CONTENTS

INTRODUCTION.......................................................................................................................................3

WARNING LABELS & SAFETY INSTRUCTIONS.............................................................................4

PRE-INSTALLATION PROCEDURES..................................................................................................5

INSPECTION FOR SHIPPING DAMAGE...............................................................................5

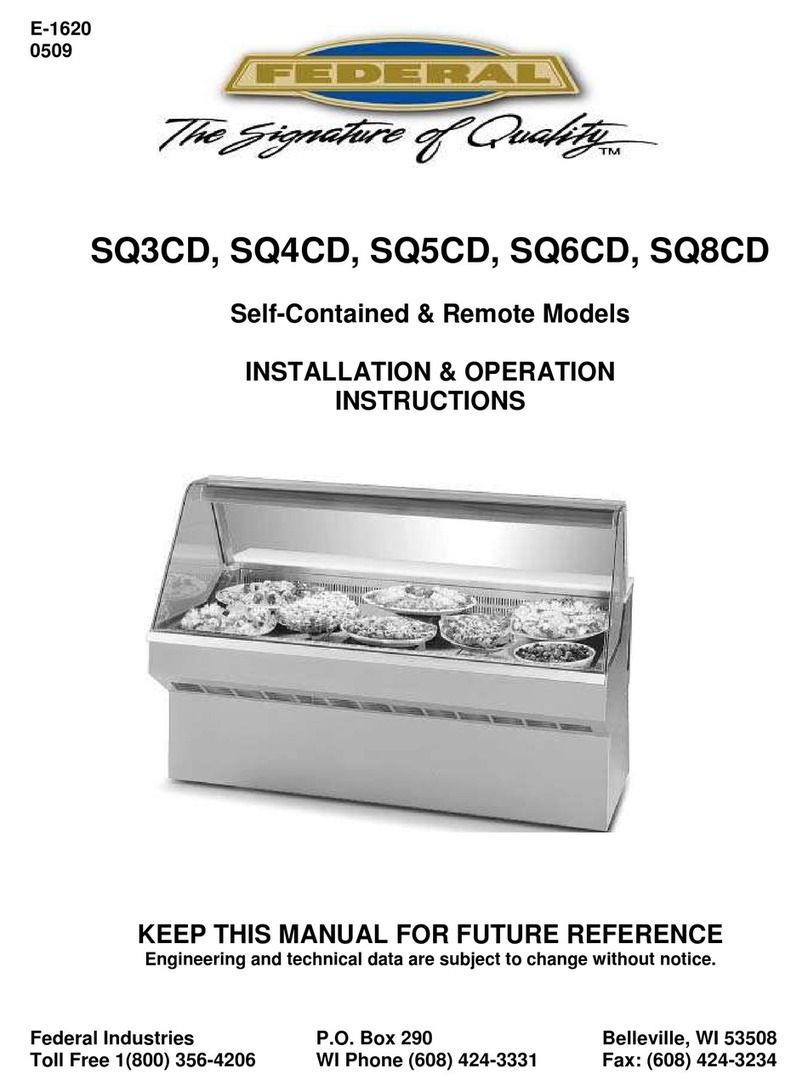

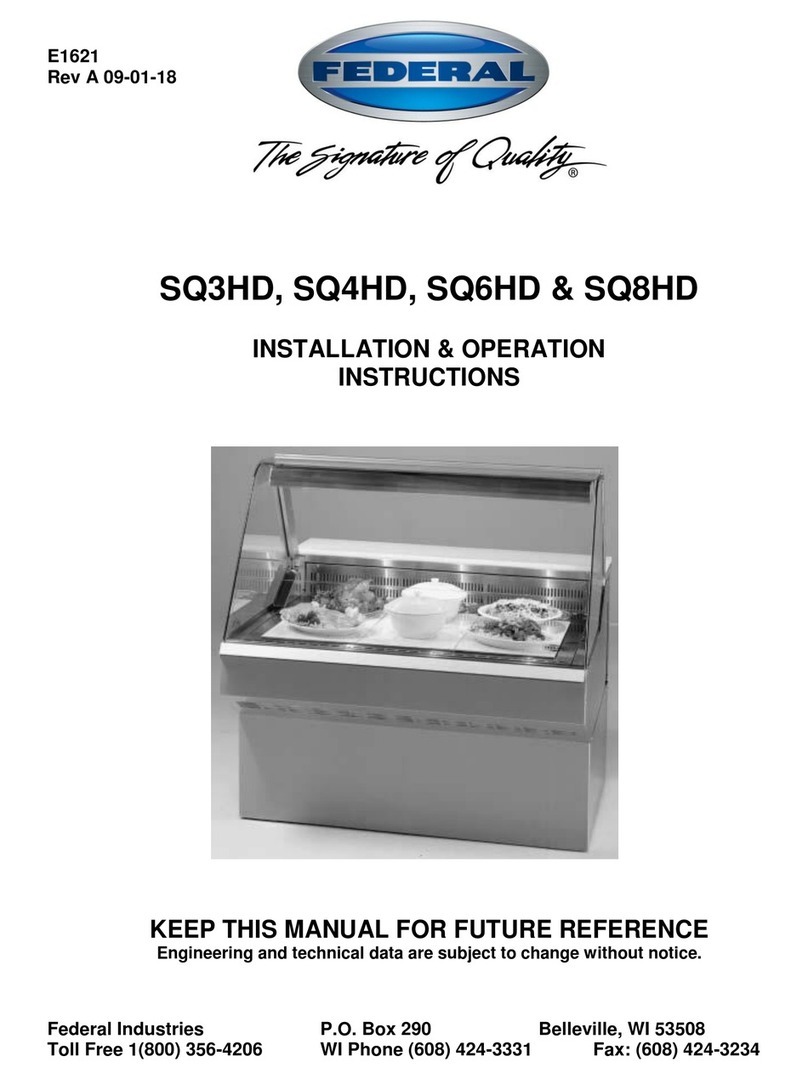

INSTALLATION INSTRUCTIONS......................................................................................................5-8

