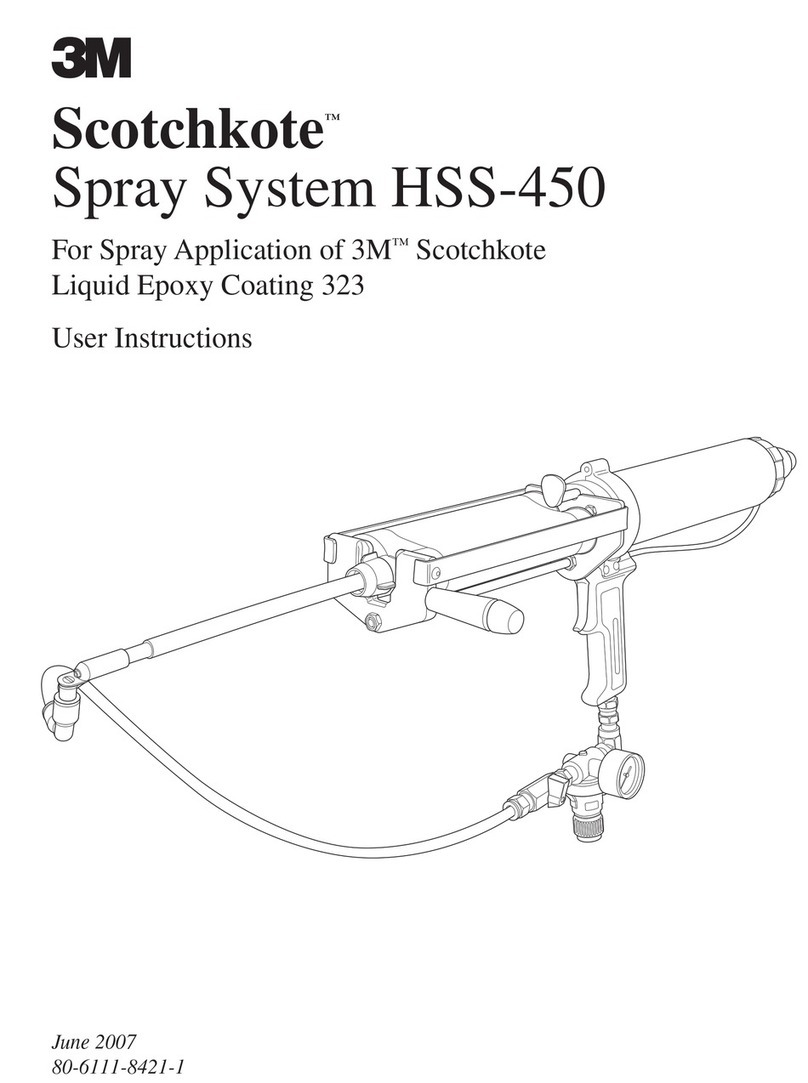

Attach Fluid Hose Whip to base of spray gun.

2

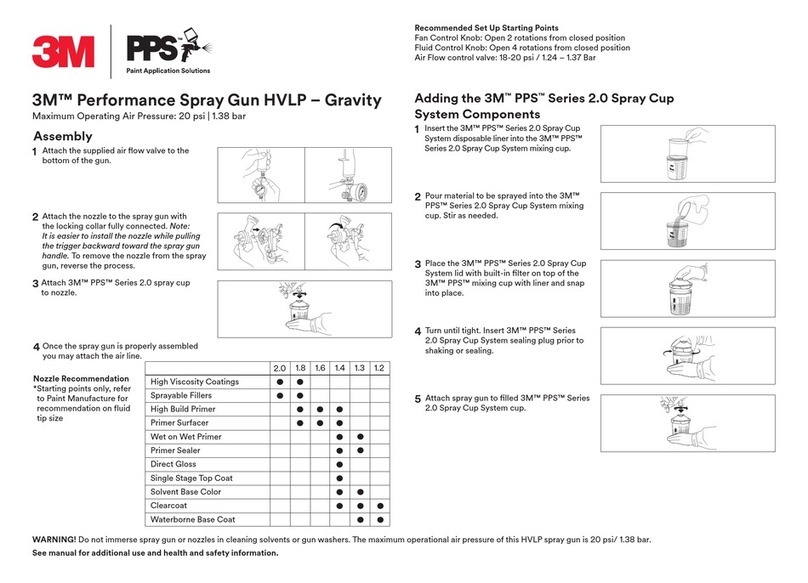

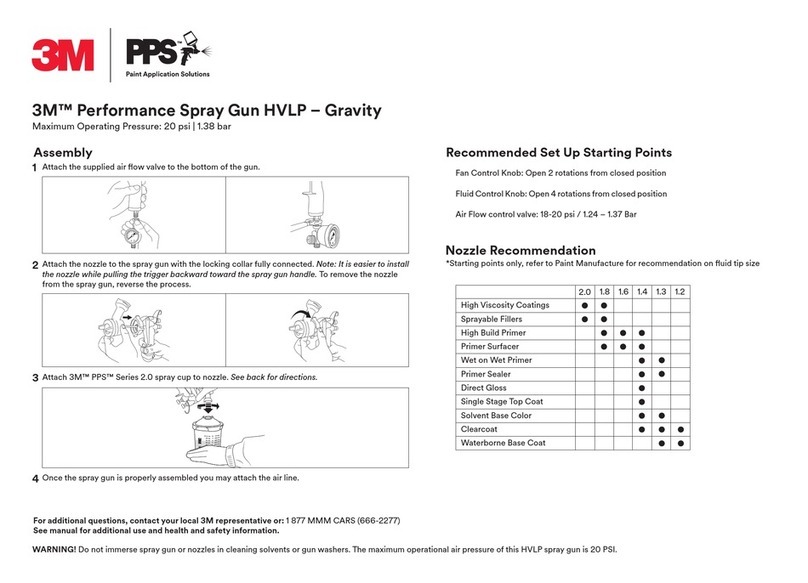

1Attach the supplied air ow valve to the bottom of the gun.

