FAST AG Solutions Fast Sprayers 9500 Series User manual

HIGH-CLEARANCE

CENTER PIVOT

SUSPENDED BOOM

FIELD SPRAYER

9500 & 9600

SERIES

OPERATOR'S MANUAL

960 9500 & 9600 SPRAYER 4-19-2019

LIMITED WARRANTY

FAST AG Solutions warrants to the buyer that the new machinery is free from defects in

material and workmanship.

This warranty is only effective as to any new machinery which has not been altered,

changed, repaired or treated since its delivery to the buyer, other than by FAST AG

Solutions or its authorized dealers or employees, and does not apply to accessories,

attachments, tools or parts, sold or operated with the new machinery, if they have not been

manufactured by FAST AG Solutions.

FAST AG Solutions shall only be liable for defects in the materials or workmanship

attributable to faulty material or bad workmanship that can be proved by the buyer, and

specifically excludes liability for repairs arising as a result of normal wear and tear of the

new machinery or in any other manner whatsoever, and without limiting the generality

of the foregoing, excludes application or installation of parts not completed in

accordance with FAST AG Solutions operator's manual, specifications, or printed

instructions.

Written notice shall be given by registered mail, to Fast Distributing within seven (7) days

after the defect shall have become apparent or the repairs shall have become necessary,

addressed as follows: FAST AG Solutions 4130 Commerce Boulevard, Windom, MN

56101.

This warranty shall expire two (2) years after the date of delivery of the new machinery.

If these conditions are fulfilled, Fast shall at its own cost and at its own option either repair

or replace any defective parts provided that the buyer shall be responsible for all expenses

incurred as a result of repairs, labor, parts, transportation or any other work, unless Fast

has authorized such expenses in advance.

The warranty shall not extend to any repairs, changes, alterations, or replacements made

to the new equipment other than by Fast or its authorized dealers or employees.

This warranty extends only to the original owner of the new equipment.

Rubber parts are not warranted. (including tires, hoses, grommets)

This warranty is limited to the terms stated herein and is in lieu of any other warranties

whether express or implied, and without limiting the generality of the foregoing, excluded

all warranties, express or implied or conditions whether statutory or otherwise as to quality

and fitness for any purpose of the new equipment. Fast disclaims all liability for incidental

or consequential damages.

This sprayer is subject to design changes and FAST AG Solutions shall not be required

to retro-fit or exchange items on previously sold units except at its own option.

Fast Distributing Inc.

SERIAL NUMBER LOCATION

Always give your dealer the serial number of your Fast Distributing Center Pivot High-Clearance Sus-

pended Boom Field Sprayer when ordering parts or requesting service or other information.

The serial number is stamped on a serial tag attached to the trailer frame by the ladder where indicated.

Please mark the number in the space provided for easy reference.

