Favor.it RS10 Manual

RS10/18/22 Favor.it

INSTALLATION AND MAINTENANCE MANUAL INDUSTRIAL WASHER-

PUBLICATION DATE: 2 Oct 2006 EXTRACTORS

523323

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 1

1. CONTENTS

Publication date 2 Oct 2006 Page:

1. CONTENTS.....................................................................................................................1

2. WARNINGS AND SYMBOLS .........................................................................................2

2.1. PERSONAL SAFETY RULES.............................................................................................................2

2.2. SYMBOLS ON THE MACHINE...........................................................................................................2

2.3. IMPORTANT INFORMATION BEFORE INSTALLATION....................................................................3

3. TECHNICAL INFORMATION..........................................................................................4

3.1. TECHNICAL SPECIFICATIONS 10/18/22 kg - 25/40/50 lbs CAPACITY..............................................4

3.2. DIMENSIONS AND COMPONETS OF THE MACHINE ......................................................................6

4. INSTALLATION OF THE MACHINE...............................................................................8

4.1. HANDLING, TRANSPORT, STORAGE AND UNPACKING.................................................................8

4.2. SPACE REQUIREMENTS..................................................................................................................8

4.3. MACHINE'S POSITIONING................................................................................................................8

4.4. CONNECTIONS...............................................................................................................................11

4.5. PUTTING INTO SERVICE................................................................................................................14

5. MAINTENANCE............................................................................................................15

5.1. INTRODUCTION..............................................................................................................................15

5.2. DAILY...............................................................................................................................................15

5.3. EVERY THREE MONTHS................................................................................................................15

5.4. EVERY SIX MONTHS ......................................................................................................................15

5.5. WATER FILTER...............................................................................................................................16

5.6. TIGHTENING OF BOLTS.................................................................................................................16

5.7. DOOR SEAL ....................................................................................................................................16

5.8. BELTS OF DRIVE ............................................................................................................................16

1.9. FUSES.............................................................................................................................................18

6. TROUBLE SHOOTING AIDS........................................................................................19

6.1. EMERGENCY DOOR OPENING......................................................................................................19

6.2. FILLING TIME TOO LONG...............................................................................................................19

6.3. HEATING TIME TOO LONG.............................................................................................................19

6.4. DRAIN TIME TOO LONG .................................................................................................................19

6.5. PROGRAMMER PROBLEMS...........................................................................................................19

7. LIST OF RECOMMENDED SPARE PARTS.................................................................20

8. PUTTING THE MACHINE OUT OF SERVICE..............................................................21

8.1. DISCONNECTING THE MACHINE...................................................................................................21

8.2. MACHINE LIQUIDATION..................................................................................................................21

2 INSTALLATION AND MAINTENANCE MANUAL 523323 PUBLICATION DATE 2 OCT 2006.DOC

2. WARNINGS AND SYMBOLS

TO MINIMIZE THE RISK OF FIRE, INJURY BY ELECTRIC SHOCK OR SERIOUS INJURIES

OF PERSONS OR PROPERTY DAMAGE, PLEASE READ AND FOLLOW THE FOLLOWING

INSTRUCTIONS:

2.1. PERSONAL SAFETY RULES

GENERALLY

•This English version isthe original version.

•This instruction is not complete without „User’s“, „Programming“, and „Spare parts manual”.

•Before installation, operation and maintenance of the machine read carefully the complete instructions supplied

with the machine, i.e. this „Installation and maintenance manual“, „User’s manual“, „Programming manual“ and

„Instruction manual for frequency inverter“. Keep the manuals in a handy place.

•Do not bypass the safety instructions stated in manuals and warnings on the labels. Basic safety instructions

stated in chapters „2. Warnings and symbols“ of the supplied manuals should be printed and located near

the machine for the operator's use. The labels must be readable and permanently located on the machine!

•Follow all valid local safety instructions and laws !

•Do not use the machine with its parts damaged, missing parts or opened covers!

•Do not store any flammable materials near the machine. Storing of chemicals near the machine or operating

dry cleaning machines in bad technical conditions can cause a health damage or the machine parts corrosion.

•Do not tamper with themachine controls.

•The washer extractor isintended to be permanently connected to fixed wiring.

•The machine must be connected to the power, ground, water and ventilation according to the installation manual,

in compliance with the local standards done by qualified technicians with proper authorization. The valid

standards for connecting to the local power network (TT / TN / IT, ...)must be followed. In the standard

execution, the washer may not be suitable for connecting to an IT supply system.

•If you have a machine with frequencyinverter do not change the parameters of the inverter. Doing so can cause

serious injury, fire, machine damage, etc.

•Instructions and warnings included in this manual do not cover all possible conditions and situations that can

occur at installation, maintenance or operations of the machine. They must be understand in common sense.

Caution and carefulness are factors that can not be achieved by the design of machine. These factors are

conditioned by qualification and competence of personnel who install, operate and maintain the machine.

•In case of a problem or situationsthat you can not solve by yourselves, contact your qualified serviceman,

manufacturer or the dealer. Always state the model and serial number of your machine from the completed

last page of themanual.

•The emergency stop deviceis omitted on machines design for coin, token, external payment system or similar

operation for use in self-service situation. The owner-installer-user must provide a remote-located emergency

stop device that is connected to each machine.

FOR MAINTENANCE

•When the main switch is off, the inlet terminals of the switch are still under current!

•Do not bypass any safety devices or their parts. Anyinterference to the machine function and design are

prohibited and the manufacturer does not bear any responsibilities in such cases!

•Before maintenance activities always disconnect the machine power supply!

•Do not repair or replace any machine parts and do not perform machine service work if it is not recommended

in the maintenance instructions. All other service activities should be provided by qualified service workers.

•Do not repair or adjust themachine belt drives while in operation. Turn off the main switch!

•Original or identical parts must be used for replacement inthis machine. After servicing replace and secure all

panels in the original way. Takethese measures for continued protection against electrical shock, injury, fire

and/or property damage.

•Once in 3 months, check the earthing and the emergency function.

•Keep the machine top clean and free of flammable materials. Do not wash or spray the machine by water.

INSTALLATION AND SERVICE CAN BE DONE BY A SERVICE ORGANIZATION WITH PROPER

AUTHORIZATION FROM THE MANUFACTURER.

The machine warranty can be cancelled if the instructions of this manual are not followed.

2.2. SYMBOLS ON THE MACHINE

Danger, read and follow written instructions

Caution, high power voltage, electrical devices

Press push button in case of emergency

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 3

2.3. IMPORTANT INFORMATION BEFORE INSTALLATION

FOR TRANSPORTATION AND STORAGE

IN CASE OF TRANSPORTATION AND STORAGE, WATCH COMPONENTS PROTRUDING FROM THE

CONTOUR LINE OF MACHINE (DOOR LOCKS ETC.), TO AVOID INJURIES.

•Never push, pull or exert pressure on components protruding from the machine contour line (controls, door locks

etc.).

•Make sure that these components are secured so as to avoid damages during machine manipulation and

installation.

•In case of the machine transportation by the customer, follow the manufacturer's instructions for transportation,

handling and storage of the product. In case of transportation of machine bythe customer the manufacturer is

not responsible for possible damage of machine in the course of transportation.

•The ambient temperature of transportation and storage must be between -25°C - +55°C. Relative humidity must

be between 30% - 90% without condensation. In case of storagethe machine in a free areait must be protected

against mechanical damage and weather condition factors.

FOR INSTALLATION

ELECTRICAL CONNECTION, EARTHING AND VENTING OF THE MACHINE, WATER INLETS AND

DRAINAGE MUST BE PERFORMED BY QUALIFIED PERSONNEL WITH A PROPER AUTHORIZATION

ACCORDING THE INSTALLATION MANUAL IN COMPLIANCE WITH LOCAL STANDARDS

(APPLICABLE ALSO FOR STEAM CONNECTION ON STEAM HEATED MACHINES).

•Do not install the machine at places exposed to climatic effects or excessive humidity. The machine is not

designed to accept environment with sprayed water.

