FAUDE C-Guide User manual

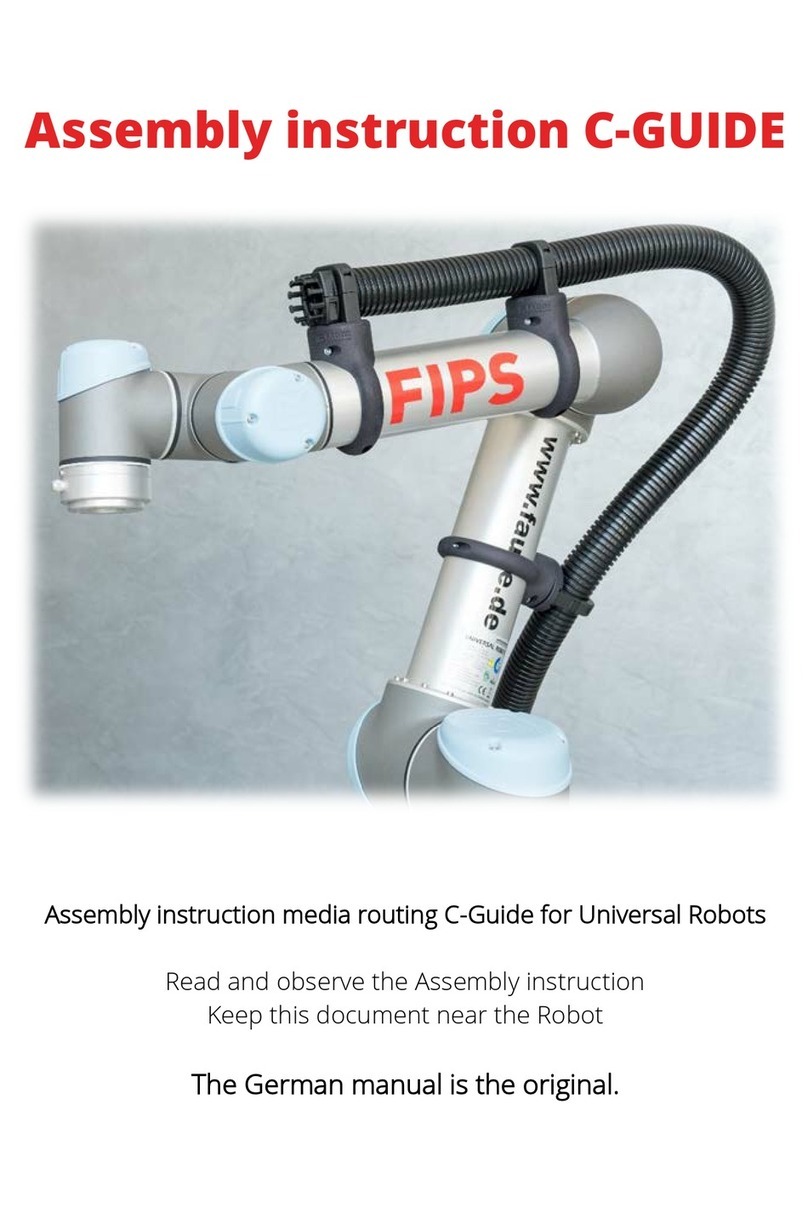

Assembly instruction C-GUIDE

Assembly instruction media routing C-Guide for Universal Robots

Read and observe the Assembly instruction

Keep this document near the Robot.

2

CONTENT

1. INCLUDED ITEMS...................................................................3

2. PRODUCT DESCRIPTION........................................................4

3. INSTALLATION ON THE ROBOT .............................................4

3.1 ASSEMBLY RIGID HOLDER.....................................................7

3.2 ASSEMBLY ROTATABLE HOLDER...........................................8

3.3 IMAGESDIRECTORY ...............................................................9

3.4 FURTHER ACCESSORIES FOR THE UR..................................10

3

1. INCLUDED ITEMS

The C-Guide for the UR3 consists of following parts.

Image1: Scope of supply C-Guide UR3

1. Fixed Holder with pressure interception

2. Media hose

3. Rotation bracket

4. Hose clamp

1

2

3

4

4

2. PRODUCT DESCRIPTION

FAUDE offers the possibility by the attachment of the media routing C-

Guide of supplying electrical and pneumatic lines over the robot to the final

effector.

Due to the innovative robust design of the C-Guide the lines are guided safely

and flexible along the robot. The design allows a long lifetime without kinks or

injuries at the lines and hoses in every robot position.

3. INSTALLATION ON THE ROBOT

The following chapter describes the assembly of the FAUDE C-Guides at the

Universal Robot UR3.

The UR3 must be built up and be able to work before you can start with the

assembly of the C-Guide. The following illustration shows a robot

construction that allows easy assembly of the C-Guide.