Model Number 9_ _ _

Sprayer Serial Number 9_ _ _ _ _ _ _ _ _ _

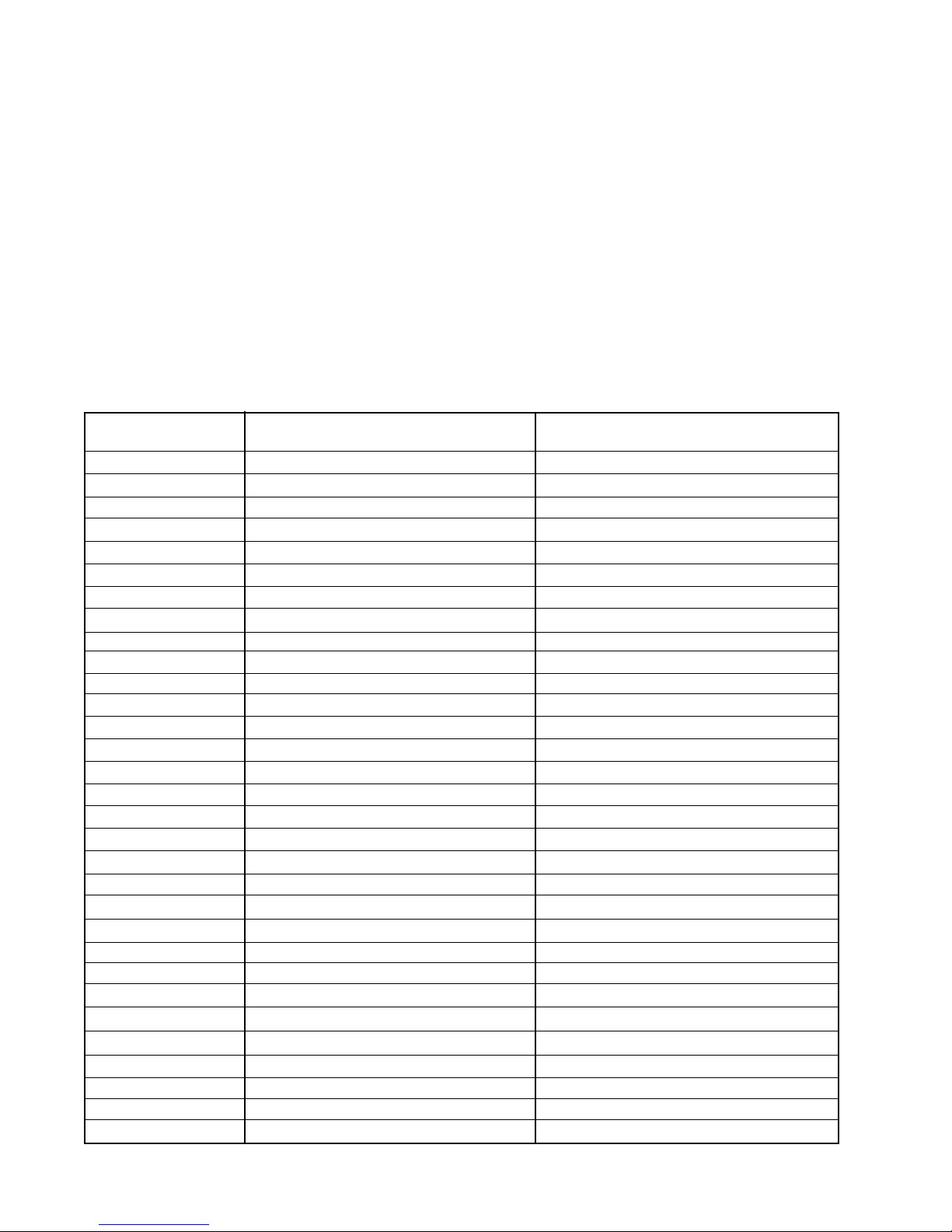

TABLE OF CONTENTS

SECTION DESCRIPTION

PAGE

1 Introduction ............................................................. 1

2 Safety ................................................................... 2

2.1 General Safety ...................................................... 3

2.2 Operating Safety ................................................... 4

2.3 Chemical Safety ................................................... 5

2.4 Maintenance Safety .............................................. 6

2.5 Hydraulic Safety ................................................... 6

2.6 Transport Safety ................................................... 7

2.7 Tire Safety ............................................................ 7

2.8 Storage Safety ...................................................... 7

2.9 Safety Signs ......................................................... 7

2.10 Sign-Off Form ....................................................... 8

3 Safety Sign Locations ........................................ 9

4 Operation ........................................................... 13

4.1 To the New Operator or Owner ........................... 13

4.2 Machine Components ......................................... 14

4.3 Break-In .............................................................. 15

4.4 Pre-Operation Checklist...................................... 15

4.5 Equipment Matching ........................................... 16

4.6 Controls .............................................................. 18

4.7 Installing Controllers ........................................... 24

4.8 Attaching/Unhooking Tractor .............................. 25

4.9 Sprayer Calibration ............................................. 28

4.9.1 Engine RPM ....................................................... 28

4.9.2 Controller Calibration.......................................... 29

4.9.3 Nozzle Calibration .............................................. 29

4.9.4 Machine Yard Calibration ................................... 31

4.9.5 Ground Speed Calibration .................................. 31

4.9.6 Area Covered ..................................................... 33

4.9.7 Field Calibration ................................................. 33

4.10 Field Operation ................................................... 34

4.11 Transport/Field Conversion ................................ 55

4.12 Transport ............................................................ 57

4.13 Storage ............................................................... 59

4.13.1 Placing In Storage .............................................. 59

4.13.2 Removing From Storage..................................... 60

5 Service and Maintenance ................................. 61

5.1 Service................................................................ 61

5.1.1 Fluids and Lubricants ......................................... 61

5.1.2 Greasing ............................................................. 61

5.1.3 Servicing Intervals .............................................. 63

5.1.4 Service Record ................................................... 68

5.2 Maintenance ....................................................... 69

SECTION DESCRIPTION

PAGE

5.2.1 Filter Cleaning .................................................... 69

5.2.2 Tank Cleaning .................................................... 70

5.2.3 Boom Break-Aways ............................................ 71

5.2.4 Wheel Tread ....................................................... 72

5.2.5 Boom Straightness ............................................. 73

6 Trouble Shooting .............................................. 74

7 Specifications ................................................... 77

7.1 Mechanical ......................................................... 77

7.2 Bolt Torque ......................................................... 81

7.3 Hydraulic Fitting Torque ..................................... 81

7.4 Chemical Circuit Schematic................................ 82

7.5 Electrical Schematic ........................................... 83

7.6 5 Function Hyd. Block Parts................................ 85

7.7 5 Function Hyd. Cab Box .................................... 86

7.8 5 Function Hyd. Cab Box Switch Wiring ............. 87

7.9 6 Function Hyd. Block ......................................... 88

7.10 6 Function Hyd. Cab Box .................................... 89

7.11 6 Function Hyd. Cab Box Switch Wiring ............. 90

7.12 6 Function Hyd. Yaw Block 120-132' .................. 91