•Any changes in the machine installations must be approved by dealer or manufacturer. Otherwise the

dealer/manufacturer is not responsible for possible injuries or damages. Interference and changesin the

machine construction are not allowed and the manufacturer refuses any responsibilities in such cases.

•Define dangerous areas in the laundry room and do not allow people to enter if themachine is in operation.

MACHINE VERSION

•This manual contain information for the whole series of rigid mounted machine types with filling of dry linen 10,

18 and 22 kg (25, 40 and 50 lb). Check, please, the type of your machine on the production label (located on

back of machine) and look for right information in the manual.

•Machines are equipped with an electronic programmer MCB EC. The „OPL“ is a version with a programmer

controlled only by push-buttons.

•The version with an electronic programmer is : 1 motor controlled by frequency inverter.

•Starting of the machine comes by a start push-button.

•Heating is provided by electrical heating elements.

•Water valves are used for cold hard, cold soft and if necessary warm water.

•The machine electrical connection is three-phases 3AC/380-415V+N. Machines in accordance to CE directives

are „CE“ marked on themachine name plate.

•The machine design which fulfilsThe European Agreement requirements is stated in the name plate by the

symbol „CE“.

•All machines types are produced according the EMC-directive (Electro-Magnetic-Compatibility). They can be

used in restricted surroundings only (comply minimally with class A requirements). For safety reasons there must

be kept the necessary precaution distances with sensitive electrical or electronic device(s).

•The product fulfils the technical requirements for a product determined by the law no. 22 / 1997 of Digest of

Czech Republic.

•The used electrical standard for concerned machines covered by this manual depends on the scope

of the considered standards in which the machine best fits. The chosen electrical standard ismentioned in the

declaration of conformity that is delivered by each machine.

4 INSTALLATION AND MAINTENANCE MANUAL 523323 PUBLICATION DATE 2 OCT 2006.DOC

3. TECHNICAL INFORMATION

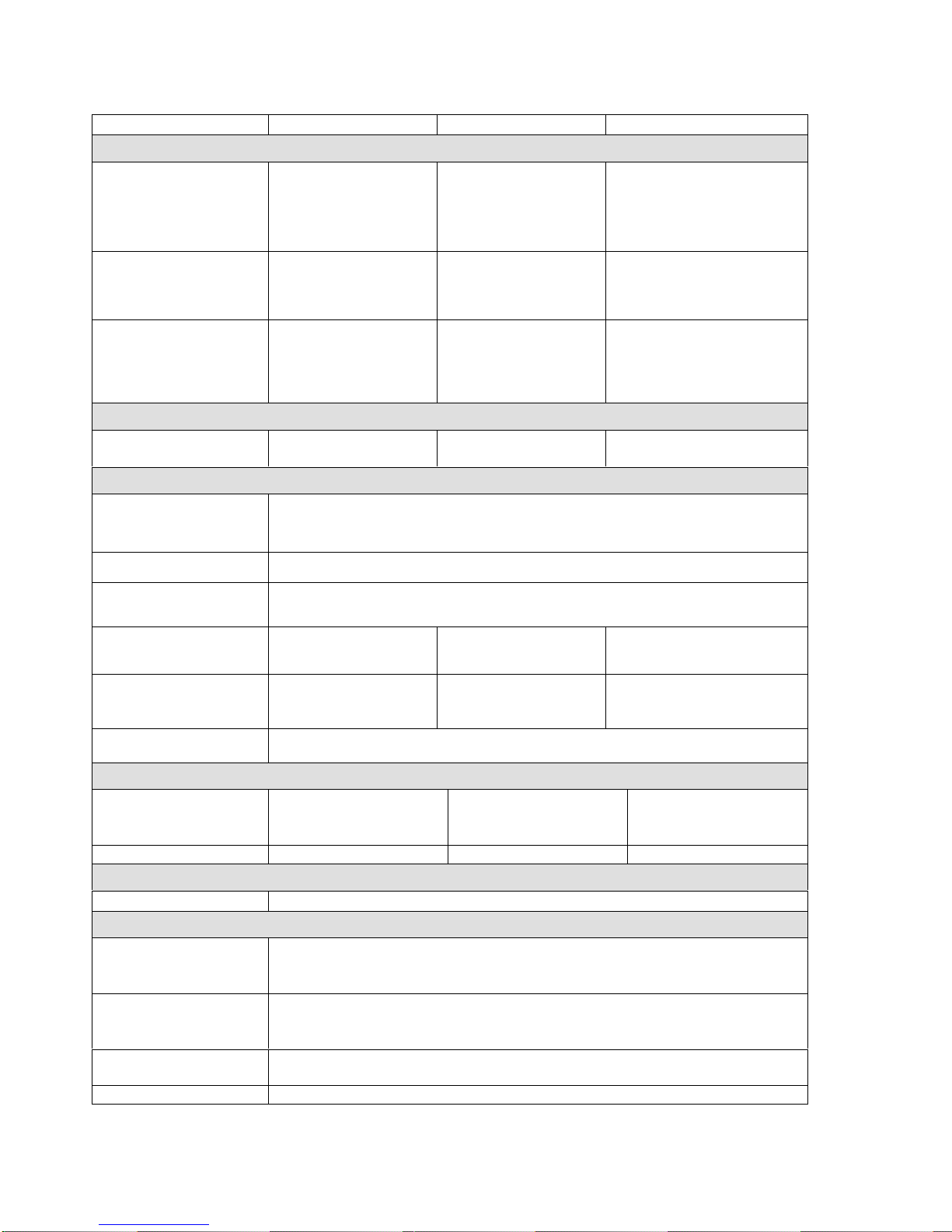

3.1. TECHNICAL SPECIFICATIONS 10/18/22 kg - 25/40/50 lbs CAPACITY

CAPACITY: 10 kg / 25 lb 18 kg / 40 lb 22 kg / 50 lb

DIMENSIONS

PACKING:

width

depth

height

transportation capacity

carton box

700 mm / 27.6"

880 mm / 34.64"

1280 mm / 50.39"

0.8 m3/ 28.25 ft3

carton box

935 mm / 36.8"

955 mm / 37.6"

1530 mm / 60.2"

1.37 m3/ 48.4 ft3

carton box

935 mm / 36.8"

1050 mm / 41.3"

1530 mm / 60.2"

1.5 m3/ 52.9 ft3

MACHINE:

width

depth

height

660 mm / 26"

865 mm / 34"

1140 mm / 44.9""

855 mm / 33.7"

895 mm / 35.2"

1315 mm / 51.8"

855 mm / 33.7"

990 mm / 39"

1315 mm / 51.8"

INNER DRUM:

diameter

depth

drum capacity

door opening

530 mm / 21"

420 mm / 16.5"

95 dm3/ 25 gal

290 mm / 11.4"

700 mm / 27.6"

470 mm / 18.5"

181 dm3/ 47.8 gal

410 mm / 16.1"

700 mm / 27.55"

565 mm / 22.4"

217 dm3/ 57.3 gal

410 mm / 16.1"

WEIGHT

netto

brutto 185 kg / 408 lb

210 kg / 463 lb 300 kg / 662 lb

335 kg / 739 lb 305 kg / 673 lb

350 kg / 772 lb

ELETRICAL DATA

Permitted deviations

of feeding voltage for

machines (with load

and without load): ±10%, with a maximal standard deviation of the frequency 1%

Electrical system of

the machine: 3x380-415V+N 50/60Hz

Minimal power supply

voltage

(validforfrequencycontroll) 350V

NOMINAL MOTOR

OUTPUT 600 W 1,5 kW 1,5 kW

INPUT PROTECTION

FOR ONE MACHINE:

Heating power / fuse 9kW / 20A 12kW / 25A 18kW / 32A

Overload protection

of the motor: external thermal motor protection or electronic protection by the frequency inverter

WASHING FUNCTION

RPM OF THE DRUM:

washing

extracting 45 rpm

525 rpm 44 rpm

505 rpm 44 rpm

480 rpm

G - factor of spinning 100 100 90

HEATING

TYPE OF HEATING: 100% electric

CONNECTIONS

WATER INLETS:

water pressure

water inlet 0.4 - 1.0 MPa / 60-145 PSI

3/4"

