FC Curtis NX Series User manual

CAP-835

June, 2018

Rev. E

WARNING

Personal injury and/or equipment damage will be result by failing to pay attention to the vital safety

information and instructions in this manual. Carefully read, understand, and retain all safety information and

instructions before operating this compressor.

NX Series

Oil –Injected Rotary Screw Compressor

Operator Manual

18 –185 kW (25 –250 HP)

CAP-835 3

Information on these operating instructions

These instructions enable you to use the

machine safely and efficiently. The instructions

are a component part of the machine and must

be accessible for staff at all times.

Staff must have carefully read and understood

these instructions before starting all work. The

basic prerequisite for safe working is compliance

with all the safety instructions and instruction for

actions included in these operating instructions.

The local occupational health and safety

regulations and general safety rules for

operational area of the machine also apply.

The instructions for the machine do not cover

operation of the controller. Therefore, the

instructions and content of the instructions for

the controller in question must also be taken into

account.

Copyright

These instructions are protected by copyright

and for internal purposes only.

These instructions must not be made available

to third parties, reproduced in any way -

even excerpts - and the content must not be

utilized and/or communicated, except for internal

purposes, without the written permission of the

manufacturer.

Any infringement shall be subject to

compensation for damages. We reserve the

right to assert further claims.

Limitation of liability

All information and instructions in this manual

have been compiled taking account of the

applicable standards and regulations, state-of-

the-art technology and our years of knowledge

and experience.

The manufacturer assumes no liability for

damages caused by:

◼failure to adhere to these instructions

◼improper use

◼use of unqualified staff

◼unauthorized conversions

◼technical modifications

◼use of non-approved spare parts

The actual scope of supply may differ from the

descriptions and illustrations in these

instructions in the case of special designs, the

inclusion of additional ordering options or as a

result of the latest technical modifications.

The obligations agreed in the contract of supply,

the manufacturer's general terms and conditions

of business and delivery and the legal

regulations valid at the time of completion of the

contract apply.

Technical Service

Our Technical Service department is available to

provide technical information.

In addition, our employees are always interested

in receiving new information and hearing of your

experiences from usage which could be valuable

for the improvement of our products.

Safety

It is assumed that your safety department will

have established a program of safety based

upon a thorough analysis of industrial hazards.

Before installing and operating or performing

maintenance on the equipment described in this

instruction book, it is suggested that you again

review this program to be certain that it covers

the hazards arising from high speed rotating

machinery.

It is also important that due consideration be

given to those hazards which arise from the

presence of electrical power, hot oil, high

pressure and temperature, steam, toxic gases

and flammable liquids and gases. Proper

installation and care of protective guards,

shutdown devices and over-pressure protection

should also be considered essential parts of any

safety program.

CAP-835

4

1Safety..........................................................................................................................................................................................6

1.1 Symbols in these instructions...........................................................................................................................................6

1.2 Proper use.......................................................................................................................................................................7

1.3 Safety devices.................................................................................................................................................................8

1.3.1 Position of the safety devices ....................................................................................................................................9

1.3.2 Description of the installed safety devices .................................................................................................................9

1.4 Environmental protection ...............................................................................................................................................10

1.5 Signage.........................................................................................................................................................................10

2Transportation, packaging and storage..................................................................................................................................12

2.1 Safety instructions for transportation..............................................................................................................................12

2.2 Inspection on receipt of delivery.....................................................................................................................................12

2.3 Packaging......................................................................................................................................................................12

2.4 Symbols on the packaging.............................................................................................................................................12

2.5 Transportation ...............................................................................................................................................................13

2.6 Storage..........................................................................................................................................................................13

3Installation and commissioning..............................................................................................................................................14

3.1 Safety instructions for the installation and commissioning..............................................................................................14

3.2 Requirements in the installation location........................................................................................................................15

3.3 Installation.....................................................................................................................................................................15

3.3.1 Remove shipping spacers .......................................................................................................................................15

3.3.2 Ventilation ...............................................................................................................................................................15

3.3.3 Connection to the compressed air network..............................................................................................................16

3.3.4 Connecting to the power supply...............................................................................................................................16

3.4 Checking the oil level.....................................................................................................................................................17

3.5 Start-up lubrication of the compressor airend.................................................................................................................17

3.6 Switching on after installation.........................................................................................................................................18

3.7 Work after the initial commissioning...............................................................................................................................18

4Design and function.................................................................................................................................................................20

4.1 Overview .......................................................................................................................................................................20

4.2 Brief description.............................................................................................................................................................24

4.3 Assembly description.....................................................................................................................................................24

4.3.1 Enclosure doors ......................................................................................................................................................24

4.3.2 Screw Compressor..................................................................................................................................................24

4.3.2.1 Drive unit.................................................................................................................................................................24

4.3.2.1.1 Screw compressor with V-belt drive ....................................................................................................................25

4.3.2.1.2 Screw compressor with direct drive.....................................................................................................................25

4.3.3 Intake filter...............................................................................................................................................................25