7.13 6 Function Hyd. Yaw Cab Box 120-132' ............. 92

7.14 6 Function Hyd. Yaw Cab Box120-132' .............. 93

7.15 6 Function Hyd. Yaw Cab Box Wiring 120-132'.. 94

8 Index .................................................................. 95

1

1 INTRODUCTION

Congratulations on your choice of a FAST AG Solutions 9500, 9600 Series Center Pivot High-Clearance

Suspended Boom Field Sprayer to complement your farming operation. This equipment has been

designed and manufactured to meet the needs of a discriminating buyer for the efficient spraying of

crops.

Safe, efficient and trouble free operation of your FAST AG Solutions Field Sprayer requires that you

and anyone else who will be operating or maintaining the Sprayer, read and understand the Safety,

Opera-tion, Maintenance and Trouble Shooting information contained in the Operator's Manual.

This manual covers 9500, 9600 Series Center Pivot High-Clearance Suspended Boom Field Sprayers built

by FAST AG Solutions. Use the Table of Contents or Index as a guide when searching for specific

information.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your

Fast dealer or distributor if you need assistance or information.

OPERATOR ORIENTATION - The directions left, right, front and rear, as mentioned throughout this

manual, are as seen from the tractor driver's seat and facing in the direction of travel.

Accidents Disable and Kill

Accidents Cost

Accidents Can Be Avoided

3 Big Reasons

2 SAFETY

SAFETY ALERT SYMBOL

SIGNAL WORDS:

Note the use of the signal words DANGER,

WARNING and CAUTION with the safety

messages. The appropriate signal word for

each message has been selected using the

following guide-lines:

situation that, if not avoided, will result

in death or serious injury. This signal

word is to be limited to the most

extreme situations, typically for ma-

chine components that, for functional

purposes, cannot be guarded.

Indicates a potentially hazardous

situation that, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

Indicates a potentially hazardous

situation that, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

DANGER - Indicates an imminently hazardous

WARNING -

CAUTION -

The Safety Alert symbol identifies

important safety messages on the

Fast Distributing Center Pivot High-

Clearance Suspended Boom Field

Sprayer and in the manual. When

you see this symbol, be alert to the

possibility of personal injury or

death. Follow the instructions in the

safety message.

This Safety Alert symbol means

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Why is SAFETY important to you?

2

If you have any questions not answered in this manual or require additional copies or the manual is

damaged, please contact your dealer or FAST AG Solutions, 4130 Commerce Boulevard, Windom,

MN 56101, (Telephone) 507-427-3861, (FAX) 507-427-3030.

2.1 GENERAL SAFETYSAFETY

YOU are responsible for the SAFE operation and

maintenance of your Fast Distributing Center

Pivot High-Clearance Suspended Boom Field

Sprayer. YOU must ensure that you and anyone

else who is going to operate, maintain or work

around the Sprayer be familiar with the operating

and maintenance procedures and related

SAFETY information contained in this manual.

This manual will take you step-by-step through

your working day and alerts you to all good safety

practices that should be adhered to while operat-

ing the Sprayer.

Remember, YOU are the key to safety. Good

safety practices not only protect you but also the

people around you. Make these practices a

working part of your safety program. Be certain

that EVERYONE operating this equipment is

familiar with the recommended operating and

maintenance procedures and follows all the safety

precautions. Most accidents can be prevented. Do

not risk injury or death by ignoring good safety

practices.

• Sprayer owners must give operating instruc-

tions to operators or employees before

allowing them to operate the Sprayer, and at

least annually thereafter per OSHA regulation

1928.57.

• The most important safety feature on this

equipment is a SAFE operator. It is the

operator’s responsibility to read and under-

stand ALL Safety and Operating instructions

in the manual and to follow these. All acci-

dents can be avoided.

• A person who has not read and understood all

operating and safety instructions is not quali-

fied to operate the machine. An untrained

operator exposes himself and bystanders to

possible serious injury or death.

• Do not modify the equipment in any way.

Unauthorized modification may impair the

function and/or safety and could affect the life

of the equipment.

• Think SAFETY! Work SAFELY!