WATER DRAINAGE:

dimension

capacity 76 mm / 3“

Connections to external

liquid soap supply: standard 5 or 8 pcs,

(see electrical scheme)

Soap hoppers: 3

Tab. 3.1

*

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 5

CAPACITY: 10 kg / 25 lb 18 kg / 40 lb 22 kg / 50 lb

CONSUMPTION

Average water

constumption: 90 dm3/ 24 gal 160 dm3/ 43 gal 191 dm3/ 50,5 gal

WORKING CONDITIONS

ambient temperature:

average ambient

temperature in 24 hrs:

relative humidity:

height above sea level:

from +5°C to +40°C

to +35°C

30% ÷95% without condensation

to 1000 m

ANCHORING

Bolt: 6 pcs M16 x 160

max.static loading of floor:

(with linen and water)

max.dynamic loading:

(alternative stress when

extracting)

frequency of dynamic

loading:

216 kg / 474 lb

450 kg/m2

8,42 Hz

310 kg / 682 lb

890 kg/m2

8,42 Hz

320 kg / 704 lb

960 kg/m2

8 Hz

NOISE

Average noise level at

max. loading: 66.6 dB (A)

Tab. 3.1. continuation

maximum dimensions including protruding parts

*

6 INSTALLATION AND MAINTENANCE MANUAL 523323 PUBLICATION DATE 2 OCT 2006.DOC

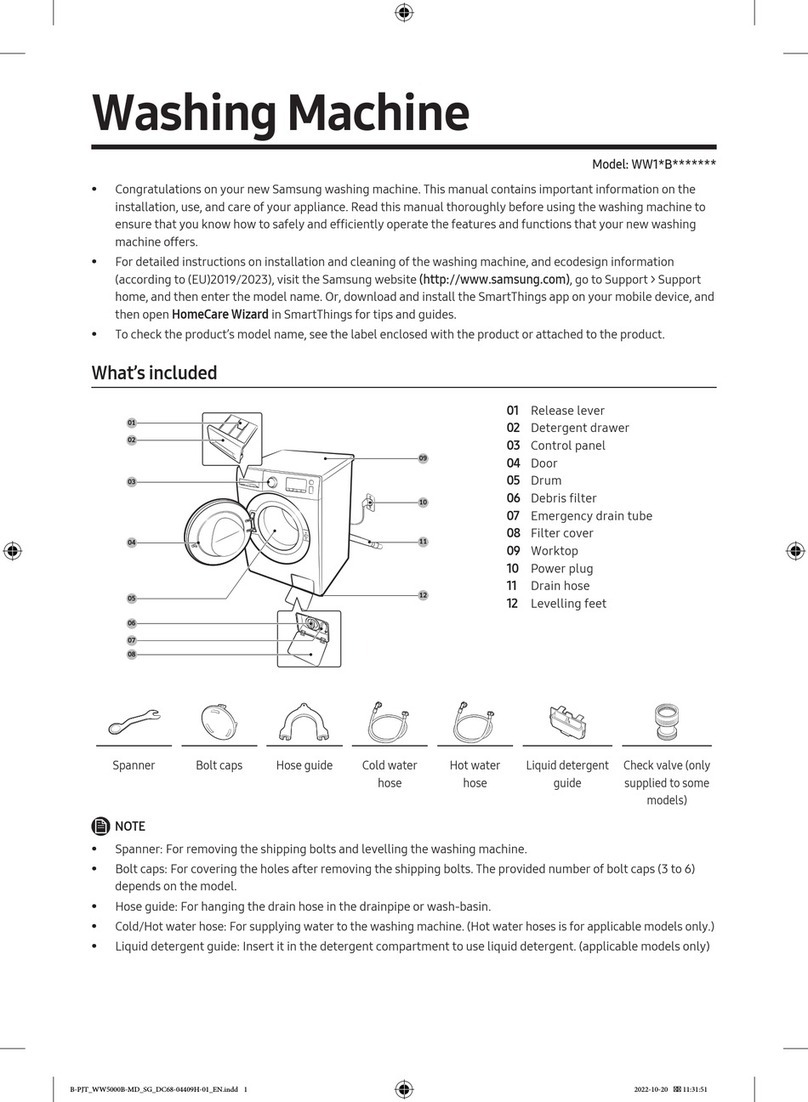

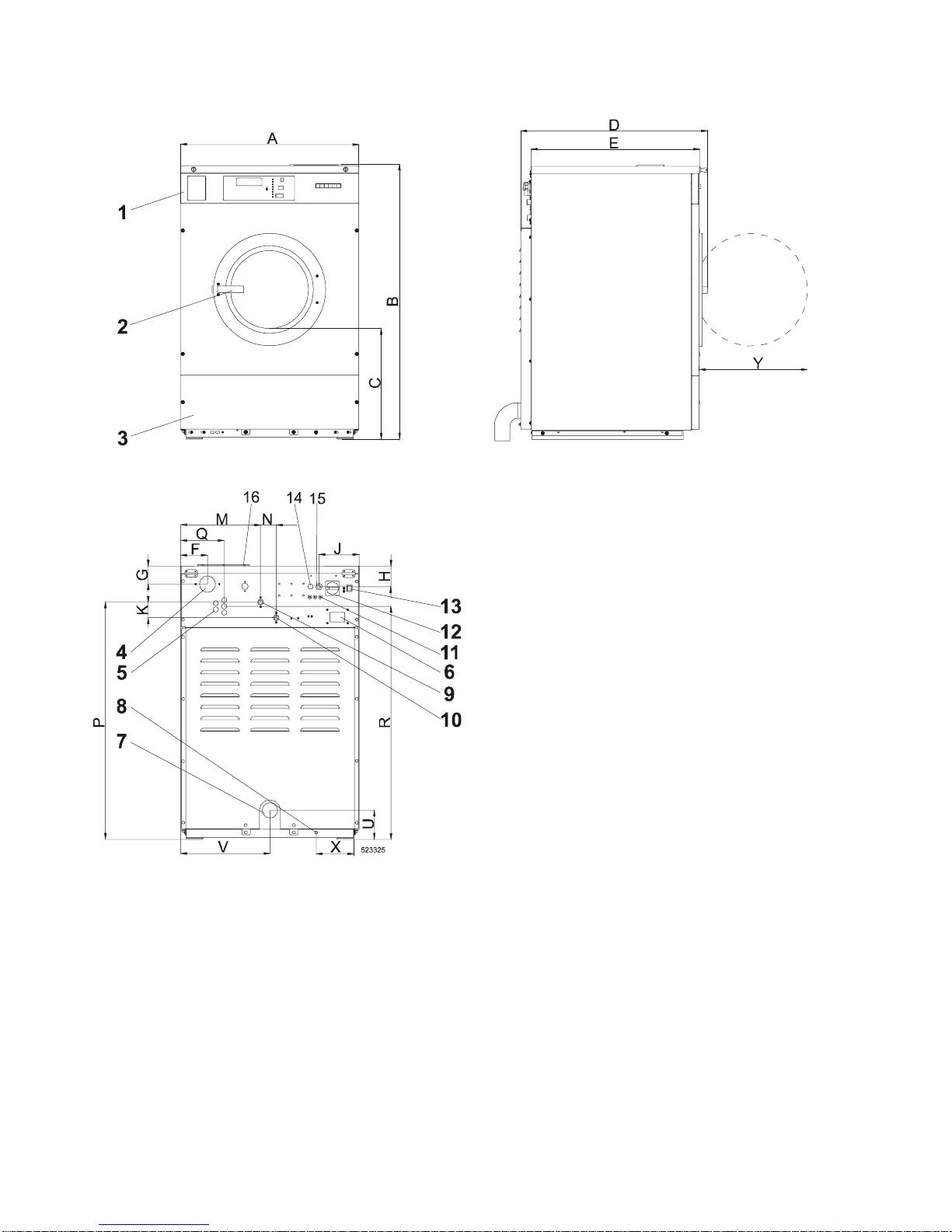

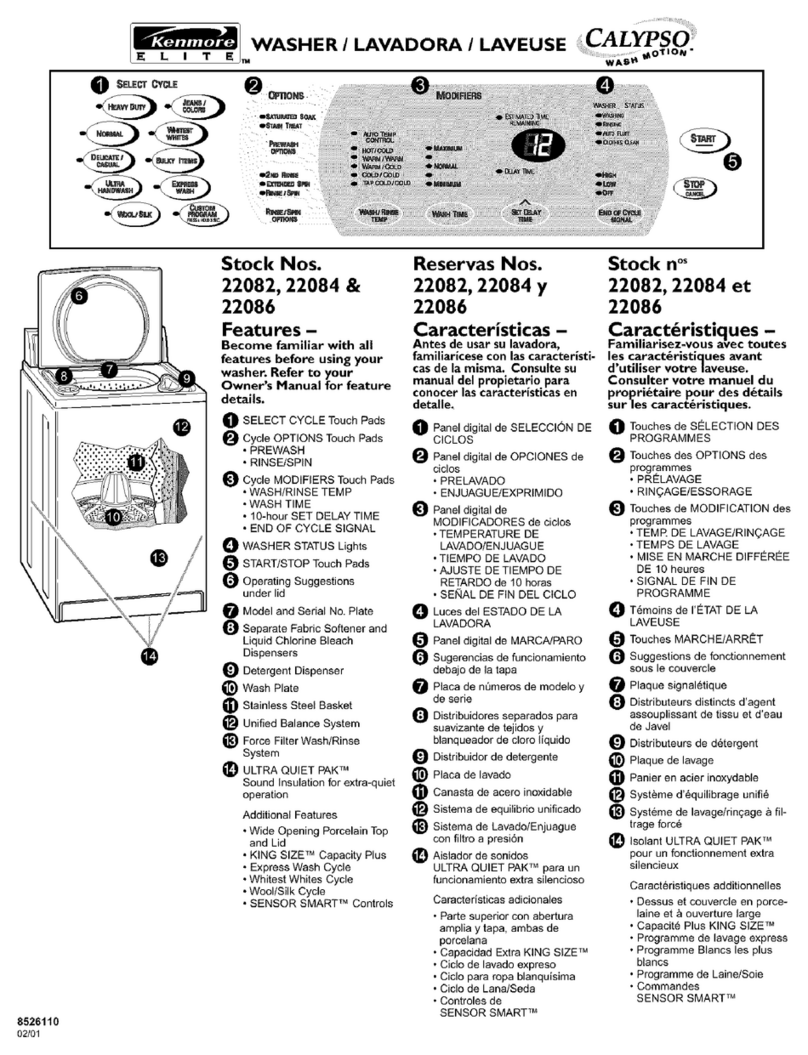

3.2. DIMENSIONS AND COMPONETS OF THE MACHINE

Fig. 3.2

1. Control panel

2. Door handle

3. Service panel

4. Air vent

5. Liquid soap hose connections

6. Name plate

7. Drain connection

8. Earthing connection

9. Hot water connection

10. Cold soft water connection

11. Fuses

12. Main switch

13. Program accelerator button

14. Electrical connection to liquid soap

pumps

15. Electrical connection of machine

16. Soap hoppers

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 7

Machine capacity: 10 kg

25 lbs 18 kg

40 lbs 22 kg

50 lbs

A660 mm

26" 855 mm

33.7 " 855 mm

33.7 "

B1140 mm

44.9 " 1315 mm

51.8 " 1315 mm

51.8 "

C460 mm

18.1 " 528 mm

20.8 " 528 mm

20.8 "

D865 mm

34 " 895 mm

35.24 " 990 mm

38.97 "

E775 mm

30.5 " 855 mm

33.7 " 950 mm

37.4 "

F102 mm

4 " 140 mm

5.12 " 140 mm

5.12 "

G86 mm

3.4 " 94 mm

3.7" 94 mm

3.7"

H147 mm

5.8 " 157 mm

6.2 " 157 mm

6.2 "

J188 mm

7.4 " 190 mm

7.5 " 190 mm

7.5 "

K75 mm

3 " 75 mm

3 " 75 mm

3 "

M267 mm

10.5 " 382.5 mm

15.1 " 382.5 mm

15.1 "

N60 mm

2.4 " 75 mm

3 " 75 mm

3 "

P992 mm

39.1 " 1138 mm

44.8 " 1138 mm

44.8 "

Q182 mm

7.2 " 207.5 mm

8.2 " 207.5 mm

8.2 "

R949 mm

37.4 " 1117 mm

43.5 " 1117 mm

43.5 "

U92 mm

3.6 " 134 mm

5.3 " 134 mm

5.3 "

V330 mm

13 " 427,5 mm

16.8 " 427,5 mm

16.8 "

X109 mm

4.3 " 205.5 mm

8.1 " 205.5 mm

8.1 "

Y415 mm

16.3 " 521.5 mm

20.5" 521.5 mm

20.5"

Tab. 3.2

8 INSTALLATION AND MAINTENANCE MANUAL 523323 PUBLICATION DATE 2 OCT 2006.DOC

4. INSTALLATION OF THE MACHINE

4.1. HANDLING, TRANSPORT, STORAGE AND UNPACKING

Only a qualified person can handle or operate the machine.

STORAGE

The machine is delivered to the customer in a cardboard packing and the machine is additionally protected

