3

CONTENTS

1. ECOKITCHEN ELECTROSTATIC PURIFIER ........................................................................................ 4

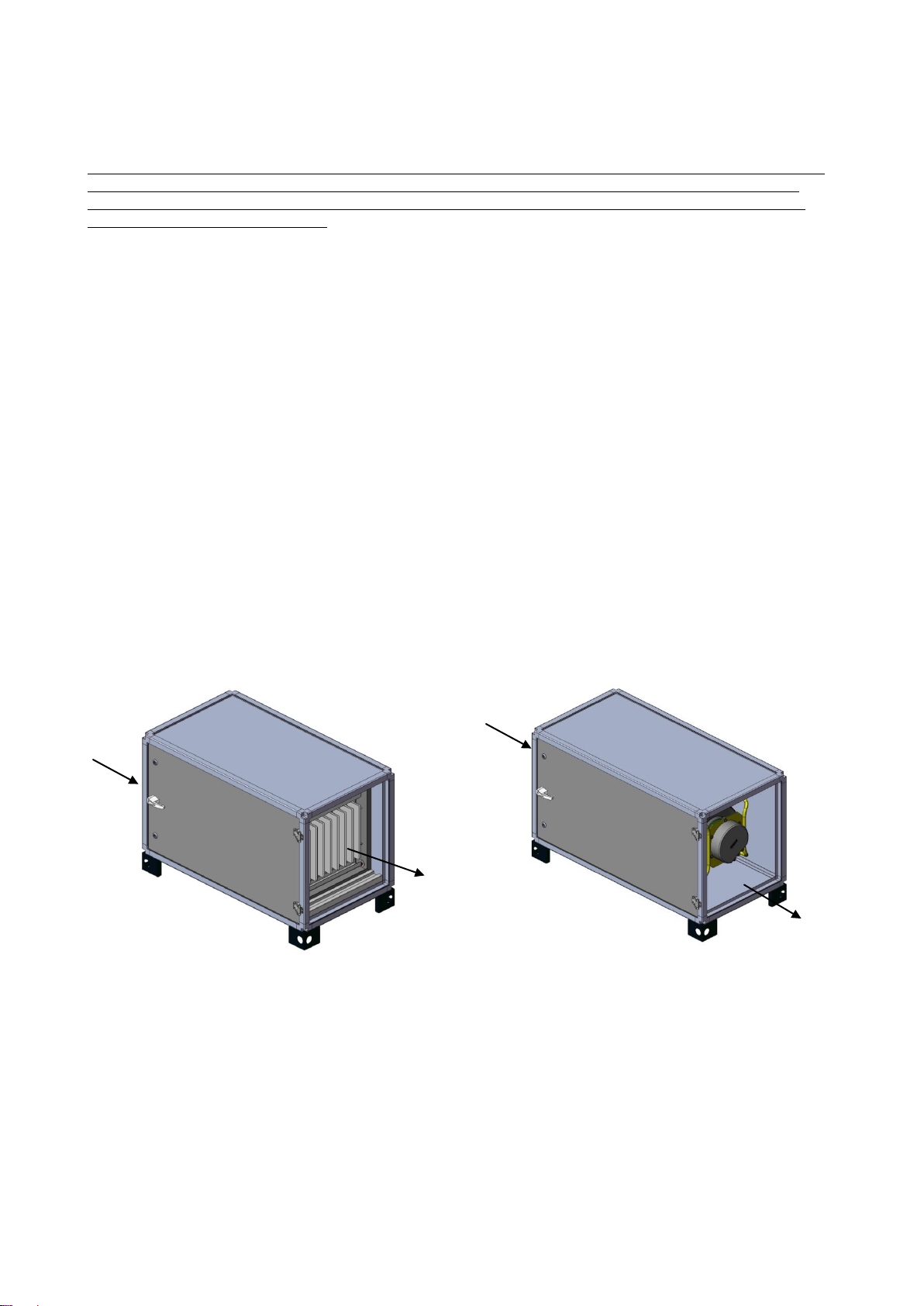

MACHINE COMPONENTS.............................................................................................................................................. 4

