener Type M6 or 1/4-28

Flatness Tolerance [mm] 0.10

Keep-Out

Dimensions

[mm]

Inner keep-out diameter [mm]

3.5

130 310 395 545

Outer keep-out diameter [mm] 300 475 560 700

Mass [kg] S-Ring ST [kg]

3.2

0.185 0.337 0.420 0.490

S-Ring IM [kg] 0.218 0.409 0.470 0.593

L-Ring (threaded inserts) [kg] 1.407 2.424 3.230 3.759

L-Ring (thru holes) [kg] 1.397 2.403 3.200 3.729

Maximum Load

Segment [N]

Z-Axis

3.6

6800

Tangential 1500

Radial 500

Maximum Load

System [N]

Z-Axis (Out of Plane)

3.6

81,600 163,200 190,400 244,800

X- or Y-Axis (In Plane) 12,000 24,000 28,000 36,000

Stiffness Linear ±25% [N/m]

3.7

1.5E+08 3.5E+08 4.5E+08 8.0E+08

Rotational ±25% [Nm/rad] 2.3E+05 6.8E+06 1.0E+07 2.0E+07

Separation Nominal Separation Signal

3.13.2

24VDC for 0.5s

Average Separation Time [s] 0.10

Thermal [°C] Lower Operating Limit

-

- 34

Upper Operating Limit +71

Lower Survival Limit - 55

Upper Survival Limit +130

Figure 1:

CarboNIX Coordinate System

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

5 / 4

4

Introduction

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

6 / 4

4

2.1 What is CarboNIX

CarboNIX is a family of separation systems for small satellites up to 500 kg. Since the first CarboNIX demonstration

on orbit in 2019, CarboNIX has deployed 38 customer satellites to orbit with 100% success rate. CarboNIX users

include the undisputed leaders in the smallsat industry, including Planet, Iceye, Satellogic, NanoAvionics and Loft

Orbital.

CarboNIX uses shock-free technology to reduce the risk of damaging sensitive satellite optical payloads and

electronic components. CarboNIX also uses a unique spring pusher system which separates the satellite before the

shocks are generated. This means that all shock forces can only reach the spacecraft by traveling through the

linkages, and since shock forces are attenuated by joints and distance, the shock loads that reach the spacecraft

are substantially reduced. In addition, every pusher arm in the spring pusher system is linked together and moves

at the same velocity, guaranteeing a tip-off rate of less than 2 deg/s regardless of the location of the satellite Center

of Gravity. All these features make CarboNIX the most advanced separation system ever used in space.

The unique design gives CarboNIX best-in-class compatibility with satellites and launch vehicles while delivered

unparalleled reliability and performance. CarboNIX is currently available in 8”, 15”, 18.25” and 24” versions and can

also be designed to custom sizes to meet your needs. Contact Exolaunch for details.

CarboNIX is also designed and manufactured entirely within Europe, meaning it is not subject to strict export

regulations such as ITAR. This reduces the cost and complexity of using CarboNIX and allows it to fly on any

launcher in the world.

CarboNIX is manufactured using only COTS components. As with all Exolaunch technology, CarboNIX is

manufactured in Germany in a facility certified to ISO 9001:2015 standard, which requires regular inspection of the

manufacturing and assembly facilities and ensures a stable quality of the final product. These same quality

standards are applied to the qualification and acceptance testing processes.

8”

15”

18,25”

24”

Figure 2: Available CarboNIX Sizes

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

7 / 4

4

CarboNIX has some unique advantages over other

microsatellite separation systems

›Flight Heritage. CarboNIX has deployed 38 customer satellites for industry-leading

customers in Europe and the US.

›Fast Integration and Reset Time. The whole system can be triggered and reset in minutes.

Constellation customers benefit from fast and consistent processing times at the launch site

when launching multiple satellites.

›Shock-Free Separation. Very low shocks are generated during separation, making it

very gentle on delicate satellite components. Relative to other separation systems

on the market CarboNIX is virtually shock-free.

›Low Tip-Off Rates. The average tip-off rate is less than 0.6 deg/s in all three axes.

No tip-off rate higher than 2 deg/s has ever been recorded in space.

›Licensing. Operating CarboNIX does not require expensive training and licensing.

›Lightweight. The CarboNIX flyaway mass is half that of other’s separation systems

of the same diameter.

›Scalable. The unique design centered around a single clamp element which is repeated

along the circumference, allows CarboNIX to be easily scaled to different sizes.

›Flexible. CarboNIX can be used with and adapted to any launch vehicle.