4.3.4 Compressor airend..................................................................................................................................................25

4.3.5 Oil separator tank....................................................................................................................................................26

4.3.6 Air/oil separator.......................................................................................................................................................26

4.3.7 Minimum pressure and non-return valve..................................................................................................................27

4.3.8 Coolers....................................................................................................................................................................27

4.3.9 Oil filter....................................................................................................................................................................28

4.3.10 Cooling air fan.........................................................................................................................................................28

4.4 Interfaces.......................................................................................................................................................................29

CAP-835 5

5Technical data..........................................................................................................................................................................30

5.1 Serial tag.......................................................................................................................................................................30

5.2 General specifications....................................................................................................................................................31

5.2.1 Operating conditions................................................................................................................................................31

5.2.2 Oil............................................................................................................................................................................31

5.2.3 Oil Capacity.............................................................................................................................................................31

6Operation..................................................................................................................................................................................32

6.1 Safety instructions for operation.....................................................................................................................................32

6.2 Modulation Control.........................................................................................................................................................32

7Maintenance.............................................................................................................................................................................33

7.1 Environmental protection ...............................................................................................................................................33

7.2 Spare parts....................................................................................................................................................................33

7.3 Maintenance schedule...................................................................................................................................................33

7.4 Service kits....................................................................................................................................................................34

7.5 Maintenance work..........................................................................................................................................................36

7.5.1 Checking for leaks...................................................................................................................................................36

7.5.2 Checking the electrical connections.........................................................................................................................36

7.5.3 Checking the oil level/topping up the oil...................................................................................................................36

7.5.4 Checking the build-up of condensation....................................................................................................................37

7.5.5 Checking the compressor temperature....................................................................................................................38

7.5.6 Inspect/clean coolers...............................................................................................................................................38

7.5.7 Checking the drive unit............................................................................................................................................38

7.5.8 Re-lubricating the electric motor ..............................................................................................................................38

7.5.9 Replacing the oil/changing the oil filter.....................................................................................................................39

7.5.10 Replacing the air/oil separator.................................................................................................................................40

7.5.10.1 Spin on/off separator style.......................................................................................................................................40

7.5.10.2 Drop in style separator............................................................................................................................................40

7.5.11 Replacing the intake filter ........................................................................................................................................40

7.6 Clean/replace return line................................................................................................................................................41

7.7 Measures after maintenance has been performed.........................................................................................................41

8Faults........................................................................................................................................................................................42

8.1 Safety instructions for fault clearance.............................................................................................................................42

8.2 Fault displays.................................................................................................................................................................43

8.3 Troubleshooting.............................................................................................................................................................44

8.4 Work for fault clearance.................................................................................................................................................45

8.5 Commissioning after remedied fault...............................................................................................................................45

9Index .........................................................................................................................................................................................46

10 Appendix...................................................................................................................................................................................47

10.1 Bolt tightening torque requirements................................................................................................................................47

10.2 Oil change intervals at elevated temparatures................................................................................................................47

CAP-835

6

1 Safety

This section is a summary of important safety

aspects to ensure optimum protection of the

personnel and safe and trouble-free operation.

The owner, lessor or operator of this com-

pressor is hereby notified and forewarned

that failure to observe these safety

precautions may result in injury and/or

property damage.

FS Curtis does not mean to imply that the

following safety precautions are all-inclusive or

that the observance of these precautions will

prevent all injury or property damage.

FS Curtis expressly disclaims responsibility or

liability for any injury or property damage caused

by failure to follow these specified precautions or

by failure to exercise ordinary caution and due

care required in operating or handling this

equipment even though not expressly specified.

1. Read and understand all the instructions

found in this manual before operating your

compressor.

2. Disconnect the main power source before

working on or performing any maintenance

procedures on this unit. Use a lock out and

tag out process.

3. Do not attempt to remove any parts, break

any connection, loosen oil fill plug or drain

plug until the unit has been shut down and

air pressure has been relieved.

4. Do not operate the compressor in excess of

its rated pressures and speeds indicated on

the compressor nameplate.

5. Do not remove guards, shields, or screens

while the compressor is in operation. If

removed for maintenance replace before

resuming operation.

6. Observe the delivery pressure gauge daily

to be sure the automatic control system is

operating within proper limits.

7. Periodically check all safety and relief

devices for proper operation.

8. Use compressed air properly. Pressurized

air can cause serious injury to personnel.

9. Be sure that no tools, rags or loose parts are

left in or on the compressor or drive parts.

10. Do not use flammable solvents for cleaning

parts.

11. Exercise cleanliness during maintenance

and when making repairs. Keep dirt away

from parts and exposed openings by

covering with clean rags or plastic to prevent

cross contamination.

12. Do not install a shut-off valve in the

discharge line without installing a pressure

relief valve between the shut-off and the

compressor package.

13. Do not operate the compressor in areas

where there is a possibility of flammable or

toxic substances entering the system.

14. Never disconnect (or jump) the air discharge

temperature switch or any other safety

device and attempt to operate the

compressor.