1. Read and understand the

Operator’s Manual and all

safety signs before operating,

maintaining or adjusting the

Sprayer.

3

2. Only trained competent persons shall operate

the Sprayer. An untrained operator is not

qualified to operate the machine.

- A hard hat

- Rubber boots

- Protective goggles

- Neoprene gloves

- Water repellent

clothing

- Respirator or filter

mask

6. Place all controls in neutral, stop tractor

engine, turn monitor off, set park brake,

remove ignition key, wait for nozzles to stop

spraying before servicing, adjusting, repairing

or unplugging.

7. Read chemical manufacturers warnings,

instructions and procedures before starting

and follow them exactly.

8. Post Poison Control Emergency telephone

number for your area on sprayer before using

Agricultural chemicals.

Ottawa: (613) 992-5606

Washington DC: (202) 962-4525

Have container label handy when seeking

medical attention.

9. Review safety related items with all personnel

annually.

3. Have a first-aid kit available for

use should the need arise and

know how to use it.

5. Wear appropriate protective

gear. This list includes but is

not limited to:

4. Do not allow riders.

4

2.2 OPERATING SAFETY

1. Read and understand the Operator’s Manual

and all safety signs before using.

2. Place all controls in neutral, stop tractor

engine, turn monitor off, set park brake,

remove ignition key, wait for nozzles to stop

spraying before servicing, adjusting, repairing

or unplugging.

3. Before spraying a field, be familiar with all

potential hazards: trees, rocks, ditches,

gullies, etc. Plan the spraying route to avoid

hazards. Remember you are driving a wide

machine. USE CAUTION WHEN CORNER-

ING.

4. Keep hands, feet, hair and clothing away from

all moving and/or rotating parts.

5. Do not allow riders on the sprayer or tractor

during operation or transporting.

6. Clear the area of all bystanders, especially

children, before starting or filling with water or

chemical.

7. Stay away from wing pinch points when

folding or extending wings. Keep others

away.

8. Stay away from power lines when extending

or folding wings. Electrocution can occur

without direct contact.

9. Read chemical manufacturers warnings,

instructions and procedures before starting

and follow them exactly.

10. Do not breathe, touch or ingest chemicals.

Always wear protective clothing and follow

safe handling procedures.

11. Spray only when potential for chemical drift is

at a minimum. Even small amounts can affect

neighboring crops or sensitive plants and

people.

12. Dispose of chemical containers by triple

rinsing them into the sprayer tank or thor-

oughly rinsing, crushing and delivering to

regional disposal site.

13. In case of poisoning, get immediate medical

attention.

14. Only rinse sprayer while still in the field.

Spray the rinse thinly over the field already

sprayed. Never contaminate the farmyard or

drainage systems with sprayer rinse.

15. Do not eat in the field when spraying.

16. Before applying pressure to the hydraulic

system, make sure all components are tight

and that steel lines, hoses and couplings are

in good condition.

17. Before applying pressure to chemical system

make sure that all connections are tight and

that all hoses and fittings are in good condi-

tion.

18. Review safety instructions annually.

2.3 CHEMICAL SAFETY

1. Some Agricultural chemicals are among the

most toxic substances known to man. Minute

quantities can contaminate clothing, machin-

ery, the workplace and the environment.

Follow the chemical manufacturers' instruc-

tions exactly. Death can result from their

improper use.

2. Misuse, including excessive rates, uneven

application, wind drift, and label violations can

cause injury to crops, livestock, persons and

the environment.

3. Do not breathe, touch or ingest chemicals,

Always wear protective clothing and follow

safe handling procedures.

4. Follow the manufacturers' instructions for

chemical storage. Avoid unnecessary storage

by purchasing only the quantity needed for the

crop year.

5. Keep all chemicals out of reach of children

and away from livestock and animals.

6. Store chemicals only in their original contain-

ers and in a locked area.

7. Check with state environment department

regarding the disposal of small quantities of

chemicals, chemical containers and wash

water. Follow their disposal instructions.

8. Do not burn the containers or leave them lying

in the field or ditches. Dispose of them by

triple rinsing and leaving at a pesticide con-

tainer disposal site.

9. Wash thoroughly before eating. Use a deter-

gent to remove all chemical residue. Rinse

carefully and dry with disposable towels.

10. Do not eat in the field when spraying.

11. In case of chemical poisoning, get immediate

medical attention. Have container label handy

when seeking medical attention.

12. Post Poison Control Emergency telephone

number for your area on sprayer before using

Agricultural chemicals.

Ottawa: (613) 992-5606

Washington DC: (202) 962-4525

Have container label handy when seeking

medical attention.

13. Thoroughly wash clothing and equipment

contaminated by chemicals.

