FASTflo WH42 Guide

Working towards

a cleaner future

FASTflo

Installation Design Guide

This manual must be kept with the appliance October 2010

Part No E835

Continuous Flow Wall Hung Balance Flue

Water Heaters for Natural Gas an Propane

WH42, WH56, WHX56, LWH56, WHX56, LWHX56

Repro uction of any information in this publication by any metho is not permitte

unless prior written approval has been obtaine from An rews Water Heaters.

An rews Storage Water Heaters have been esigne an manufacture to comply

with current international stan ar s of safety. In the interests of the health an safety

of personnel an the continue safe, reliable operation of the equipment, safe working

practices must be employe at all times. The attention of UK users is rawn to their

responsibilities un er the Health an Safety Regulations 1993.

All installation an service on An rews Water Heaters must be carrie out by properly

qualifie personnel an , therefore, no liability can be accepte for any amage or

malfunction cause as a result of intervention by unauthorise personnel.

An rews Water Heaters’ policy is one of continuous pro uct improvement an ,

therefore, the information in this manual, whilst completely up to ate at the time of

publication, may be subject to revision without prior notice.

Further information an assistance can be obtaine from:

An rews Water Heaters

Woo Lane, Er ington,

Birmingham B24 9QP

Tel: 0845 070 1055

Fax: 0845 070 1059

Email: an rews@baxigroup.com

Website: www.an rewswaterheaters.com

THE ANDREWS WATER HEATERS COVERED IN THIS GUIDE

ARE FOR USE WITH NATURAL GAS OR PROPANE ONLY

Copyright An rews Water Heaters 2010

Andrews Installation Design Guide for WH and WHX Model Water Heaters

Fig No. DESCRIPTION

1Typical Installation - Single Heater

2Typical Installation - Single Heater with Secondary Return

3Typical Installation - Two Heaters

4Typical Installation - Two Heaters with Quick Connect Cord

5Typical Installation - Three Heaters with Secondary Return

6Typical Installation - Four Heaters with Electronic System Controller Kit

7Technical Note - Water Flow Rates and Performance Chart

8Typical Installation - Electronic System Controller Kit

9Technical Note - Unvented System Kits

10 Typical Installation - Single Heater with ST Range Storage Cylinder

11 Typical Installation - Two Heaters with ST Range Storage Cylinder,

Quick Connect Cord and Secondary Return

12 Typical Installation - Three Heaters with ST Range Storage Cylinder

and Secondary Return

13 Technical Note - Flow Rate Head Loss and Pump Sizing

14 Technical Note - Pump Curves

15 Heater Dimensions - WH56 and LWH56

16 Heater Dimensions - WHX42, LWHX42, WHX56 and LWHX56

17 WH42, LWH42, WH56 and LWH56 Pre-assembled dual manifold unit dimensions

18 WH42, LWH42, WH56 and LWH56 Pre-assembled triple manifold unit dimensions

19 WHX56 and LWHX56 Pre-assembled dual manifold unit dimensions

20 WHX56 and LWHX56 Pre-assembled triple manifold unit dimensions

Please refer to the

FASTflo Specification

Sheet and Flue Selection

Guide for Flue Kit and

termination details

Remote controller kit

(part no. B285)