15. Know what state of operation the

compressor is in before working around the

unit. The power may be on and the machine

not running if it is in the auto restart mode.

Adhere to note #2 above.

16. Make sure to follow the local electrical and

environmental code requirements in your

area to ensure compliance prior to installing

the compressor.

1.1 Symbols in these instructions

Safety instructions

The safety instructions and safety information in

these instructions are denoted by symbols. The

safety instructions are prefaced by signal words

which express the extent of the risk.

DANGER!

This combination of symbol and

signal word indicates a direct

hazardous situation which will lead to

serious or even fatal injuries if not

avoided.

WARNING!

This combination of symbol and

signal word indicates a possibly

hazardous situation which may lead

to serious or even fatal injuries if not

avoided.

CAUTION!

This combination of symbol and

signal word indicates a possibly

hazardous situation which may cause

minor or light injuries if not avoided.

CAP-835 7

NOTICE!

This combination of symbol and

signal word indicates a possibly

hazardous situation which may

cause material damage if not

avoided or possible hazards for the

environment.

Safety instructions in action sequences

Safety instructions may relate to certain,

individual instructions for actions. These safety

instructions are embedded in the instruction for

action so that they do not interrupt the flow of

reading when performing the action. The signal

words described above are used.

Example:

1.

Unfasten the screw.

2.

CAUTION!

Risk of entrapment on the

cover!

Close the cover carefully.

3.

Tighten the screw.

Special safety instructions

The following symbols are used in conjunction

with the safety instructions in order to draw

attention to particular hazards:

Warning –high-

voltage.

Warning –explosive

substances.

Warning –danger

zone.

Tips and recommendations

This symbol indicates tips and

recommendations and information

for efficient and fault-free operation.

Further markings

The following markings are used in these

instructions for emphasizing instructions for

actions, results, lists, cross references and other

elements:

Marking

Explanation

Step-by-step instructions for

actions

Results of actions

References to sections of these

instructions and other

applicable documents

Lists without a set order

[Button]

Operating controls (e.g.

buttons, switches), display

elements (e.g. indicator lamps)

"Display"

Screen elements (e.g. buttons,

assignment of function keys)

1.2 Proper use

The machine is designed and constructed

exclusively for the proper use described here.

Do not operate the compressor in excess of

its rated pressures, operating conditions,

and speeds indicated on the compressor

nameplate.

The proper use also includes adherence to all

details in this manual.

Any use beyond the proper use or other type of

use counts as misuse.

WARNING!

Danger due to misuse!

- The compressed air may not be

used for breathing without

appropriate after-treatment.

- The compressed air may not be

used directly for the handling of

food without appropriate after-

treatment.

- The screw compressor may not

be operated outdoors.

- The screw compressor or

individual components may not

be rebuilt, modified or re-

equipped.

CAP-835

8

Claims of any type for damage due to misuse

are excluded.

1.3 Safety devices

WARNING!

Danger to life from nonfunctional

safety devices!

If safety devices are not functioning

or are disabled, there is a danger of

injury or death.

- Check that all safety devices are

fully functional and correctly

installed before starting work.

- Never disable or bypass safety

devices.

- Ensure that all safety devices

are always accessible.

