Fast CR-110 User guide

*

†

Assume temp =20 oC, Vs= 9V, unloaded output

CR-110 units

Preamplification channels 1

Equivalent noise charge (ENC)*

ENC RMS 180 electrons

Equivalent noise in silicon 1.6 keV (FWHM)

2.1 keV (FWHM)

ENC slope 3elect. RMS /pF

Gain 1.4 volts /pC

Rise time †7ns

Decay time constant 140 s

Unsaturated output swing volts

Maximum charge detectable per event 2.6 x107electrons

4.2 pC

Output impedance 50 ohms

Power supply voltage (Vs)

maximum volts

volts

Power supply current mA

Vs= 13

Vs= 6

-6 to +6

minimum

Equivalent noise in CdZnTe

CR-110 charge sensitive preamplifier: application guide

General Description

Cremat's CR-110 is a single channel, low noise charge sensitive

preamplifier intended for use with various types of radiation detectors

including semiconductor detectors, photomultiplier tubes (PMTs),

photodiodes, avalanche photodiodes (APDs), and various gas-based

detectors. The CR-110 is small (less than one square inch in area),

allowing for compact multichannel detection systems to be created

using a modular design. The CR-110 can provide equal performance

with pulses of either polarity.

Detector coupling

The CR-110 can be used either in a

direct coupled

(DC) mode, or an

AC coupled

mode. These configurations are discussed below. If the

detector current exceeds 10 nA, it is recommended that an AC

coupled mode be used to prevent the resulting DC offset of the

preamplifier output from saturating.

Direct coupled operation

The above figure illustrates a typical configuration in which the CR-110

preamplifier is used to readout a detector in a 'DC coupled'

configuration. Detector current flows directly into the preamplifier input,

which is held at approximately a couple tenths of a volt below ground

potential. Detector current also produces an offset in the preamplifier

output voltage at a rate of 0.2 V per nA. A DC coupled configuration is

recommended unless high detector current causes the DC level at the

output to saturate.

Bypassed (AC coupled) operation

In cases in which detector current exceeds approximately 10 nA, an

AC coupled configuration is recommended to prevent the DC level of

the output from saturating. The above figure shows the connections

typically made in such a situation.

Package Specifications

The CR-110 circuit is contacted via an 8-pin SIP connection (0.100"

spacing). Leads are 0.020 inches wide. Pin 1 is marked with a white

dot for identification.

Measured with input unconnected, using Gaussian shaping amplifier with time constant =1

s. With a detector attached to the input, noise from the detector capacitance, leakage

current, and dielectric losses will add to this figure.

Pulse rise time (defined as the time to attain 90% of maximum value) has a linear

relationship with input capacitance. Value cited in the table assumes zero added input

capacitance. To calculate pulse rise time for practical situations, use the equation: tr=0.4 Cd

+ 7 ns, where tris the pulse rise time in ns, and Cdis the added capacitance (e.g. detector

capacitance) in pF.