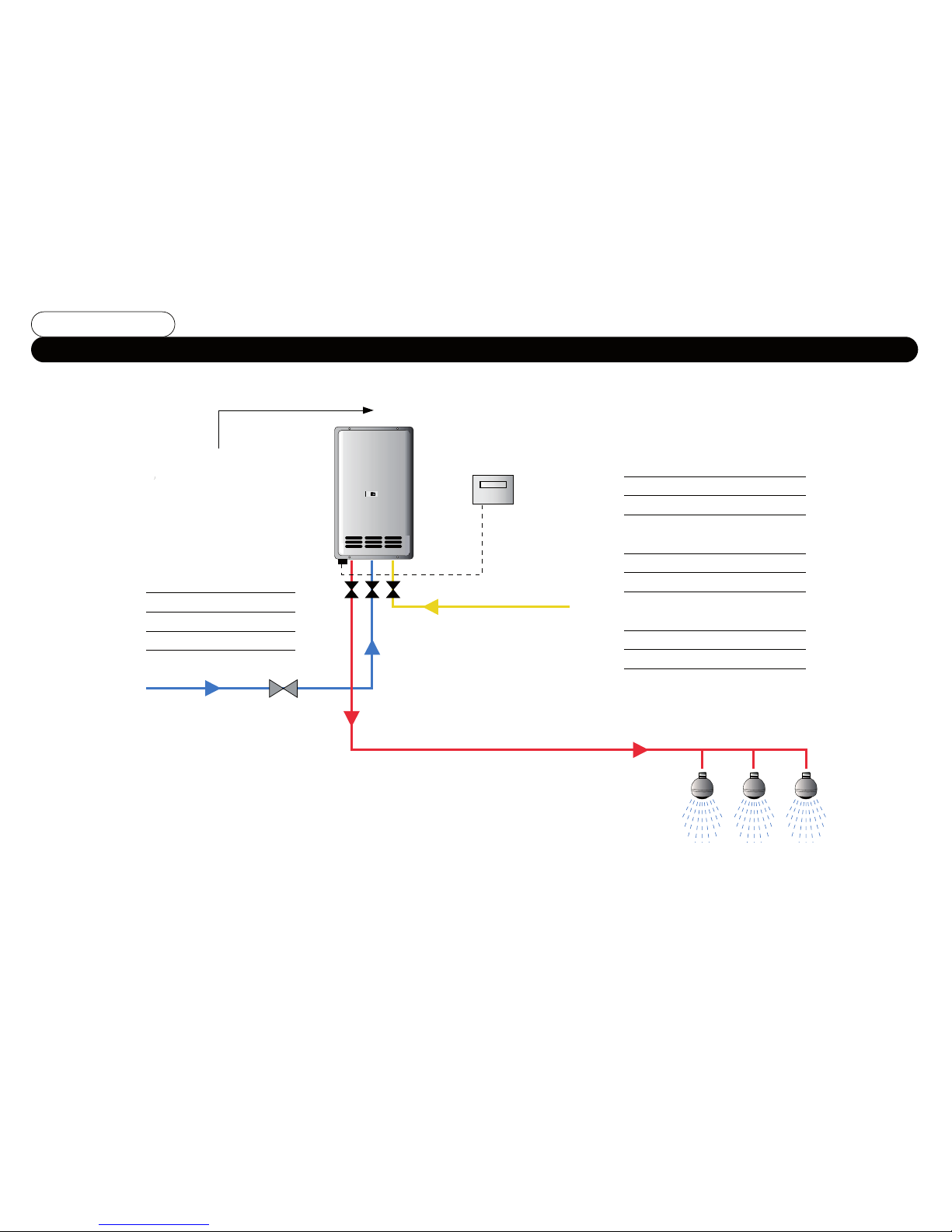

Gas

HWS flow

Hot Outlets

Water Supply Pressure

Min 1.0 bar

Max 10.0 bar

Min flow 3.5 ltrs/min

1. Stop cock

Gas rate for NG units

WH42 - 5.1 m3/hr

WH56, WHX56 - 6.5 m3/hr

Gas rate for Propane units

LWH42 - 1.9 m3/hr

LWH56, LWHX56 - 2.5 m3/hr

Dynamic Pressure

NG 20 mbar

Propane 37 mbar

1

Andrews WH and WHX Single Water Heater Installation Without Secondary Return

Fig No.1

Cold Supply

Please refer to the

FASTflo Specification

Sheet and Flue

Selection Guide for

Flue Kit and

termination details

Remote controller kit

(part no. B285)

Gas

HWS flow

Hot Outlets

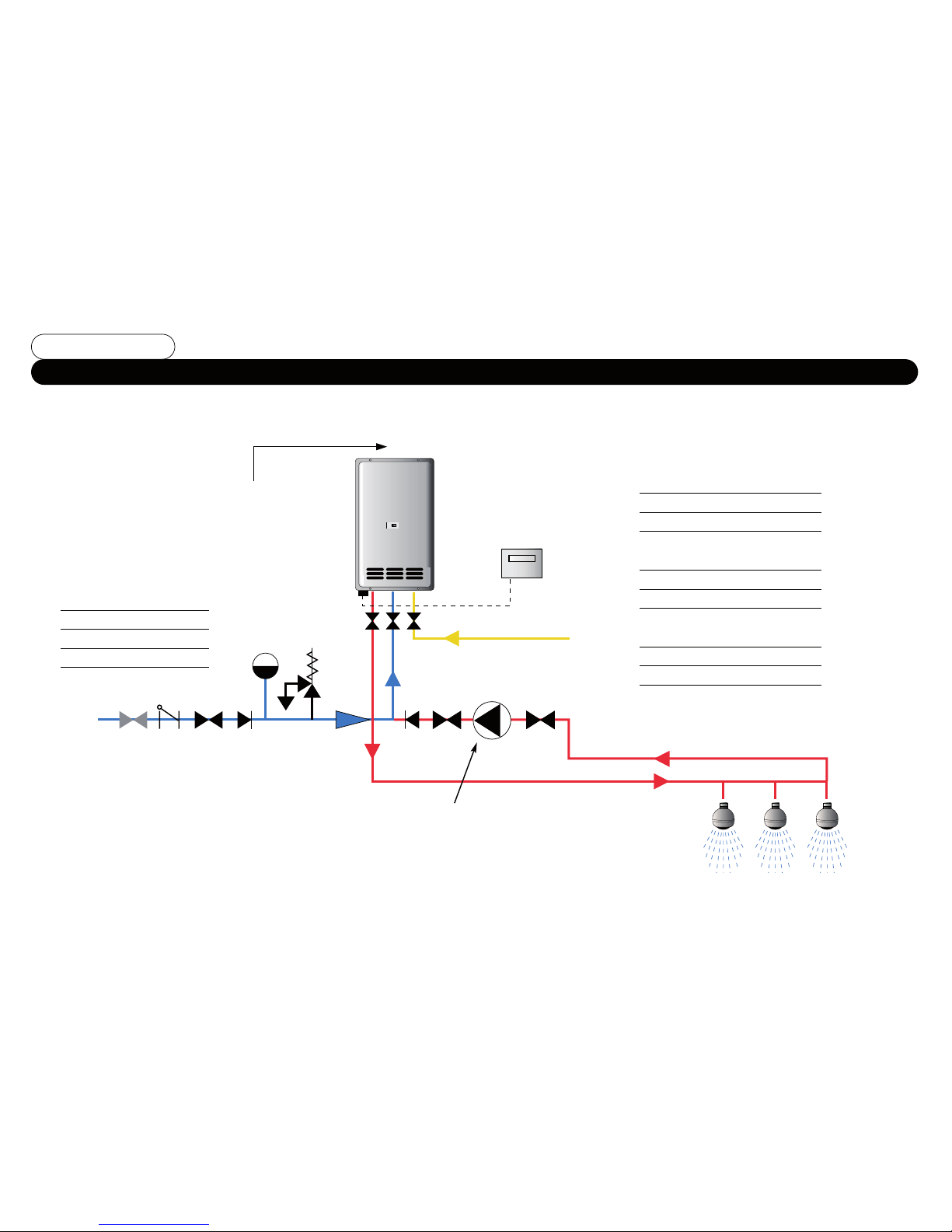

Cold Supply

1. Stop cock

2. Strainer

3. Pressure reducing valve

4. Non return valve

5. Expansion vessel

6. Expansion valve + tundish

7. Andrews bronze pump c/w

ball valve unions (part no. B249)

Water Supply Pressure

Min 1.0 bar

Max 10.0 bar

Min flow 3.5 ltrs/min

Bronze secondary return pump

see Fig. No’s. 13 and 14

Gas rate for NG units

WH42 - 5.1 m3/hr

WH56, WHX56 - 6.5 m3/hr

Gas rate for Propane units

LWH42 - 1.9 m3/hr

LWH56, LWHX56 - 2.5 m3/hr

Dynamic Pressure

NG 20 mbar

Propane 37 mbar

123 4

5

6

7

Andrews WH and WHX Single Water Heater Installation with Secondary Return

Fig No.2

Remote controller kit

(part no. B285)

Gas

HWS flow Where output may be below

7 ltrs/min see Fig. No. 4

Cold Supply

1. Stop Cock

Water Supply Pressure

Min 1.0 bar

Max 10.0 bar

Gas rate for NG units

WH42 - 5.1 m3/hr

WH56, WHX56 - 6.5 m3/hr

Gas rate for Propane units

LWH42 - 1.9 m3/hr

LWH56, LWHX56 - 2.5 m3/hr

Dynamic Pressure

NG 20 mbar

Propane 37 mbar

1

Andrews WH and WHX Multiple Water Heater Installation without Secondary Return

Fig No.3

Please refer to the

FASTflo Specification

Sheet and Flue Selection

Guide for Flue Kit and

termination details

Andrews WH and WHX Multiple Water Heater Installation with Quick Connect Cord Kit

Fig No.4

Single remote

controller

Gas

HWS flow

Hot Outlets

Cold Supply

1. Stop Cock

Water Supply Pressure

Min 1.0 bar

Max 10.0 bar

Quick Connect Cord Kit

(part no. B286)