by polyethylene foil. Do not store or install the machine where it can be exposed to environmental conditions

(rain, wind) or extreme humidity.

HANDLING DURING INSTALLATION

All activities can be done only by a worker, which knows all information about the machine. The machine is

fixed to the wooden palette by four bolts M12x60.

To remove the machine to its final location follow these precautions:

•Check all passages and spaces where the machine has to be transported through, they must have

sufficient dimensions to meet the height and width of the machine including the package.

•Never push, pull orpress the components protruding from the contour line of machine (front part, filling

door, control elements, belt cover, water inlet and outlet pipes etc.).

MAKE SURE THAT THESE COMPONENTS ARE PROTECTED, TO AVOID THEIR DAMAGE DURING

HANDLING AND INSTALLATION OF THE MACHINE.

•Make sure that the filling door are secured to avoid its opening during the handling.

•Lift the machine up bylift truck or hand-operated pallettruckusing a transport skid to which the machine has

been attached.

UNPACKING

Before you install the machine in its place, remove the package, release four bolts and lift up the machine

using the high lift truck and remove the wooden palette. It is possible to handle the machine by the fork lift

or the manual truck in such a way, so that the forks would not damage the components located in its lower

part. After unpacking, check if the machine has not been damaged and if all the accessories are included

according to your order. Verify the type of your machine by a name plate located on the machine rear and

find corresponding information in the manual. The accessories and the manual are placed inside the drum,

which can be opened according to chapter 6.1.

4.2. SPACE REQUIREMENTS

REQUIRED MACHINE WORKING CONDITIONS

See chapter „3. TECHNICAL SPECIFICATION“.

The machine may not be installed within the reach of directly spraying water. Do not install the machine

where it will be exposed to weather condition and excessive humidity. When steamed up due to temperature

changing, water must not run over the machine walls and covers, nor to cover the floor under and around it.

REQUIRED ROOM DIMENSIONS

Provided that the requirements in respect to room dimensions are not met, the maintenance of the machine

may be difficult. Leave at least a 0.6 m / 2 ft free space between the rear panel of machine and the wall.

Leave at least a 0.04m / 1.57“ free space between the side panel of machine and the wall or other machine.

Leave at least a 0.6m / 2 ft free space between the top panel of machine and the ceiling, which cannot be

dismantled (see fig. 4.3.D, dimension „J“).

4.3. MACHINE'S POSITIONING

MACHINE'S POSITIONING ON THE FLOOR

The machines must always be fixed to the floor which complies with static and dynamic machine stress.