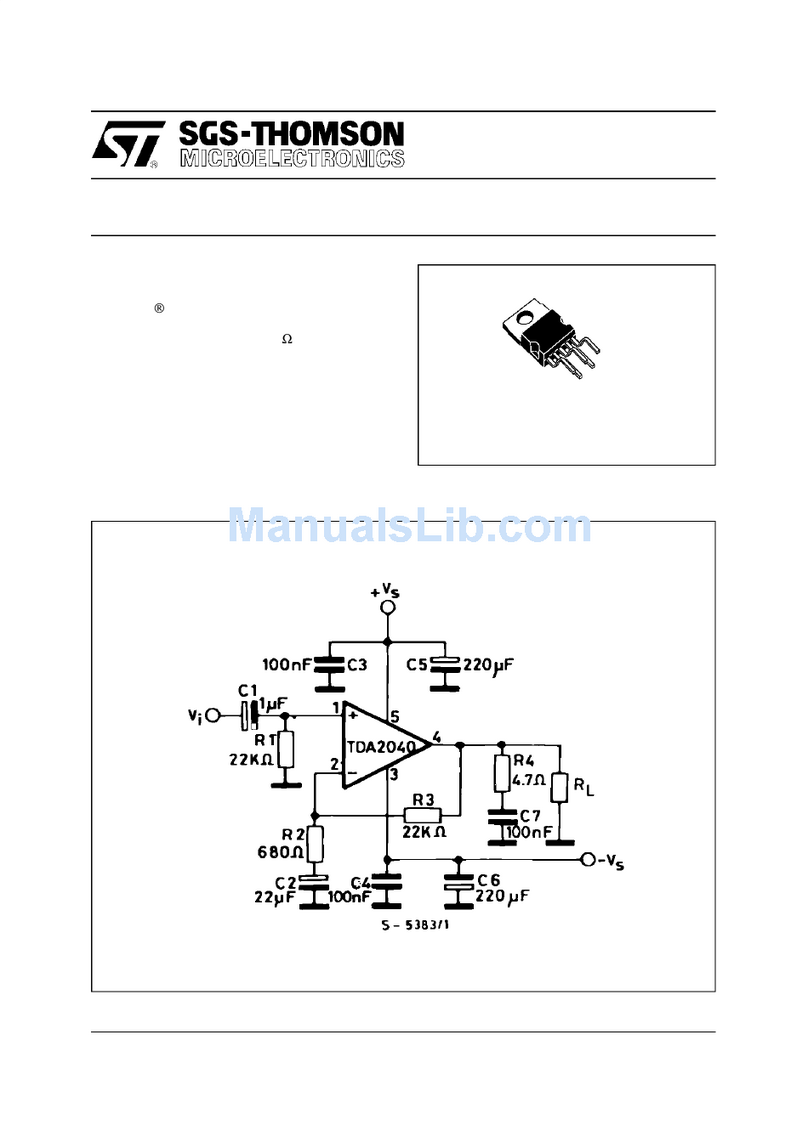

Equivalent circuit diagram

The figure below shows an simplified equivalent circuit diagram of the CR-110, which is a

two stage amplifier. The first stage is high gain, and the second stage is low gain with an

emphasis on supplying sufficient output current to drive a terminated coaxial cable.. Pin

numbers corresponding with the CR-110 preamplifier are shown. Rf(100 M ) and Cf

(1.4 pF) are the feedback resistor and capacitor respectively.

Output offset -0.5 to -0.1

0.03 femtoCoul.

volts

0.85"

0.88" 0.14"

CR-110

12345678Figure 3.

input

GND

NC

GND

Vs

+Vs

NC

output

Cremat, Inc.

Operating temperature -40 to +85 oC

Figure 1.

output

filtered bias

Det bias

input

10M

0.01uF

detector

-Vpower

+Vpower

CR-110

12345678

Figure 2.

output

input

Det bias CR-110

200M

10M

0.01uF

0.01uF

12345678

detector

+Vpower

-Vpower

Amplification polarity inverting

Maximum output current (under load) mA70

18

6

2, 4

Cf

Rf

5

++

G= -20k G=+2

Figure 4.

3, 7NC

(GND)

11

Power dissipation see Figure 7

Minimization of Electronic Noise

The magnitude of the equivalent noise charge (ENC) of charge sensitive

preamplifiers is affected by a number of different factors. Although these

factors produce a certain unavoidable level of noise, additional and

preventable noise may also be introduced into the detection system by

some aspects of the circuit design. The purpose of this section is to

help the engineer design detector circuits

having the minimum electronic noise

possible, given the constraints of the

detector.

One of the more avoidable noise sources

which may be present is inductive 'pick-up'

from nearby circuitry. This can generally

be eliminated by adequately shielding the

detection circuitry and by avoiding 'ground

loops' in the layout of the circuitry. The

power supply may also contain 'ripple' that

will not be completely rejected by the

amplification circuitry. For this reason, it is advisable to RC filter both the

positive and negative power supply lines at a point close to the preamplifiers.

In addition to ensuring a quiet power supply, it is also important to RC filter

the detector bias supply at a point near the detector and preamplifier. The

types of noise described in this paragraph can be identified by their periodic

behavior. With careful circuit design, these noise sources can be eliminated

as significant factors affecting the performance of the circuitry.

One final note on providing clean power supply voltages

: Surprisingly,

some power supply regulation ICs (such as the LM317 and LM337) produce

outputs that are very noisy. This noise can couple to the preamplifier

output, producing unsatisfactory results. If these regulator chips are used to

provide supply voltages for the CR-110, it is recommended that an RC filter

combination of 4.7 /1000 F be used to filter both the positive and negative

power supplies. Alternatively, a quieter regulator circuit (such as that used

in the CR-150-X evaluation boards) could be used. See

http://www.cremat.com/CR-150.pdf for more information on this regulator

circuit.