›Compact. In the stowed state, CarboNIX is less than 50 mm thick.

Figure 3:

Four CarboNIX 15 L-Rings mounted

on an EXOport Adapter and ready for

microsat integration on the SpaceX

Transporter-2 mission

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

8 / 4

4

Figure 4:

Three CarboNIX 15 units were

used on the June 13, 2020

SpaceX Starlink-9 Rideshare Mission.

Each SkySat had a mass of 110 kg

CarboNIX 15

CarboNIX 15

Figure 5-6: Ten CarboNIX 15’s successfully deployed on the SpaceX Transporter-2 Mission in July 2021

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

9 / 4

4

CarboNIX 8

CarboNIX 15 x4

Figure 7: CarboNIX 8 ready for microsat mate (left). CarboNIX 8 deployed in orbit on Transporter-4 (right)

Figure 8:

Three CarboNIX 24 units

undergoing qualification testing

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

10 / 4

4

2.2 Qualification Status

CarboNIX has a TRL of 9 and has flight heritage on multiple launch vehicles. By far, the most common launch

configuration is on the Falcon 9 Transporter missions, which the CarboNIX mounted in the “wall-mounted”

configuration. Contact Exolaunch for details.

The CarboNIX lock mechanism is the only shock-sensitive element of the CarboNIX system. It has been qualified

for environments up to 2000g shock loads at 1 kHz and 5000g at 10 kHz, both in a standalone lock mechanism test

and in an integrated lock mechanism system test.

Figure 9: CarboNIX 15 qualification testing (left). Four CarboNIX 15s on an EXOport adapter (right)

Figure 10:

Lock Mechanism Shock Testing

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

11 / 4

4

2.3 Components and Features

The main components of the CarboNIX separation system are shown in the figure below.

Figure 11: Main Components of the CarboNIX Separation System

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

12 / 4

4

2.3.1 S-Ring

The S-Ring is the part of CarboNIX that is attached to the satellite. It is fastened to the bottom of the satellite using

either M6 or 1/4-28 screws in a circular pattern. It comes in two variants: S-Ring ST and S-Ring IM. The S-Ring ST

is the standard configuration, and it has the lowest flyaway mass of any microsatellite separation system.

The S-Ring ST is able to achieve such an incredibly low weight due to its unique protrusions at each of the screw

mounting points. These protrusions relieve the mounting fasteners of having to withstand shear loads during

launch. A corresponding counterbore feature is required on the satellite base plate to be compatible.

For customers that have designed their satellite to accommodate clamp-band style separation systems,

the S-Ring IM has been designed to match this interface so that no changes to the satellite are required.

The S-Ring IM is about 25% heavier compared to the ST.

Figure 12:

CarboNIX S-Ring

Figure 13:

S-Ring ST Protrusions

Figure 14:

CarboNIX S-Ring IM

S-Ring ST Protrusion

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

13 / 4

4

2.3.2 S-Ring Cable Tie Mounts

The S-Ring has cable tie mounts located on the circumference of the ring to assist with harness routing. Harness

may be routed both above or below the cable tie mounts; above and outside the mounts is preferred.

NOTE: Harness routing may not pass over the lock mechanism box.

2.3.3 L-Ring

The L-Ring is the portion of the separation system that stays attached to the launch vehicle

after separation. It is mechanically and electrically connected to the launch vehicle adapter.

In can be fastened to the launch vehicle with either ¼-28 or M6 screws.

2.3.3.1 Lock Mechanism

The locking mechanism uses a unique magnetic system that can be released either using an electrical

input signal from the launch vehicle, or from the Exolaunch electronic sequencer unit EXObox.

The lock allows quick integration and de-integration within minutes. For maximum reliability, CarboNIX uses

redundant locks that can trigger the opening independently from separate deployment signal channels.

There are two elements of the lock mechanism, the Clamp Ring Inhibit Pin and the magnetic locks,

which are toggled by pushing in the lock indicators. Operating instructions for the lock mechanism

can be found in Section 4.2.5.

The locking mechanism receives the firing signal through one of two 9-pin D-Sub ports.

As needed, either one or both of these ports can be used for redundancy during the mission.

Figure 15:

Cable Tie Locations

on the S-Ring

Figure 16:

CarboNIX S-Ring IM

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

14 / 4

4

2.3.3.2 Lock Rings

The S-Ring is secured to the L-Ring using the lock ring assembly, which consists of two contra-rotating clamping

rings. In the stowed configuration, these rings grip the feet of the S-Ring and prevent any movement. Once the lock

mechanism releases, the springs rotate the rings apart, unclamping and releasing the S-Ring.