There are two systems possible. The machine can be fixed to a concrete socle by bolts (see fig. 4.3.A, pos. 1).

It can also be bolted on a metal socle (fig. 4.3.B, pos. 9) which is fixed to the floor by bolts. The manufacturer

recommends to fix machines of the 18 kg / 40 lbs and 22 kg / 50 lbs type to the base of height 18 cm / 7“ for

easier manipulation with the linen.

For 18 kg / 40 lbs and 22 kg / 50 lbs type:

In case there are gaps between the frame of the machine and the concrete or metal socle before tightening

the bolts, use the shims delivered with the machine (see fig. 4.3.A, fig. 4.3.B, pos. 7) to fill this gaps.

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 9

Fig. 4.3.A Fig. 4.3.B

Fig. 4.3.C. Position of foundation bolts for machines

6 kg / 15 lbs to 22 kg / 50 lbs

1. Foundation bolt 6. Existing floor

2. Nut

3. Machine socle 7. Shim for machine type 16 kg / 35 lbs

8. Bolt

4. Washer 9. Metal socle

5. Concrete base

Fig. 4.3.D. Base description

10 INSTALLATION AND MAINTENANCE MANUAL 523323 PUBLICATION DATE 2 OCT 2006.DOC

Kapacita

stroje 10 kg

25 lb 18 kg

40 lb 22 kg

50 lb

A530 mm

20.9 " 700 mm

27.6 " 700 mm

27.6 "

B65 mm

2.6 " 77,5 mm

3.1 " 77,5 mm

3.1 "

C100 mm

4" 100 mm

4" 100 mm

4"

D20 mm

0.79" 20 mm

0.79" 20 mm

0.79"

E48 mm

1.9 " 110 mm

4.33 " 110 mm

4.33 "

F365 mm

14.4 " 360 mm

14.17 " 500 mm

19.7 "

G295 mm

11.6 " 295 mm

11.61 " 251 mm

9.88 "

H28 mm

1.10" 39 mm

1.53 " 39 mm

1.53 "

Imin. 600 mm

27.56 " 700 mm

27.56 " 600 mm

27.56 "

J min. 600 mm

27.56 " 700 mm

27.56 " 700 mm

27.56 "

K40 mm

1.6" 40 mm

1.6" 40 mm

1.6"

L120 mm

4.7 " 120 mm

4.7 " 120 mm

4.7 "

Mmin. 300 mm

11.8 " 400 mm

15.7 " 400 mm

15.7 "

N50 mm

2" 50 mm

2" 50 mm

2"

O135 mm

5.3 " 140 mm

5.6 " 140 mm

5.6 "

PM16 x 160 M16 x 160 M16 x 160

Tab. 4.3. Dimensions of machine

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 11

4.4. CONNECTIONS

ELECTRICAL CONNECTION

GENERAL

WARNING !

THE MACHINE MUST BE CONNECTED TO THE POWER, GROUND, WATER, VENTILATION AND STEAM

SUPPLY ACCORDING TO THE INSTALLATION MANUAL, IN COMPLIANCE WITH THE VALID LOCAL STANDARDS

DONE BY QUALIFIED TECHNICIANS WITH PROPER AUTHORIZATION.

THE VALID STANDARDS FOR CONNECTING TO THE LOCAL POWER NETWORK (TT / TN / IT, ...) MUST BE

FOLLOWED.INTHESTANDARD EXECUTION, THE WASHER MAY NOT BE SUITABLE FOR CONNECTING

TO AN IT SUPPLY SYSTEM.

THE WASHER EXTRACTOR IS INTENDED TO BE PERMANENTLY CONNECTED TO THE ELECTRICAL

SUPPLY.

The machines have been designed for connecting to the electrical network according to the specifications of your

order. Before connection check if the electrical values stated on the serial plate of the machine correspond

to your electrical network. If not do not connect the machine, please contact your dealer.

If the machine is not equipped with a supply disconnecting device, like a main switch then a supply disconnecting

device need to be provided in the installation for all electrical supplies connected to the machine, in accordance

with EN 60204-1 standard, point 5.3. This device shall disconnect the electrical equipment of the machine

from the supply when required e.g. maintenance.

EMERGENCY STOP DEVICE

The machines are equipped with an emergency stop device in accordance with ISO13850 - category 0 stop

function. Nevertheless, the emergency stop device is omitted on machines design for coin, token, external

payment system or similar operation for use in self-service situation. The owner-installer-user must provide

remote-located emergency stop device(s). This emergency stop device(s) needs to stop each machine

in accordance with ISO13850 - category 0. There are made provisions in the wiring harness, were immediate

removal of power to the actuators can be accomplished. See the electrical schematic of the machine for correct

connection of the device.

SUPPLY CABLE AND SAFETY DEVICES

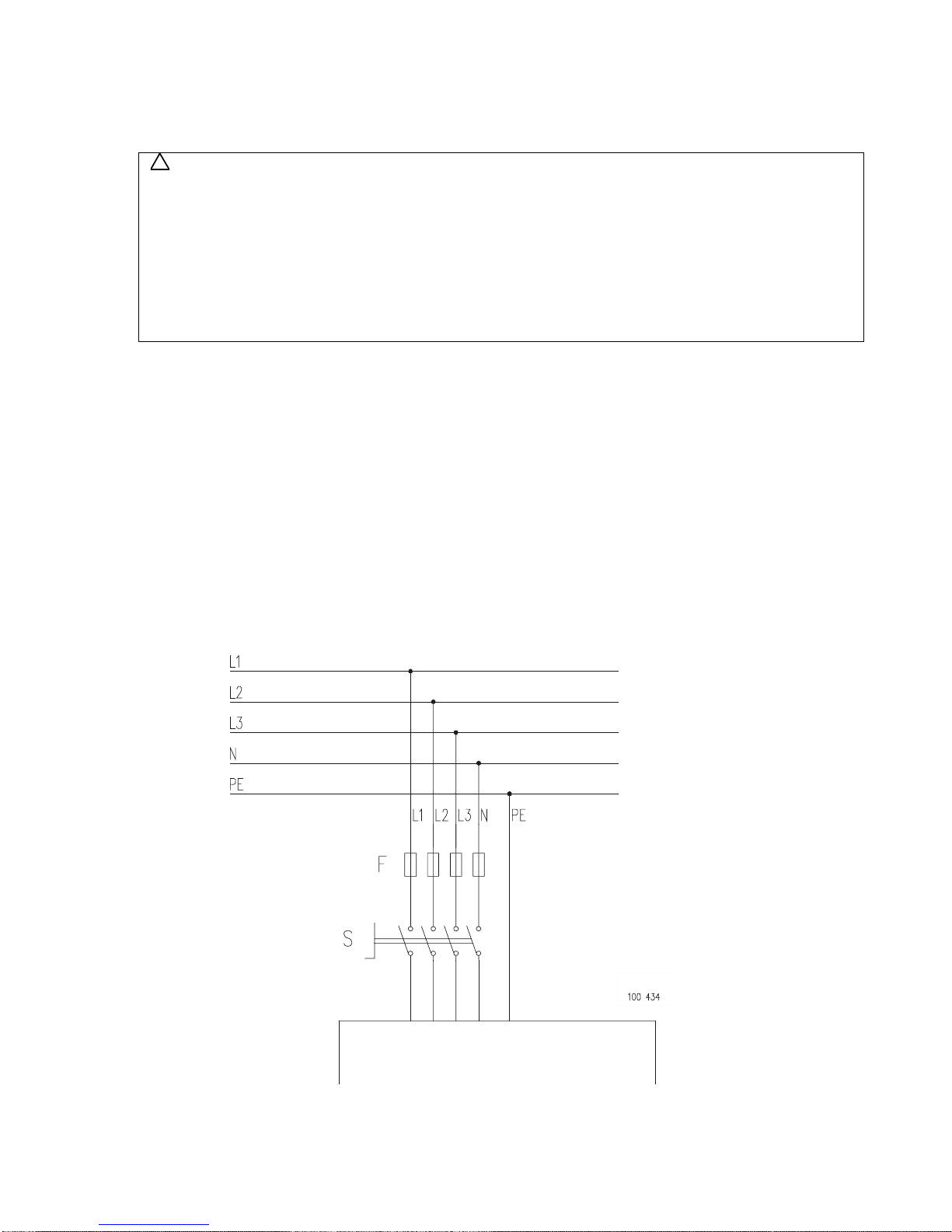

Fig. 4.4.A. Example of electrical connection

!