LOCATING THE DISPLAY CASE ..........................................................................................5

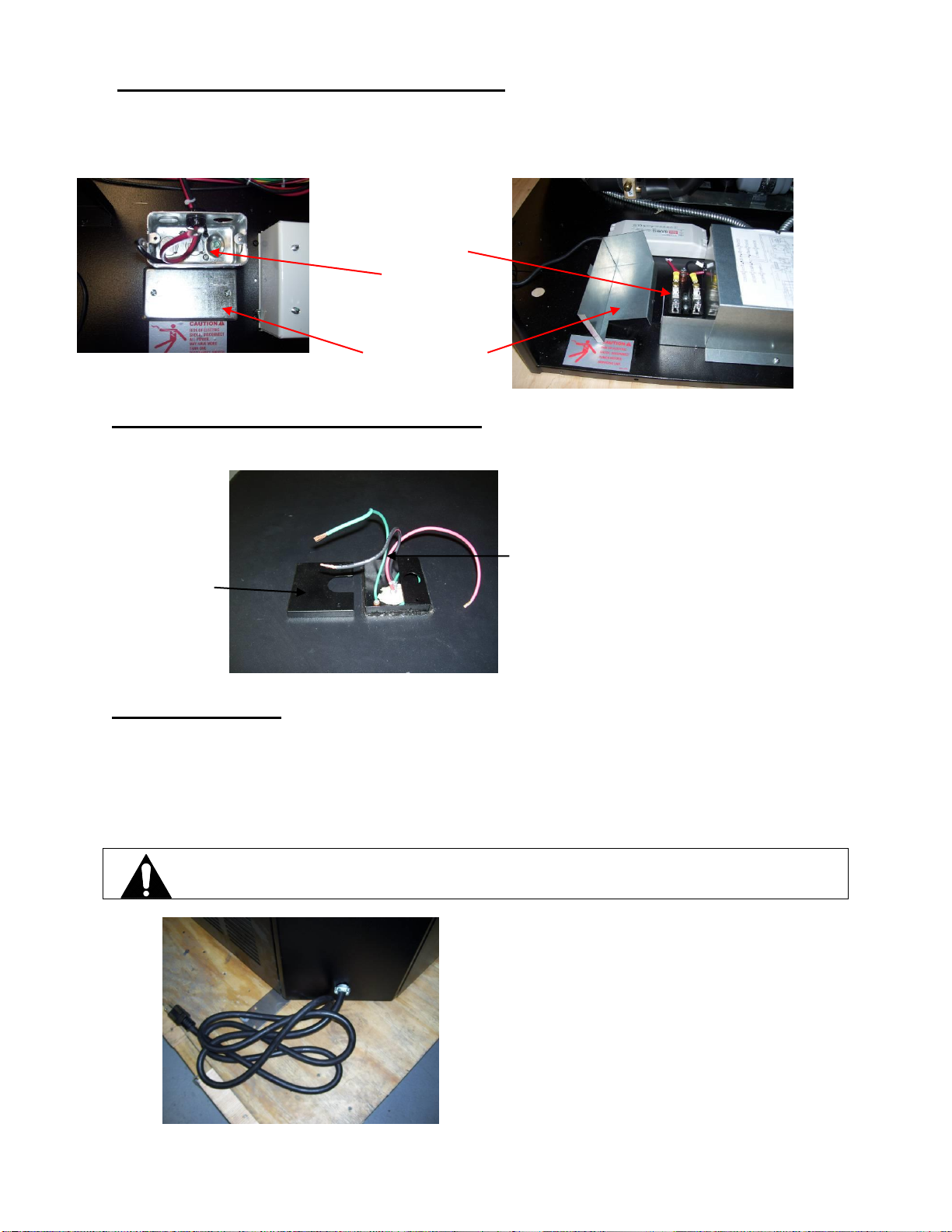

ELECTRICAL CONNECTION ..............................................................................................5-6

PERMANENT CONNECTED..................................................................................................5

STANDARD BASE ELECTRICAL CONNECTION ..........................................................5-6

TOP ELECTRICAL CONNECTION....................................................................................... 6

CORD CONNECTED ................................................................................................................ 6

REMOVING CASE FROM SHIPPING SKID ..........................................................................7

REMOVING PACKAGING MATERIAL.................................................................................7

LEVELING THE CASE.............................................................................................................7

