2.0– Hull Assembly

After unpacking the hulls, verifying the contents and verifying they did not receive any

damage in transport, find a flat level area to begin the assembly of your boat. Using

the foam end blocks set the hulls so they are parallel and approximately 84 1/2” apart

as measured from the centerline of each hull. The hulls of the F18 are canted outboard

3 degrees. Use a wedge on the base of the foam blocks to set the hulls so that they

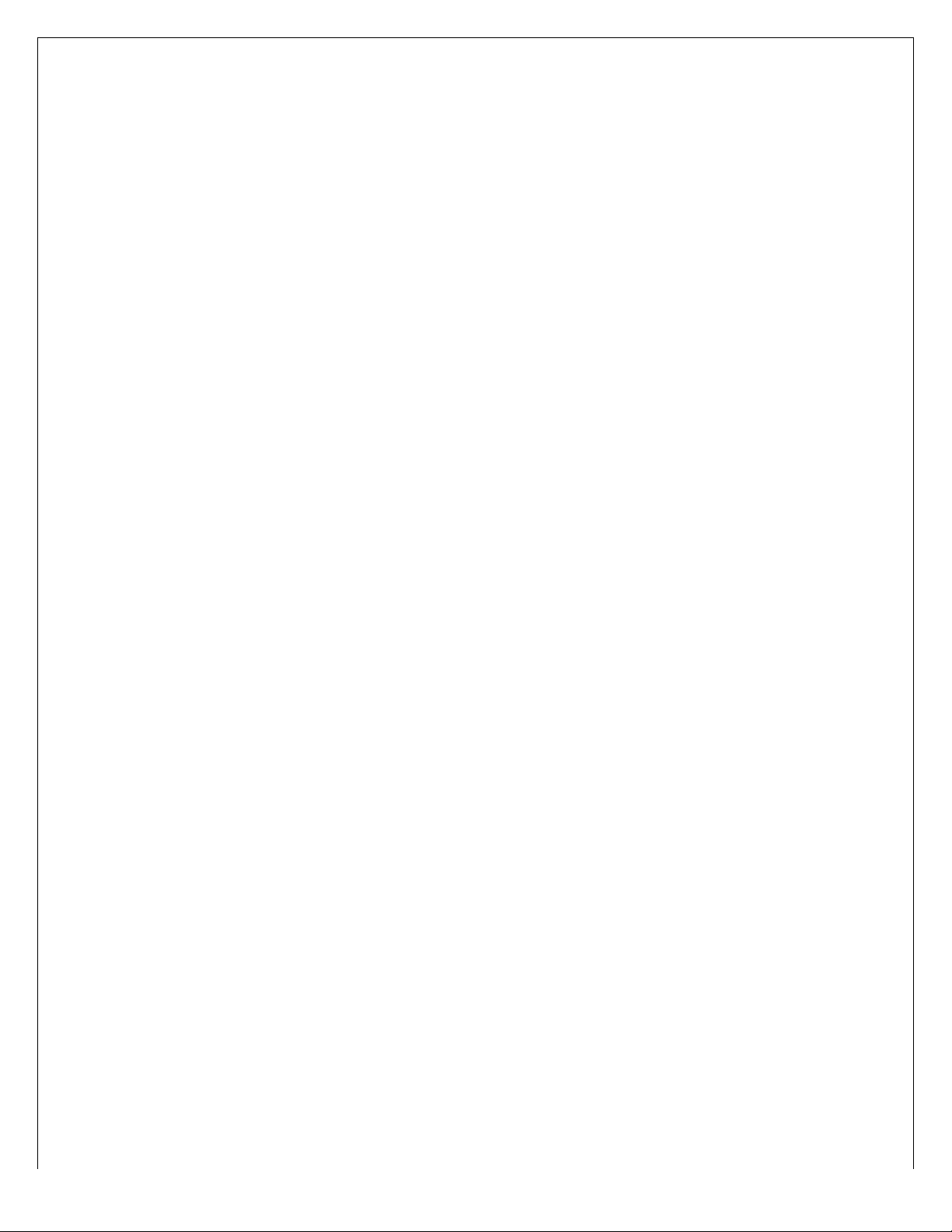

are at this 3 degree canted position. To verify the placement of the hulls, use a bubble

level placed in the beam pocket of each hull. The pocket base will be level once the

hulls are adjusted to the proper degree of

cant. If you do not have the foam

shipping blocks, place the hulls on

carpet, foam blocks, or other smooth item

where they can be moved without

damaging the surface. You can use

towels or wedges to ensure that the hulls

are set parallel and at the same pitch

angle relative to each other.

