Faulhaber MC 5004 P STO User manual

WE CREATE MOTION

Installation

Instructions

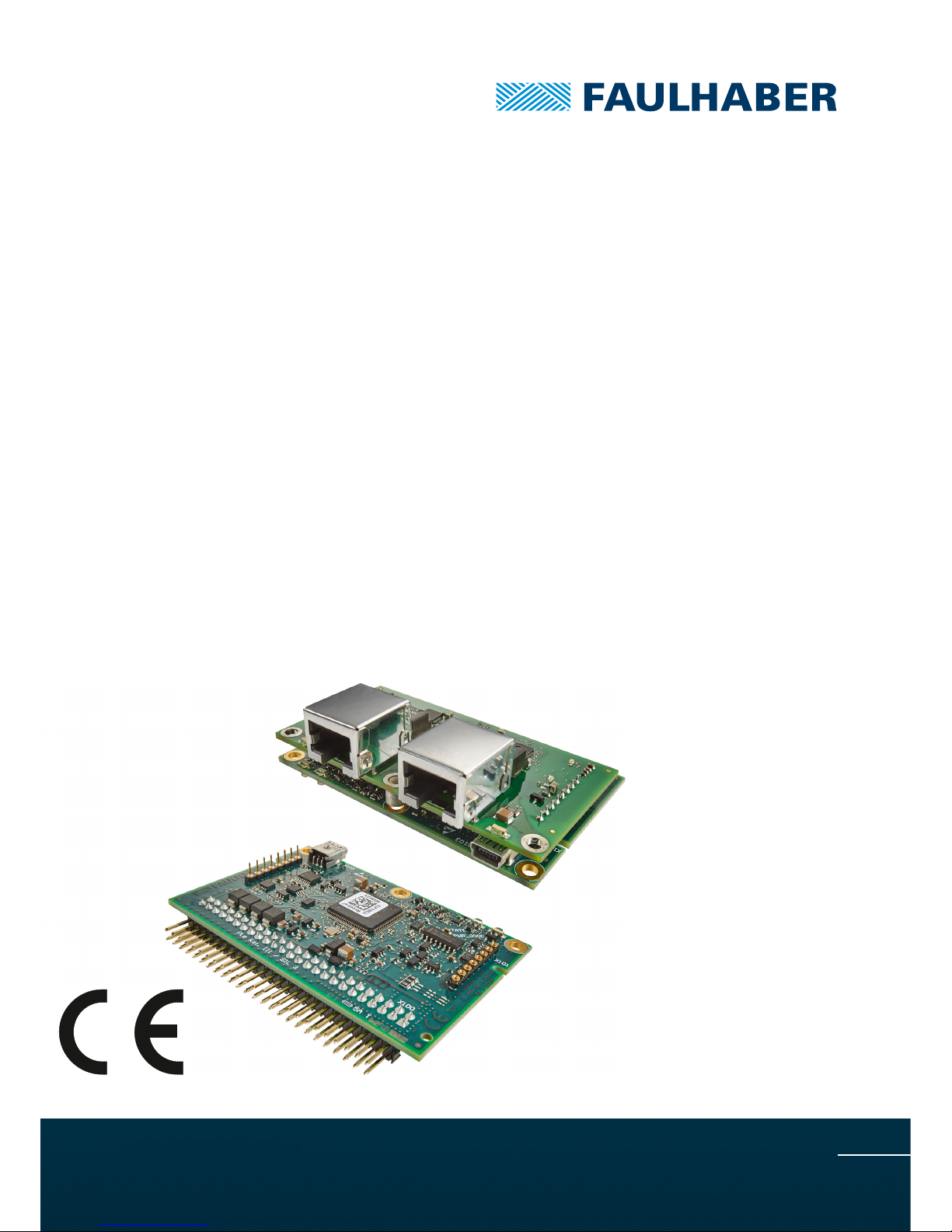

MC 5004 P STO

Original Instructions

EN

Imprint

2

Version:

1st edition, 03-05-2018

Copyright

by Dr. Fritz Faulhaber GmbH & Co. KG

Daimlerstr. 23 / 25 · 71101 Schönaich

All rights reserved, including those to the translation.

No part of this description may be duplicated, reproduced,

stored in an information system or processed or

transferred in any other form without prior express written

permission of Dr. Fritz Faulhaber GmbH & Co. KG.

This document has been prepared with care.

Dr. Fritz Faulhaber GmbH & Co. KG cannot accept any

liability for any errors in this document or for the

consequences of such errors. Equally, no liability can be

accepted for direct or consequential damages resulting

from improper use of the equipment.

The relevant regulations regarding safety engineering

and interference suppression as well as the requirements

specified in this document are to be noted and followed

when using the software.

Subject to change without notice.