SEALING THE UNIT TO THE FLOOR...................................................................................8

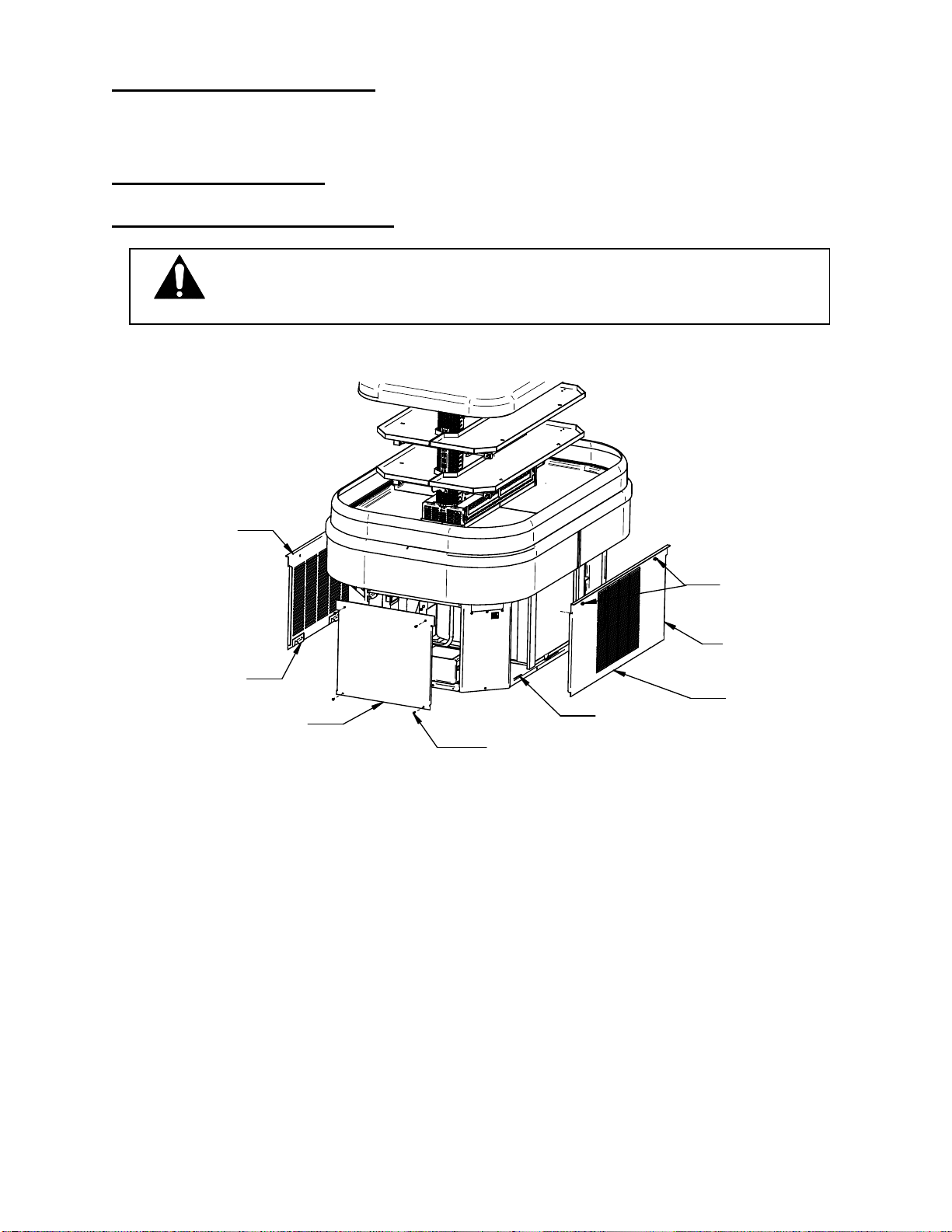

BASE PANELS REMOVAL IMSS60 & IMSS84.....................................................................8

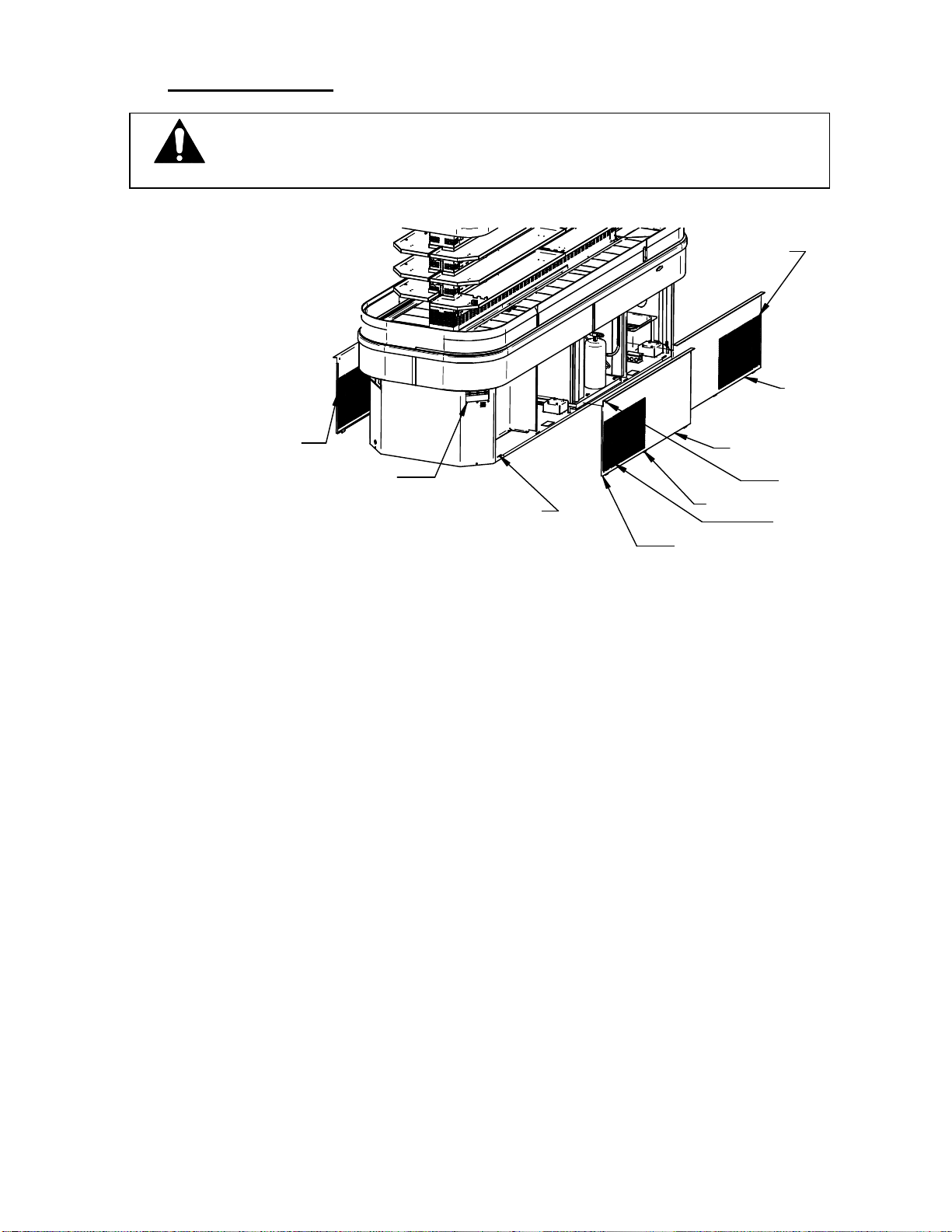