14. Do not allow children or workers on contami-

nated sprayer.

15. Rinse sprayer while still in the field. Spray the

rinse thinly over the field already sprayed.

Never contaminate the farmyard or drainage

systems with sprayer rinse.

16. Do not use the sprayer to transport drinking

water.

17. Wash down the Sprayer immediately after

field work. Dispose of the wash water in an

environmentally safe manner. Wash water

can contaminate the soil or a clean water

supply.

5

6

2.4 MAINTENANCE SAFETY

1. Review the Operator's Manual and all safety

items before working with, maintaining or

operating the Sprayer.

2. Place all controls in neutral, stop the tractor

engine, turn monitor off, set park brake,

remove ignition key, wait for nozzles to stop

spraying before servicing, adjusting, repairing

or unplugging.

2.5 HYDRAULIC SAFETY

1. Always place all tractor hydraulic controls in

neutral before dismounting.

2. Make sure that all components in the hydrau-

lic system are kept in good condition and are

clean.

3. Replace any worn, cut, abraded, flattened or

crimped hoses and steel lines.

4. Do not attempt any makeshift repairs to the

hydraulic lines, fittings or hoses by using tape,

clamps or cements. The hydraulic system

operates under extremely high-pressure.

Such repairs will fail suddenly and create a

hazardous and unsafe condition.

6. If injured by a concentrated high-pressure

stream of hydraulic fluid, seek medical atten-

tion immediately. Serious infection or toxic

reaction can develop from hydraulic fluid

piercing the skin surface.

7. Before applying pressure to the system, make

sure all components are tight and that lines,

hoses and couplings are in good condition.

5. Wear proper hand and eye

protection when searching

for a high-pressure hydrau-

lic leak. Use a piece of

wood or cardboard as a

backstop instead of hands

to isolate and identify a

leak.

3. Follow good shop practices:

- Keep service area

clean and dry.

- Be sure electrical

outlets and tools

are properly

grounded.

- Use adequate

light for the job at

hand.

4. Before applying pressure to a hydraulic system,

make sure all components are tight and that steel

lines, hoses and couplings are in good condition.

5. Before applying pressure to chemical system

make sure that all connections are tight and that

all hoses and fittings are in good condition.

6. Relieve pressure from hydraulic circuit before

servicing or disconnecting from tractor.

7. Keep hands, feet, clothing and hair away from all

moving and/or rotating parts.

8. Clear the area of bystanders, especially children,

when carrying out any maintenance and repairs

or making any adjustments or filling.

9. Place stands or blocks under the frame before

working beneath the machine.

10. Wear safety goggles, neoprene gloves and

protective clothing when working on the sprayer

filled with active chemical.

11. Wash machine to remove all chemical residue

before working on unit. Wear appropriate protec-

tive gear at all times.

12. Protect yourself from chemical contamination.

2.6 TRANSPORT SAFETY

1. Read and understand ALL the information in

the Operator’s Manual regarding procedures

and SAFETY when operating the Sprayer in the

field and/or on the road.

2. Check with local authorities regarding sprayer

transport on public roads. Obey all applicable

laws and regulations.

3. Always travel at a safe speed. Use caution and

appropiate speed when making corners or

meeting traffic.

4. Make sure the SMV (Slow Moving Vehicle)

emblem and all the lights and reflectors that are

required by the local highway and transport

authorities are in place, are clean and can be

seen clearly by all overtaking and oncoming

traffic.

5. Be sure that the Sprayer is hitched positively to

the towing vehicle. Always use a retainer

through the pin and a safety chain between the

machine and the tractor.

6. Keep to the right and yield the right-of-way to

allow faster traffic to pass. Drive on the road

shoulder, if permitted by law.

7. Do not exceed 20 mph (32 km/h). Reduce

speed on rough roads and surfaces.

8. Always use hazard warning flashers on tractor

when transporting unless prohibited by law.

9. Never transport with the tank filled with water or

chemical.

7

2.7 TIRE SAFETY

1. Failure to follow proper procedures when

mounting a tire on a wheel or rim can produce

an explosion which may result in serious injury

or death.

2. Do not attempt to mount a tire unless you have

the proper equipment and experience to do the

job.

3. Have a qualified tire dealer or repair service

perform required tire maintenance.

2.8 STORAGE SAFETY

1. Store unit in an area away from human

activity.

2. Do not permit children to play on or around

the stored sprayer.

3. Unhook and store in the transport configura-

tion.

2.9 SAFETY SIGNS

1. Keep safety signs clean and legible at all

times.

2. Replace safety signs that are missing or have

become illegible.

3. Replaced parts that displayed a safety sign

should also display the current sign.