In typical detection systems using charge sensitive preamplifiers, the ENC

(equivalent noise charge) is due to a combination of 5 factors:

1). The

series thermal noise

of the input JFET in the preamplifier (which is

proportional to the total capacitance to ground at the input node),

2). The

parallel thermal noise

of the feedback resistor and any 'biasing'

resistor attached to the detector,

3). The

shot noise

of the detector leakage current,

4). The

series 1/f noise

, which is produced by the electrical contacts of the

detector and preamplifier input JFET,

5). The

parallel f noise

caused by the proximity of lossy dielectric material

near the preamplifier input node.

These noise sources can often be individually quantified in an operating

detection system by measuring the dependence of the ENC on the "shaping

time" of the pulse amplifier which usually follows the preamplification stage.

This method is described in more detail in the article:

Bertuccio G; Pullia A; "A Method for the Determination of the Noise

Parameters in Preamplifying Systems for Semiconductor Radiation

Detectors", Rev. Sci. Instrum., 64, p.3294, (1993).

Other articles which describe typical noise sources and signal processing

techniques when using charge sensitive preamplifiers are:

Radeka V; "Low-Noise Techniques in Detectors", Ann. Rev. Nucl. Part.

Sci., 38, p.217, (1988).

Goulding FS; Landis DA; "Signal Processing for Semiconductor

Detectors", IEEE Trans. Nuc. Sci., NS-29, p.1125, (1982).

In the interest of avoiding unnecessary noise, there are a few factors

requiring attention. If AC coupling is used, an important decision to make is

the value of the "bias resistor" (resistor placed between the detector and

the filtered detector bias supply). Because this resistor is effectively "in

parallel" with the preamplifier input, it is a source of

parallel thermal noise

.

The magnitude of this noise is proportional to the reciprocal of the square

root of the resistor value. To choose a good value for this resistor, one

should have approximate knowledge of the detector leakage current. It

should be noted that the thermal noise of the bias resistor has the same

power spectrum as the

shot noise

produced by the detector leakage current.

To keep the bias resistor from being a significant source of noise, one

should choose a bias resistance that keeps the thermal noise of the bias

resistor significantly less than the detector shot noise. The point at which

the thermal noise of the resistor equals this shot noise is when the bias

resistor voltage drop is =2kT/q, or approximately 50 mV. If the voltage drop

is significantly greater than this, then you can be certain that the thermal

noise of the resistor is not limiting the performance of the circuit. To be

safe, you can use a bias resistor that will drop approximately half a volt.

Because the CR-110 uses a 100 M feedback resistor (which produces its

own thermal noise) there is no need to increase the value of the bias

resistor higher than approximately 200 M . Another consideration in the

choice of bias resistor is that a very large voltage drop across it (in excess

of several volts) may significantly subtract from the voltage drop across the

detector.

Another source of electronic noise is the thermal noise of resistances

effectively "in series" between the detector and the preamplifier input. The

thermal noise voltage that the effective series resistance produces is

converted to a "noise charge" (remember that the preamplifier output is

proportional to the charge flowing into the input) which is proportional to the

capacitance to ground at the preamplifier input. Of course it is

recommended that the circuitry minimize the series resistance between the

preamplifier input and the detector, and usually this resistance can be

reduced to a figure of less than a few ohms. Unfortunately, effective

resistance in the input stage of the preamplifier add to this figure, making it

the dominant source of the "series thermal noise". As mentioned, this

noise component is proportional to the capacitance at the preamplifier input,

and for this reason it is important to seek to minimize the input capacitance

as much as possible. Using even short sections of coaxial cable to connect

a detector to the preamplifier, for example, can significantly degrade

the noise performance. Assuming a shaping time of 1 s, this noise

component adds 3 electrons RMS of noise charge for each pF of

capacitance added to the input.