BASE PANELS REMOVAL IMSS120.....................................................................................9

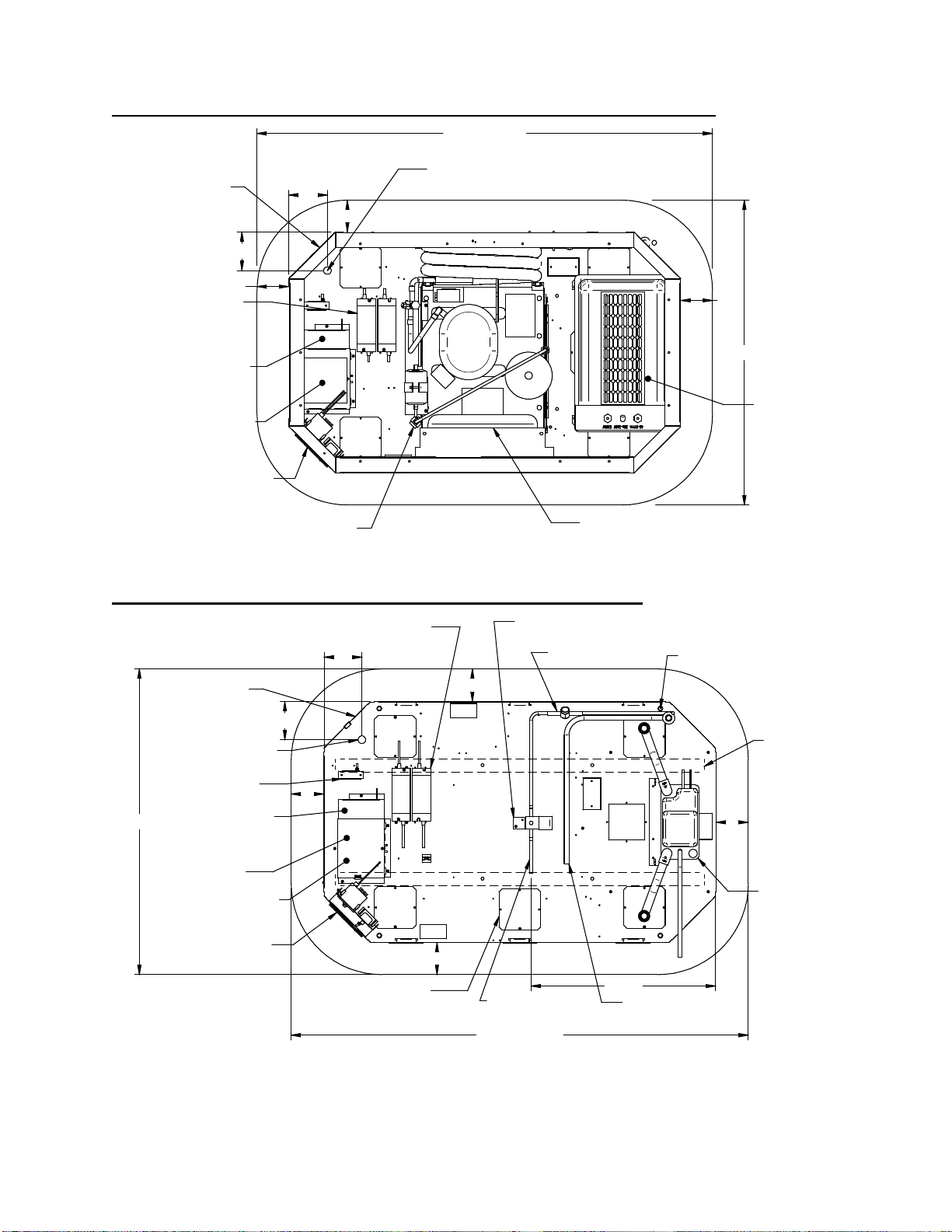

BASE COMPONENT LAYOUT IMSS60 & IMSS84 ............................................................10

BASE COMPONENT LAYOUT IMSS120.............................................................................11

CONDENSATE EVAPORATOR............................................................................................12

CONDENSATE PUMP ...........................................................................................................12

