Contents

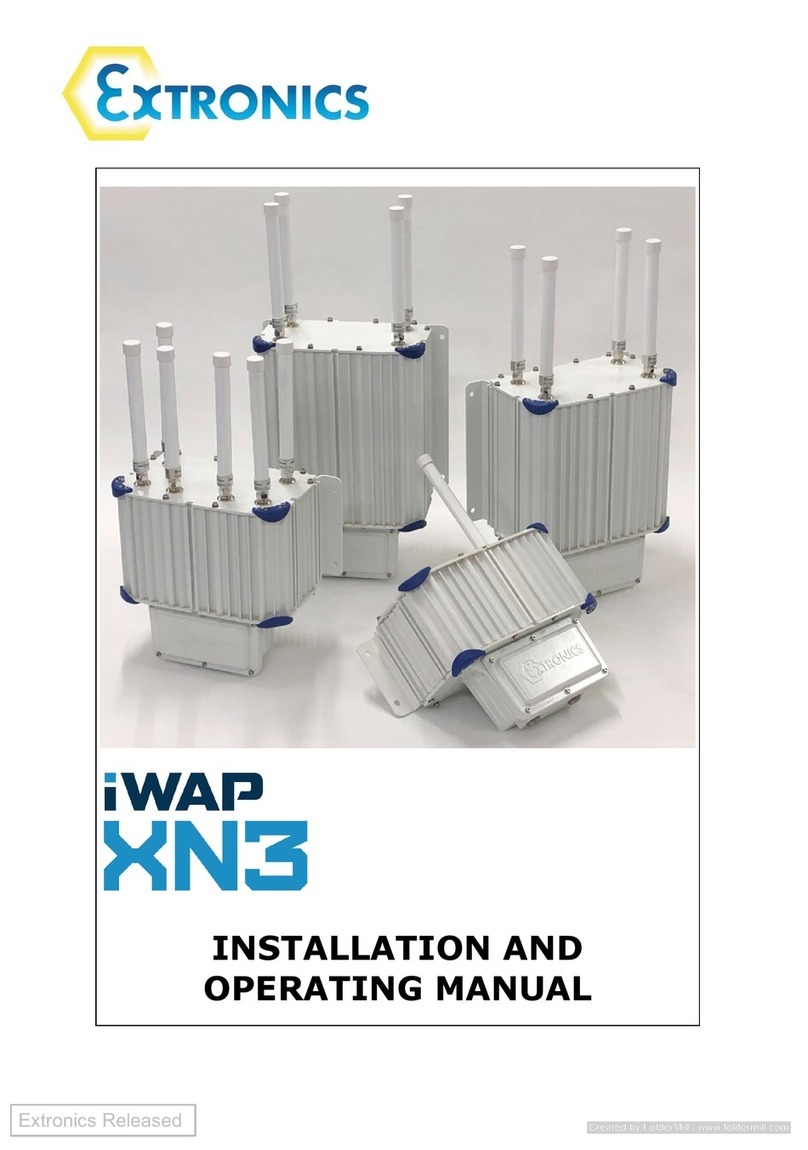

1Introduction ................................................................................................... 4

2Safety Information and Notes ........................................................................... 5

2.1 Storage of this Manual ............................................................................... 5

2.2 Special Conditions for Safe Use / Conditions particulières d’utilisation .............. 5

2.2.1 ATEX/IECEx .............................................................................................. 5

2.2.2 MET......................................................................................................... 5

2.3 List of Notes ............................................................................................. 6

3Installation....................................................................................................10

3.1 Mounting.................................................................................................10

3.2 Opening and Closing the Enclosure .............................................................12

3.2.1 Opening the front cover plate ....................................................................12

3.2.2 Closing the Enclosure................................................................................12

3.3 Cable Entries ...........................................................................................13

3.3.1 Typical Cable Entries and Connections ........................................................13

3.4 Earthing ..................................................................................................14

3.4.1 Location of XN3 enclosure external earth bond points ...................................14

3.5 Electrical Installation ................................................................................15

3.6 Power Supply / Input Connector.................................................................16

3.7 Fuse Rating .............................................................................................16

3.8 External Overcurrent Protection .................................................................16

3.9 Data Connections .....................................................................................17

3.9.1 Copper Ethernet.......................................................................................17

3.9.2 Power-Over-Ethernet (POE) .......................................................................17

3.9.3 Optical Fibre ............................................................................................17

3.9.4 Console Port ............................................................................................18

3.10 Intrinsically Safe RF Outputs......................................................................18

3.10.1 Example of RF threshold power calculation ..................................................18

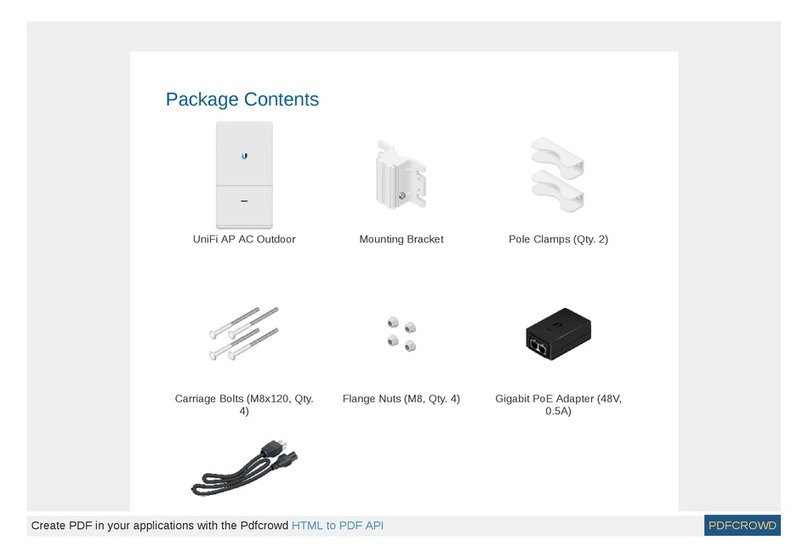

3.11 Antenna Requirements..............................................................................20

3.12 Antenna Installation .................................................................................20

3.13 Ex Main Enclosure Test .............................................................................20

4Intended Purpose Usage .................................................................................21

4.1 Transportation and Storage .......................................................................21

4.2 Authorized Persons ...................................................................................21

4.3 Cleaning and Maintenance .........................................................................21

4.4 Cleaning and Maintenance Intervals............................................................21

4.5 Aggressive substances and environments ....................................................21

4.6 Exposure to external stresses ....................................................................21

5Pole Mounting................................................................................................22

6Technical Data...............................................................................................23

7Marking information .......................................................................................24

7.1.1 ATEX/IECEx .............................................................................................24

7.1.2 MET........................................................................................................25

8Type Codes ...................................................................................................26

8.1.1 ATEX/IECEx .............................................................................................26

8.1.2 MET........................................................................................................26

9EU Declaration of Conformity...........................................................................27