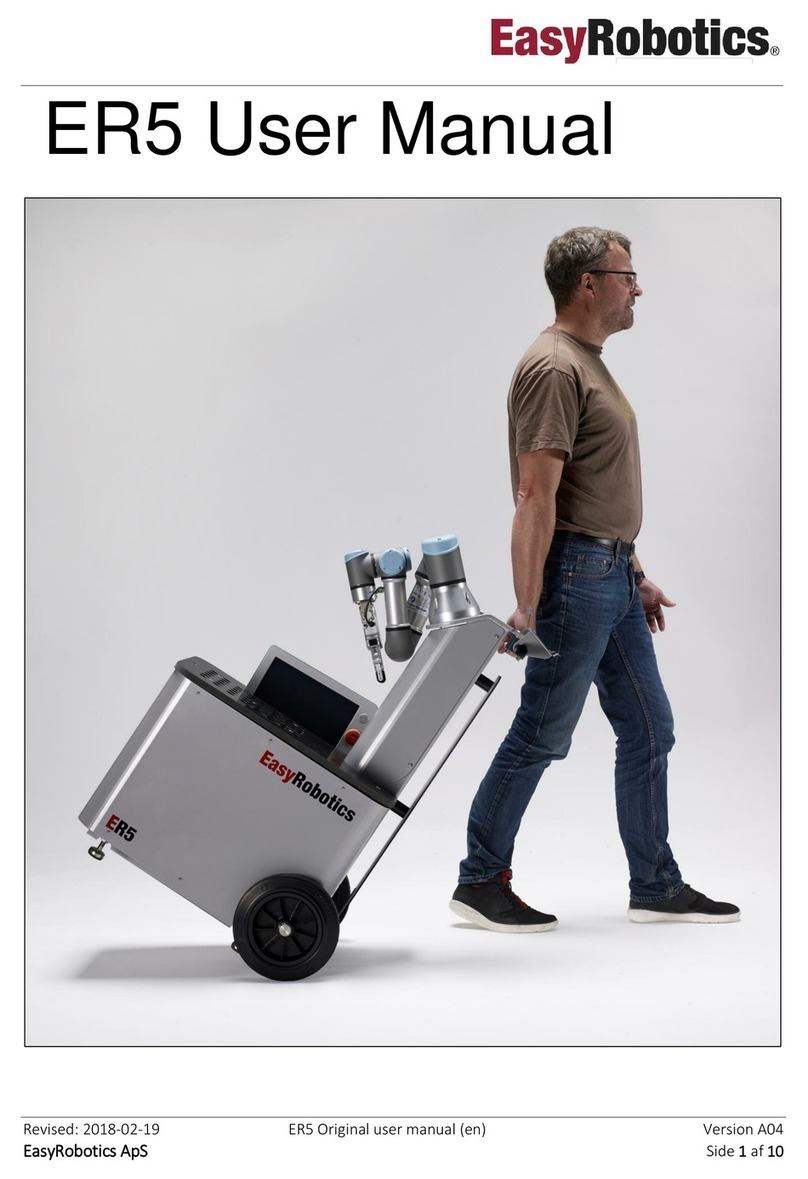

Image 2: Possible position for the assembly

5

The C-Guide of the UR3 is kept safely on the robot arm by the two included

holders. The holders are one fixed holder with a cable clamp and a rotatable

holder. These holders are preassembled at delivery like in Image 1. Before

mounting the holders you have to disassembly them first by unscrewing the

three Hexagon head screws M4x20 (size 3) on each holder.

Image 3: Explosion view of the C-Guide holders

The fixed holder with the cable clamp is fastened at the forearm, the

rotatable holder at the upper arm of the robot. It has to be taken care at the

assembly of the rigid holder that the comb which serves for the cable clamp

of the tubes and lines, points in the direction of the robot tool. There isn’t any

predefined orientation for the rotatable holder. Moreover, it has to be taken

care at the attachment of the C-Guide that the surface of both robot arms

are free from oil and dust. If this is not the case all robots from the Company

Universal Robot can be cleaned with a customary industry cleaner. The care

notes of the operator’s manual have to be taken into account.

6

Image 4: UR3 with mounted C-Guide holders

The hose clamp listed under position 5 in the description of included parts is

used to attach the media hose to the system part, the table plate etc. on

which the robot is mounted. This is to be mounted individually as a result of

the requirements.

Forearm

Rigid holder

Cable clamb

Rotation bracket

Upper arm

7

Image 5: Forearm with one part of the holder

Image 6: Forearm with both parts of the holder

Image 7: Forearm with C-Guide

3.1 ASSEMBLY RIGID HOLDER

After opening the three

M4x20 screws the rigid

holder can be pulled apart.

The comb for the cable

clamping as well as the tube

holder remain on one side

of the C- Guide holder each.

Then one side of the holder

is placed on the forearm.

When this is done, the

second side of the holder is

put on.Afterwards the

three Hexagon head screws

M4x20 (size 3) have to be

tightened. Please ensure

that all screws are

tightened evenly.

At the last step of the

assembly of the rigid C-

Guide holder, the media

hose will be clipped into the

holder.

8

Image 8: Upper arm with one side of the holder

Image 9: Upper arm with one side of the holder

3.2 ASSEMBLY ROTATABLE HOLDER

After opening the three screws

(M4x20) the rotatable holder can

be pulled apart. The ball bearing,

including the hose holder,

remains on one side of the C-

guide holder. After that, one side

of the holder has to be put on

the robot arm.