Gas rate for NG units

WH42 - 5.1 m3/hr

WH56, WHX56 - 6.5 m3/hr

Gas rate for Propane units

LWH42 - 1.9 m3/hr

LWH56, LWHX56 - 2.5 m3/hr

Dynamic Pressure

NG 20 mbar

Propane 37 mbar

1

Please refer to the

FASTflo Specification

Sheet and Flue Selection

Guide for Flue Kit and

termination details

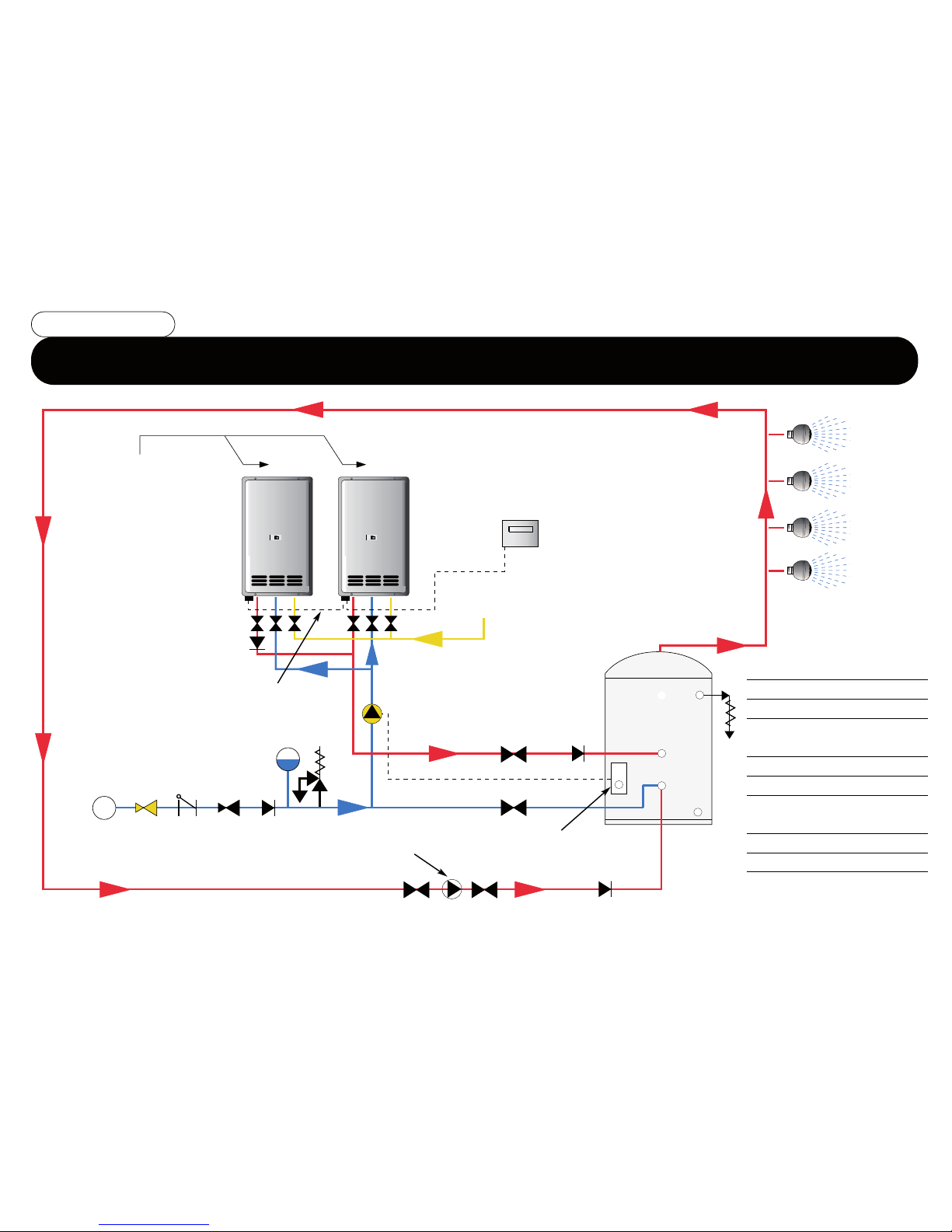

Andrews WH and WHX Multiple Water Heater Installation with Secondary Return

Fig No.5

Remote

controller

kit (part no

B285)*

*An Electronic System Controller Kit

can be used as an alternative when

manifolding up to six units. (see Fig.

No’s 6 and 8)

Gas

HWS flow

Hot Outlets

Cold Supply

Bronze secondary return pump

see Fig. No’s. 13 and 14

Gas rate for NG units

WH42 - 5.1 m3/hr

WH56, WHX56 - 6.5 m3/hr

Gas rate for Propane units

LWH42 - 1.9 m3/hr

LWH56, LWHX56 - 2.5 m3/hr

Dynamic Pressure

NG 20 mbar

Propane 37 mbar

1 2 3 4

7

5

6

4

Please refer to the

FASTflo Specification

Sheet and Flue Selection

Guide for Flue Kit and

termination details

1. Stop cock

2. Strainer

3. Pressure reducing valve

4. Non return valve

5. Expansion vessel

6. Expansion valve + tundish

7. Andrews bronze pump c/w

ball valve unions

(part no. B249)

Andrews WH56 and WHX56 Multiple Water Heater Installation with System Controller Kit

Fig No.6

Single remote

controller

System Controller in unit No. 1

(see Fig. No. 8)