CAP-835 9

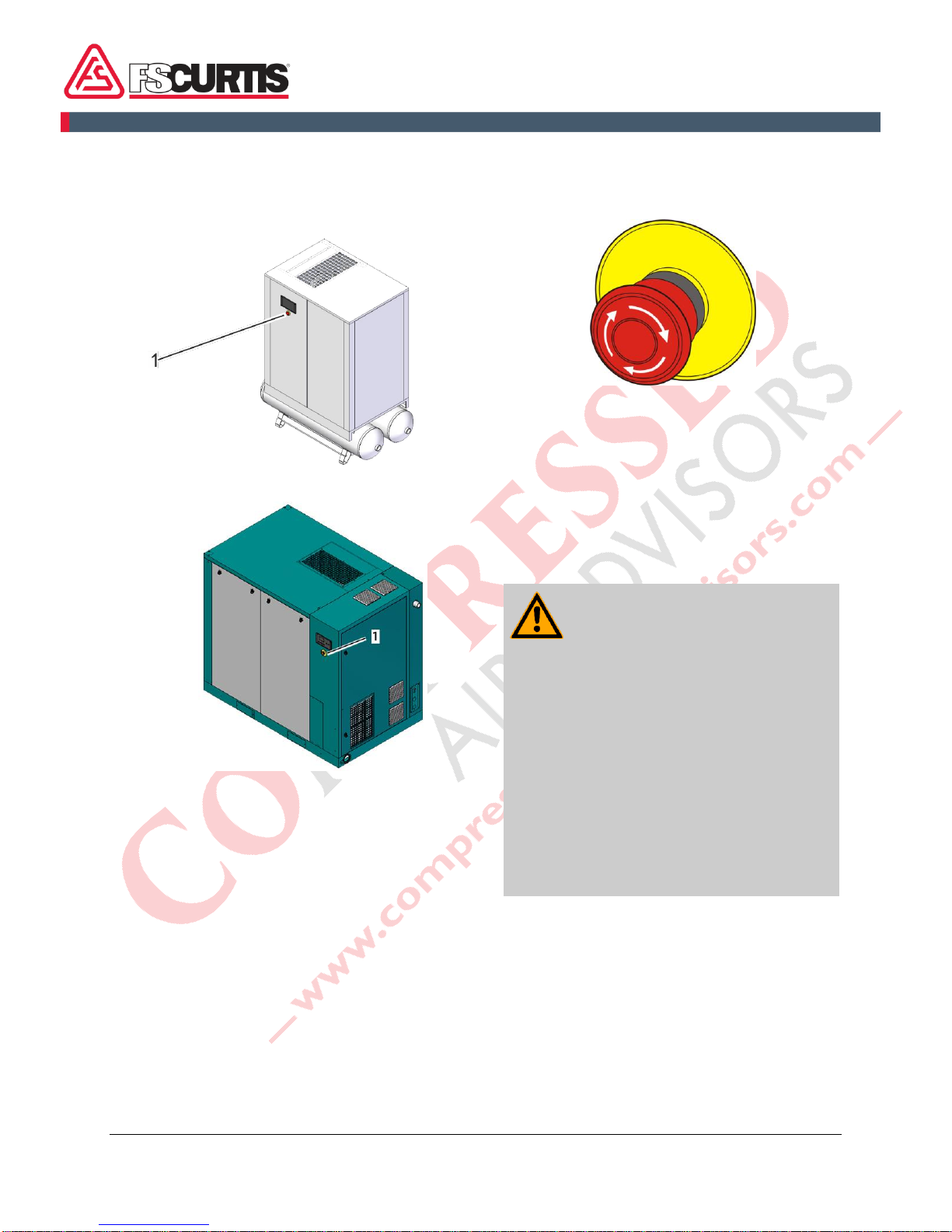

1.3.1 Position of the safety

devices

The following illustrations show the position of

the safety devices.

Fig. 1: Emergency stop button (Fig.1-1) on the screw

compressor 18–37 kW with tank (optional)

Fig. 2: Emergency stop button (Fig.2-1) on the screw

compressor 45–185 kW

1.3.2 Description of the installed

safety devices

Emergency stop button

Fig. 3: Emergency stop button

By pressing the emergency stop button, the

machine is stopped by an immediate switching

off of the compressor. After the emergency stop

button has been pressed, it must be unlocked by

turning it so that the button is released. The

controller fault must be reset. Refer to the

controller documentation for information on

fault displays.

WARNING!

Danger to life from an

unauthorized restart!

An uncontrolled restart of the

machine may cause serious injuries

including death.

- Before switching the machine

back on, make sure the cause of

the emergency stop has been

removed and all safety devices

have been installed and function

properly.

- Do not unlock the

EMERGENCY-STOP button

until there is no more danger.

Relief valves

Relief valves are unburdening equipment for

areas under pressure such as pressure vessels

and pipes. In case of an impermissible pressure

increase, relief valves bleed off gases, vapors or

liquids into the atmosphere.

CAP-835

10

Fig.4: Pressure Relief Valve

Do not change the pressure setting of the

pressure relief valve, restrict the function of

the relief valve or replace the relief valve with

a plug.

1.4 Environmental protection

NOTICE!

Danger to the environment from

incorrect handling of pollutants!

Incorrect handling of pollutants,

particularly incorrect waste disposal,

may cause serious damage to the

environment.

- Always observe the instructions

below regarding handling and

disposal of pollutants.

- Take the appropriate actions

immediately if pollutants escape

accidentally into the

environment. If in doubt, inform

the responsible municipal

authorities about the damage

and ask about the appropriate

actions to be taken.

The following chemicals are used:

Oil

Oils can contain substances that are harmful to

the environment. They must not be allowed to

escape into the environment. Store oils in

suitable containers and dispose of in

accordance with applicable local, state and

federal regulations

Lubricants

Lubricants such as greases and oils can contain

harmful substances. They must not be allowed

to escape into the environment. Dispose of

lubricants in accordance with applicable local,

state and federal regulations.

1.5 Signage

WARNING!

Danger of injury from illegible

symbols!

Stickers and signs can become dirty

or otherwise obscured over time,

with the result that dangers cannot

be recognized and the necessary

operating instructions cannot be

complied with. This, in turn, poses a

risk of injury.

- All safety, warning and operating

instructions must always be

maintained in a completely

legible condition.

- Damaged signs or stickers must

be replaced immediately.

Direction of rotation

There is a direction of rotation sticker on the

drive unit and on the cooling air ventilator. This

sticker shows the appropriate direction of

rotation.