4. Safety signs are available from your Distribu-

tor or the factory.

How to Install Safety Signs:

• Be sure that the installation area is clean and

dry.

• Be sure temperature is above 50°F (10°C).

• Decide on the exact position before you

remove the backing paper.

• Remove the smallest portion of the split

backing paper.

• Align the sign over the specified area and

carefully press the small portion with the

exposed sticky backing in place.

• Slowly peel back the remaining paper and

carefully smooth the remaining portion of the

sign in place.

• Small air pockets can be pierced with a pin

and smoothed out using the piece of sign

backing paper.

8

DATE EMPLOYEES SIGNATURE EMPLOYERS SIGNATURE

2.10 SIGN-OFF FORM

FAST AG Solutions follows the general Safety Standards specified by the American Society of Agricul-

tural Engineers (ASAE) and the Occupational Safety and Health Administration (OSHA). Anyone who will

be operating and/or maintaining the FAST AG Solutions Sprayer must read and clearly understand ALL

Safety, Operating and Maintenance information presented in this manual.

Do not operate or allow anyone else to operate this equipment until such information has been reviewed.

Annually review this information before the season start-up.

Make these periodic reviews of SAFETY and OPERATION a standard practice for all of your equipment.

We feel that an untrained operator is unqualified to operate this machine.

A sign-off sheet is provided for your record keeping to show that all personnel who will be working with

the equipment have read and understand the information in the Operator’s Manual and have been in-

structed in the operation of the equipment.

SIGN-OFF FORM

REMEMBER - If Safety Signs have been damaged, removed, become illegible or parts replaced without

safety designs, new signs must be applied. New safety signs are available from your authorized dealer.

9

3 SAFETY SIGN LOCATIONS

The types of safety signs and locations on the equipment are shown in the illustration below. Good safety

requires that you familiarize yourself with the various Safety Decals, the type of warning and the area, or

particular function related to that area, that requires your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

C

WARNING

To prevent serious injury or death

from high pressure fluid:

• Relieve pressure on system before

repairing, adjusting or disconnecting.

• Wear proper hand and eye protection

when searching for leaks. Use wood

or cardboard instead of hands.

• Keep all components in good repair.

HIGH-PRESSURE FLUID HAZARD

B

WARNING

Install the safety pin and secure

before transporting sprayer.

A

CAUTION

BB

802

1. Read and understand the Operator's Manual before

using.

2. Read Chemical manufacturers' WARNINGS, instruc-

tions and procedures before starting and follow them

exactly.

3. Stop tractor engine, place all controls in neutral, set

park brake, remove ignition key and wait for all

moving parts to stop before servicing, adjusting,

repairing, unplugging or filling.

4. Always wear proper eye, breathing and clothing

protection.

5. Stay away from chemicals, spray and drift. Keep

others away.

6. Install and secure all guards before starting.

7. Keep hands, feet, hair and clothing away from

moving parts.

8. Do not allow riders.

9. Keep all chemical and hydraulic lines, fittings and

couplers tight and free of leaks before starting and

operating.

10. Stay away from overhead power lines.

11. Clear the area of bystanders before extending or

folding wings.

12. Release second wing extend switch before first wing.

13. Hitch can upend . Do not stand over hitch when

unhooking. Support hitch and sprayer on stands

before removing pin.

14. Review safety instructions with all operators annu-

ally. 800

809

B

BB

K

AFGHJ

10

REMEMBER - If Safety Signs have been damaged, removed, become illegible or parts replaced without

safety designs, new signs must be applied. New safety signs are available from your authorized dealer.

F

TOXIC CHEMICAL HAZARD

WARNING

Agricultural chemicals can be dangerous.

Improper selection or use can seriously

injure persons, animals, plants, soil or other

property. BE SAFE: Select the right

chemical for the job. Handle it with care.

Follow the instructions on the container

label and instructions from the equipment

manufacturer.

The types of safety signs and locations on the equipment are shown in the illustration below. Good safety

requires that you familiarize yourself with the various Safety Decals, the type of warning and the area, or

particular function related to that area, that requires your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

D

WARNING

G

DANGER

ELECTROCUTION HAZARD

KEEP AWAY FROM POWER LINES

1. Stay well away from power lines

when folding or extending wings.

Electrocution can occur without

direct contact.

2. Lower wings completely before

moving or transporting.

To prevent serious injury or death from

electrocution:

B

B

FALLING HAZARD

801

• Use care when climbing

ladder or working on

platform.

• Keep unauthorized people

off machine.