MACHINE

12 INSTALLATION AND MAINTENANCE MANUAL 523323 PUBLICATION DATE 2 OCT 2006.DOC

Supply cable of the machine must have copper wires. The cross section of the supply wires depends

on the supply voltage and on the total electrical power input of the machine (see table 3.1). The supply cable

safety device against a short-circuit fault and overloading must be performed by automatic breakers or fuses

in the laundry switchboard. The recommended minimal cross-section of the supply wires as well as the values

of fuses (F) for the supply are stated in table 4.4.A.

In all cases were thelocal standardsrequirements are higher, these has to be followed above the recommendation

in table 4.4.A. If the local standards requireinstallation of the earth leakage trip, we suggest toinstall one of 100 mA

for the machines equipped with frequency inverter. The main contacts of the earth leakage trip must comply

with the specified power input of the machine.

POWER SUPPLY

PROTECTION (A)

MINIMAL PHASE

CONDUCTOR SECTION

(mm2)

16 2.5

25 - 32 4

40 6

50 10

60 - 80 16

Tab. 4.4.A. Minimal wire section is recommended by manufacturer.

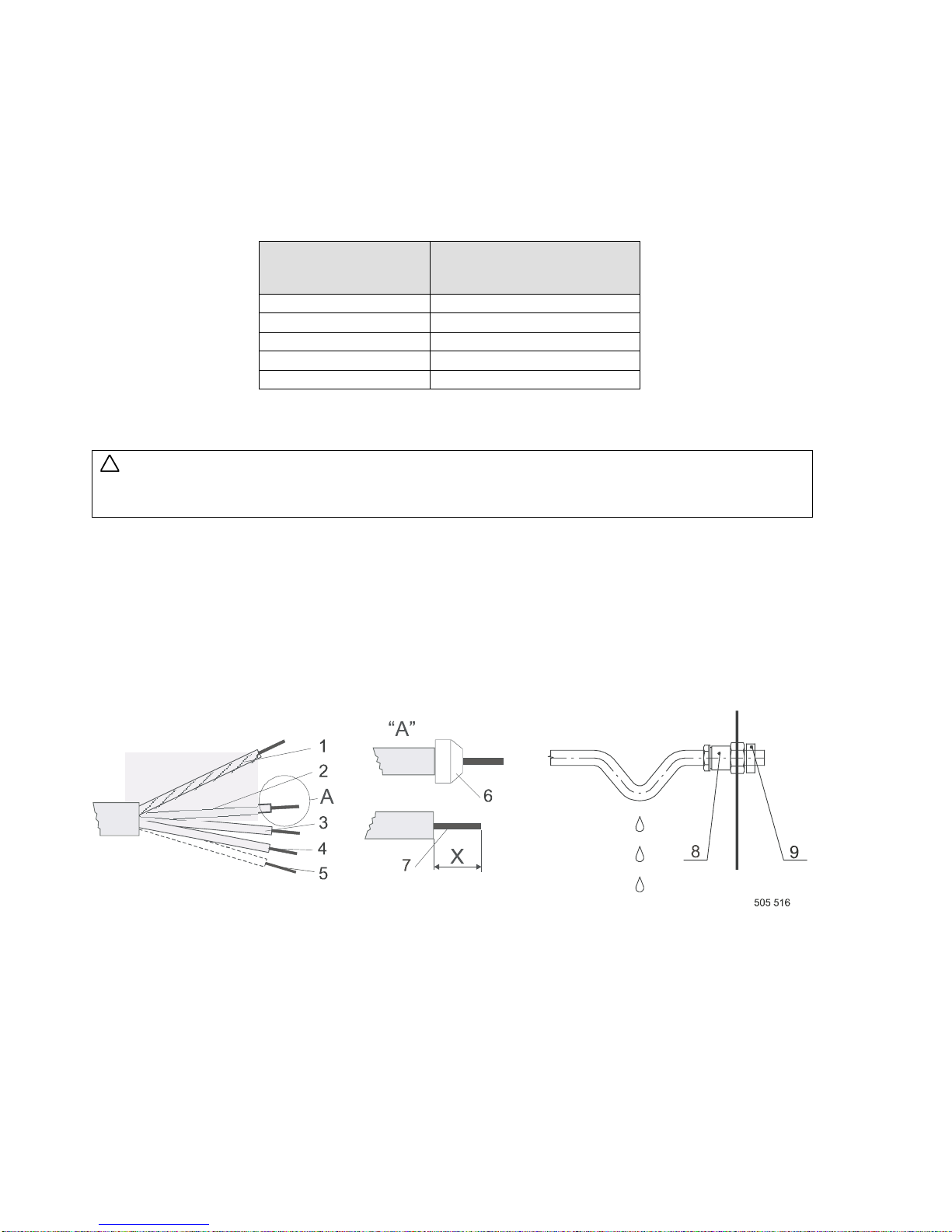

INSTALL SUPPLY CABLE TO THE MACHINE

WARNING !

THE PROTECTIVE CONDUCTOR MUST BE LONGER SO THAT WHEN THE CABLE IS PULLED OUT

ACCIDENTALLY, THIS CONDUCTOR IS DISCONNECTED AS THE LAST ONE!

When using the cable (hard copper conductors), strip individual cores in such a way to avoid the protrusion

of a stripped part from the terminal when the conductor is connected into the device (7 - dimension X).

When using a cord (stranded copper conductors) the individual cores can be strippedin a similar way as in the case

of a cable, or use moulded tubes (6). In this case use tubes with an insulated neck to avoid a contact to a part

under tension after the conductor connection.

1. Green-yellow - protection conductor

2. Black - phase conductor

3. Brown - phase conductor

4. Black - phase conductor

5. Blue - neutral conductor

6. A neck of the moulded tube

7. The stripped length of conductors

8. Bush

9. Securing clamp

Fig. 4.4.B. Adaptation of conductor ends and supply power cable attachment

The cable can be attached to the machine in two ways. From a cable channel (from below) and from a cable

grate (from above). If the cable is attached from above, it is recommended to secure the cable against

sagging in front of the entry into the cable bush. In this way an ingress of the running condensed water into

the bush and/or machine can be avoided.

Open the top cover of the machine. When the cable is put through the bush (8), tighten the sealing bolt

of the bush. In this way the rubber ring in the bush is pressed, thus securing the cable against the water.

Provided that this mechanical securing is insufficient, use the securing clamp (9). The supply cable is connected

to the main switch of the machine (see fig. 4.4.C, pos. 1) or connection clamp (2). The phase terminals are

marked by U, V, W (L1, L2, L3). If the machine is not equipped with a main switch then supply disconnecting

devices need to be provided in the installation for all electrical supplies connected to the machine, in

accordance with EN 60204-1 standard, point 5.3. Connect the protection conductor directly to the protection

terminal located on the switchboard side. The terminal is identified by means of PE.

!

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 13

1. Main switch

2. Connection clamp

3. Bush

Fig. 4.4.C. Connection of power supply cable to the machine

DURING EXTRACTION THE DRUM SHOULD ROTATE IN CLOCKWISE DIRECTION (WHEN YOU ARE

IN FRONT OF THE DOOR OF THE MACHINE). IF THIS IS NOT THE CASE THEN YOU MUST INTERCHANGE

U (L1) AND V (L2) WIRES ON SUPPLY CABLE TO MAIN SWITCH – NOT VALID FOR FREQUENCY

CONTROL.

PROTECTION

The circuit breakers and fuses are available in the laundry switchboard against the occurrence of short-circuit

or overloading. Verify, please, the number of phases and the machine voltage according to the name plate.