2.3.3.3 Pusher Mechanism

Once the S-Ring has been released, the pusher mechanism creates the separation velocity between the launch

vehicle and the satellite. This is done by three or four equally spaced pusher arms located external to the rings, as

shown below in Figure 19.

Clamp Ring

Inhibit Pin

Lock

Indicators

Figure 17:

CarboNIX Lock Mechanism

Figure 18:

Left, S-Ring is Securely Clamped

to L-Ring. Right, S-Ring Released

Figure 19:

CarboNIX in the Deployed State

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

15 / 4

4

Each pusher mechanism is fitted with a starter spring on the lower arm. This provides the initial force to begin the

separation, as the main separation springs are at a very oblique angle when stowed.

2.3.3.4 Deployment Sensors

The CarboNIX has built-in deployment sensors which transmit the deployment status back to the launch

vehicle. Deployment sensors are located in two positions. These sensors indicate whether the locking

mechanism has been opened, and whether the pushing mechanism has been successfully deployed.

In each position, there are two sensors for redundancy.

The switch status is transmitted to the launch vehicle through the lock mechanism connector. The Customer does

not need to dedicate separation switches or breakwire loops in order to satisfy launch

vehicle telemetry requirements.

Figure 20:

A Pushing Mechanism Arm

in the Stowed Position.

The Starter Spring is Highlighted

Figure 21:

A magnet on the pusher mechanism ring

activates two reed sensors

Magnet

Reed

Sensors

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

16 / 4

4

2.3.4 Separation Switch

Customers may choose to mount one or several separation switches on the S-Ring in order to communicate the

separation event to the satellite. These ITW 65-401000 switches are extremely rugged and have extensive flight

heritage. The “over-travel” actuator ensures that the switch will not toggle until full separation has occurred.

Separation switches are for satellite-side telemetry only. Launch vehicle-side telemetry shall be transmitted

through the built-in deployment sensors.

2.3.5 Separation Connector

The separation connector can be used to provide an electrical connection to the satellite after it has been integrated

on the launch vehicle. It can be used to charge the satellite batteries, satellite-side separation telemetry through

breakwires, or to otherwise connect with the satellite after encapsulation. Separation connectors are for satellite-

side telemetry only. Launch vehicle side telemetry shall be transmitted through the built-in deployment sensors.

Figure 22:

CarboNIX Separation Switch

Figure 23:

CarboNIX separation connector.

The green arrows show possible

harness routing directions

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

17 / 4

4

The separation connector can be used for a variety of mission scenarios, such as charging batteries after payload

fairing encapsulation or activating the satellite before separation.

All electrical interfaces must adhere to limitations determined by the launch authority.

2.3.6 Separation Switch and Connector Clocking

The separation switch and separation connector can each be connected to CarboNIX at one of four separate

locations around the outside of the ring. Only three of these interfaces are available on the CarboNIX 8.

This provides flexibility in harness routing for the satellite designer. Harness routing shall not pass over the lock

mechanism.

Figure 24:

CarboNIX separation connector,

pin configuration.

Figure 25:

CarboNIX Separation Connector

and Separation Switch Locations

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

18 / 4

4

2.3.7 Harness Routing on the S-Ring

To simplify launch site operations, Exolaunch recommends incorporating separation switches and connectors with

pigtail connectors, as shown below in Figure 26. This allows the harness to be routed along the S-Ring before it is

installed on the satellite base plate so that access is optimized. This connector shall be located outside of the S-

Ring; routing through the CarboNIX is not permitted.

The image below shows a Micro Dsub-9 connector as an example. Satellite manufacturers are encouraged to select

the connector of their choice when manufacturing the pigtail.

2.3.8 Remove Before Flight (RBF) Elements

CarboNIX uses two types of RBF elements. Two pins are used to secure the clamping rings in the closed position

and prevent accidental release of the S-Ring. Four additional pins are used to secure the pusher arms in the down

position, which is useful for securing the arms while locking the S-Ring to the L-Ring.