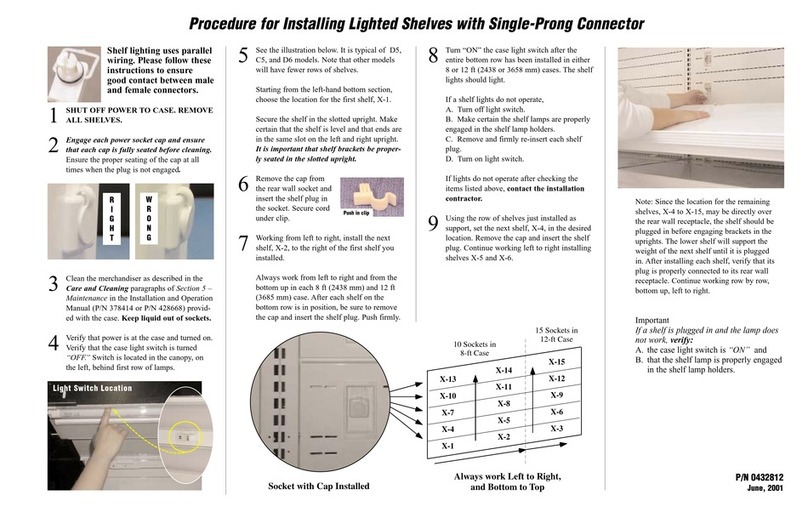

SHELVES............................................................................................................................13-14

OPERATING INSTRUCTIONS........................................................................................................15-17

USER CONTROLS ..................................................................................................................15

POWER SWITCH ................................................................................................................... 15

LIGHT SWITCH ..................................................................................................................... 15

ELECTRONIC CONTROL................................................................................................15-17

INITIAL START UP................................................................................................................18

PLACING PRODUCT IN CASE.............................................................................................18

CLEANING INSTRUCTIONS................................................................................................................18

ACRYLIC AIR DEFLECTOR.................................................................................................18

DAILY CLEANING................................................................................................................19

WEEKLY CLEANING .......................................................................................................19-20

MAINTENANCE ...................................................................................................................21

CLEANING CONDENSER COIL..........................................................................................21

SERVICE INFORMATION....................................................................................................................22

PRE-SERVICE CHECKLIST..................................................................................................23

SPECIAL SERVICE SITUATIONS ........................................................................................24

SALE & DISPOSAL.................................................................................................................................24