With a tape measure first check the

width, then make sure that they are

positioned the same fore and aft, by

taking opposing diagonal measurements

from the same location on each hull. Note, that once the hulls are canted to the proper

3 degrees, the width measurement along the hull centerline will not be same along the

length due to the contour of the hull shape. It is important to try and start with the hulls

as close to the final position as possible. The beams have been prefit at the factory

and the beam sockets in the hulls have very little slop. If they are positioned correctly,

the beams will drop right in place, The forward beam pocket is much deeper and may

be snug. Note: on the rear beam, the tramp lacing buttons should be aligned to the aft

end. On the front beam the traveler track should be placed forward.

(Figure 2.A).

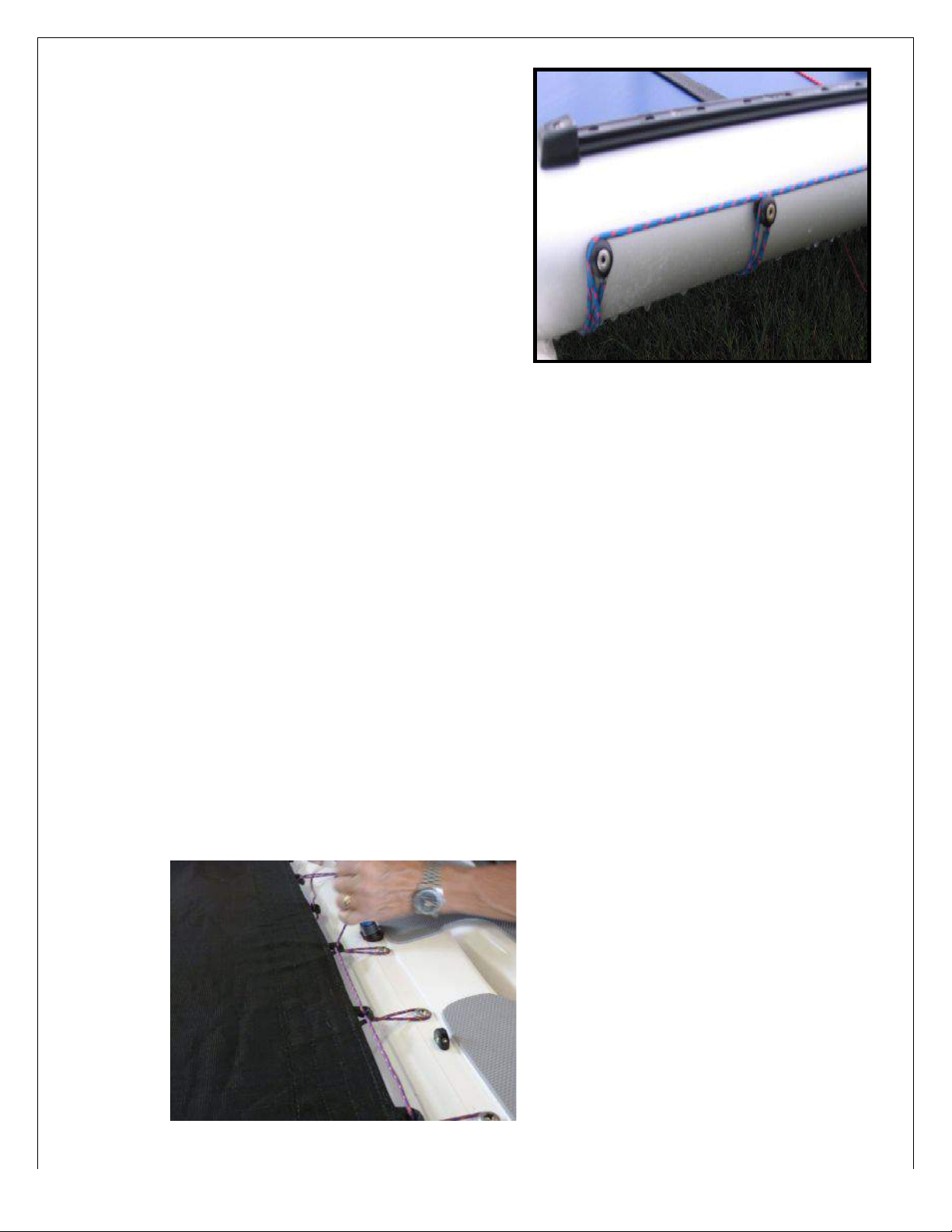

Once the hulls are set, remove the end

caps and the bolts from the cross bars and

set on the hulls. Dry fit the bolts to ensure

everything will fit smoothly. The hulls were

pre-assembled in the factory, so if they are

aligned properly, the bolts should slide

smoothly into the hulls. After you are

confident of the fit, lift the beams and place