CAP-835 11

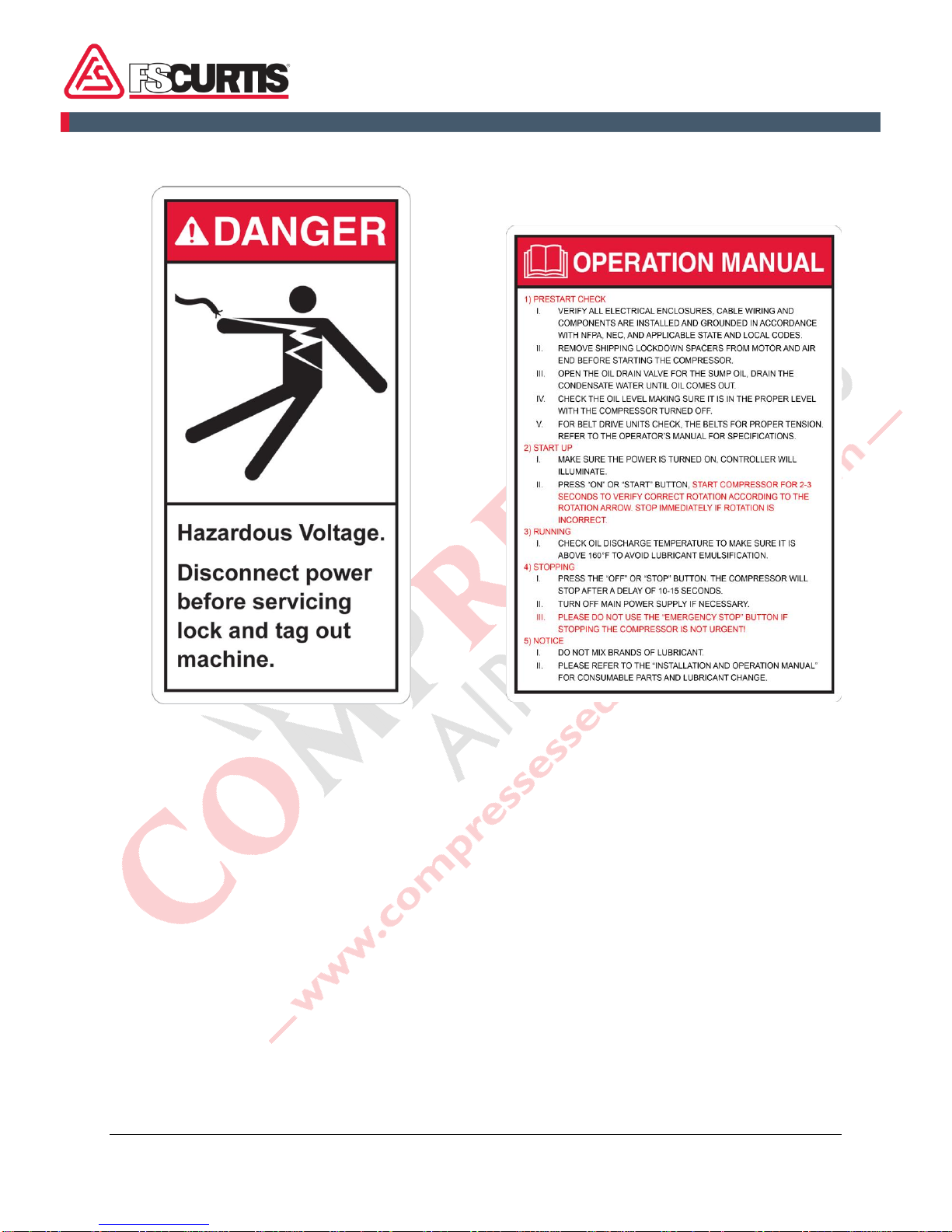

Hazardous Voltage Brief instructions for operation

This sticker is on the enclosure and contains

brief instructions for operation.

CAP-835

12

2 Transportation, packaging and storage

2.1 Safety instructions for

transportation

Improper transport

NOTICE!

Damage to property due to

improper transport!

Air compressors may fall or tip over

as a result of improper transport.

This can cause a significant level of

property damage.

- Proceed carefully when

unloading compressor units at

delivery and during in-house

transport; observe the symbols

and instructions on the

packaging.

- Only use the attachment points

provided.

- Only remove the packaging

shortly before assembly.

2.2 Inspection on receipt of

delivery

On receipt, immediately inspect the delivery for

completeness and transport damage.

Proceed as follows in the event of externally

apparent transport damage:

◼Do not accept the delivery, or only accept it

subject to reservation.

◼Note the extent of the damage on the

transport documentation or the shipper's

delivery note.

◼Initiate complaint procedures.

Issue a complaint in respect of each

defect immediately following

detection. Damage compensation

claims can only be asserted within

the applicable complaint deadlines.

2.3 Packaging

About the packaging

The individual screw compressors are packaged

in cartons or sometimes on wooden frames and

according to the anticipated transport conditions.

Only environmentally-friendly materials are used

for the packaging.

The packaging should protect the individual

components against transport damage,

corrosion and other damage until assembly.