Gas

HWS flow

Hot Outlets

Cold Supply

Gas rate per NG units

WH42 - 5.1 m3/hr

WH56, WHX56 - 6.5 m3/hr

Gas rate for Propane units

LWH42 - 1.9 m3/hr

LWH56, LWHX56 - 2.5 m3/hr

Dynamic Pressure

NG 20 mbar

Propane 37 mbar

1

1. Stop Cock

Water Supply

Pressure

Min 1.0 bar

Max 10.0 bar

Please refer to the

FASTflo Specification

Sheet and Flue

Selection Guide for

Flue Kit and

termination details

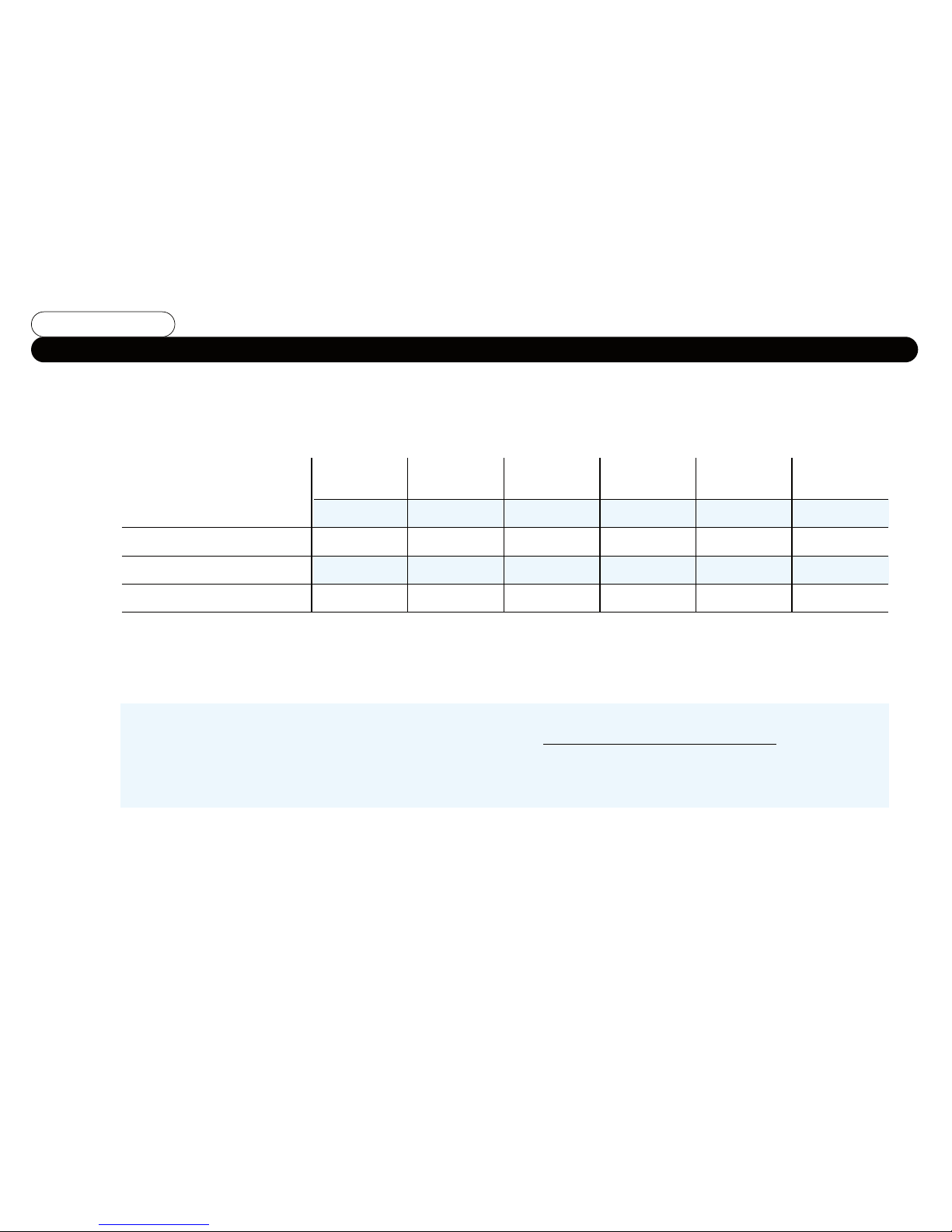

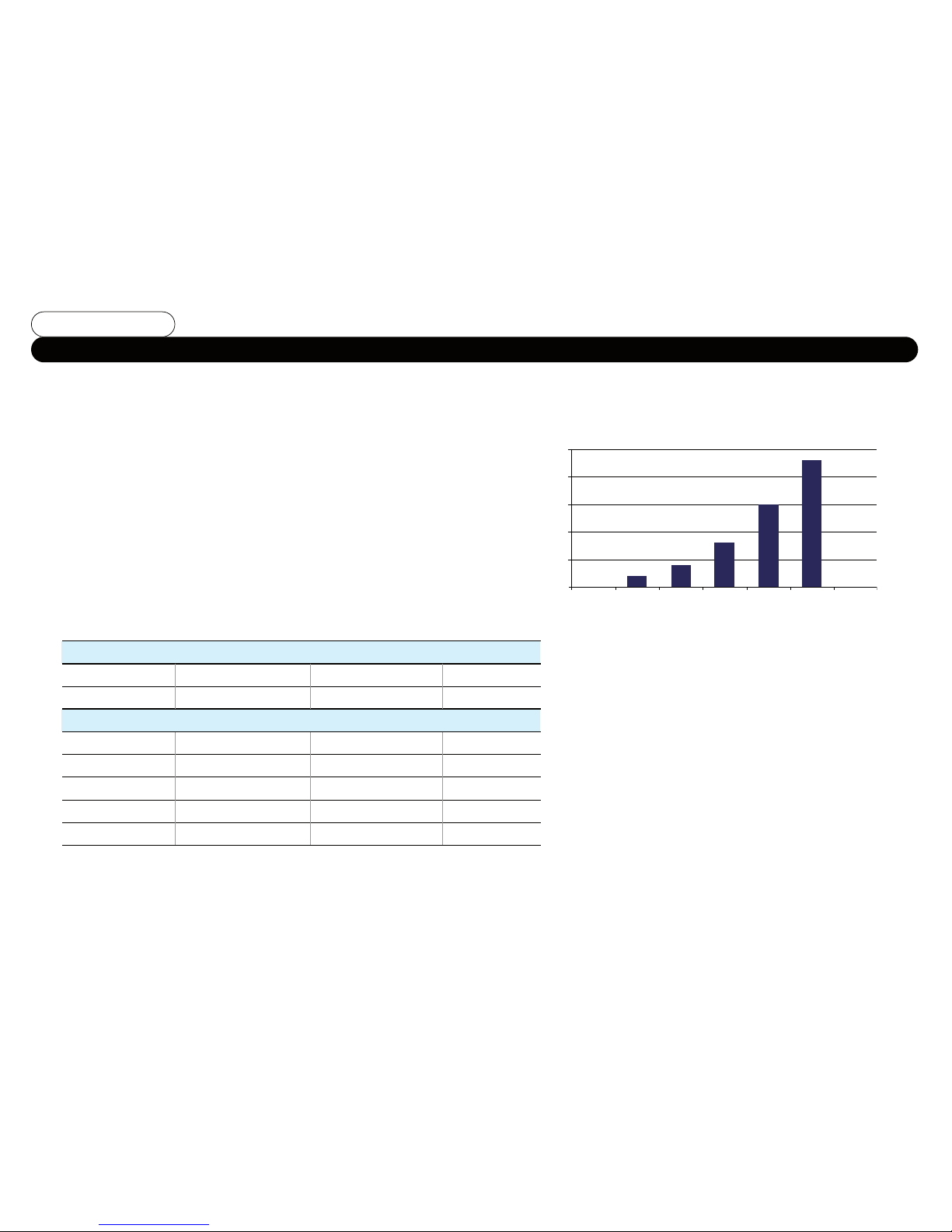

Andrews WH and WHX Water Flow Rates

Performance Chart

Fig No.7

Andrews Model Temperature Temperature Temperature Temperature Temperature Temperature