The respective current version of this technical manual is

available on FAULHABER's internet site:

www.faulhaber.com

1st edition, 03-05-2018 7000.05063, 1st edition, 03-05-20187000.05063

1st edition, 03-05-2018 7000.05063, 1st edition, 03-05-20187000.05063

Content

3

1 About this document ....................................................................................................... 5

1.1 Validity of this document ...................................................................................... 5

1.2 Associated documents ............................................................................................ 5

1.3 Using this document .............................................................................................. 5

1.4 List of abbreviations ............................................................................................... 6

1.5 Symbols and designations ...................................................................................... 7

2 Safety ................................................................................................................................ 8

2.1 Intended use ........................................................................................................... 8

2.2 Safety instructions .................................................................................................. 9

2.2.1 Dangers in the event of damages and changes.................................... 9

2.2.2 Correct installation and commissioning .............................................. 10

2.2.3 Heat development ................................................................................ 10

2.3 Environmental conditions .................................................................................... 10

2.4 Requirements on the higher-level control .......................................................... 11

2.5 EC directives on product safety ........................................................................... 12

3 Product description ........................................................................................................ 13

3.1 General product description ................................................................................ 13

3.2 Product information ............................................................................................. 15

3.3 Technical data ....................................................................................................... 16

3.4 Product variants .................................................................................................... 17

3.4.1 Controller PCBs...................................................................................... 17

3.4.1.1 Standard PCB.......................................................................... 17

3.4.1.2 EtherCAT PCB ......................................................................... 18

3.4.1.3 State machine and start routine ........................................... 20

3.4.2 Motherboard......................................................................................... 23

4 Installation ...................................................................................................................... 25

4.1 Mounting .............................................................................................................. 25

4.1.1 Mounting instructions .......................................................................... 25

4.1.2 Installing the Motion Controller PCB on the motherboard ............... 26

4.1.3 Installing the Motion Controller PCB in the top-hat-rail housing ..... 27

4.2 Electrical connection ............................................................................................ 28

4.2.1 Notes on the electrical connection ...................................................... 28

4.2.2 Drive connections.................................................................................. 29

4.2.3 Screening ............................................................................................... 30

4.2.4 Connection of the power supply ......................................................... 31

4.2.4.1 Power supply.......................................................................... 31

4.2.5 Connector pin assignment.................................................................... 32

4.2.5.1 Pin assignment of the X100 connector strip of the

Motion Controller.................................................................. 32

4.2.5.2 Pin assignment of the motherboard (motor side) ............... 34

4.2.5.3 Pin assignment of the motherboard (supply side)............... 39

4.2.6 Motherboard: connection at the motor side ...................................... 41

4.2.7 I/O circuit diagrams ............................................................................... 44

4.2.7.1 Inputs...................................................................................... 44

4.2.7.2 Outputs................................................................................... 47

4.2.8 External circuit diagrams ...................................................................... 50

1st edition, 03-05-2018 7000.05063, 1st edition, 03-05-20187000.05063

Content

4

4.3 Information on initial commissioning ................................................................. 54

5 Maintenance and diagnostics ........................................................................................ 55

5.1 Maintenance tasks ................................................................................................ 55

5.2 Diagnostics ............................................................................................................ 55

5.2.1 Standard PCB ......................................................................................... 55

5.2.2 EtherCAT PCB ........................................................................................ 56

5.2.3 Self-test .................................................................................................. 57

5.3 Troubleshooting ................................................................................................... 57

6 Accessories ...................................................................................................................... 58

7 Warranty ......................................................................................................................... 59

8 Additional documents .................................................................................................... 60

8.1 Data sheet ............................................................................................................. 60

8.2 Declaration of Incorporation ............................................................................... 62

8.3 Declaration of Conformity ................................................................................... 63

8.4 EC type-examination certificate .......................................................................... 66

1st edition, 03-05-2018 7000.05063, 1st edition, 03-05-20187000.05063

About this document

5

1 About this document

1.1 Validity of this document

This document contains the information necessary for the intended use of the

MC 5004 P STO series.

This document is intended for use by trained experts authorised to perform installation and

electrical connection of the product.

All data in this document relate to the standard versions of the series listed above.

1.2 Associated documents

The following documents are part of these installation instructions. They can be down-

loaded in pdf format from the web page www.faulhaber.com/manuals.

If it is not possible to download the documents, please contact us (see reverse of this docu-

ment).

You can find the data sheet for Motion Controller series MC 5004 P STO in chap. 8.1, p. 60.

1.3 Using this document

Read the document carefully before undertaking configuration, in particular chapter

"Safety".

Retain the document throughout the entire working life of the product.

Keep the document accessible to the operating and, if necessary, maintenance person-

nel at all times.

Pass the document on to any subsequent owner or user of the product.

Document Description

Motion Manager 6 Operating instructions for FAULHABER Motion Manager PC software

Quick start guide Description of the first steps for commissioning and operation of FAULHABER

Motion Controllers

Drive functions Description of the operating modes and functions of the drive

Accessories manual Description of the accessories

Table of contents

Other Faulhaber Motherboard manuals