1Foreword

Dear Customer!

Thank you for choosing our product!

By purchasing this product you receive guarantee for

good quality originating from the usage of the finest and proven materials,

operating security which is controlled according to German and European norms (Corresponds to

the standards DIN 18891 Construction Shape 1 and EN 13240.),

long life ensured by the robust structure.

In order to be able to use your new fireplace for a long time please read the following instructions

manual. You will find all the necessary information in it and some additional advice.

2FETY INSTRUCTIONS

This equipment has been certified under the requirements of standard DIN EN 13240 or DIN EN

12815 (see the model plate).

For setting purposes and connection to the chimney, the fire protection requirements as

prescribed in the given locations, as well as standards DIN 4705, DIN EN 13384, DIN EN 1856-2

and DIN EN 15287 should be complied with. For the problem-free functioning of the equipment,

the chimney that the fireplace is to be connected to has to be in perfect conditions (Germany).

Before the first commissioning and connection to the chimney, these user instructions are to be

read thoroughly, and the competent chimney sweeper has to be informed.

It is recommended to use clean cotton gloves for the setting of the equipment in order to avoid

the appearance of fingerprints that would be hard to eliminate later on.

In order to keep the air clean and maintain the equipment properly, the maximum fuel

quantities specified in these safety instructions may not be exceeded, and the doors of the

eqipment have to be kept closed, otherwise the equipment may overheat, leading to damage.

No guarantee is provided for such damage.

During operations, the doors of the equipment are to be kept always closed.

Permissible fuels:

- natural wood (max. 35 cm in length)

- brown coal briquette (see user instructions)

Never use liquid igniters. Use special ignition materials or wood wool for the kindling of the

fire.

Never use wastes, fine wooden chips, mulch, coal debris, particle board wastes, wet wood or

wood treated with wood-protective agents, paper or cardboard or similar materials for burning.

Upon the first kindling, smoke and unpleasant smell may be generated. Always ensure the

proper ventilation of the room (by opening windows and doors), and heat the fireplace at

maximum rated heating performance. If with the first heating the maximum temperature is not

reached, the above-mentioned effects may as well arise later on.

The operating elements and adjustment units are to be used as described in these user

instructions. If the equipment is hot, use auxiliaries or protective gloves for the handling of the

equipment.

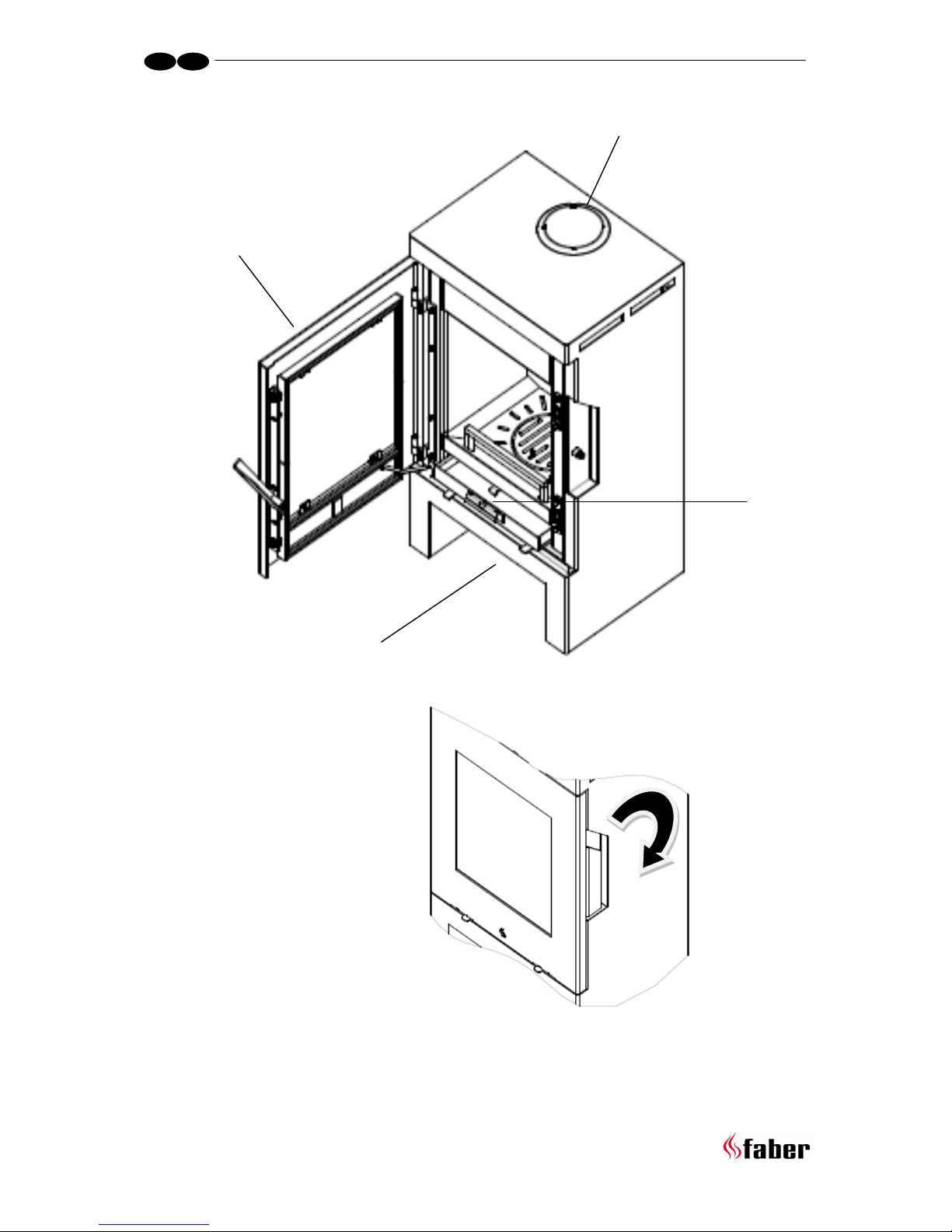

When opening the furnace chamber door, any incorrect handling or insufficient draught may

induce smoke. Always ensure that the furnace chamber door may be opened only slowly, first

just to a small extent, and then fully after a few seconds. In addition, if you intend to put

additional fuel into the fire, before the opening of the door only there may be only ember bed

in the burning space, i.e. no flames may be visible.

In heating mode, the surfaces, inspection glasses and handles may become very hot. Warn

children of these threats, and keep them away from the fireplace when heated.

Ensure that the ashtray should be fully inserted, and in particular never remove hot ash from

the fireplace (fire risk).

In transitional periods, chimney draught may drop, resulting in the imperfect suction of the

generated flue gases. In such cases, the fireplace is to be filled with smaller quantities of fuel,

preferably wooden chips or wood wool, and it is to be commissioned under control with the

stabilization of the chimney draught. The fire grate should always be kept clean.

After the heating season, it is recommended to have the equipment inspected by an expert. It

is also advisable to clean the routes of flue gases and pipes.