2

Table of Contents

Table of Contents ................................................................................................................................................................ 2

Introduction.......................................................................................................................................................................... 3

Manufacturer information .............................................................................................................................................. 3

Principle of operation ....................................................................................................................................................... 3

Hardware –System parts ................................................................................................................................................ 4

Hardware –Setup............................................................................................................................................................... 5

Hardware –Handling the Piezo Sensors................................................................................................................... 6

Maintenance..................................................................................................................................................................... 6

Fixing................................................................................................................................................................................... 6

Measurement................................................................................................................................................................... 6

Removal ............................................................................................................................................................................. 6

Hardware –Amplifier boxes .......................................................................................................................................... 7

Hardware –Battery Box................................................................................................................................................... 7

Hardware –Bluetooth and serial connection.......................................................................................................... 8

Establishing Bluetooth connection to the Battery Box................................................................................... 8

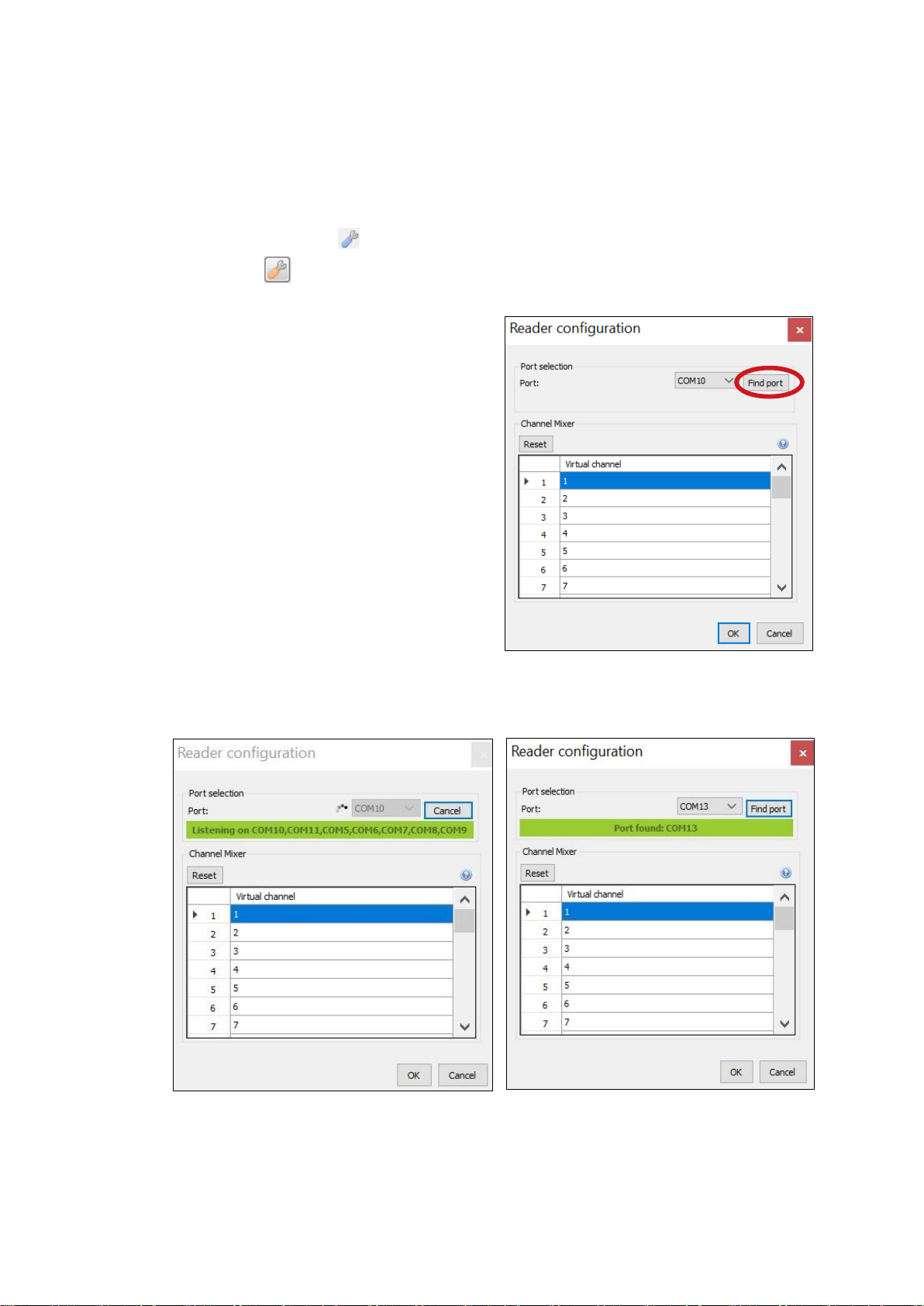

Selecting COM port........................................................................................................................................................ 9

Software –Basics ..............................................................................................................................................................11

Software –Application Settings..................................................................................................................................12

Software –Tree Properties...........................................................................................................................................13

Software –Sensor Geometry –Basics ......................................................................................................................15

Software –Sensor Geometry –Circular, Elliptical, Rectangular and Irregular .......................................16

Circular.............................................................................................................................................................................16

Elliptical ...........................................................................................................................................................................17

Rectangular.....................................................................................................................................................................17

Irregular...........................................................................................................................................................................18

Software –Sensor Geometry –Compass.................................................................................................................18

Description .....................................................................................................................................................................18

Usage.................................................................................................................................................................................18

Software –Time Data......................................................................................................................................................19

Software –Tomograms –Single-layer mode.........................................................................................................20

Software –Tomograms –Multi-layer mode ..........................................................................................................21

Software –Biomechanics...............................................................................................................................................22

Software –Image Container .........................................................................................................................................24

Software –Generating reports....................................................................................................................................25

Report generator –earlier version.......................................................................................................................25

Testing and troubleshooting........................................................................................................................................26

Testing before going to the field............................................................................................................................26

Most common troubles and solutions.................................................................................................................27

Advice and safety regulations......................................................................................................................................30

Maintenance........................................................................................................................................................................31

Guarantee.............................................................................................................................................................................31