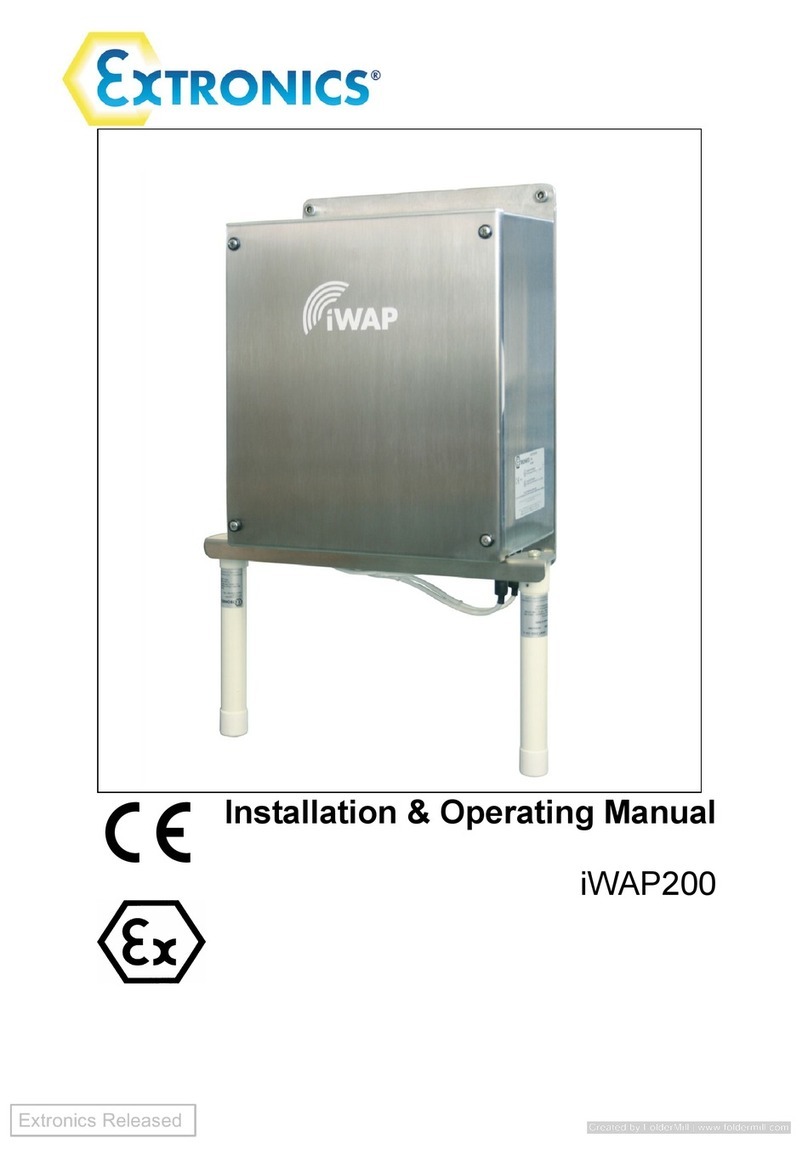

Operating Manual

3

Contents

1Introduction.......................................................................................................... 4

2Safety Information and Notes.............................................................................. 5

2.1 Storage of this Manual ................................................................................. 5

2.2 List of Notes ................................................................................................. 5

3Installation and Setting-to-Work .......................................................................... 6

3.1 Installation.................................................................................................... 6

3.1.1 Removing the cover.............................................................................. 6

3.1.2 Fitting the cables................................................................................... 6

3.1.3 Mains Variant Cable Installation............................................................ 7

3.1.4 Fibre Ethernet Input .............................................................................. 9

3.1.5 24VDC Variant Cable Installation.......................................................... 9

3.1.6 Fibre Ethernet Input .............................................................................11

3.1.7 Thermostat Control ..............................................................................11

3.1.8 Fitting the antennas..............................................................................11

3.1.9 Mounting The Antennas.......................................................................12

3.1.10 Setting to work .....................................................................................12

4Intended Purpose Usage....................................................................................13

4.1 Transportation and Storage.........................................................................13

4.2 Authorized Persons.....................................................................................13

4.3 Cleaning and Maintenance..........................................................................13

4.4 Safety Precautions......................................................................................13

4.5 Cleaning and Maintenance Intervals...........................................................14

4.6 Aggressive substances and environments..................................................14

4.7 Exposure to external stresses.....................................................................14

5Technical Data ...................................................................................................15

5.1 Specification................................................................................................15

5.2 Enclosure Dimensions.................................................................................16

6Type Codes........................................................................................................17

7Manual Revision.................................................................................................18