Therefore, do not destroy the packaging and

only remove it shortly before assembly.

Handling packaging materials

Dispose of packaging material in accordance

with the relevant applicable legal requirements

and local, state and federal regulations.

2.4 Symbols on the packaging

The following symbols can be on the packaging.

Always heed these symbols during transport.

Top

The arrow tips on the sign mark the top of the

package. They must always point upwards;

otherwise the content could be damaged.

Fragile

Marks packages with fragile or sensitive

contents.

Handle the package with care; do not allow to

fall and do not expose to impacts.

CAP-835 13

Protect against moisture

Protect packages against moisture and keep

dry.

2.5 Transportation

Transportation with a fork lift

Packages can be transported with a fork lift

under the following conditions:

◼The fork lift must be engineered for the

weight of the packages.

◼Existing guide rails on the frame must be

used.

◼The length of the forks must be at least 55

inch (1400 mm).

Transporting

Fig. 5: Transportation with a fork lift

1.

Drive the fork lift with the forks as shown in

Fig. 5.

2.

Insert the forks so that they stick out on the

other side.

3.

Ensure that the package cannot tip if the

centre of gravity if off-centre.

4.

Lift the package and begin transportation.

2.6 Storage

Storage of the packaged compressor

Store the compressor under the following

conditions:

◼Do not store outdoors.

◼Store dry and dust-free.

◼Do not expose to any aggressive media.

◼Protect against solar radiation.

◼Avoid mechanical jolts.

◼Storage temperature: 60 to 95F (15 to 35

°C).

◼Relative humidity: max. 60 %.

◼In case of storage for longer than 3 months,

check the general condition of all parts and

the packaging regularly. If necessary, refresh

or replace the rust-proofing.

Under some circumstances there

may be notes about storage on the

packaging that extend beyond the

requirements named here. Adhere

to these accordingly.

◼Extended storage: Rotate the compressor

and motor by hand every thirty to sixty days

to prevent flat spots on the bearings that can

lead to premature failure.

CAP-835

14

3 Installation and

commissioning

3.1 Safety instructions for the

installation and

commissioning

Electrical system

DANGER!

Danger to life from electric

power!

Contact with live parts may prove

fatal. When switched on, electric

components can be subject to

uncontrolled movements and may

cause grave injury or death.

- Switch off the power supply

before starting work and make

sure that it cannot be switched

on again. Follow lockout/ tagout

procedure.

Improper initial commissioning

WARNING!

Danger of injury due to improper

initial commissioning!

Improper initial commissioning can

result in serious injury and

significant damage to property.

- Before the initial commissioning,

ensure that all installation work

has been carried out and

completed in accordance with

the information and instructions

in this manual, National Electric

Code, and local state and

federal regulations.

Securing to prevent restart

WARNING!

Danger to life from an

unauthorized restart!

In the event of an unauthorized

restart of the power supply during

installation, there is a danger of

serious injuries or death for persons

in the danger zone.

- Switch off all power supplies

before starting work and make

sure they cannot be switched on

again. Follow lockout/ tagout

procedure.

Improper installation and commissioning

WARNING!

Risk of injury due to improper

installation or commissioning!

Improperly performed installation

and commissioning may lead to

serious injury and significant

material damage.

- Provide for sufficient mounting

clearance before starting to

work.

- Use caution when handling

exposed components with sharp

edges.

- Keep the assembly area tidy and

clean! Loose components and

tools lying around or on top of

each other may lead to

accidents.

- Mount all components properly.

Tighten all screws to the

prescribed torque.

- Secure components to prevent

them from falling down or tipping

over.

- Observe the following prior to

commissioning:

- make sure that all installation

work has been performed

and completed following the

instructions and information

provided in this manual.

- make sure that no persons

are still in the danger zone of

the machine.

CAP-835 15

3.2 Requirements in the

installation location

Set up the screw compressor so that the

following conditions are fulfilled:

◼The installation location is level.

◼The machine is easily accessible and can be

accessed from all sides.

◼There is sufficient lighting.

◼There is sufficient ventilation.

◼There is a power supply available.

◼Escape paths and rescue equipment are

freely accessible.

◼The machine is not subjected to an explosive

atmosphere.

◼The machine is not subjected to a corrosive

atmosphere.

◼The machine is not subjected to direct solar

radiation.

◼Outside heating from surrounding heat

sources is excluded.

◼There is no dust accumulation.

◼Fire protection measures have been taken.

◼The machine is not subjected to vibrations.

◼The floor is resistant to solvents,

impermeable to liquids, anti-static and easy

to clean.

◼There are no machines in the vicinity that

cause electrical or electromagnetic

disturbance.

3.3 Installation

3.3.1 Remove shipping spacers

To protect the vibration isolators underneath the

motor/airend assembly during transport, there

are red spacers that hold the assembly in place.

Make sure all of these spacers are removed

before first startup of the compressor. Failure

to remove the spacers will result in excessive

vibration and can cause damage to the

compressor.