Look for an adequate value of the circuit breaker in technical information.

MACHINE PROTECTIVE CONNECTION

From the safety reasons it is necessary to connect the washing machine to the laundry protection system.

The external protective terminal M6 of the washing machine located on the right rear part of the washing

machine frame serves for this purpose and it identified with an earthing mark, see fig. 3.2, pos. 8.

The protection conductor enabling this connection is not part of the delivery with the washing machine.

However, for the protection purposes with the supply cable section of min. 4 mm2we recommend to select

a larger conductor section, i.e. 6 mm2.

WATER SUPPLY

The machine is equipped with 3/4“ cold (hot) water inlet valves. Use inlet pressure hoses, adapted to the

valves with seal. The best operation of the inlet valves will be obtained when the water pressure is situated

between 0.4-1 MPa / 60-145 PSI. A water pressure that is too low can unnecessary lengthen the wash cycle.

WATER HARDNESS

It is advisable to contact the water supplier for information concerning the properties of the water in your area.

Good wash results are dependent also on the water hardness. For medium to very hard water, consideration

should be made to make the water softer.

Only in some cases is the use of hard water desirable, such as adding softener in the linen.

The soap supplier can help you with making the right decisions concerning hard water, soft water, washing

programs, type of soap and other related items to have the best wash results.

Characteristics mmol / dm3dH -

Germany fH -

France England gr/gal

USA

soft 0 - 1,25 0 - 7° 0 - 12° 0 - 8,75° 0 - 3

medium 1,25 - 2,5 7 - 14° 12 - 25° 8,75 - 17,5° 3 - 7

hard 2,5 - 3,75 14 - 21° 25 - 37° 17,5 - 26,3° 7 - 15

very hard above 3,75 above 21° above 37° above 26,3° above 15

Tab. 4.4. B

WATER CONNECTION

Most machines are made with 2 or 3 water inlets. One is always marked with „soft water“. If more inlets are

present, they are marked with „Hot water“ or „Hard water“. For connection dimensions (see fig. 3.2). Always

use the flexible hose delivered with the machine, if not present, contact your dealer. In each case do not

use a fixed connection to the water supply.

For the proper function of the machine, it is necessary to keep the water pressure within the limits stated in

the technical data. It is also necessary to connect all available water inlets to a water supply. If a hard water

supply is not present, connect it with soft water. If no hot water supply is present, contact your dealer for the

proper required action.

14 INSTALLATION AND MAINTENANCE MANUAL 523323 PUBLICATION DATE 2 OCT 2006.DOC

WATER DRAIN CONNECTION

The machine is equipped with 76 mm / 3“ drain valve without pump, which should be connected to the main

drain pipe or to the gutter. The main drain pipe must have the capacity to be able to handle the total output

of all connected machines.

DRAIN

MODEL dm3gal

10 kg / 25 lbs 247 65.3

18 kg / 40 lbs 270 71.3

22 kg / 50 lbs 278 73.4

Tab. 4.4.C. The amount of drain water

AIR VENT CONNECTION

WARNING!

WATCH OUT, VAPOURS ESCAPE FROM THE MACHINE THROUGH THE AIR VENT OPENING!

DO NOT COVER OR CONNECT TO ANYTHING!

On the backside, the washers are provided with an air vent opening of O.D. 75 mm / 3".

Do not cover the washer air vent opening. It is part of the back flow prevention water system. It also takes

care that the tub can not be pressurized by water intake and vapor of the hot water, this allows for proper

measuring of the water level.

For the safety of everyone make sure that unauthorized persons cannot reach the backside of the machine.

4.5. PUTTING INTO SERVICE

1. For machine version with electronic programmer read carefully Programming manual of the programmer

delivered with your machine.

2. After machine installation initialisate the machine according instructions stated in manual.

!

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 15

5. MAINTENANCE

WARNING !

ALWAYS FOLLOW SAFETY INSTRUCTIONS! DO NOT BYPASS ANY SAFETY DEVICES OR THEIR

PARTS. ANY INTERFERENCE TO THE MACHINE FUNCTIONS AND CONSTRUCTION ARE PROHIBITED!

USE THE PROPER CHEMICAL AGENTS WHICH AVOID CALCIUM SEDIMENTS ON HEATINGELEMENTS

AND OTHER MACHINE PARTS. DISCUSS THIS ISSUE WITH YOUR SUPPLIER OF WASHING PRODUCTS.

THE MANUFACTURER OF THE MACHINE IS NOT RESPONSIBLE FOR THE DAMAGE OF HEATING

ELEMENTS AND OTHER MACHINE PARTS DUE TO CALCIUM SEDIMENTS.

DO NOT OPERATE THE MACHINE WITH BROKEN / MISSING PARTS OR OPENED COVERS!

BEFORE MAINTENANCE WORK DISCONNECT THE MACHINE POWER SUPPLY!

WHEN THE MAIN SWITCH IS TURNED OFF THE INLET TERMINALS OF THE MACHINE MAIN SWITCH

ARE STILL UNDER CURRENT! THAT IS THE WAY TO AVOID INJURIES.

When replacing any parts of the machine, exchange them with original parts obtained from your dealer or ordered

through the spare parts manual!

5.1. INTRODUCTION

Preventive maintenance has been reduced to a minimum by the careful design of the machine, and the choice

of reliable components and materials.

5.2. DAILY

CHECK:

•Water (steam) inlets for leaks

•Check that the drain valve is not leaking during the washing process, and that it opens properly afterwards

(valve is open without electrical power).

•The machine should always be clean.

•Clean upper side and body regularlyin order to remove all soap traces.

•The soap hopper should be cleaned at the end of each working day. Scrap sediments whichmay have set

inside the soap hopper with a plastic spatula and flush them with warm water.

•Clean the sediments from the door seal (mainly bottom part).

•After cleaning the machine, at the end of a working day, open the door of the machine to enable airing the machine.

At the end of the day it is recommended to shut off all main water (steam) and electrical supply. However,

we don't mean the individual faucets of the machines that may not be touched once adjusted, but only

the main valves.

5.3. EVERY THREE MONTHS

•Make sure that themachine is switched off by the main switch when maintenance work is being performed and

that the other workers are informed about it.

•Dismantle the rear machine panel and check if the belt of wash motor is not damaged andif it has

the correct tension (see chapter 5.8.).

•Check visually that all tubing, piping and connections inside machine are free from leaks.

•Wipe and clean the inside of the machine, making sure that the control components are protected from moisture

and dust, during the cleaning operation.

•Put on the cover panels and turn on the power supply.

5.4. EVERY SIX MONTHS

•Regularly clean the filters of the water inlet.

•Check the tightness of the bolts according tochapter 5.6.

•For serious defects, the technical service of your dealer is always available.

BEFORE REMOVING TOP OR BACK PANEL OF THE MACHINE, SWITCH POWER OFF AND WAIT

FOR AT LEAST 10 MINUTES. BEFORE STARTING INSPECTION OF FREQUENCY INVERTER,

CHECK FOR RESIDUAL VOLTAGE ACROSS MAIN CIRCUIT TERMINALS + AND -. THIS VOLTAGE

MUST BE BELOW 30VDC BEFORE YOU CAN ACCESS THE INVERTER FOR INSPECTION.

•Clean and remove dirt and dust from:

–the cooling fin of the inverter

–the motor cooling fins

–the internal ventilator of the inverter (if present)

–the external ventilator (if present)

–the external air relieves of the machine

–check if ventilator in coolfins of inverter (if present) is functional

–check if external ventilator (if present) is functional

!

!

16 INSTALLATION AND MAINTENANCE MANUAL 523323 PUBLICATION DATE 2 OCT 2006.DOC

5.5. WATER FILTER

CLEANING OF FILTER

Close the main water supply.

IF MACHINE HOT WATER SUPPLY LINE IS TOO HOT, DO NOT CONTINUE !

DANGER OF INJURY!

If machine hot water supply line is cold and closed

you can clean the filter. Water filter is accessible after disconnecting the supply hose. Clean up the filter

and put it back.