Another noise concern in the design of your detection system is the

introduction of

parallel f noise

, which is introduced by the proximity of lossy

dielectric materials at the preamplifier input. To minimize this source

of noise, which in some situations can be quite significant in magnitude,

detector circuit designs should keep the input traces on the circuit board as

short as possible. This is because the circuit board itself is often the lossy

dielectric material introducing this form of noise. Epoxy and glass, which

are usually considered to be good dielectrics (and circuit board materials) in

most circuit applications, are actually too lossy to be used in the usual

manner when designing detector circuits. Better construction materials are

Teflon and to a lesser extent alumina. These materials, however, are more

unusual and expensive than standard FR-4. To avoid the expense of Teflon

boards, consider lifting the input lines off the circuit board in some fashion,

perhaps by suspending the input lines above the board using Teflon

standoffs. If electronic noise is not a primary consideration, however, it

may suffice to use short traces on an epoxy-based circuit board. The use of

coaxial cable to couple the detector to the preamplifier may introduce noise,

not only by adding capacitance (as mentioned previously), but also because

of the lossiness of the cable's dielectric layer. If coaxial cable absolutely

must be used between the detector and preamplifier, its length should be

as short as possible.

Estimating the Electronic Noise in a Detection System

It is often useful to know what the expected electronic noise will be in a

detection system while the system is still in the design phase.

The following equation can be used to estimate the noise level in a detection

system based on the CR-110 charge sensitive preamplifier. Estimates have

been made for factors (d) and (e) mentioned previously, assuming short

traces on an FR-4 circuit board (such as those found on Cremat's CR-150-

AC-C evaluation board). This equation may be useful in allowing the user to

calculate the optimal shaping time ( in s) minimizing the electronic noise

(ENC in electrons rms) for a given detector capacitance (Cin in pF) and

detector leakage current (Idin pA).

Frequently Asked Questions

What are charge sensitive preamplifiers?

Charge sensitive preamplifiers were developed to detect the total amount of

charge flowing from a detector as the result of a 'pulse' event, such as the

detection of individual particles or gamma-rays. The preamplifiers integrate

the pulse of current flowing from the detector over time (by virtue of a small

Figure 5. Ground loops, caused

by multiple paths to ground, can

make a detection system

sensitive to external RF.

det.

capacitance in the feedback loop) to produce an output which is proportional

to the charge into the preamplifier input. A large valued resistor in parallel

to the feedback capacitor slowly discharges the capacitor, restoring the

preamplifier output to its original state. Unlike voltage sensitive preamplifiers,

charge sensitive preamplifiers must have low input impedance so that the

preamplifier can easily sink (or supply) charge from the detector.

How are charge sensitive preamplifiers more suitable for use with

particle detectors than voltage sensitive preamplifiers?

Ionizing events within detectors generally produce an amount of ionized

charge that is proportional to the energy of the incoming particle or gamma-

ray. For this reason, the detector preamplifier should be configured in a

way to produce an output that is precisely proportional to this ionized

charge. Voltage sensitive preamplifiers were first used to read out solid

state detectors when they were first developed in the '40s. A problem was

noted, however, in that the signal voltage at the preamplifier input was not

only proportional to the ionized charge, but also inversely proportional to

the input capacitance. Because the detector capacitance is usually a weak

function of the temperature, temperature drifts were causing drifts in the

preamplifier gain and degrading the energy resolution. For this reason the

charge sensitive preamplifier was developed, which has a gain equal to the

reciprocal of the feedback capacitance, and more importantly independent

of the input capacitance. For many decades, charge sensitive preamplifiers

have been the standard design for use in detectors where the energy

measurement of individual ionizing events is of interest.

The decay time of the preamplifier output pulse is quite long. Do I

have to worry that pulses will build on previous pulses and cause a

'pile up' of events?

The point at which to be concerned about the effects of pulse 'pile up' is

after the preamplifier output pulse has been filtered through a shaping

amplifier. The shaping amplifier (also called 'linear amplifier', 'spectroscopy

amplifier', or 'pulse amplifier') dramatically changes the shapes of the pulses,

generally giving them a longer risetime and a much quicker fall time, and

restores the baseline to prevent pile up as much as possible. Events that

appear to pile up before the shaping amplifier often become very clearly

separated after the shaping amplifier.

What is the bandwidth of the CR-110?

The term 'bandwidth' is generally not used when discussing charge sensitive

preamplifiers - instead one describes their rise time due to a delta current

pulse input (which charges the feedback capacitance), and their decay time

due to the discharge of the feedback capacitance through the feedback

resistance. In general, one seeks a fast pulse rise time, but not necessarily

a short decay time. In fact, if the feedback resistor value were substantially

decreased in order to quicken the decay time, the added thermal noise due

to this decreased resistance would be unacceptable.