To prevent serious injury or

death from falling:

807

805

C

The types of safety signs and locations on the equipment are shown in the illustration below. Good safety

requires that you familiarize yourself with the various Safety Decals, the type of warning and the area, or

particular function related to that area, that requires your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

REMEMBER - If Safety Signs have been damaged, removed, become illegible or parts replaced without

safety designs, new signs must be applied. New safety signs are available from your authorized dealer.

11

H

WEAR RUBBER

GLOVES

• Do not allow

chemical or

solution to touch

skin. Some can

be absorbed

through the skin.

• Wear rubber

gloves and

protective gear

at all times.

CHEMICAL HAZARD

DANGER

DON'T INGEST

CHEMICAL

DON'T BREATHE

VAPOR

• Chemicals can be toxic.

• If in eyes or mouth, read

chemical manufacturers'

instructions and follow

them exactly.

• Seek medical attention

immediately.

• A poison control number

is normally inside the

front cover of your

telephone book.

• Stay away from

chemical splash

and vapor. Keep

others away.

• Do not breathe

vapor.

• Wear proper

respirator when

working with

chemicals.

J

WARNING

OVERHEAD HAZARD

KEEP AWAY

To prevent serious injury or

death from overhead hazard:

• Stay away from machine when

extending or folding wings.

• Keep others away.

• Move wings only from tractor seat.

K

CRUSHING HAZARD

To prevent serious personal injury or death:

• Read and understand the owners manual

before using machine.

• Keep hands and body out of hitch area

when attaching towing vehicle.

• Always use the safety chains provided.

• Do not tow over 25 MPH, slower on

uneven ground. Allow no riders.

DANGER

To prevent serious injury or death:

806

808

812

12

REMEMBER - If Safety Signs have been damaged, removed, become illegible or parts replaced without

safety designs, new signs must be applied. New safety signs are available from your authorized dealer.

The types of safety signs and locations on the equipment are shown in the illustration below. Good safety

requires that you familiarize yourself with the various Safety Decals, the type of warning and the area, or

particular function related to that area, that requires your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

Raise boom and turn cylinder

valve off before transporting or

working under the boom.

WARNING

L

L

JL

13

4 OPERATION

Many features incorporated into this machine are the

result of suggestions made by customers like you.

Read this manual carefully to learn how to operate

the machine safely and how to set it to provide

maximum field efficiency. By following the operating

instructions in conjunction with a good maintenance

program, your Sprayer will provide many years of

trouble-free service.

4.1 TO THE NEW OPERATOR OR OWNER

Todays Agricultural industry works closely with the

chemical industry to develop and use the appropri-

ate compound for control of insects, weeds and

fungus. Effective results are closely related to

application methods and techniques. Fast Distribut-

ing Inc. has designed a field sprayer that will place

the chemicals exactly where they are needed.

It is the responsibility of the owner or operator to

read this manual and the chemical container

label before starting. Follow all safety instruc-

tions exactly. Safety is everyone's business. By

following recommended procedures, a safe

working environment is provided for the opera-

tor, bystanders and the environment.

OPERATING SAFETY

1. Read and understand the Operator’s Manual

and all safety signs before using.

2. Place all controls in neutral, stop tractor engine,

turn monitor off, set park brake, remove ignition

key, wait for nozzles to stop spraying before

servicing, adjusting, repairing or unplugging.

3. Before spraying a field, be familiar with all

potential hazards: trees, rocks, ditches, gullies,

etc. Plan the spraying route to avoid hazards.

Remember you are driving a wide machine.

USE CAUTION WHEN CORNERING.

4. Keep hands, feet, hair and clothing away from

all moving and/or rotating parts.

5. Do not allow riders on the sprayer or tractor

during operation or transporting.

6. Clear the area of all bystanders, especially

children, before starting or filling with water or

chemical.

7. Stay away from wing pinch points when folding

or extending wings. Keep others away.

8. Stay away from power lines when extending or

folding wings. Electrocution can occur without

direct contact.

8. Read chemical manufacturers warnings, instruc-

tions and procedures before starting and follow

them exactly.

9. Do not breathe, touch or ingest chemicals.

Always wear protective clothing and follow

safe handling procedures.

10. Spray only when potential for chemical drift

is at a minimum. Even small amounts can

affect neighboring crops or sensitive plants

and people.

11. Dispose of chemical containers by triple

rinsing them into the sprayer tank or thor-

oughly rinsing, crushing and delivering to

regional disposal site.

12. In case of poisoning, get immediate medical

attention.

13. Only rinse sprayer while still in the field.

Spray the rinse thinly over the field already

sprayed. Never contaminate the farmyard

or drainage systems with sprayer rinse.

14. Do not eat in the field when spraying.

15. Before applying pressure to the hydraulic

system, make sure all components are tight

and that steel lines, hoses and couplings are

in good condition.