Reference

Rise 25ºC Rise 35ºC Rise 45ºC Rise 55ºC Rise 65ºC Rise 75ºC

L sec L min L sec L min L sec L min L sec L min L sec L min L sec L min

WH42,LWH42 0.40 24.0 0.29 17.4 0.22 13.2 0.18 10.8 0.15 9.2 0.13 8.0

WH56, LWH56 0.53 31.8 0.38 22.8 0.30 18.0 0.24 14.4 0.20 12.3 0.18 10.6

WHX56,LWHX56 0.53 31.8 0.38 22.8 0.30 18.0 0.24 14.4 0.20 12.3 0.18 10.6

The flow rate will vary dependant upon the temperature selected at outlet and the incoming water temperature.

The flow rate can be calculated using the following formula or by reference to the charts above.

In addition to the above the maximum flow through each heater is pre-set independent of temperature, maximum flow rate for the

WH42 is 24 L/min and maximum flow rate for the WH56 and WHX56 is 31.8 L/min.

WH42, LWH42 = 42 kW output

WH56, LWH56 = 55.8kW output

WHX56, LWHX56 = 55.8 kW output

(heater output) kW

Δt (temperature rise) x 4.2 specific heat

Flow rate L/S =

Water flow

at different

temperature

rises

Andrews System Controller Kit (Part No. B287) for WH56, LWH56, WHX56

Fig No.8

P

C

B

P

C

B

P

C

B

P

C

B

P

C

B

P

C

B

The System Controller Kit can be used as an alternative to the Quick Connect Cord Kit (two unit installation) or for controlling up to six

manifolded water heaters. The master unit (No.1) contains the System Controller module and includes plug connectors to enable the control

cords from the other units to be connected up to the master unit. In addition the System Controller incorporates the following standard

features, BEMS fault indication, Remote ‘Power On’ indication, Primary Pump connection via cylinder thermostat, Secondary Circulation

Pump connection and Remote Switching. A comprehensive installation manual is available from our sales department.

Single remote

controller

System controller Kit

(Part No. B287)

Typical installation

System operation

The control panel randomly selects some heaters at the ready stage and some at the standby stage, and heaters will start dependent upon

water flow and temperature settings. The system rotates the lead and standby units after every eight hours operating time. As the flow rates

increases additional units will fire thus maintaining the required system flow temperature. The remote controller must be connected to Unit

No. 1 and temperature settings on this controller will be communicated to the other manifolded heaters on the system. The System Controller

is not required when the installation incorporates a storage cylinder/ buffer vessel or if a constant large volume of hot water is required.

Unit No.1

Unit No.2Unit No.3

Unit No.4Unit No.5Unit No.6

Andrews WH & WHX Unvented System Kits

Fig No.9

If continuous flow water heaters are used on circulation systems or linked to a storage cylinder/buffer vessell

an unvented system kit is required to allow for expansion of the hot water system. The kit includes the

necessary safety devices required to conform to the current building regulations.

Three sizes of kit can be supplied and each contains a combined strainer/pressure reducing valve set to 3.5

bar, check valve, expansion valve set to 6.0 bar, tundish, 5 litre expansion vessel, wall bracket and hose.

When the system includes a storage cylinder/buffer vessel, a combined temperature/pressure relief valve

must be sized to suit the total input of all the water heaters installed (see table below).

This valve must be located at the top of the storage unit (see Fig. No. 10). In addition the size of the

expansion vessel must also be increased to suit both the storage cylinder plus the contents of the system

pipework (see expansion vessel table).

Unvented System Kit

Part No. Size

B235 3

/

4inch dia.

B234 1 inch dia.

B276 11

/

4inch dia.

Expansion Vessel

Part No. Size

C782 25 litre, 3.5 bar

C789 40 litre, 3.5 bar

E047 60 litre, 3.5 bar

C890 80 litre, 3.5 bar

Temperature and pressure Relief Valves Tundishes

Part No. Total Output Quantity & Size of Valves Part No. Size

C380

Up to 56kw 1 x 1 inch

C384 1 inch - 11

/

4inch

E242 Up to 112kw 1 x 11

/

2inch E326 1 1/2 inch - 2 inch

E242+C456 Up to 126kw 1 x 11

/

2inch + 1 x 3

/

4inch E497 2 inch - 21

/

2inch

E291 Up to 168kw 1 x 2 inch E497 2 inch - 21

/

2inch

E291+C380 Up to 224kw 1 x 2 inch + 1 x 1 inch E497+C384

2 inch - 21

/

2inch+ 1 inch - 11

/

4inch

Andrews WH and WHX Single Water Heater Installation with ST Range Storage Cylinder

Fig No.10

Remote

controller set

to 70ºCGas

Supply

Pump

(See Fig. No’s. 12/13)

HWS

flow

Storage

cylinder

Tank thermostat kit (part no.

C927) set to 65ºC

Cold Supply

NB. Size mains pressure group

to suit building design flow rate

Gas rate for NG units

WH42 - 5.1 m3/hr

WH56, WHX56 - 6.5 m3/hr

Gas rate for Propane units

LWH42 - 1.9 m3/hr

LWH56, LWHX56 - 2.5 m3/hr

Dynamic Pressure

NG 20 mbar

Propane 37 mbar

1 2 3 4

5

6

7

1. Stop cock

2. Strainer

3. Pressure reducing valve

4. Non return valve

5. Expansion vessel

6. Expansion valve + tundish

7. Andrews bronze pump c/w

ball valve unions (part no.

B249)

8. Combined temperature

and pressure relief valve

+ tundish

Please refer to the

FASTflo Specification

Sheet and Flue Selection

Guide for Flue Kit and

termination details

Hot Outlets

8

Andrews WH and WHX Multiple Water Heater Installation with ST Range Storage Cylinder,

Quick Connect Cord Kit and Secondary Return

Fig No.11

Remote controller

set to 70ºC

Gas

Supply

Pump

(See Fig. No’s. 12/13)

Quick connect

cord kit (part no.

