Page iii

TABLE OF CONTENTS

Owner’s Manual and Service Guide

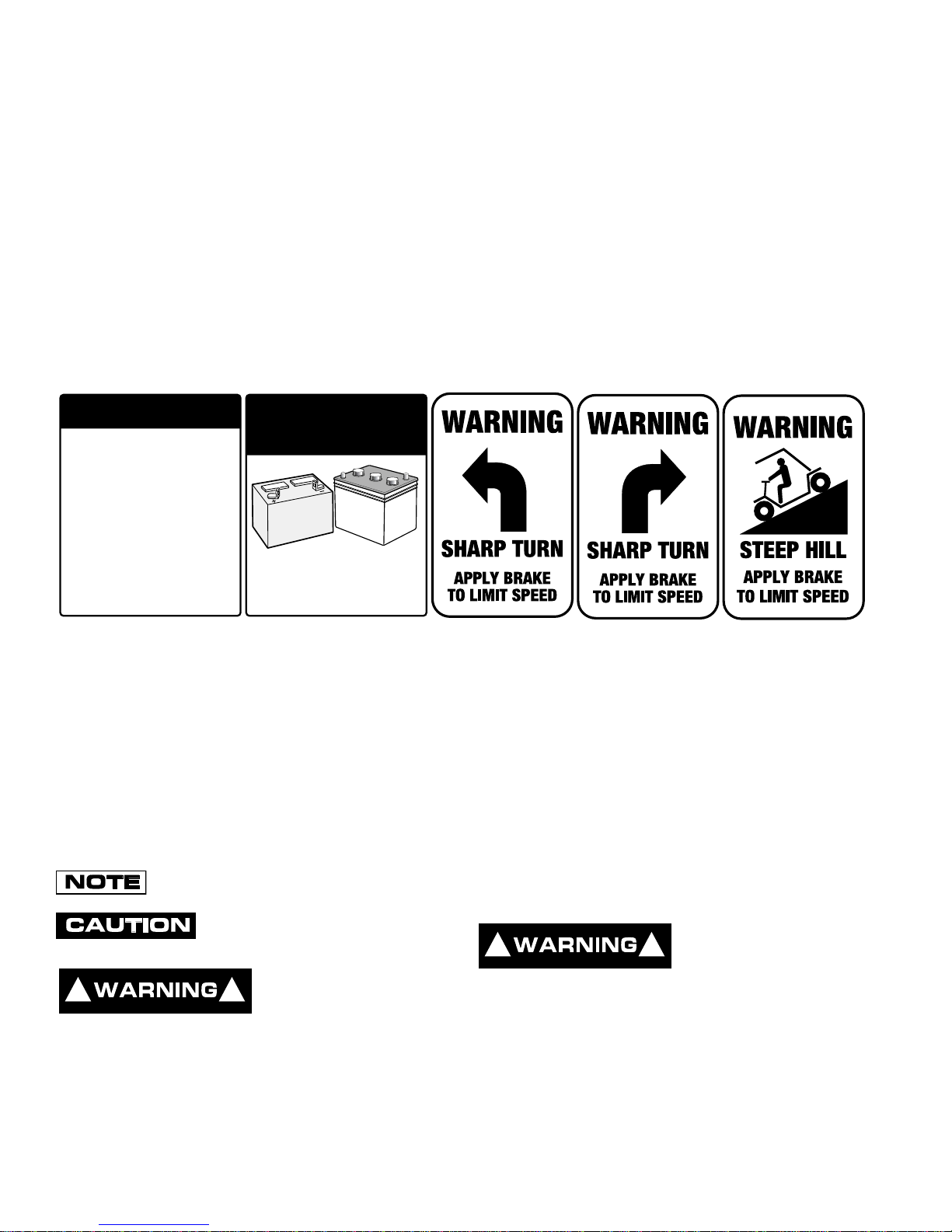

SAFETY ...................................................................................................................Inside covers

NOTES.........................................................................................................................................ii

SAFETY INFORMATION............................................................................................................. v

BEFORE INITIAL USE ...............................................................................................................1

Fig. 1 Initial Service Chart ......................................................................................................................1

Preparation of Seats for Service ..........................................................................................................................1

Charger Installation ..............................................................................................................................................1

Fig. 2 Charger Installation ......................................................................................................................2

Fig. 3 Charger Receptacle .....................................................................................................................2

SERIAL NUMBER PLATE LOCATION ......................................................................................2

Fig. 4 Serial Number Plate Location ......................................................................................................2

CONTROLS AND INDICATORS ................................................................................................2

Key/Light Switch ..................................................................................................................................................2

Fig. 5 Key/Light Switch ..........................................................................................................................3

Accelerator Pedal ................................................................................................................................................3

Fig. 6 Accelerator and Brake Controls ...................................................................................................3

Service Brake Pedal ............................................................................................................................................3

Parking Brake ......................................................................................................................................................3

Direction Selector ................................................................................................................................................3

Fig. 7 Direction Selector ........................................................................................................................3

Horn .....................................................................................................................................................................4

Fig. 8 Horn Button ..................................................................................................................................4

State of Charge Meter .........................................................................................................................................4

Run - Tow/Maintenance Switch (on PDS vehicles only) ......................................................................................4

Fig. 9 Run-Tow/Maintenance Switch .....................................................................................................4

Controller Diagnostics (PDS vehicles only) .........................................................................................................5

BEFORE ENTERING VEHICLE .................................................................................................5

OPERATING THE VEHICLE ......................................................................................................5

Additional Warnings and Cautions (applicable to PDS vehicles) .........................................................................6

STARTING VEHICLE ON A HILL ..............................................................................................6

General ................................................................................................................................................................6

PDS Vehicle .........................................................................................................................................................6

Non PDS Vehicle (with hand operated park brake) .............................................................................................6

Non PDS Vehicle (with foot operated park brake) ...............................................................................................6

Anti-Stall Feature (PDS Vehicle) .........................................................................................................................7

COASTING .................................................................................................................................7

Vehicle with PDS .................................................................................................................................................7

Vehicle without PDS ............................................................................................................................................7

SERVICING THE ELECTRIC VEHICLE ....................................................................................7

DIRECTION SELECTOR ADJUSTMENT ..................................................................................8

Fig. 10 Direction Selector Adjustment ...................................................................................................8

TOWING ..................................................................................................................................... 8

LIFTING THE VEHICLE .............................................................................................................8

Fig. 11 Lifting the Vehicle ......................................................................................................................9

ROUTINE MAINTENANCE ........................................................................................................9

Fig. 12 Lubrication Points ......................................................................................................................9

REAR AXLE ...............................................................................................................................9

Checking the Lubricant Level ..............................................................................................................................9

Fig. 13 Add, Check and Drain Rear Axle Lubricant .............................................................................10

BRAKES ...................................................................................................................................10

Daily Brake Test ................................................................................................................................................10