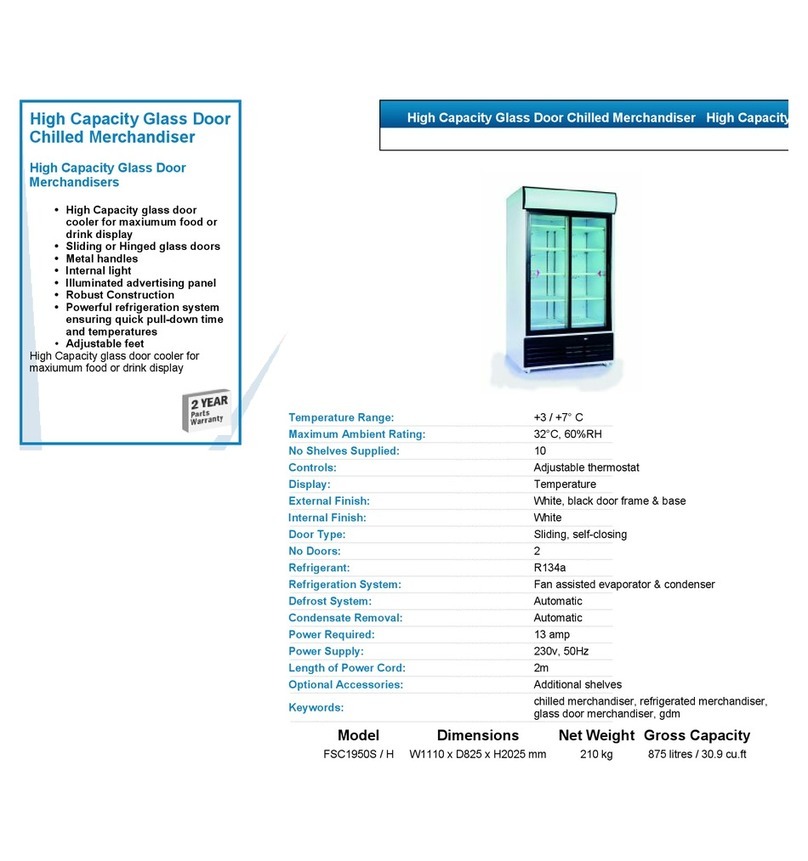

ELECTRICAL DATA..............................................................................................................................25

CONTROL OPERATION.......................................................................................................................26

ELECTRONIC CONTROL .....................................................................................................26

OPERATION...........................................................................................................................26

DEFROST CYCLE.................................................................................................................. 26

MAXIMUM RUN TIMER.......................................................................................................26

CONTROL PARAMETERS ...............................................................................................27-29

REFRIGERATION OPERATION.........................................................................................................30

SELF CONTAINED OPERATION ........................................................................................30

REMOTE OPERATION......................................................................................................30-31

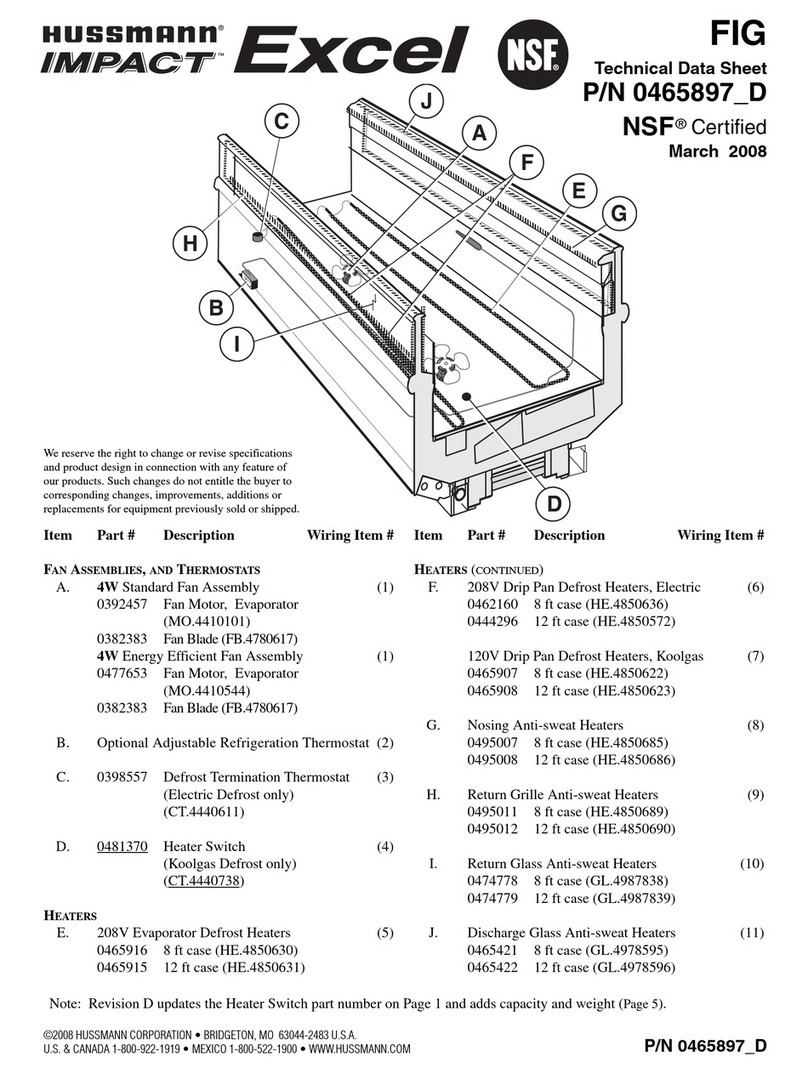

REPLACEMENT PARTS -................................................................................................................32-33

WIRING DRAWING ............................................................................................................ 34-58