When this is done, the second

side of the holder is put on.

Afterwards the three Hexagon

head screws M4x20 (size 3) have

to be tightened. Please ensure

that all screws are tightened

evenly

At the last step of the

assembly of the rotatable C-

Guide holder, the media hose

will be clipped into the holder.

Image 10: Upper arm with both sides of the holder

9

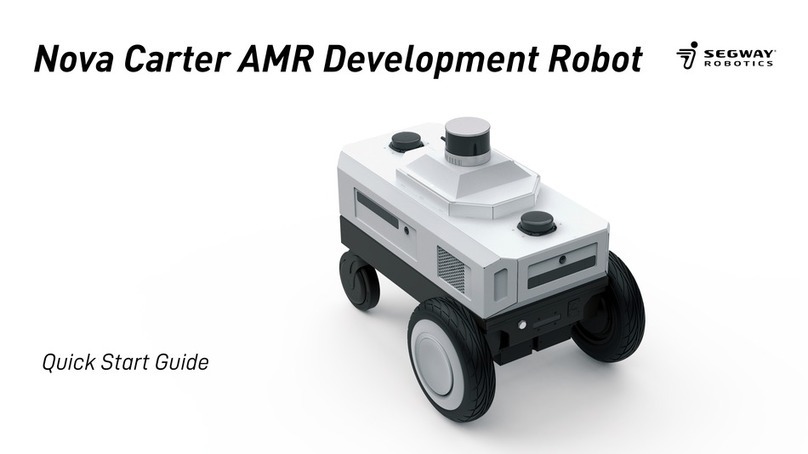

Image 11: UR3 complete mounted C-Guide

3.3 IMAGESDIRECTORY

Image 1: Scope of supply C-Guide UR3......................................................................3

Image 2: Possible positions for the assembly...........................................................4

Image 3: Explosion view of the C-Guide holders......................................................5

Image 4: UR3 with mounted C-Guide holders ..........................................................6

Image 5: Forearm with one part of the holder .........................................................7

Image 6: Forearm with both parts of the holder......................................................7

Image 7: Forearm with C-Guide....................................................................................7

Image 8: Upper arm with one side of the holder.....................................................8

Image 9: Upper arm with both sides of the holder .................................................8

Image 10: Upper arm with C-Guide.............................................................................8

Image 11: UR3 with complete mounted C-Guide ...................................................9

10

3.4 FURTHER ACCESSORIES FOR THE UR

PROLIGHT

When implementing HRC applications, special

requirements must be met.

In particular, the standards and guidelines for the

components must be observed, so that injuries to

employees cannot occur. This also includes the

connection socket of axis 6 on the UR3 and UR5

robots. This must be additionally secured.

Furthermore, operators are obligated to show that

the robot is active by a corresponding visualization.

FAUDE offers the ProLight lighting protection ring for this purpose

This is used to meet the safety requirements of industrial robots for safe “human - robot

collaborations”.

Order number: PROLIGHT: FAP17101

SACA- SAFETY- CASE

The requirements of an enabled device according to

DIN EN ISO 10218-1 are fulfilled with the retrofit of the

UR teach panels with the SaCa safety case, including

the 3-level enabling switch.

Single-handed ergonomic

operation permits additional

actuation of the button for

freedrive mode. This means

one hand is free for manual guidance of the robot. It is suitable for both

left and right handed operation.

With the 3-point set down the operating panel is available at any time for

safe and comfortable programming.

Order number: SACA- SAFETY- CASE: FAP16610

11

SAFETY- BUNDLE

According to the professional association and the standards for robots, whether it is a

lightweight robot or an HRC robot, the current robot standard DIN EN ISO 10218-1 must be

fulfilled.

It is stated there that each robot requires a mode selector and an enabling switch.

The safety system from FAUDE fulfills this with consideration of the two-channel and adaptation

of the user interface.

The FAUDE safety bundle expands the

UR robots with additional functions to

increase the safety and fulfilment of

safety specifications on industrial robots

(DIN EN ISO 10218-1).

The specified operating mode selection is

ensured by the Electronic Key System

(EKS). The EKS is used to manage access

and control of the system using an

electronic key with different authorisation

levels. Using a 3-level enabling switch on

the FAUDE safety case, the requirement

for an enabling device for set up mode is

fulfilled.

While the operator (black) can only start

and stop the system, the programmer

(green) can adjust the teach points in a specific area.

The maintenance person, on the contrary, has with the access authorization all possibilities to

put the robot into operation or to reorient it.

Using the Siemens S7 safety controls other external devices via PROFINET or PROFIsafe can be

connected.

Order number: SAFETY- BUNDLE: FAP16610

FAUDE Automatisierungstechnik GmbH

Max-Planck-Str. 10 – 71116 Gaertringen – Germany

Telephone +49-7034-2567-0 – Fax-67

Email: mailto:faude@faude.de – Web: www.faude.de/

Other manuals for C-Guide

1

Table of contents

Other FAUDE Robotics manuals