4Connect hose whip to nozzle.

5Attach uid and pressure lines from bulk feed system (or pres-

sure pot) Note: Utilize the optional manual uid shut-o valve, if

desired, between hose whip and uid supply

3Attach the nozzle to the spray gun with the locking collar fully

connected. Note: It is easier to install the nozzle while pulling

the trigger backward toward the spray gun handle.

Cleaning

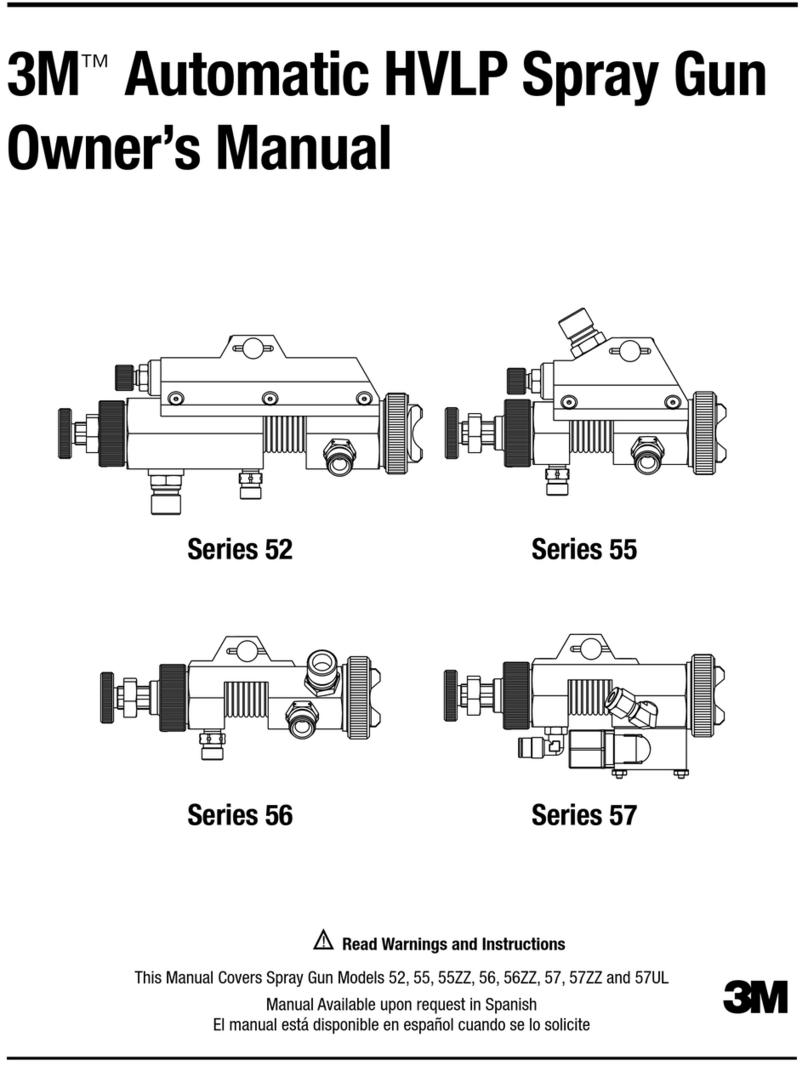

1.1 1.4 1.8

Base Coat / Single Stage Materials

Release Agents

1K Top Coats

2K Top Coats

Clear Coats

Textured Paints

Epoxy / Urethanes Primers

Adhesives

© 3M 2020. All rights reserved. 3M, Accuspray and PPS are trademarks of 3M Company, used under license in Canada. 60-4550-8097-2, 34-8717-9095-1

Once the system is adequately ushed (pot, lines),

depressurize the system (or close the optional

uid valve)

1

2After pressure is relieved, remove the hose whip

from the nozzle.

4Wipe needle tip. Store spray gun with a nozzle

attached to protect the needle.

3Remove nozzle from spray gun to clean residue

from the nozzle. Rinse out and ush cleaning solvent

through the nozzle with uid tip pointed straight

down into receptacle to collect waste solvent.

Pressure

Gravity

Once coating application is complete, disconnect

the air hose from the gun.

1

2To drain back paint into cup - Invert cup, pull trigger,

and tap the PPS™ cup on a table 3 times.

4Store spray gun with a nozzle attached to protect

the needle.

3Rinse out nozzle spout and ush cleaning solvent

through the nozzle by pulling trigger with uid tip

pointed straight down into receptacle to collect

waste solvent.

Nozzle Recommendation

*Starting points only, refer to Paint Manufacture for

recommendation on uid tip size

Assembly

For additional questions, contact your local 3M representative

or: 1 877 MMM CARS (666-2277)

See manual for additional use and safety information.

WARNING! Do not immerse spray gun or nozzles in cleaning

solvents or gun washers. The maximum operational air

pressure of this HVLP spray gun is 18 PSI.

3M™ Performance Spray Gun HVLP – Pressure

Maximum Operating Pressure: 18 psi | 1.24 bar

Recommended Set Up Starting Points

Fan Control Knob: Open 2 rotations from closed position

Fluid Control Knob: Open 4 rotations from closed position

Air Flow control valve: 18-20 psi / 1.24 – 1.37 Bar