5.6. TIGHTENING OF BOLTS

•Check protective connection of the machines and fixation by bolts in terminals.

•Disconnect the machine power supply in laundry electrical box !

Otherwise the supply terminal box of the machine is still under electricity !

If the machine isnot warm, dismantle the rear panel and tighten bolts of terminal electrical wires.

Check properly attachments of power electrical conductors in terminals (i.e.main supply terminal or switch,

contactors, motor, heating unites). After that install the panel back on themachine.

5.7. DOOR SEAL

ADJUSTMENT OF DOOR SEAL THRUST

Marking the parts during the disassembly can simplify the assembly procedure afterwards.

In order to make the maintenance and service easier, it is possible to remove separately the front panel and

service panel.

•Remove the lower service panel which is fixed by 2 bolts.

•Open the cover of the soap hopper and remove the 4 bolts whichfasten the soap hopperto the cover.

•Unlock the cover locks and remove the cover by loosening one of the hinges at the rear.

•Remove 4 bolts on the front side of thefront panel and remove the front panel. (For 18/22 kg / 40/50 Ib shift the

front panels towards each other after you unscrew 4 bolts, turn them by 90°and pull them over the open door).

•To remove the door lock, disconnect the lock electrical connection (white terminal). Loosen 2 bolts fastening

thelock to the tub.

•Loosen 6 bolts fasteningthe stainless steel foil and remove the foil from themachine,

(applicable for 10kg / 25 lbs).

•Under the door lock there are shims which can be removed to increase the pressure from the door on the tub.

•To remove the loading doorloosen the boltswhich fasten the door to the hinge.

•There are similar shims underthe hinge which can be also usedfor adjusting the door pressure.

•Assembly of thefront panel, door and door lock isdone in the reverse order of the assembly.

The door is centered towards the lock, by means of an alignment pin whichis mounted on the door.

REPLACEMENT OF DOOR RUBBER

•Open the door. Take a door glass with rubber from the stainless steel door and pull it up towards

the inside of the drum. Do it carefully not to damage the glass. Remove the rubber seal from the glass.

•Moisten the groove for door with soap water. Place a smooth cord inthe groove all around. Tighten up the

margin by cord and fit the unit tothe door opening (with the clip up). Hold one end of the cord firmly on the door.

Pull the other cord end towards the center of the glass for the rubber edge properly fit in.

5.8. BELTS OF DRIVE

REPLACEMENT OF THE FLAT BELTS FORTHE MACHINE WITH CAPACITY 10 kg / 25 lbs

•Remove the rear panel.

•Remove the belt PJ1473, see fig. 5.8.C, pos. 2 pulling it while the drum pulley (1) is rotating at same time.

•Remove the belt PJ559 (6) by pulling it off.

•Put a new belt PJ559 (6) on the tension pulley. Installation of the belt is done in reverse order compared to

its removal. Take care so that the tension springs (7) would be fasten to openingsin the pulley support and to the

frame hinge.

•The belt must be placed in the correct grooves of the motor pulley, so that it could movein the middle

of the tension pulley width.

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 17

•If it is not possible to install the belt on the tension pulley, we can move themotor (16). Loosen the bolt M8 (11)

which ensures thecorrect position of the motor. Movethe motor to enable the belt installation and fasten it.

Tighten the securing bolt (11) carefully so that it would not deform the plastic washers (14,15).

•Put a newbelt PJ1473 (2) onthepulley. Installation of the belt isdone in reverse order compared to its removal.

Take care so that the tension springs (7) would be fasten to openings in the pulley support and to theframe

hinge.

•The belt must be placed in the correct grooves of the tension pulley, so that it could move in the middle of

the drum pulley width.

•Testing force of the correctly tight belt between the drum pulley and tension pulley is 100 - 110Hz, (180 - 210N),

measured by tension meter for measuring the force in the belt.

•Testing force of the correctly tight belt between the tension pulley and motor is 175 - 205Hz, (200 - 270N),

measured by tension meter for measuring the force in the belt.

•If the belt tension does not correspond to determinedvalues, we can adjust the belt tension by means of the bolt

which holds the springs or by additional moving the motor.

1. Drum pulley

2. Belt PJ1473

3. Pulley complete

4. Securing ring

5. Bolt M6x6

6. Belt PJ559

7. Spring

8. Bolt with eye M8x50

9. Nut M8

10. Pin

11. Bolt 5/16“x11/4“

12. Spring washer 8

13. Washer 8

14. Plastic washer 8,4x25x2

15. Plastic washer 8,2x12x3

16. Motor

Fig. 5.8.A. Flat belt, valid for 10 kg / 25 lbs

REPLACEMENT OF THE BELTS FOR THE MACHINE WITH CAPACITY

18 kg / 40 lbs, 22 kg / 50 lbs

1. Drum V-pulley

2. Belt PJ1956

3. Motor

4. Motor V-pulley

5. Motor board

6. Spring

Fig. 5.8.B. Flat belt, applicable for 18 kg / 40 lb,

22 kg / 50 lb

18 INSTALLATION AND MAINTENANCE MANUAL 523323 PUBLICATION DATE 2 OCT 2006.DOC

•Turning the drum pulley (1) slowly and by the belt (2) offset from its working position at the same time, you will

reach tension reduction and you can remove the pulley.

•Put the new belt of the same type on the motor pulley (4) first and then partly on the drum pulley (1), so that the

tension spring (6) is hooked. Turning the drum pulley (1) slowly put on the belt.

•The motor pulley and the drum pulley must be in one level.

•Testing force of the correctly tight belt between the drum pulley and the motor pulley measured by tension

meter formeasuring the force in the belt is 180-250N formachines 18 kg / 40 lb, 22 kg / 50 lb.

5.9. FUSES

FUSE VALUES

You can find values of fuses on electrical scheme delivered with the machine or on the machine label.

See also chapters 3.1. and 3.2.

523323 PUBLICATION DATE 2 OCT 2006.DOC INSTALLATION AND MAINTENANCE MANUAL 19

6. TROUBLE SHOOTING AIDS

6.1. EMERGENCY DOOR OPENING

Whenever the door fails to open, e.g. in case of a current failure or in emergency situation, we recommend

you to proceed as follows:

•Before the door is open, check the washing water temperature and machine parts temperature.

IF THESE PARTS ARE TOO HOT, DO NOT OPEN ! DANGER OF INJURY !

•After cooling down, remove the lower service panel by loosening the screws. Behind this service panel, at the

left side of the machine you will find a string for emergency door opening.

•While pulling this string downwards, you will unblock the door lock.

•You can open the door.

•Install the service panel.

6.2. FILLING TIME TOO LONG

LOW WATER PRESSURE:

More machines are filling up in the same time.

Filter of inlet valve is blocked (clogged):

Stop the main water supply, remove filters from inlet valves, clean up the filters and put them back.

THE HOSE IS LEAKING:

Replace the broken hose or seal on connection.

Defected inlet valve:

Replace the inlet valve.

6.3. HEATING TIME TOO LONG

SEDIMENT OR DEFECT ON THE ELECTRICAL HEATING ELEMENTS:

Replace the heating elements.

6.4. DRAIN TIME TOO LONG

DRAIN PIPE SYSTEM IS CLOGGED :

Clean it up.

NON-FUNCTIONAL DRAIN VALVE:

Clean or replace the drain valve.

6.5. PROGRAMMER PROBLEMS

See the chapter „Troubleshooting“ in the programming manual according to your machine type:

•„Programmingmanual - Electronic timer“

Other manuals for RS10

1

This manual suits for next models

2

Table of contents

Other Favor.it Washer manuals

Popular Washer manuals by other brands

Bosch

Bosch WAN280H1 Installation and operating instructions

Kenmore

Kenmore Kalypso 22082 owner's manual

Indesit

Indesit XWE 81283 Instructions for use manual

Siemens

Siemens iQ300 WM12N280HK User manual and installation instructions

LG

LG FH4G6TDG owner's manual

Hotpoint

Hotpoint WMF 740 P Instructions for use