B286)

HWS flow

Storage

cylinder

Tank thermostat kit (part

no. C927) set to 65ºC

Bronze secondary pump

Cold Supply

NB. Size mains pressure group to

suit building design flow rate

Gas rate for NG units

WH42 - 5.1 m3/hr

WH56, WHX56 - 6.5 m3/hr

Gas rate for Propane units

LWH42 - 1.9 m3/hr

LWH56, LWHX56 - 2.5 m3/hr

Dynamic Pressure

NG 20 mbar

Propane 37 mbar

1 2 3 4

5

6

7

1. Stop cock

2. Strainer

3. Pressure reducing valve

4. Non return valve

5. Expansion vessel

6. Expansion valve + tundish

7. Andrews bronze pump c/w

ball valve unions (part no.

B249)

8. Combined temperature

and pressure relief valve

+ tundish

Hot Outlets

Please refer to the

FASTflo Specification

Sheet and Flue Selection

Guide for Flue Kit and

termination details

8

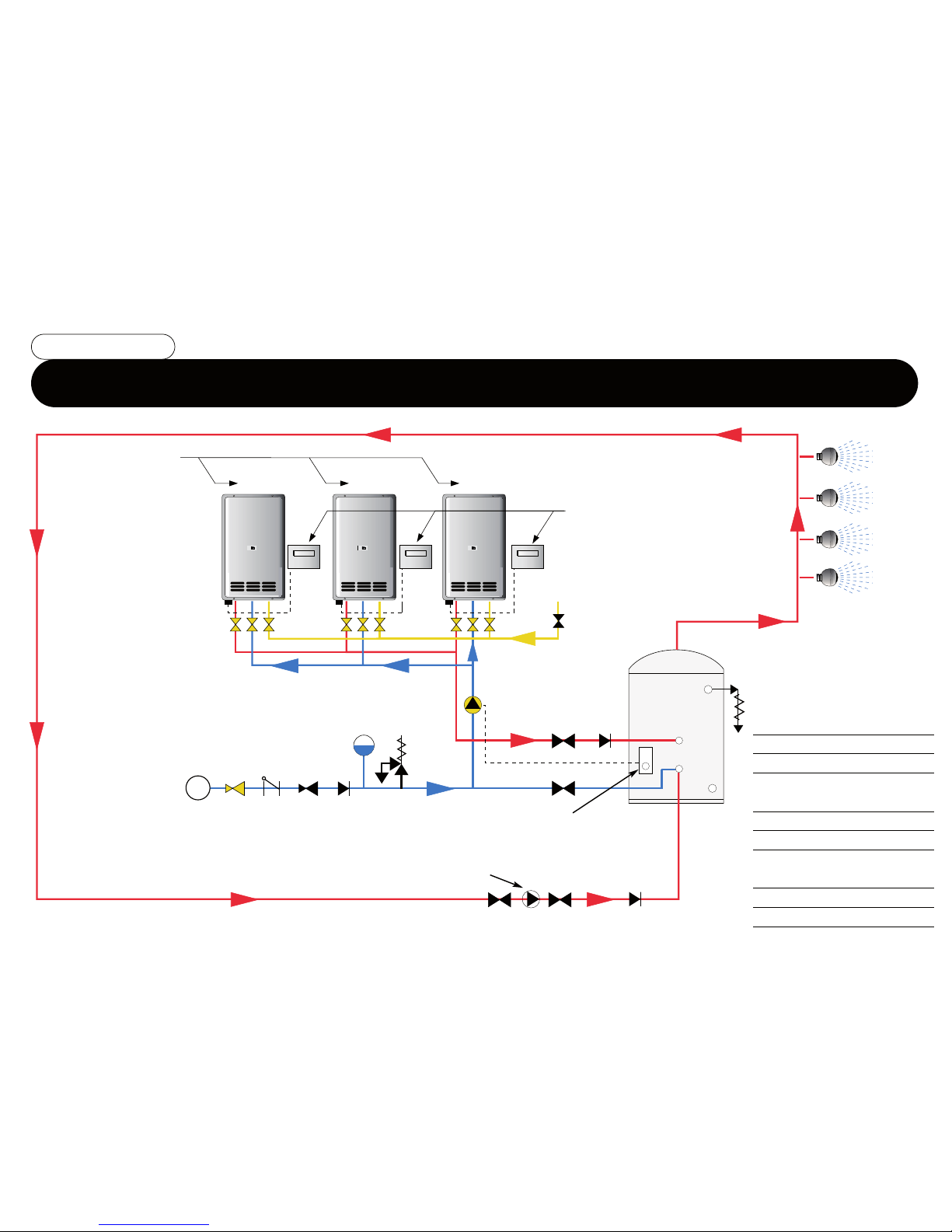

Andrews WH and WHX Multiple Water Heater Installation with ST Range Storage Cylinder and

Secondary Return

Fig No.12

Gas

Supply HWS flow Hot Outlets

Storage

Cylinder

Tank thermostat kit (part

no. C927) set to 65ºC

Bronze secondary

pump

Cold Supply

NB. Size mains pressure group to

suit building design flow rate

Gas rate for NG units

WH42 - 5.1 m3/hr

WH56, WHX56 - 6.5 m3/hr

Gas rate for Propane units

LWH42 - 1.9 m3/hr

LWH56, LWHX56 - 2.5 m3/hr

Dynamic Pressure

NG 20 mbar

Propane 37 mbar

1 2 3 4

4

5

6

7

1. Stop cock

2. Strainer

3. Pressure reducing valve

4. Non return valve

5. Expansion vessel

6. Expansion valve + tundish

7. Andrews bronze pump c/w ball

valve unions (part no. B249)

8. Combined temperature

and pressure relief valve

+ tundish

When using multiple units in conjunction

with a storage vessel the full output of all

heaters is required to provide maximum

recovery volume. In this case the primary

pump must be sized to give 8 litres/min

for each heater. See Fig No’s. 12 and 13.

Pump

(See Fig.

No’s. 12/13)

Remote

controller

kit (part no

B285)*

*An Electronic System

Controller Kit can be used

as an alternative when

manifolding up to six units.

(see Fig. No’s 6 and 8)

Please refer to the

FASTflo Specification

Sheet and Flue Selection

Guide for Flue Kit and

termination details

68

Flow Rate Head Loss and Pump Sizing

Fig No.13

The WH and WHX units will operate within a water inlet pressure

range from 1.0 bar to 10.0 bar.

When a pump is used with a storagae system or for secondary

return circulation only bronze or stainless steel pumps must be used.

The pump must be sized to give a minimum flow rate of 8 L/min

through each heater.

The head loss through the FASTflo range of products is due to the

friction generated when the water flows through the heat exchanger

and associated components.