Fig.6 : Shipping spacer

3.3.2 Ventilation

DANGER!

Risk of fatal injury from the use

of explosive gas mixtures,

vapors, dust or aggressive

hazardous substances!

The use of explosive gas mixtures,

vapors, dust or aggressive

hazardous substances to ventilate

the screw compressor can cause

severe or even fatal injuries as well

as significant material damage.

- Never use explosive gas

mixtures, vapors, dust or

aggressive hazardous

substances to ventilate the

screw compressor.

- Make sure that no potentially

explosive gas mixtures, vapors,

dust or aggressive hazardous

substances enter into the

ventilation for the screw

compressor.

The air fed via the intake openings is used for

compression and for cooling the machine.

CAP-835

16

NOTICE!

Risk of material damage from

condensation!

Cooling air with moisture content

can cause condensation.

- Make sure that the cooling air is

cool, dry and free of dust.

1.

Provide the required rate of cooling air as per

the technical data sheet for the screw

compressor.

2.

Extract the exhaust air as per the technical

data sheet for the screw compressor.

This prevents the installation room and the

screw compressor from heating up.

3.3.3 Connection to the

compressed air network

WARNING!

Danger of injury due to

unpredictable movement of the

compressed air hose!

Load switches in the compressed

air network causes jerky

movements of the compressed air

hose with high force.

- Anchor and fasten the

compressed air hose sufficiently.

The prerequisite for the correct

installation is the presence of a

professionally-planned, installed

and maintained compressed air

network and an additional shut-off

valve installed at the entrance to the

compressed air network.Relief

valves are to be placed ahead of

any potential blockage point,

including but not limited to shut-off

valves, heat exchangers and

discharge silencers.Always direct

discharge from relief valves away

from areas where personnel may

be.

FSC base mounted compressor packages come

with a mounted starter. Ensuring that the starter

is mounted per national and local NEL

requirements, it’s responsibility of the owner.

1.

Connect the compressed air.

2.

Ensure that the compressed air connection

does not represent a stumbling hazard.

3.

Anchor and fasten the compressed air

connection sufficiently.

Air piping requirements:

1. Install required accessories.

2. Main piping should have 1˚- 2˚ slant away

from the compressor to drain the condensate.

3. Pressure drop of piping must not exceed 5%

of discharge pressure. Select larger piping than

required for better efficiency.

4. Branch line must be located at the topside of

main piping to avoid condensate from flowing

into the facilities.

5. To prolong service life of pneumatic tools,

install an air filter regulator unit on the outlet.

6. Do not randomly reduce the size of the main

piping. If necessary, use the proper

reducer or a large pressure loss may incur .

7. The common installation arrangement is; air

compressor + air tank + dryer. An air tank is

capable of draining some of the condensate and

cooling down the temperature of compressed

air. This will lead to more efficient dryer opera-

tion.

8. If the air requirement is large for a short peri-

od, install a higher volume air tank to reduce the

frequency of full/off load control.

9. The ideal piping main would be constructed

around the factory as a loop for delivering com-

pressed air from both sides at any point.

3.3.4 Connecting to the power

supply

Personnel:

◼Qualified Electrician

NOTICE!

Property damage to the

compressor airend due to

incorrect connection of the power

supply!

In case of incorrect connection of

the power supply, there is a danger

that the compressor airend will be

CAP-835 17

destroyed due to the drive turning

incorrectly.

- Connect the power according to

the wiring diagram and check the

airend and motor for correct

rotation before starting the

compressor.

The prerequisite for the correct

installation are professionally sized

fuses in the network supply

(person/system protection) and an

appropriate main switch (for switching

the supply on and off).

1.

Using the data in the wiring diagram, check

whether the existing supply network is

suitable. Voltage deviations of more than

10% are not permitted.

2.

Connect the power according to the wiring

diagram.

3.

Check correct direction of rotation by briefly

starting the compressor and verifying that the

rotation of the machine follows the arrows on

the main motor and fan motor.

4.

Ensure that the power cable does not

represent a stumbling hazard.

5.

Select the correct wire diameter according to

the rated power of the air compressor. Do not

use wire diameter that is too small, or power

cord will be easily burnt out and generate

danger.

6.

Avoid use with other systems with different

power consumption in parallel. If it is used in

parallel, excessive voltage drop or three-

phase current unbalance will result in electri-

cal overload and the protective devices will

shut down the machine.

7.

Power supply cable, fuse and air-break

switch need to match the compressor power

supply requirements to ensure the safety of

all electrical components.

8.

It is necessary to confirm the correct voltage

while performing power distribution of the air

compressor.

9.

The grounding wire of a motor or system

must be reliably installed and grounding wire

cannot be connected to air delivery pipe or

cooling water pipe. Air compressor must be

reliably grounded to prevent danger from

electrical leakage.

10.

Ensure that the power supply is shut off be-

fore any electrical maintenance work. Use

lockout tag out.

3.4 Checking the oil level

1.

Switch the compressor off and secure it to

prevent it from being switched back on

again.

