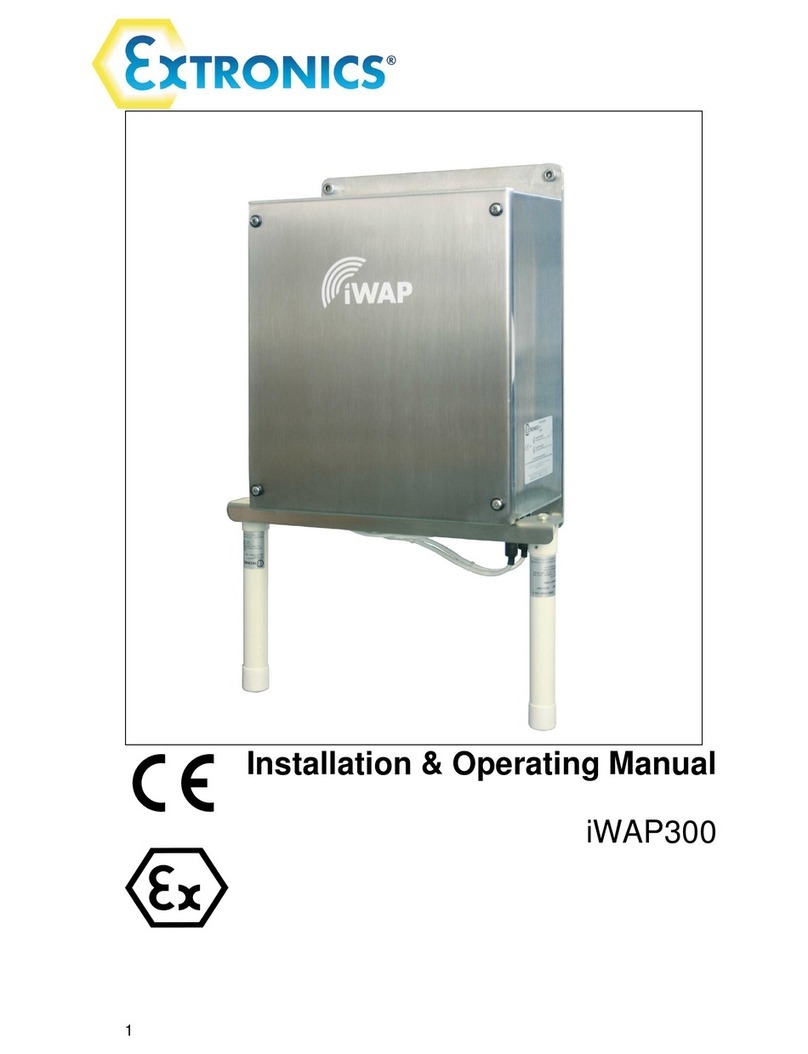

3.1.2 Fitting the cables

Depending on the configuration of the iWAP200, the connections for power and

communication will need to be terminated into the enclosure via the correct cable

entries shown in Diagram 3.1.1.

The cables used to connect the power and/or Ethernet connection to the PCB screw

terminals must conform to the following specification;

All wires should be stripped and, if stranded cable is used, should be crimped using

2.5mm bootlace ferrules. The stripped/crimped wires should then be placed into the

corresponding screw terminal and securely screwed in place.

If using solid core cable;

Minimum cross section of cable = 0.2mm2

Maximum cross section of cable = 2.5mm2

Maximum cross section of cable for 24VDC connector ONLY = 6mm2

If using crimped stranded core cable;

Minimum cross section of cable = 0.25mm2

Maximum cross section of cable = 1.5mm2

Maximum cross section of cable for 24VDC connector ONLY = 4mm2

Warning The iWAP200 MUST be earthed.

Important All cables should be connected to the iWAP200 via the correct cable

gland, fitted by a competent person.

Important If cable glands different to those supplied by Extronics are used, these

must be M20 sized cable glands meeting the requirements of

EN60079-0:2009 for ATEX Category III GD equipment, and not

compromise the IP66 rating of the iWAP200 enclosure.

Important Changes in the design and modifications to the equipment are not

permitted. This includes adding heaters/fans which are not installed at

the factory.

Important The installer MUST ensure that that all cables have adequate mechanical

protection to avoid damage to the wires.

3.1.3 Mains & PoE Variant Cable Installation

Diagram 3.1.3.1 shows the connectors on the mains and PoE variant of the iWAP200. Table

3.1.3.2 describes the pin out connection required for operation. There are two blocks of

screw terminals and one RJ45 connector. The Ethernet input screw terminals are wired in

parallel with the RJ45 connector. Do not make an Ethernet connection to the RJ45 connector

and the screw terminals at the same time, the installer should use only one of these

connectors.

Follow the instructions in section 3.1.2 to correctly prepare the cables and feed them through

the correct cable gland. Follow table 3.1.3.2 to connect the correct cable to the correct screw

terminal. If using the RJ45 connector instead of the screw terminals simply connect the Cat-5

cable to the connector and ensure the cable is securely in place.