Water Flow (litres/minute)

Head Loss (bar)

0

2.5

2

1.5

1

0.5

0

510 15 20 25 30

A suitable 3 speed bronze pump kit with ball valve unions to 28mm cu. can

be supplied by Andrews, part no.B249 (see Fig No. 14)

Pump Selection using multiple heaters (pump required for first unit only)

Number of units Flow rate required Approximate head Speed setting

1 8 l/min - 0.13 l/sec 50 kPa 2

Pump selection using multiple heaters (flow through all units)

2 16 l/min - 0.27 l/sec 50 kPa 2

3 24 l/min - 0.40 l/sec 60 kPa 3

4 32 l/min - 0.53 l/sec 60 kPa 3

5 48 l/min - 0.67 l/sec 60 kPa 3

6 48 l/min - 0.80 l/sec 60 kPa 3

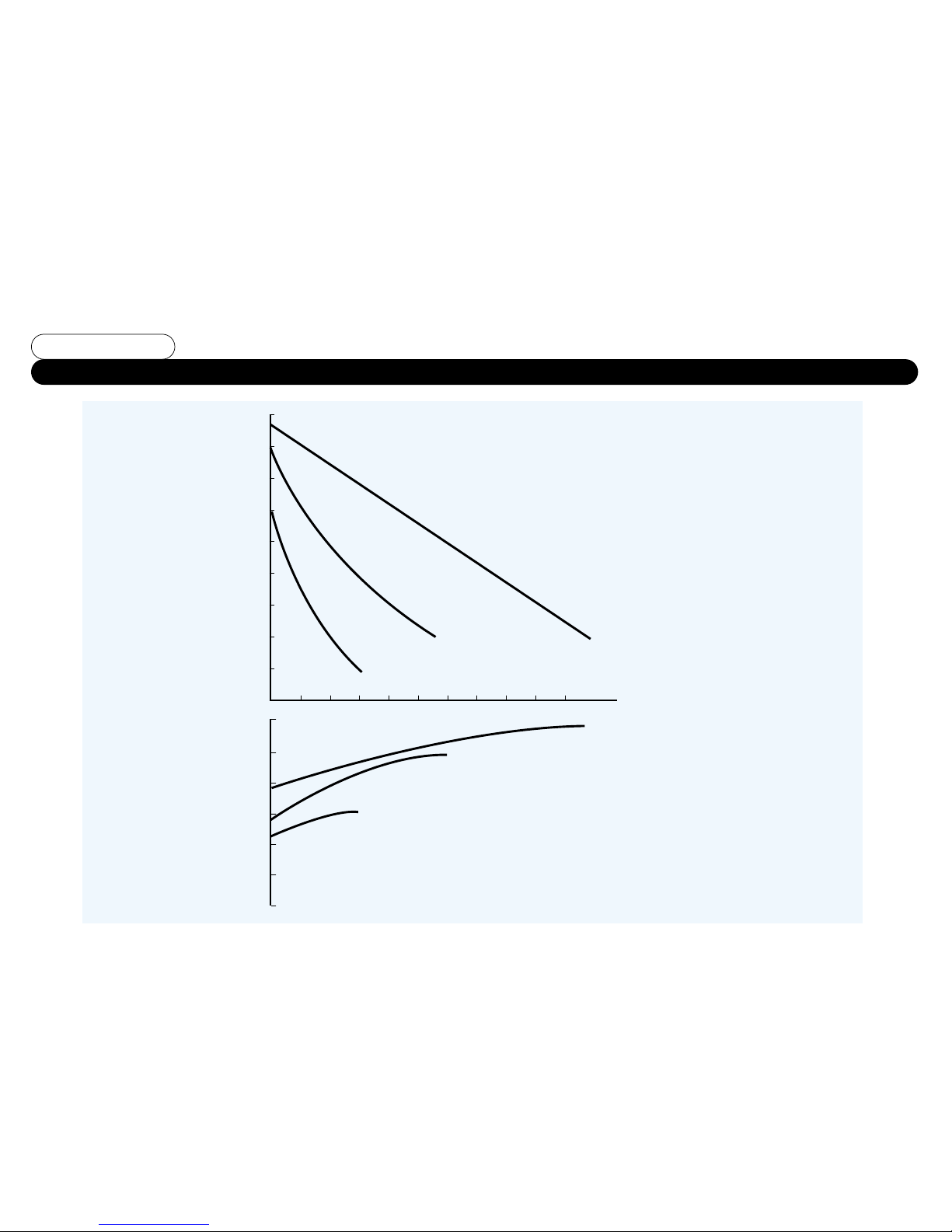

Pump Curves for Andrews 3 Speed Bronze Circulating Pump. Part No.B249

Fig No.14

0

P1

(W)

200

0 0.2

1

160

120

80

40

0

0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 Q(1/s)

2

3

4

5

6

7

8

(m)