How can we check to see whether the preamplifiers are operating

within the specified noise level?

The method described here requires the following:

1. A test circuit board (such as the CR-150-X) with an appropriate power

supply.

2. A low noise Gaussian shaping amplifier, having a shaping time of 1 s.

The CR-200-1s Shaping Amplifier used with the CR-160 evaluation board

would be suitable.

3. A pulse height analyzer.

4. A tail pulse generator or square wave generator.

5. A silicon p-i-n photodiode (Hamamatsu S1223 or equivalent), and a bias

supply (100 volts if using the Hamamatsu S1223).

6. A small 241Am isotopic source.

To measure the noise of the preamplifier, the gain of the detection system

must first be precisely measured (in keV per channel). To do this, construct

the circuit shown in Figure 2 (the CR-150-AC-X test board could be used

for this). A p-i-n photodiode should be used as the 'detector', and a bias

power supply should reverse bias the detector to its maximum allowed

value. The 241Am source should be oriented so that its emissions can

irradiate the photodiode. The circuitry and photodiode should be in a well

shielded, light tight box. Route the preamplifier output to the Gaussian

shaping amplifier (1 s), which should have its output routed to a pulse

height analyzer. Acquire a 241Am pulse height spectrum, in which you

should be able to clearly detect the 60 keV gamma-ray emission (see

Figure 6). Note the channel number at which the 60 keV photopeak is

observed. The gain of the detection system is the ratio: peak channel

number / 60 keV.

Next, disconnect the input lead of the preamplifier (pin 1) from the test

circuit board. This can be done a using a variety of methods, but make sure

that pin 1 is left floating and does not touch the circuit board or other

components. Connect the tail pulse generator (or square wave generator)

to the preamplifier via a small valued capacitor of no more than just a

couple pF. Alternatively, you can use a 'dangling wire' connected to the tail

pulse generator and rely on the small capacitive coupling between the input

and the wire to make this connection (be sure, though, that the wire does

not move during the subsequent measurements). Acquire a pulse height

spectrum of the tail pulse signal, which should appear as a Gaussian

distrubution. Measure the width of this distrubution by measuring, in

channels, the full width at half the maximum value (denoted as FWHM).

The noise can then be calculated by dividing by the previously measured

gain, to yield a figure having units keV FWHM (Si). To convert this figure to

the more generally applicable units of electrons RMS, divide by 0.0036 keV

(the ionization efficiency of silicon) and divide again by 2.355 (converting

FWHM measurements to RMS).

Figure 7 above shows the

power dissipation of the

CR-110 charge sensitive

preamplifier as a function

of power supply voltage.

This assumes the output

is unloaded and the input

unconnected.

0100200300400

0

200

400

600

800

1000

1200

Figure 6

241Am spectrum

60 keV emission

# counts

channel #

0

100

200

300

400

6 7 8 9 10 11 12 13

supply voltage

power dissipation (mW)

Figure 7

Table 4: Ordering Information

Model No. Description Order No.

CRXXX Charge sensitive preamp, SHV, 2kV/10nF, 1.4V/pC HY100

CR 110 Charge sensitive preamp, SHV, 2kV/10nF, 150mV/pC HY110

CR 111 Charge sensitive preamp, SHV, 2kV/10nF, 15mV/pC HY111

CR 112 Charge sensitive preamp, SHV, 2kV/10nF, 1.5mV/pC HY112

CR 113 Charge sensitive preamp, SHV, 4kV/4.7nF, 1.4V/pC HY113

Table 1: Sensitivity Versions

preamp

model

gain (mV / pico-

Coulomb)

max. detect.

pulse (e-)

Equiv. noise in sili-

con keV (FWHM)

CR 110 1400 1071.7 keV

CR 111 150 1086.0 keV

CR 112 15 10965 keV

CR 113 1.5 1010 230 keV

preamp

model

noise (ENC) in

e-RMS*

noise (ENC)

slope e-/pF

rise time

(Cd =0pF)

rise time

slope

CR 110 200 e-4 e-/pF 7ns 0.4ns/pF

CR 111 630 e-3.7 e-/pF 3ns 0.25ns/pF

CR 112 6,800 e-28 e-/pF 6ns 0.25ns/pF

CR 113 24,000 e-27 e-/pF 20ns 0.25ns/pF

Table of contents

Other Fast Amplifier manuals