2

Installing Fan and Bracket

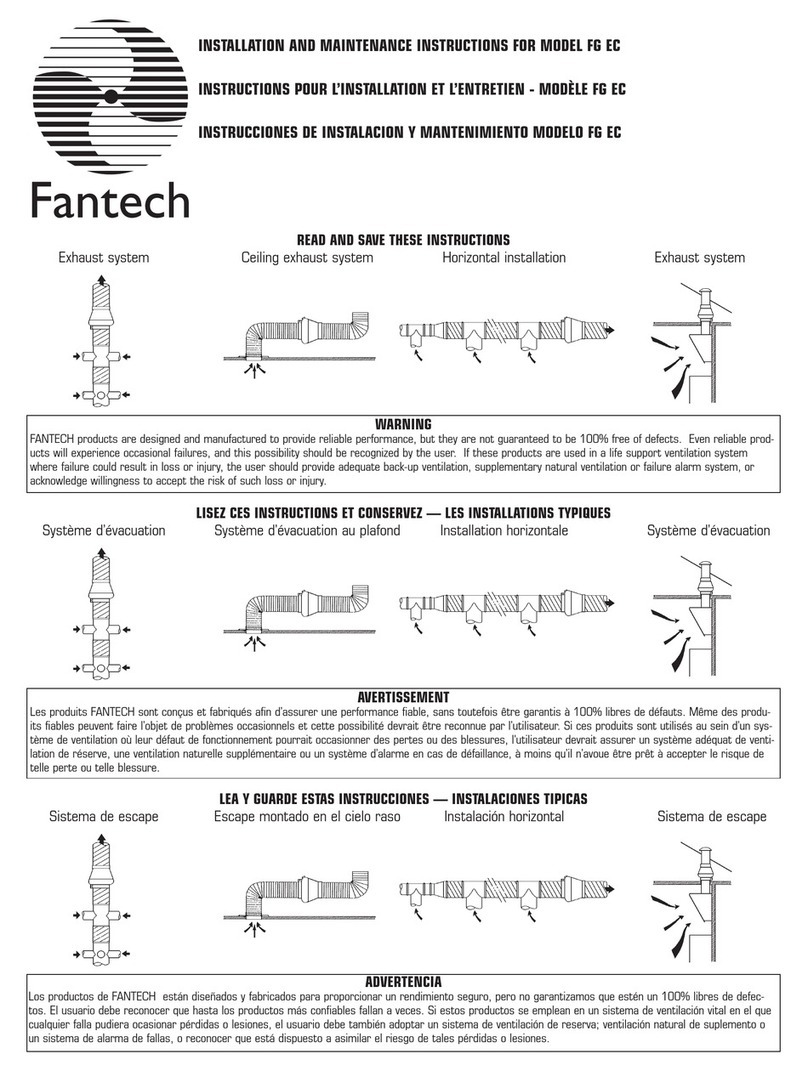

1. When selecting fan mounting location, the follow-

ing criteria should be considered:

a) mounting to

minimize noise generated by fan operation; b)

service accessibility

a) Mounting the fan as far as possible from

the intake point will minimize fan operating

noise from being transmitted back through

the duct work. Insulated flexible type duct

work (recommended for all bathroom

exhaust applications) will result in much qui-

eter operation. Fantech recommends mini-

mum 8' of insulated flexible duct between

any exhaust grille and fan for low noise level.

b) Fan location should allow sufficient access

for service.

2. Using the wood screws provided, attach the

mounting bracket to a support beam at the

selected location. Fan mounting can be at any

point along the duct and at any angle, however,

vertical mounting is recommended to reduce con-

densation buildup in the fan. If a horizontal instal-

lation is necessary and condensation buildup may

pose a problem, either wrap insulation around the fan or drill a ¹⁄₄" hole in the

bottom of the housing (along with an NPT insert [by others] and drain tubing)

allowing condensation to drain.

3. Attach fan to the mounting bracket with the

sheet metal screws provided. Wiring box

should be positioned for easy access. Bracket

is provided with rubber vibration isolation

grommets to prevent the transmission of

sound through the structure. Be careful not

to overtighten. Also, care should be taken not

to strip the plastic housing. Screws are self

tapping and do not require pilot holes.

However,pilot holes (no larger than ³⁄₃₂") are

recommended.

4. Connect duct work to inlet and outlet of fan

using plastic ties [by others] or duct tape.

When using insulated flexible duct, it is rec-

ommended that the inner vinyl core be

clamped or taped to the inlet and outlet and

that the vapor barrier surrounding the insula-

tion be duct taped to the fan housing.

Fantech recommends insulated flexible duct

for all bathroom exhaust applications).

NOTE: Steps 2 & 3 may be reversed.

Mount Bracket

Mount Fan

Mount Bracket

Mount Fan

Multiple Location Switching Wiring Diagram

Without Motor Speed Controller

With Motor Speed Controller

Electrical Connection

1. Remove the screws securing the terminal

box cover plate located on the side of the

fan. All fan motor connections are pre-wired

to an electrical terminal strip. A ³₈" romex

type cable restraint connector will be needed

to secure the wiring through the knockout

provided on the side of the terminal box.

2. Bring incoming electrical service through the

romex connector and the fan knockout. Be sure

to place the connector nut over the wiring com-

ing into the terminal box. There are two open

ports on the terminal strip. Using a small regu-

lar screwdriver, tighten the neutral (white) wire

of the incoming supply under the open terminal

strip port labeled "N". Tighten the line (black)

wire of the incoming supply under the open ter-

minal strip port labeled "L". Since the fan

motor is isolated within a plastic housing,

grounding is not necessary.

3. Secure the romex connector. Secure the

incoming supply with the romex connector.

Replace the fan terminal box cover. All fan

motor and capacitor connections have been

pre-wired from the factory. No additional fan

wiring is necessary.

Troubleshooting

If fan fails to operate, please check the following:

1. Consult wiring diagrams (at right) to ensure proper connection.

2. Check motor lead wiring, capacitor leads and incoming supply leads to

insure definite contact.

3. If possible, use a meter to test for continuity across the fan motor leads.

In order to do this, the capacitor must be disconnected (do not test the

capacitor - it will not meter continuity). If motor leads show continuity, con-

sult factory for a replacement capacitor.

Maintenance Instructions

Since fan bearings are sealed and provided with an internal lubricating material,

no additional lubrication is necessary.

Wiring Diagrams

All Models

Romex wiring – Top View

Liquid tight wiring Top View

(For outside applications).

Flexible Duct Installation Hints

Flexible insulated duct is strongly recommended where allowed by local code for

bathroom exhaust applications, where ducting passes through unconditioned space

or where noise is a factor. Failure to use insulation could result in excessive con-

densation buildup within the duct, and undesirable sound levels within the room.

For the quietest possible installations, Fantech recommends a minimum of 8' of

insulated flexible duct between any inlet grille and fan. When using flexible type

duct work, duct should be stretched as tight and straight as possible. Failure to do

so could result in dramatic loss of system performance. Flexible duct should be

connected to the fan with plastic zip ties or duct tape. All connections should be

as airtight as possible to maximize system performance