16. Before applying pressure to chemical

system make sure that all connections are

tight and that all hoses and fittings are in

good condition.

17. Review safety instructions annually.

14

Fig. 1 MACHINE COMPONENTS

4.2 MACHINE COMPONENTS

The FAST AG Solutions Center Pivot High-

Clearance Suspended Boom Field Sprayer is a

large transportable tank with spray booms to

distribute chemicals over a wide area. Chemi-

cals can be added directly into the tank

through the top tank lid bottom fill line or

through an optional eductor tank. The system

is pressurized by a hydraulically powered

pump that provides flow for tank agitation, tank

washing and boom pressure.

A 100 gallon wash tank is mounted on the

front of the frame. A 3 gallon hand rinse tank

is mounted on the right side with faucet by

ladder . Optional foam markers are available

and the tank mounts on the right side of the

frame. An optional eductor tank can be

mounted on the left side of the frame.

The chemical circuit is plumbed into the tank

for agitation to keep the solution mixed or to

the rotating ball wash heads for washing or

rinsing the tank. A solenoid to each boom

controls the flow to the wings and a butterfly

valve and flow sensor maintains the system

pressure. Nozzles along the wings, distribute

the chemical solution over the field. A screen

in the line next to the pump and after the

solenoids removes contaminants from the

system. The chemical system controller is

mounted in the tractor cab for easy operation.

The booms attach to and are suspended from

the back of the frame. The inner booms swing

back at right angles to the frame for field

operation. The outer booms pivot up and out

for field operation. The wing extensions

swings back if they hit an obstruction.

The boom position controller mounts in the cab

for easy operation. An adjustable axle pro-

vides a wheel spacing of 62, 80 and 120

inches.

A Main Tank

B Wash Tank

C Hand Rinse Tank

D Inner Boom

E Outer Boom

F Break-Away Boom

G Nozzles

H Centrifugal Pump

J Boom Controller

K Chemical Controller

D

D

GGG

M

H

D

FH

K

J

BA

C

D

E

F

G

H

4.3 BREAK-IN

Although there are no operational restrictions on

the sprayer when used for the first time, it is

recommended that the following mechanical items

be checked:

A. After operating for 1/2 hour:

1. Retorque all the wheel bolts, see

Section 7, Unit Specification

for proper torque.

2. Retorque all other fasteners and hard-

ware.

3. Check that all electrical connections are

tight.

4. Check that no chemical or hydraulic lines

are being pinched or crimped. Re-align

as required.

5. Check that all nozzles are working prop-

erly. Clean or replace as required.

6. Lubricate all grease fittings.

B. After 5 hours and 10 hours of operation:

1. Retorque all wheel bolts, fasteners and

hardware, see

Section 7, Unit Specification

for proper torque.

2. Check chemical and hydraulic line

routing.

3. Check that all nozzles are working prop-

erly.

4. Then go to the normal servicing and

maintenance schedule as defined in the

Maintenance Section.

15

Before operating the Sprayer and each time

thereafter, the following areas should be checked

off:

1. Lubricate the machine per the schedule

outlined in the “Maintenance Section”.

2. Use only a tractor of adequate power and

weight to operate the Sprayer. See Section

4.5.1 for recommendations.

3. Ensure that the machine is properly attached

to the tractor. Be sure that a mechanical

retainer is installed through the drawbar pin

and the safety chain is attached to the draw-

bar cage.

4. Check the hydraulic system. Ensure that the

hydraulic reservoir in the tractor is filled to the

required specifications.

5. Inspect all hydraulic lines, hoses, fittings and

couplers for tightness. Use a clean cloth to

wipe any accumulated dirt from the couplers

before connecting to the hydraulic system of

the tractor.

6. Check the tires and ensure that they are

inflated to the specified pressure.

7. Calibrate the sprayer if it is the start of the

season or a new chemical is being used.

8. Check the condition and routing of all chemi-

cal hoses and lines. Replace any that are

damaged. Re-route those that are rubbing,

pinched or crimped.

9. Check the spray pattern of each nozzle.

Remove and clean or replace any that have

an unusual pattern.

10. Remove the steel mesh line filters and wash

with clean water. Reinstall.

11. Check that all connections in the electrical

system are connected and tight.

4.4 PRE-OPERATION

CHECKLIST

Efficient and safe operation of the FAST AG

Solutions Sprayer requires that each operator

reads and understands the operating procedures

and all related safety precautions outlined in this

section. A pre-operational checklist is provided for

the operator. It is important for both personal

safety and maintaining the good mechanical

condition of the Sprayer that this checklist be

followed.

This manual suits for next models

1

Table of contents

Other FAST AG Solutions Paint Sprayer manuals