H

SPEED 3

SPEED 2

SPEED 1

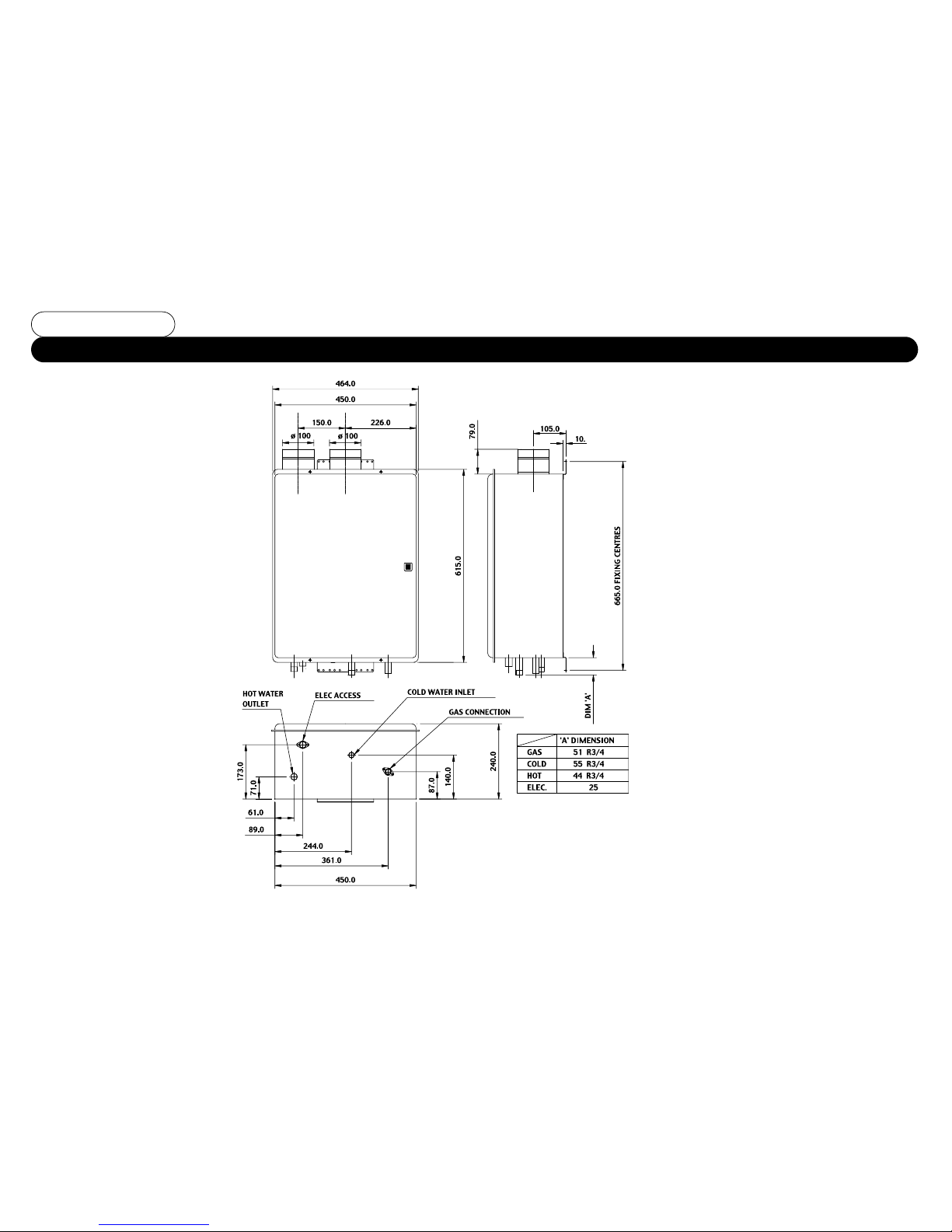

Dimensions WH42/LWH42/WH56 and LWH56

Fig No.15

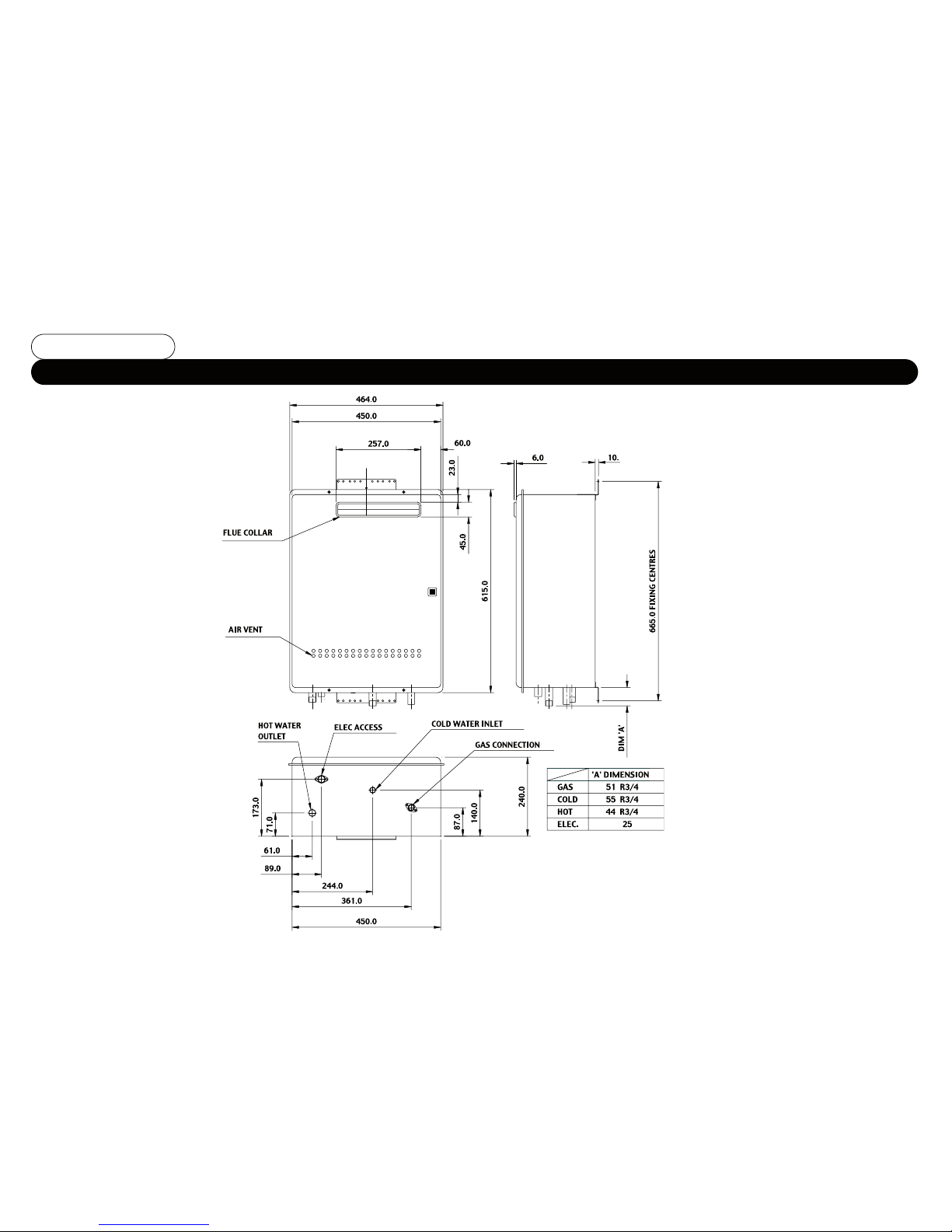

Dimensions WHX56 and LWHX56

Fig No.16

WH42, LWH42, WH56 and LWH56 Pre-assembled dual manifold unit dimensions

Fig No.17

This manual suits for next models

4

Table of contents

Popular Water Heater manuals by other brands

A.O. Smith

A.O. Smith aosbath D25A2 user guide

Weil-McLain

Weil-McLain C-1013 troubleshooting guide

Lochinvar

Lochinvar CH 600 PG CE Installation, commissioning, user & maintenance instructions

Sanyo

Sanyo SHP-TH90GDN-SW Technical manual

Bestway

Bestway Pool+ owner's manual

Lochinvar

Lochinvar 151 - 801 Operation manual

Graf

Graf RainHarvest Systems Top-Tank 323002 Installation instructions and maintenance

Nibe

Nibe UKV 200 installation instructions

STIEBEL ELTRON

STIEBEL ELTRON DHM 3 Operation and installation

Pentair

Pentair N20 instruction manual

Eurofred

Eurofred daitsu WITD-AQUATANK HP Series Installation and maintenance manual

Viessmann

Viessmann Vitocell 100-E Installation and service instructions