Finally, a tool is used to engage the system, closing the clamping mechanism and securing the locks in place.

c

Upper Separation

Connector

Satellite

Connector

Separation Switch

Figure 26:

Example of Pigtail Connector (e.g. Micro DSub-9) Incorporated with a CarboNIX Upper Separation Connector and Separation Switch

Figure 27:

CarboNIX with all RBF Elements highlighted

in red. The CarboNIX 8 (shown) has only

three pusher arm RBFs and one clamp ring

RBF due to its small size

Pusher

Arm RBF

Clamp

Ring RBF

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

19 / 4

4

The clamp ring RBF has a spring-loaded pin which allows it to be inserted before the clamp rings are engaged. This

can simplify the integration process, as the RBF will automatically lock the system shut once the clamp rings are

closed. The red indicator on the RBF provides a visual indication of the status of the clamp rings. A single clamp ring

RBF is sufficient to fully secure the system.

Figure 28: Clamping Mechanism RBF Prevents

the S-Ring from Coming Loose

Figure 29: Pushing Mechanism RBF Binds Two Arms

Together and Prevents Deployment

Indicator

Hidden

Clamp Rings

Engaged

Indicator

Visible

Clamp Rings

Disengaged

Figure 30: Clamp Ring RBF Function

Pin Extended

CarboNIX User Manual

Revision 2.0 /06.09.2022

©

2022 Exolaunch GmbH. All rights reserved. Exolaunch GmbH is the owner of the copyright in this work, and no portion hereof is to be copied,

reproduced, or disseminated without the prior written consent of Exolaunch GmbH.

20 / 4

4

System Description

This manual suits for next models

3

Table of contents

Popular Water Filtration System manuals by other brands

Morphy Richards

Morphy Richards IBFILTERLJ manual

A+ Corporation

A+ Corporation Avenger 38M Installation & operation instructions

OptiPure

OptiPure OP350 Installation, operation & maintenance manual

Pentair

Pentair EVERPURE Claris EV4339-91 quick start guide

Angel Water

Angel Water PurAzone A03 manual

HotSpring

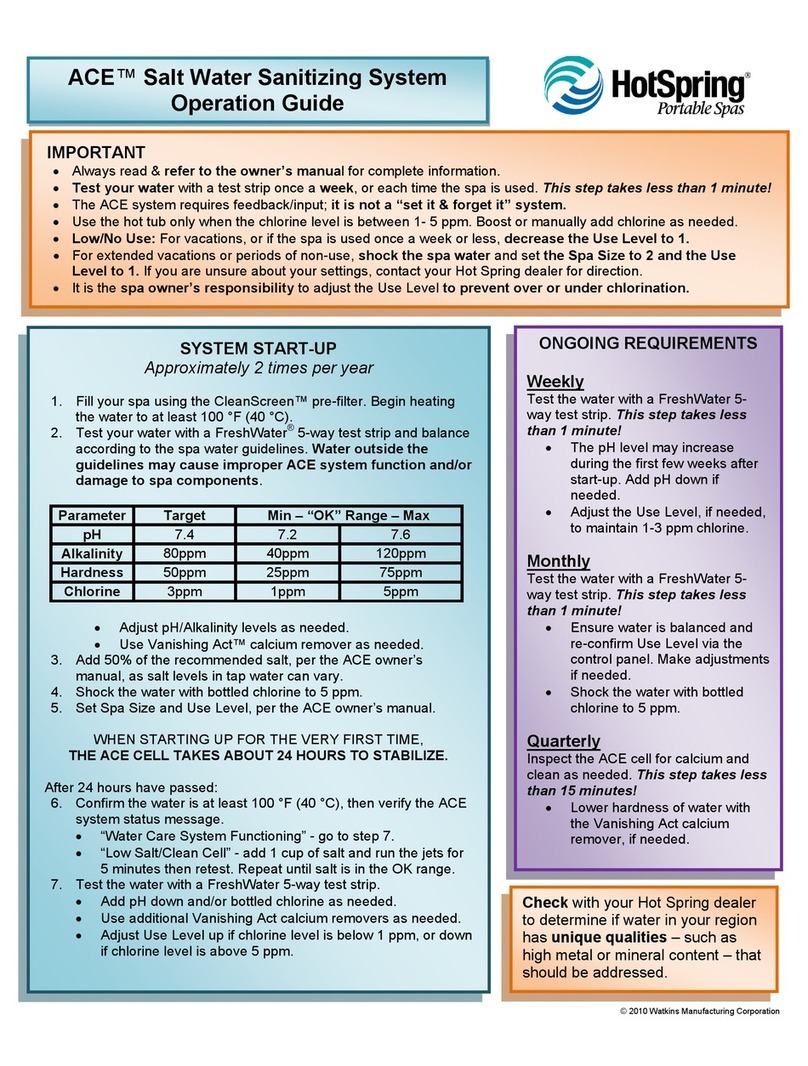

HotSpring ACE Operation guide