2.

Open and remove the enclosure panels with

the special wrench.

Fig. 7: Inspection glass

3.

Check the inspection glass (Fig. 7-1) to make

sure the oil is between the top and bottom oil

level indicator lines.

4.

If necessary, top up oil

Chapter 7.5.9

‘Replacing the oil/changing the oil filter’ on

page 39.

3.5 Start-up lubrication of the

compressor airend

NOTICE!

Risk of material damage due to a

lack of oil in the compressor

airend!

A lack of oil in the compressor

airend after longer downtimes, e.g.

between factory delivery and initial

commissioning or after a longer

1

CAP-835

18

downtime, can cause significant

material damage to the screw

compressor.

- Add 0.5 quarts of oil directly in

the compressor airend before

initial commissioning or after a

longer downtime.

Fig. 8: Intake valve fastening screw

1.

Unfasten the fastening screws on the intake

valve (Fig. 8-1).

NOTICE!

Property damage due to incorrect

oil!

Mixing different oils or using

incorrect oils causes significant

property damage to the screw

compressor.

- Only use the oil prescribed in the

technical data.

- For high temperature systems,

use only fully synthetic oil FSC-

8000.

2.

Unscrew the intake valve.

3.

Pour oil directly into the compressor airend.

4.

Re-fit the intake valve and tighten the

screws.

3.6 Switching on after installation

1.

Check all connections to make sure they are

installed correctly and all screws are properly

fastened.

2.

Make sure that there are no tools or loose

objects lying in or on the machine.

3.

Install the enclosure doors and make sure

that they are sealed.

4.

Carefully open the shut-off valve downstream

of the discharge port between the screw

compressor and the compressed air network.

The screw compressor is now connected

to the compressed air network.

5.

Switch on the main switch.

6.

Start the screw compressor

controller

documentation.

The compressor is ready and may start up

automatically at any time.

3.7 Work after the initial

commissioning

WARNING!

Danger of injury from hot

surfaces!

Surfaces of components can heat

up a lot during operation. Skin

contact with hot surfaces will cause

severe skin burns.

- Wear heat-resistant protective

clothing and protective gloves

during all work near hot

surfaces.

- Before all work, make sure that

all surfaces have cooled off to

the ambient temperature, wait at

least 30 minutes.

CAUTION!

Danger of injury from oil vapor!

In case of high temperatures oil

vapor can form. Oil vapor can

irritate eyes and the respiratory

system.

- When working on the oil system

and if an oil vapor arises, wear

breathing protection and

protective goggles and ensure

that there is a fresh air supply.

1.

Switch the screw compressor off and secure

it to prevent it from being switched back on

again.

2.

Open and remove the cubicle doors with the

special wrench.

3.

Wait until the components have cooled.

CAP-835 19

4.

Check all oil and compressed air lines for

leaks and tighten as necessary.

5.

Tighten screws where needed.

6.

Check the oil level in the inspection glass

and top up as described in

Chapter 7.5.3

‘Checking the oil level/topping up the oil’ on

page 36 if necessary.

7.

Install the enclosure doors and make sure

that they are sealed.

NOTICE!

Risk of material damage due to too

low or too high compressor

temperature!

If the compressor temperature is too

low or too high, the screw compressor

may become damaged.

- For detailed information, contact the

manufacturer.

If the compression temperature is

sufficiently high, this ensures that the

air humidity taken in does not form

condensation. Frequent switching on

and off of the screw compressor can

prevent the compressor from reaching

the required operating temperature

Chapter 7.5.4 ‘Checking the build-up

of condensation’ on page 37.

5.

Check the compressor temperature

Chapter 7.5.5 ‘Checking the compressor

temperature’ on page 38.

CAP-835

20

4 Design and function

4.1 Overview

Screw compressor

Fig. 9: Screw compressor

1

Controller

2

Emergency stop button

3

Enclosure panels

4

Air receiver (optional on 18 - 22 kW models)

This chapter shows the screw compressors described in these instructions. The compressors differ

primarily in size and the installed drive. However, their basic design is the same.

Table of contents

Popular Air Compressor manuals by other brands

EINHELL

EINHELL TH-AC 190 Kit Original operating instructions

Stanley

Stanley DN55/8/5 Instruction manual for owner's use

mycom

mycom V-Series Handling manual

Airam

Airam 38 instructions

Campbell Hausfeld

Campbell Hausfeld CE1000 Operating instructions and parts manual

RTI

RTI CS1200 Instructions and operating manual

VITO

VITO PRO-POWER VICO50A instruction manual

hecht

hecht 2360 TRANSLATION OF ORIGINAL INSTRUCTIONS FOR USE

Schneider Airsystems

Schneider Airsystems UNM 210-8-25 W operating manual

Ingersoll-Rand

Ingersoll-Rand GHH RAND SILU CS1050 LITE operating manual

Stanley

Stanley HY 227/8/6E Instruction manual for owner's use

Contimac

Contimac Silent 705 Series manual