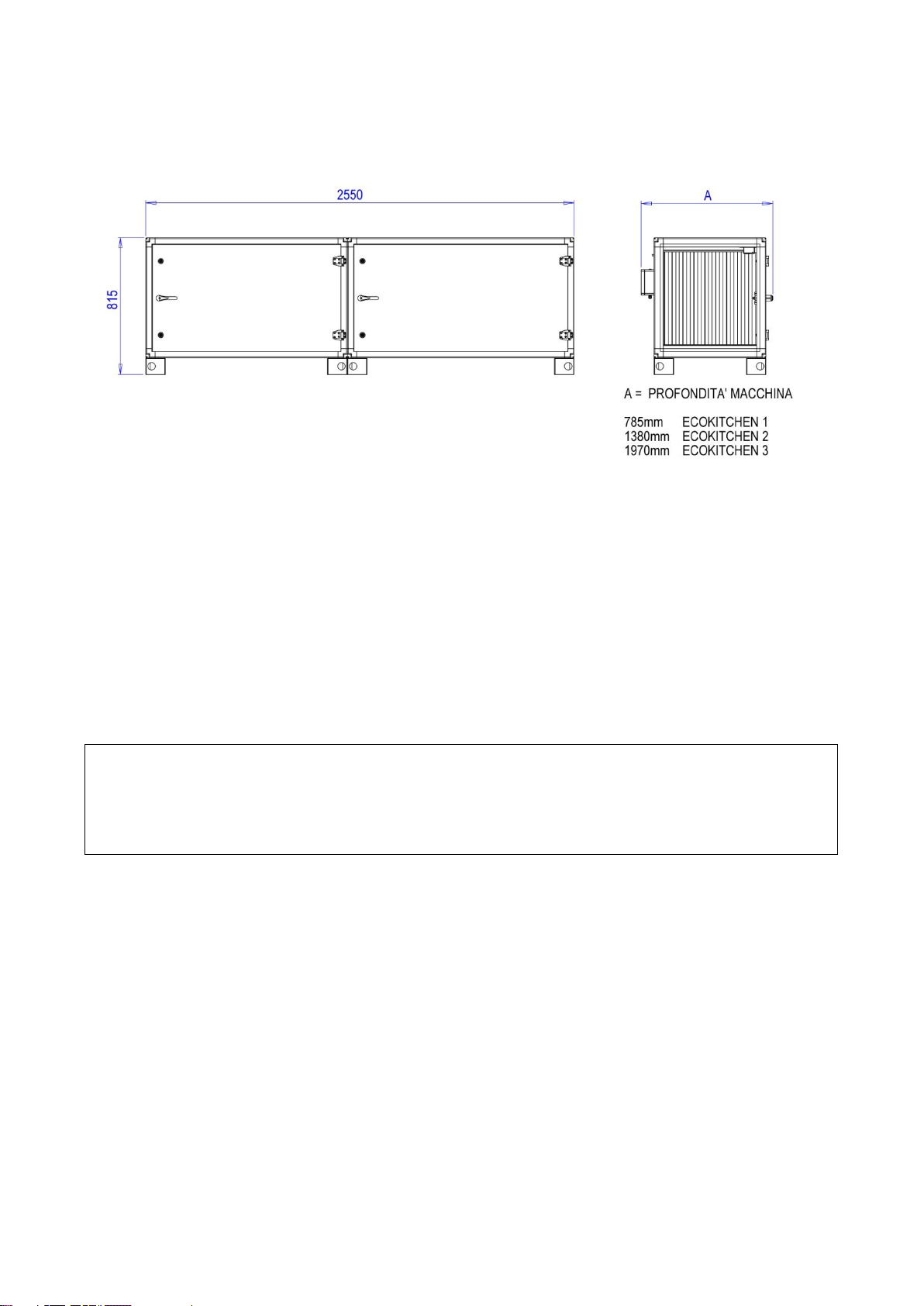

2. OVERALL DIMENSIONS.............................................................................................................................5

3. TRANSPORTATION AND PACKAGING ..................................................................................................5

4. FIELD OF APPLICATION............................................................................................................................6

5. MACHINE INSTALLATION........................................................................................................................ 7

7. DISPOSAL ..................................................................................................................................................... 11

8. WORKING PARAMETERS........................................................................................................................ 12

8.1 TABLE OF FLOW-EFFICIENCY OF THE MACHINE................................................................................. 12

9. ECOKITCHEN COMPONENTS ................................................................................................................ 12

10. FILTER MAINTENANCE........................................................................................................................... 16

11. GENERAL CONTROL OF THE ELECTROSTATIC CELL AND PRE-FILTER............................... 18

12. CONTROLS ON THE ELECTROSTATIC FILTER................................................................................ 19

12.1 CLEANING THE IONISATION WIRES........................................................................................................ 19

12.2. REPLACING ELECTROSTATIC CELL IONISATION WIRES................................................................... 19

13. ELECTRIC PANEL...................................................................................................................................... 20

2. ADJUSTMENTS POTENTIOMETER....................................................................................................... 21

3. TECHNICAL INFORMATION................................................................................................................... 23

16.1. TECHNICAL CHARACTERISTICS OF PURIFIER ..................................................................................... 23

16.2. CHARACTERISTICS OF ELECTRIC FAN................................................................................................... 23

16.3. ECOKITCHEN 1INSTALLED FILTERS...................................................................................................... 23

16.4. ECOKITCHEN 2INSTALLED FILTERS...................................................................................................... 24

16.5. ECOKITCHEN 3INSTALLED FILTERS...................................................................................................... 24

4. SPARE PARTS .............................................................................................................................................. 24